Device for directly drawing helical circular quartz tube by continuous-melt method and drawing method

A technology of spiral ring and quartz tube, which is applied in the manufacture of tools, glass molding, glass molding, etc., can solve the problems of inconsistent high pressure resistance, irregular spiral ring, uneven pitch, etc., to avoid secondary processing and uniform pitch , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

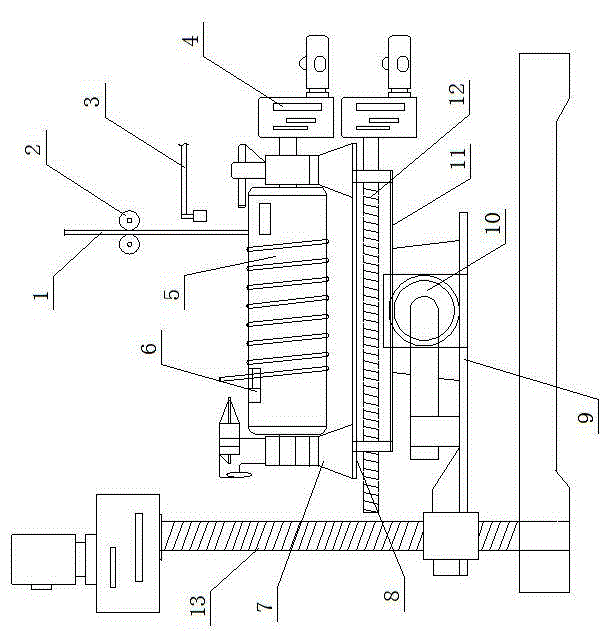

[0017] Embodiment 1, referring to the accompanying drawings, a device for directly drawing a spiral annular quartz tube by continuous melting method, including a rotary winder located below the discharge port of the continuous melting furnace, and the rotary winder is fixed on the support plate through a support frame 7 8, the bottom of the support plate 8 is provided with a left and right movement mechanism 4 that drives the rotary winder to move left and right, and a front and rear movement mechanism 10 is provided at the bottom of the left and right movement mechanism 4, and the lower end of the front and rear movement mechanism 10 is arranged on the lifting mechanism , the rotary winding device includes a rotating cylinder 5, the rotating cylinder 5 is fixed on the rotating shaft, and the rotating shaft is connected with the driving motor through a transmission device, and the rotating cylinder 5 is provided with a quartz tube pressing plate 6; A quartz tube downward tracto...

Embodiment 2

[0021] Embodiment 2, in the device for directly drawing the spiral annular quartz tube by the continuous melting method described in Embodiment 1, the left and right moving mechanism 4 includes a moving frame 11 fixed on the support plate 8, and the moving frame 11 is provided with a left and right moving guide in parallel. Axle and left and right moving screw rod 12, left and right moving screw rod 12 are connected on the mobile frame 11 by nut, and one end of left and right moving screw rod 12 links to each other with driving device.

Embodiment 3

[0022] Embodiment 3, in the device for directly drawing the spiral annular quartz tube by the continuous melting method described in embodiment 2, the left and right moving guide shafts include linear bearings arranged on the moving frame 11, and the linear guide shafts are installed on the linear bearings to prevent the support plate from 8 offset.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com