Patents

Literature

33results about How to "No secondary processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

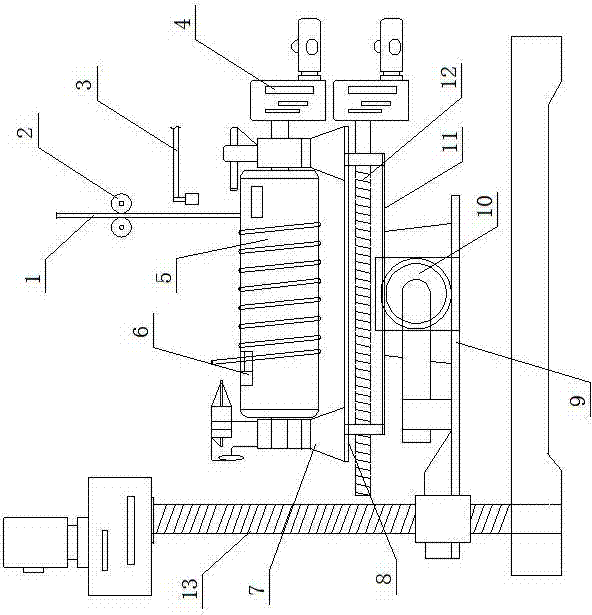

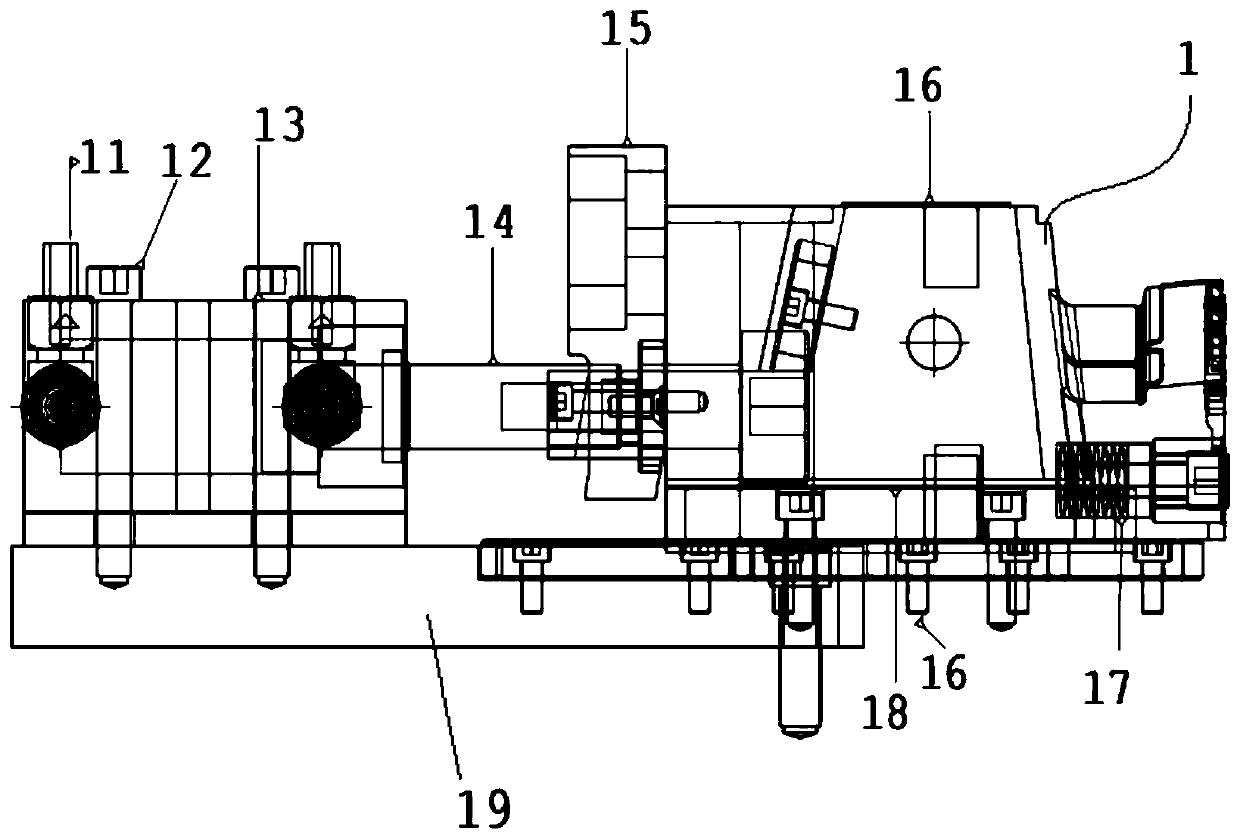

Method for processing timing gear chamber

InactiveCN102240885AIncrease in production shareNo secondary processingEngineeringMechanical engineering

The invention discloses a method for processing a timing gear chamber. The method sequentially comprises the following steps of: (1) performing rough mill on the main surface of the gear chamber by using a milling machine; (2) performing rough mill on the installation surface of the gear chamber; (3) performing finish milling on the main surface of the gear chamber; (4) performing finish milling on the installation surface of the gear chamber; (5) refining the installation surface of the gear chamber in the processing center, wherein two installation holes between which the distance is farthest on the installation surface are taken as positioning basic holes; and processing all holes at the periphery of the gear chamber; (6) refining the main surface of the gear chamber in the processing center, drilling a central hole and a bottom hole, chambering, tapping, performing rough boring on all holes, and performing finish boring on all holes; (7) milling the top surface of the gear chamber; (8) milling the side of the gear chamber; (9) milling the bottom of the gear chamber; (10) drilling and tapping the top hole of the gear chamber, chambering an orifice, and tapping; (11) drilling and tapping the side of the gear chamber, drilling the side hole and countersinking; (12) performing secondary drilling on the side hole of the gear chamber, chambering and tapping; and (13) cleaning and pressuring. The method for processing the timing gear chamber has high production efficiency, and the produced gear chamber has high accuracy and consistency.

Owner:TIANJIN ZHONGDA PRECISION MACHINERY

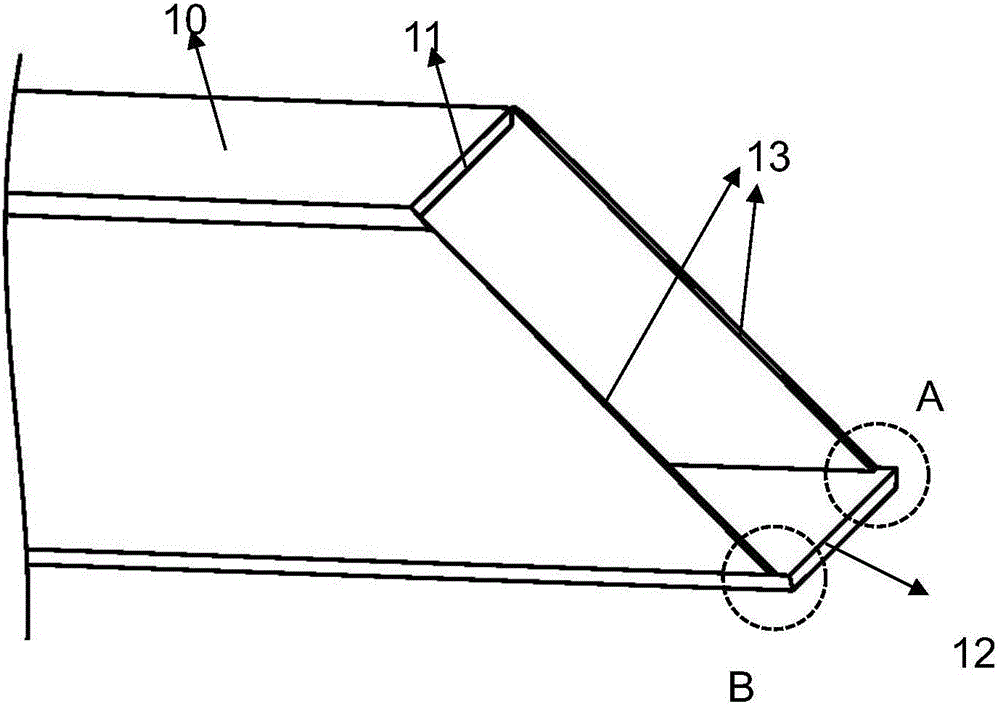

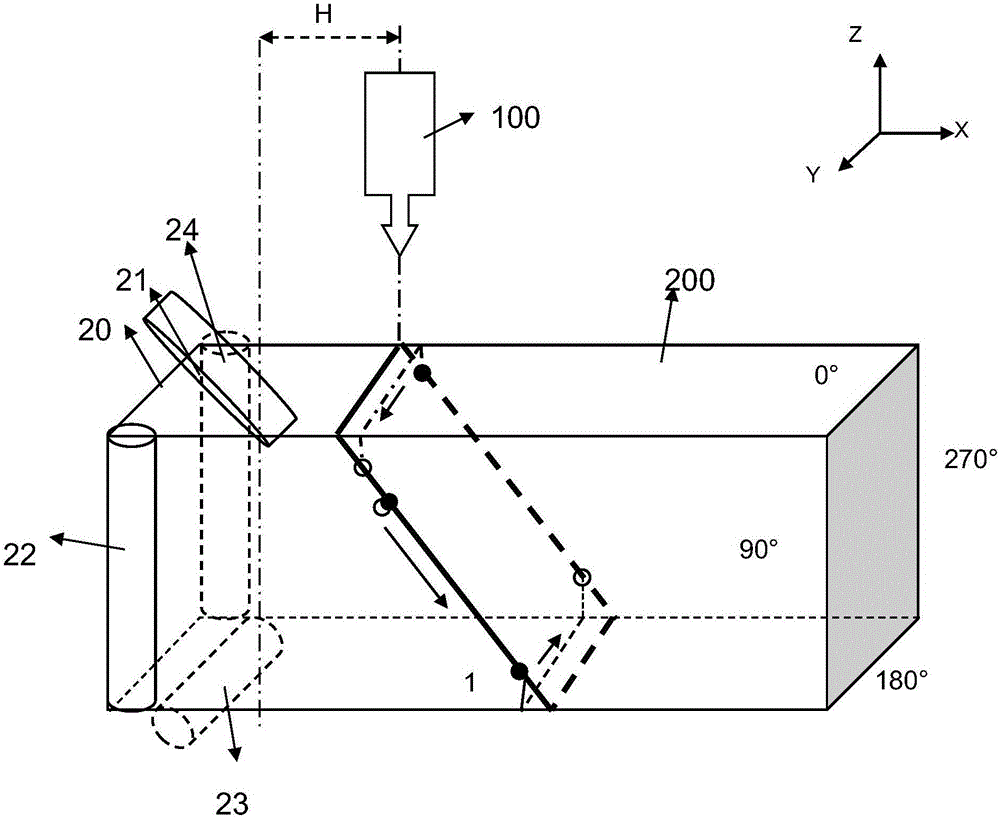

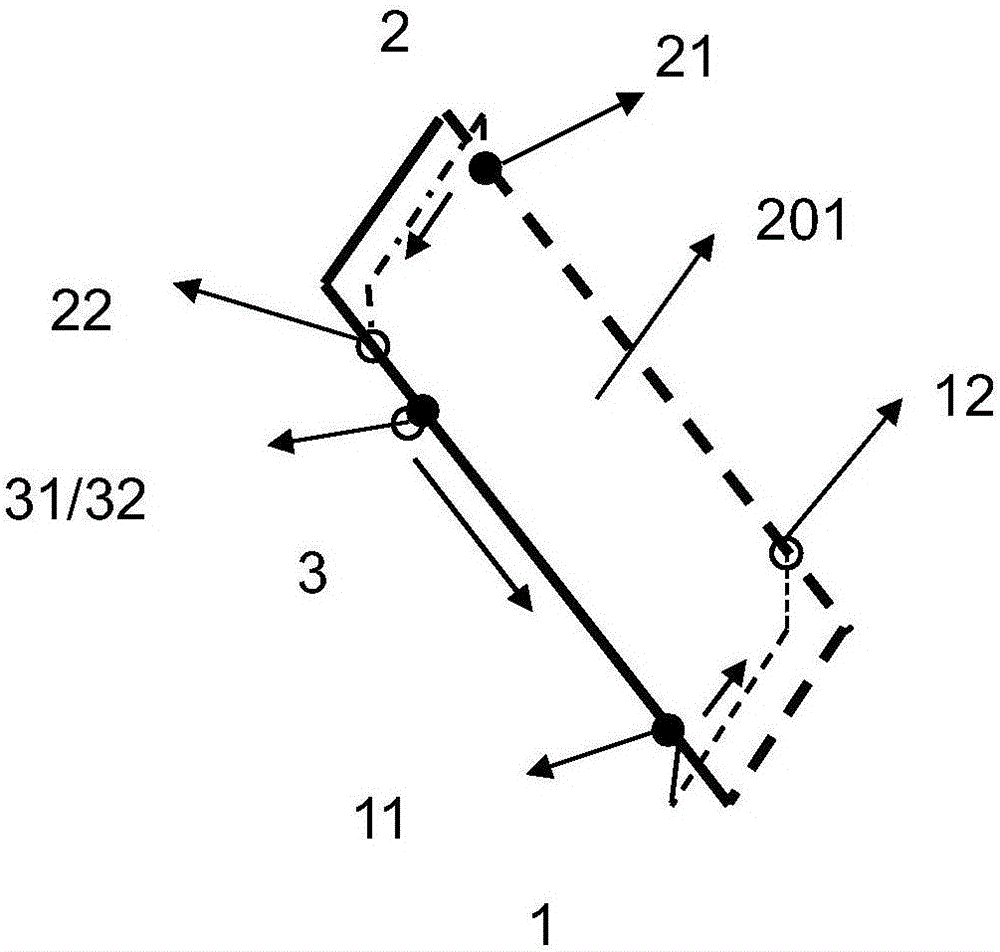

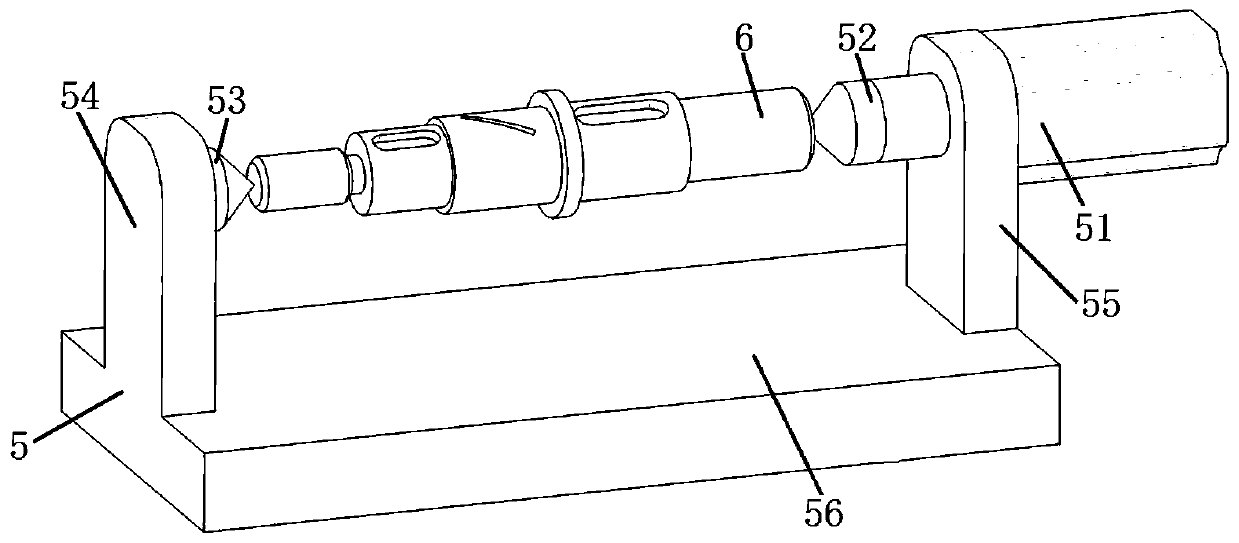

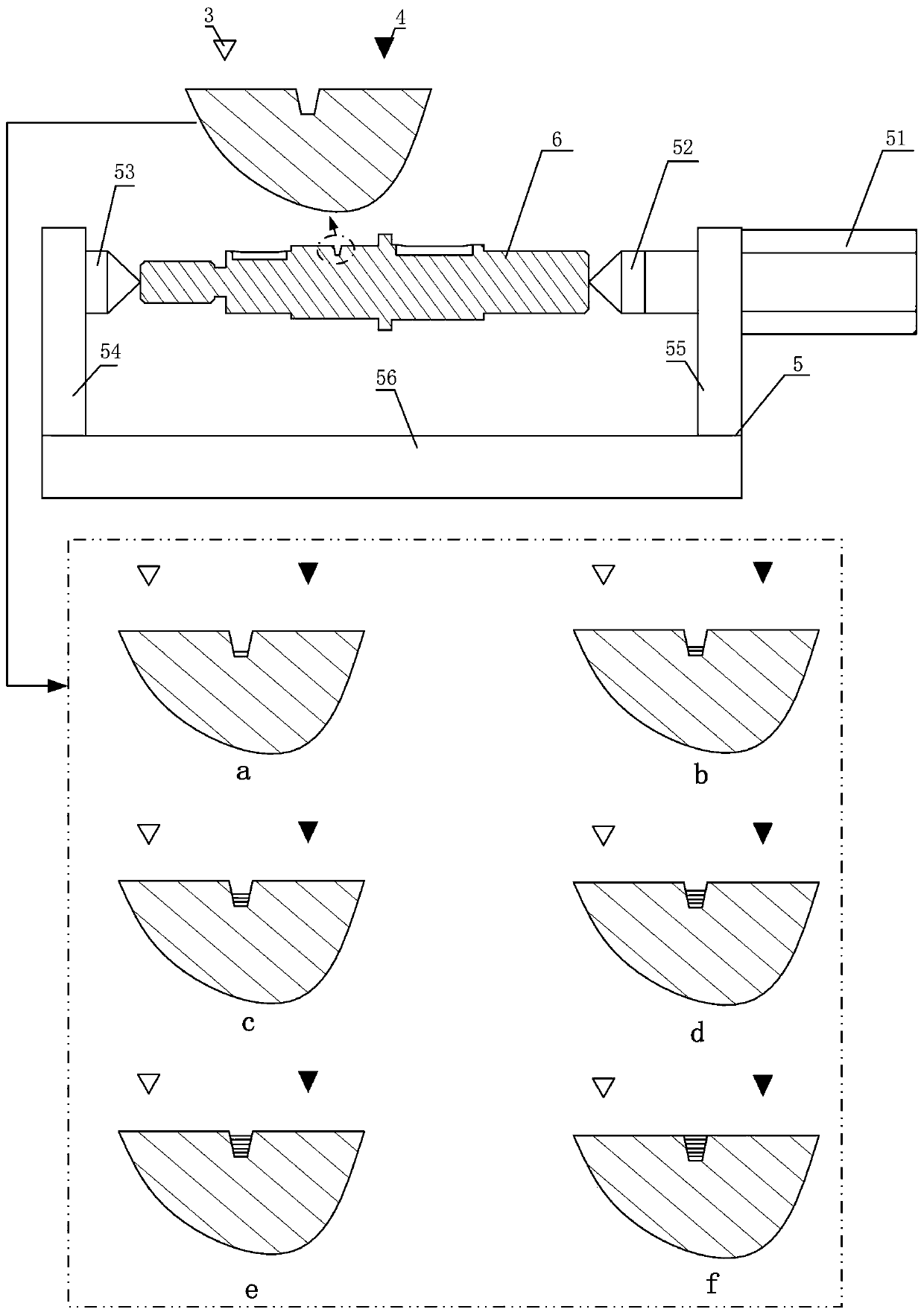

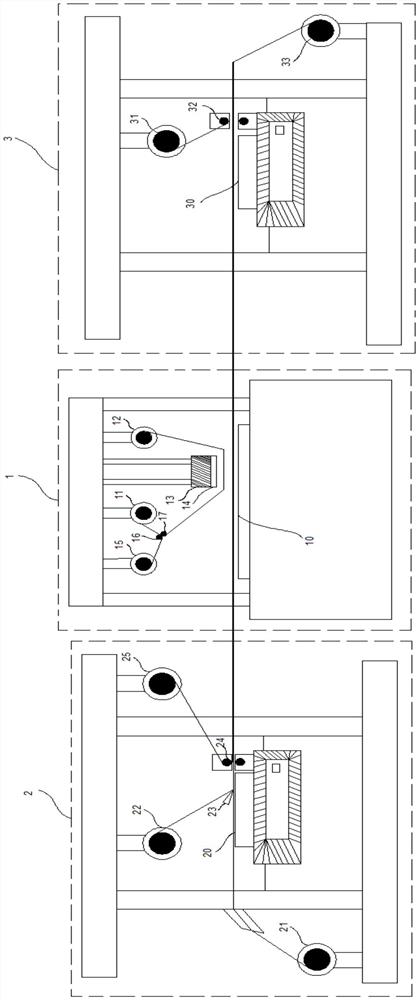

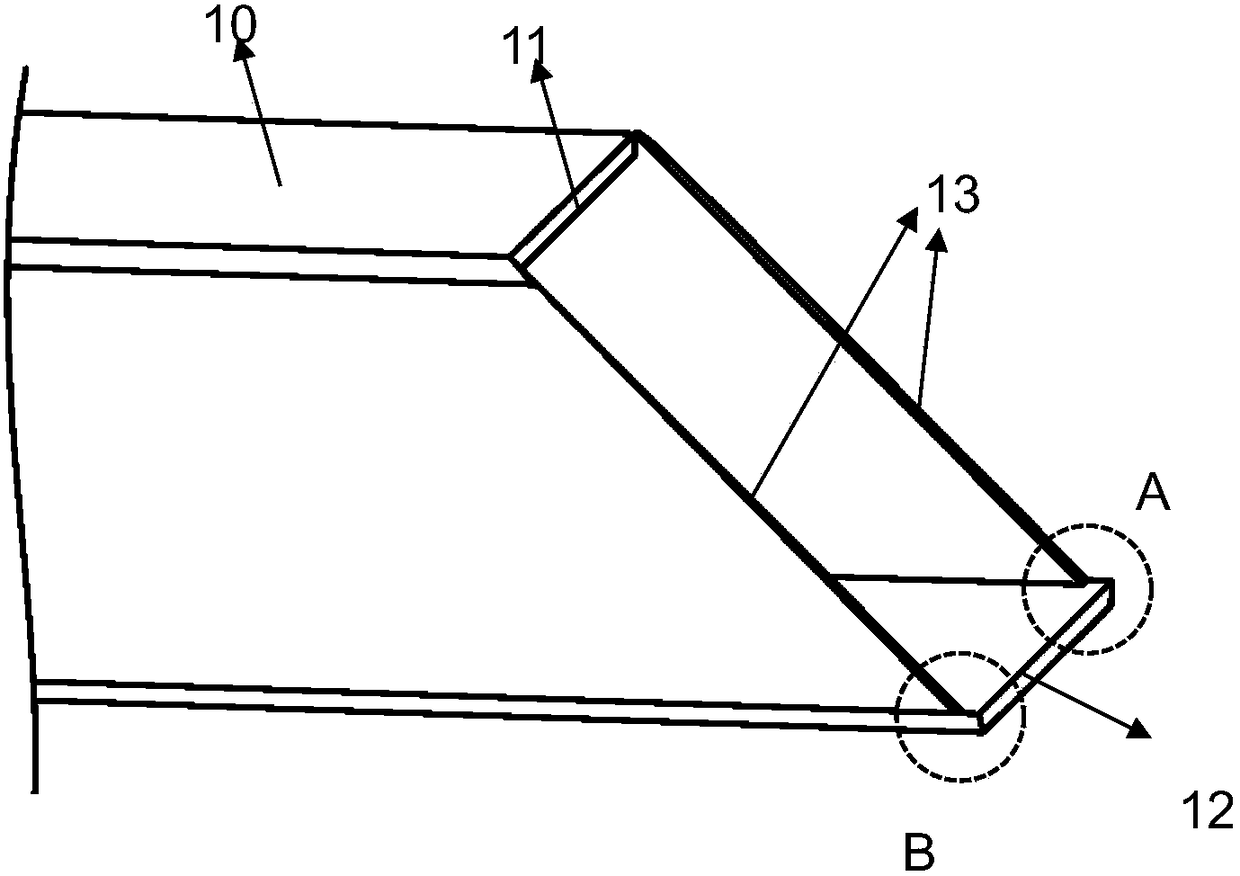

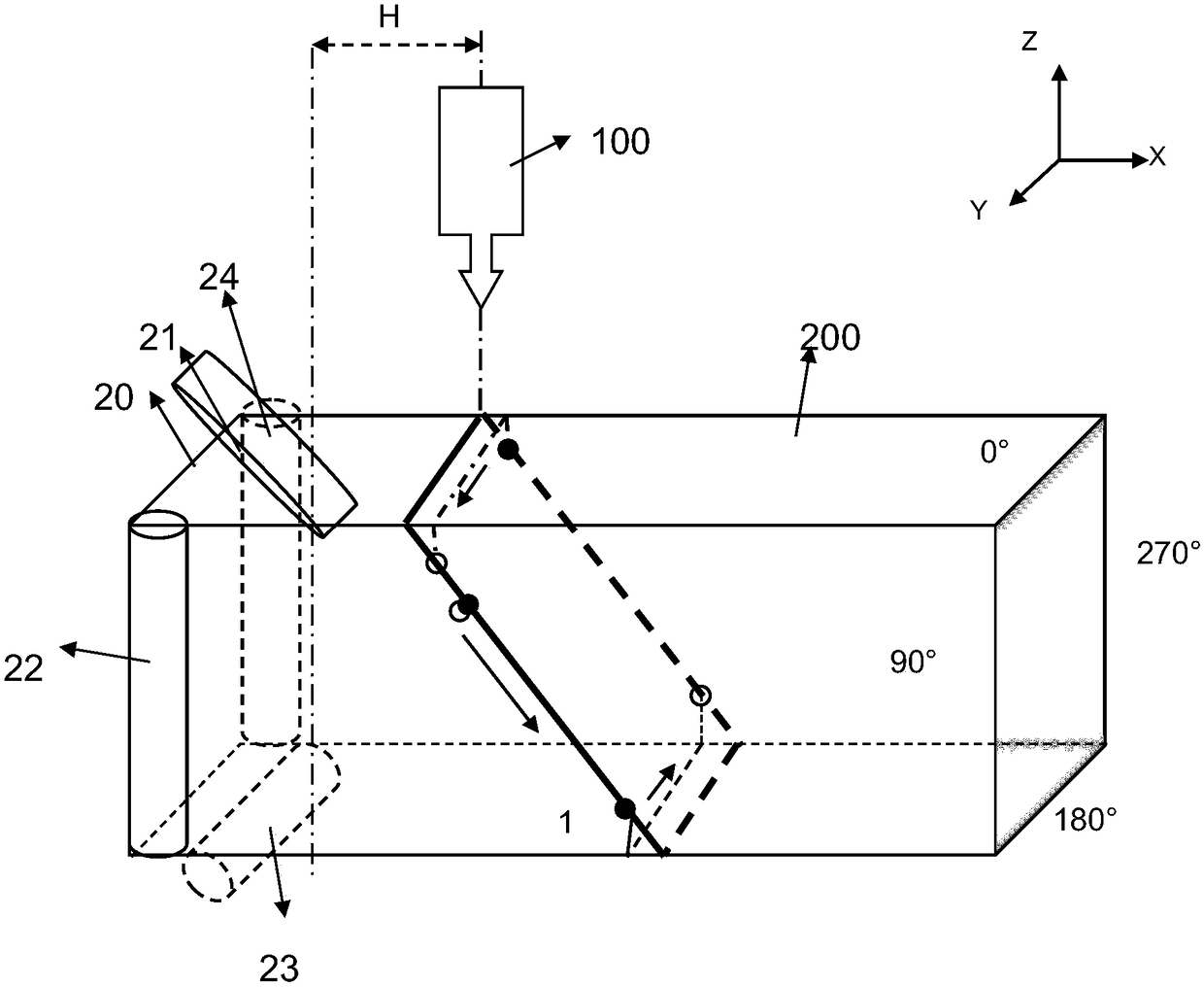

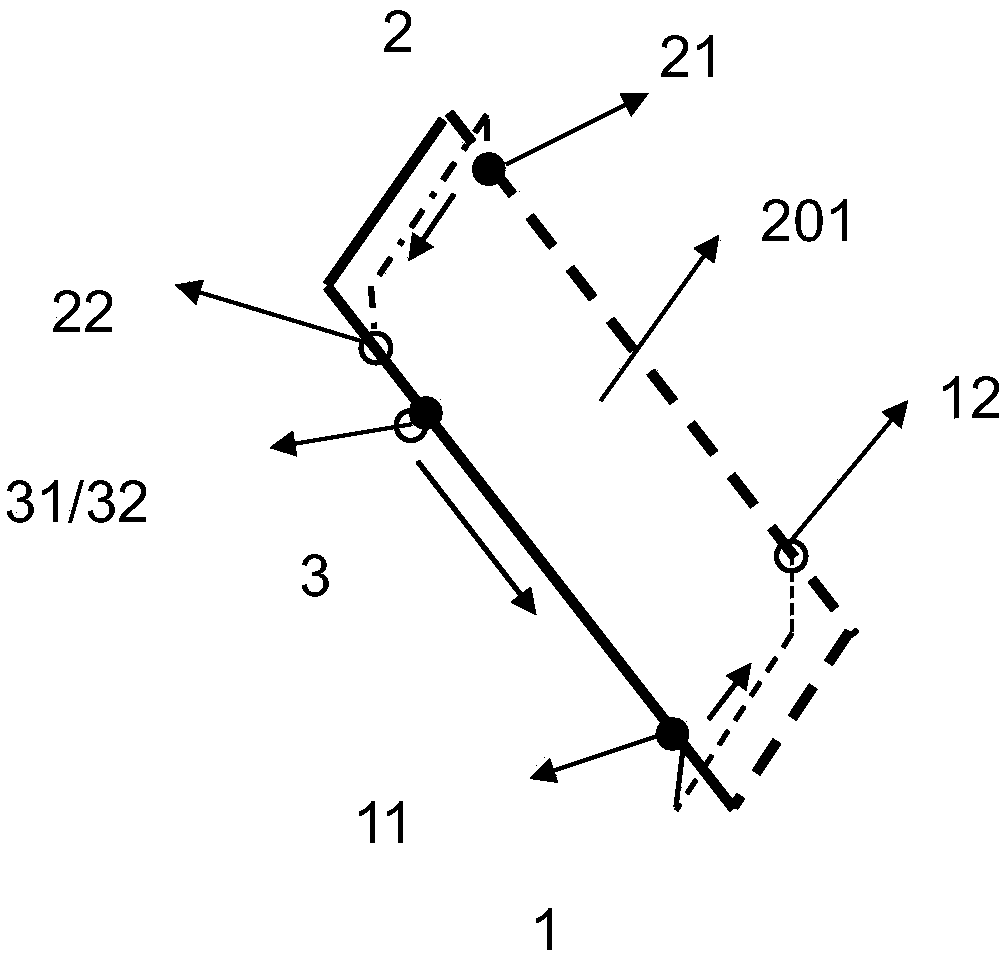

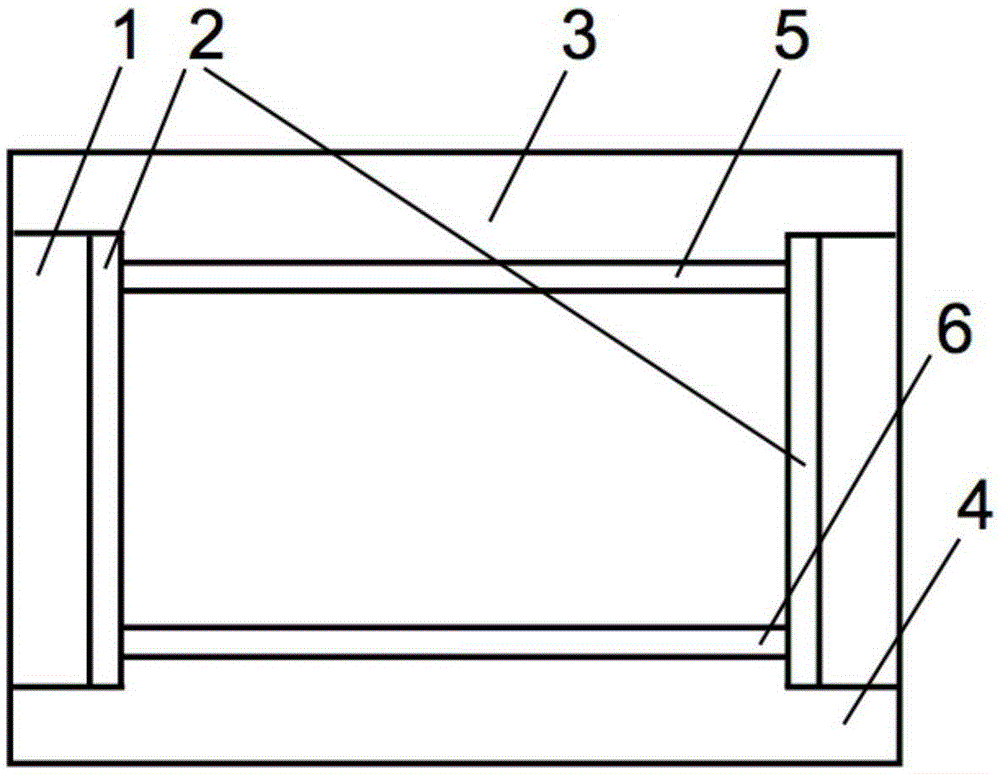

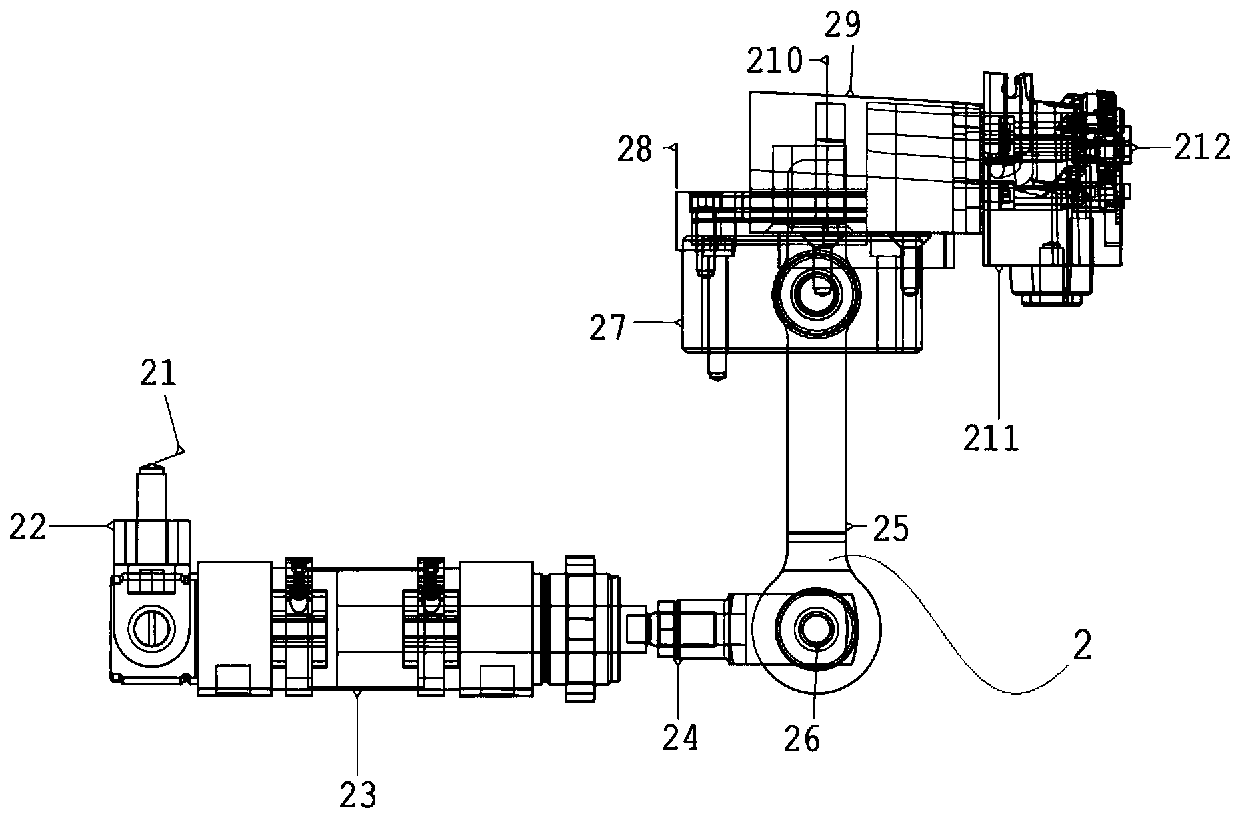

Cutting method for two-dimensional laser cutting tubular product

ActiveCN105772950AAddress the disadvantages of limitations of useIncrease profitMetal working apparatusLaser beam welding apparatusLaser cuttingBiomedical engineering

The invention provides a cutting method for a two-dimensional laser cutting tubular product. The cutting method comprises the following steps: step 1, setting a to-be-cut path of the tubular product and dividing the to-be-cut path into three sections: a first non-edge-shared contour and an edge-shared contour located at one end and a second non-edge-shared contour located at the other end, wherein the edge-shared contour is connected to the first non-edge-shared contour and the second non-edge-shared contour; step 2, cutting the first non-edge-shared contour by using a two-dimensional cutting head; step 3, cutting the second non-edge-shared contour by using the two-dimensional cutting head; and step 4, cutting the edge-shared contour by using the two-dimensional cutting head in a one-cut ring-cutting manner. The cutting method provided by the invention cuts the tubular product by using the two-dimensional cutting head, so that an effect of three-dimensional swing angle cutting can be realized, the function of the two-dimensional cutting head is enhanced and the machining range of the two-dimensional cutting head is expanded, the actual production demand is satisfied, and the shortcoming of using limitation of the two-dimensional cutting head is overcome.

Owner:HANS LASER TECH IND GRP CO LTD +1

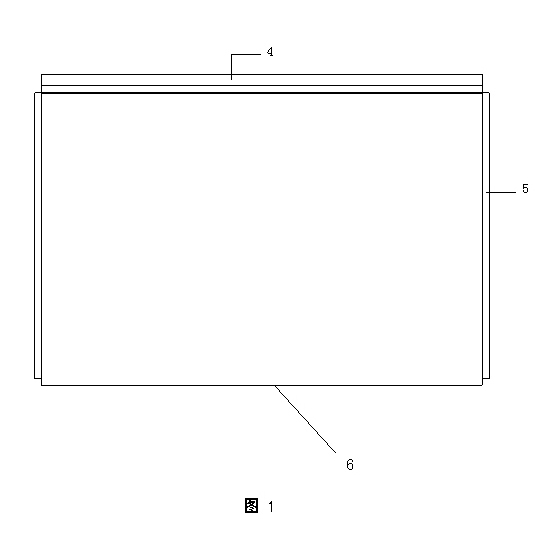

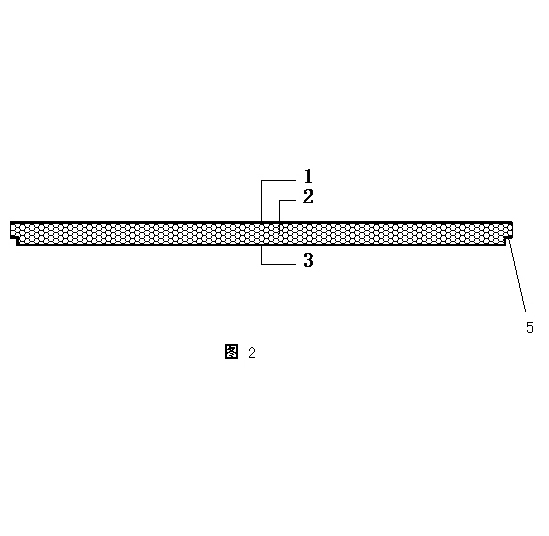

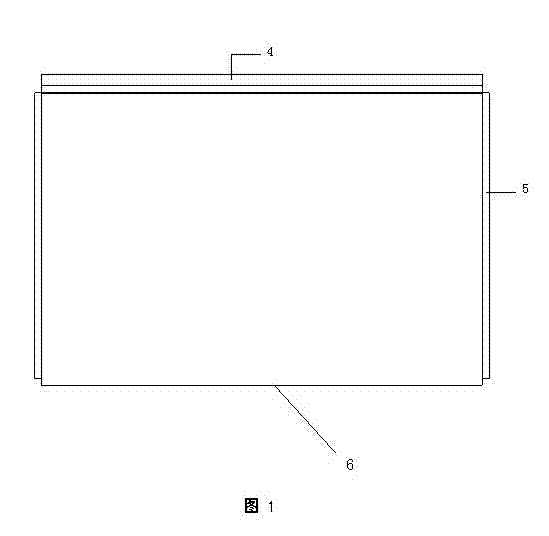

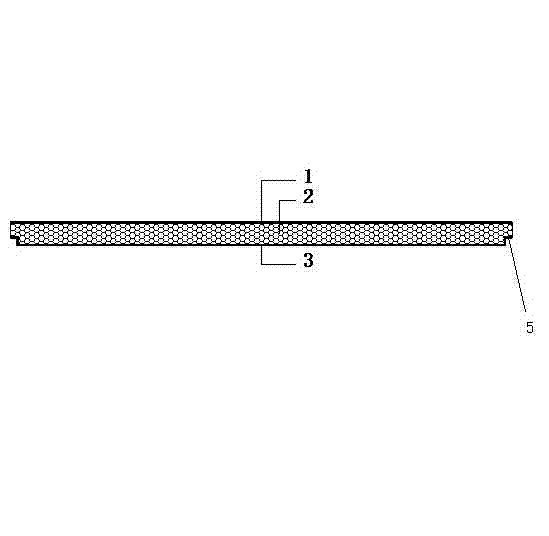

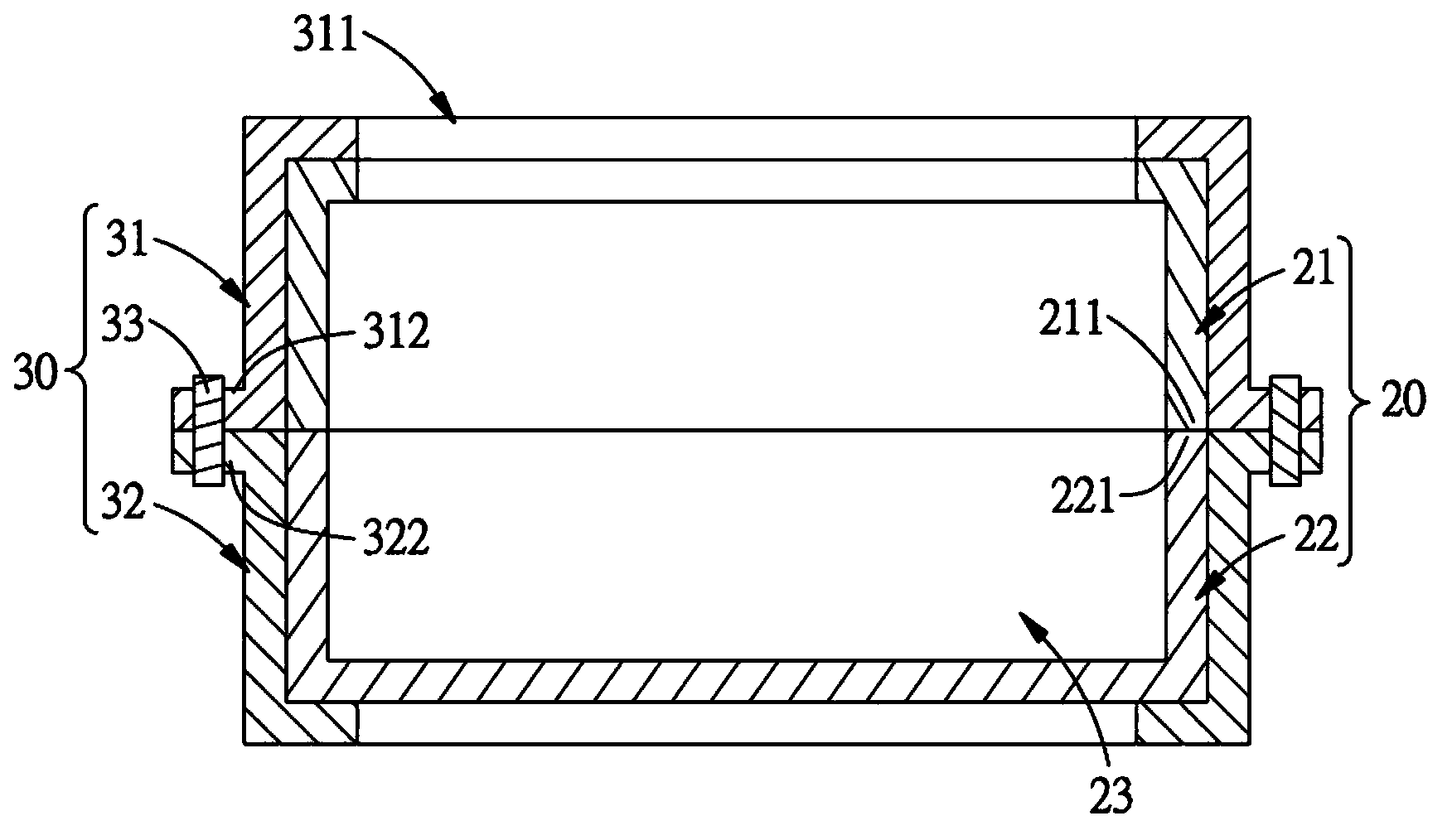

Cold bridge-blocking composite insulation board and wallboard

InactiveCN101824877AEasy to processAvoid cold bridge phenomenonBuilding componentsButt jointEngineering

The invention discloses a cold bridge-blocking composite insulation board and a wallboard. The composite insulation board comprises an inner panel, an outer panel and a sandwich layer arranged between the two panels. Two opposite end parts at the periphery of composite insulation board are provided with rabbets for overlap joint, and the edges of the outer panels at the other two opposite sides of the composite insulation board are provided with inwards-flanged bent structures which are used for the butt joint with the corresponding composite insulation board to form grooves extending along the length directions of the edges, wherein each bent structure is provided with a bottom lower than the surface of the outer panel. By adding the bent structures for forming the joint groove during the butt joint to the rabbet-free ends based on the fact that the common composite insulation board is provided with overlapping rabbets only, the invention can effectively avoid the cold bridge phenomenon generated by the air gap existing during the anterior-posterior butt joint of the traditional composite insulation boards. Besides, the invention can effectively enhance the overall insulating property of the composite insulation board.

Owner:HENAN TIANFON ENERGY SAVING PANEL SCI & TECH

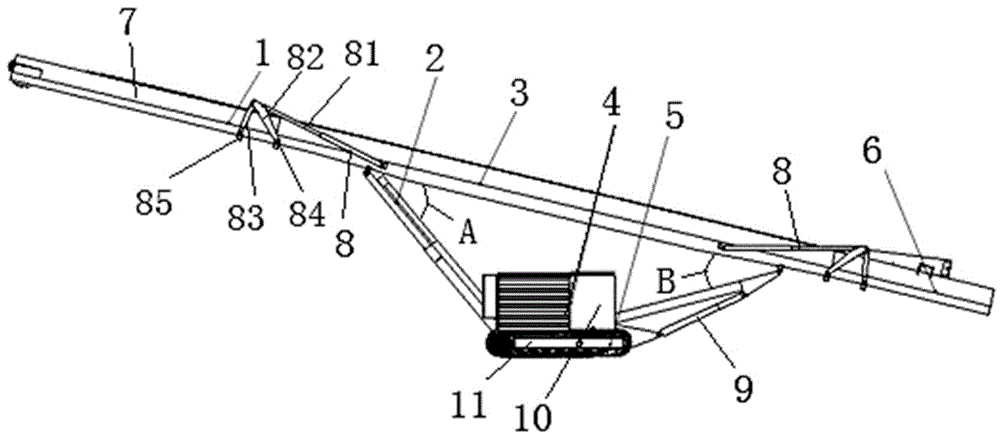

Caterpillar type folding conveying stacker

PendingCN106697978AReduce pollutionIncrease working areaConveyorsLoading/unloadingRoad surfaceStructural engineering

The invention discloses a caterpillar type folding conveying stacker which comprises a base, a caterpillar connected with the base, a hydraulic oil station and a PLC control device, wherein an upper pitching supporting arm and a lower pitching supporting arm supporting main beam are separately arranged on positions, along the two ends of a caterpillar travelling direction, of the base; the two ends of the main beam are separately connected with an upper folding beam and a lower folding beam; conveying slots are formed in the top of the upper folding beam, the top of the main beam and the top of the lower folding beam; and an inclined downward conveying channel is formed among the upper folding beam, the main beam and the lower folding beam by separately regulating angles of the upper pitching supporting arm and the lower pitching supporting arm through the upper folding beam and the lower folding beam. A feeder of the caterpillar type folding conveying stacker is suitable for various road surfaces with complex working conditions. Through a luffing device controlled by a hydraulic control system, pollution, on the environment, of dust in a stacking process can be reduced; circular-arc stacking is performed by rotating in situ, so that an operation area can be effectively increased, and stacking continuity is effectively improved; and moreover, the caterpillar type folding conveying stacker is light in equipment, is compact in structure and is convenient to move.

Owner:NANTONG UP MACHINERY ENG

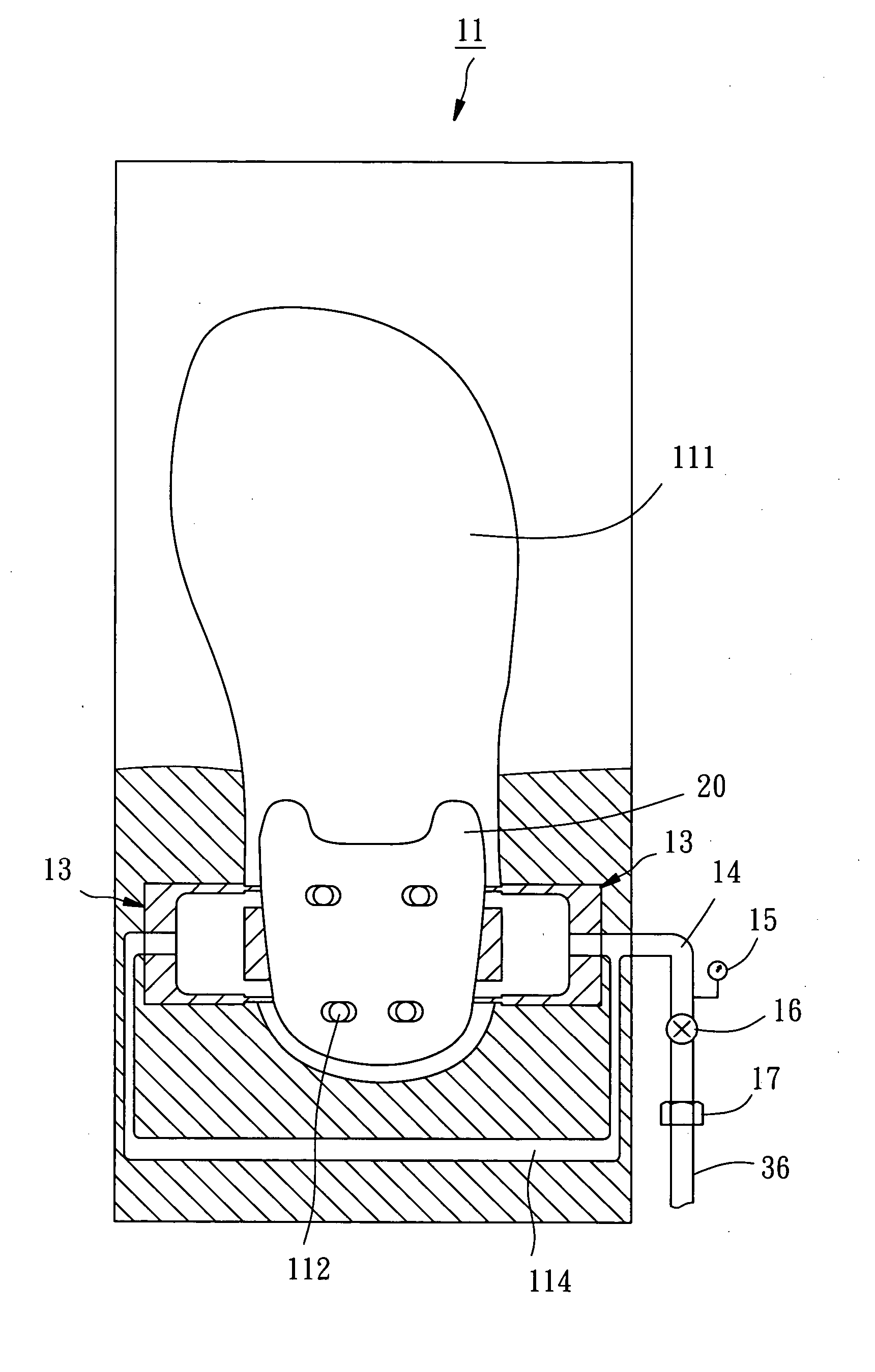

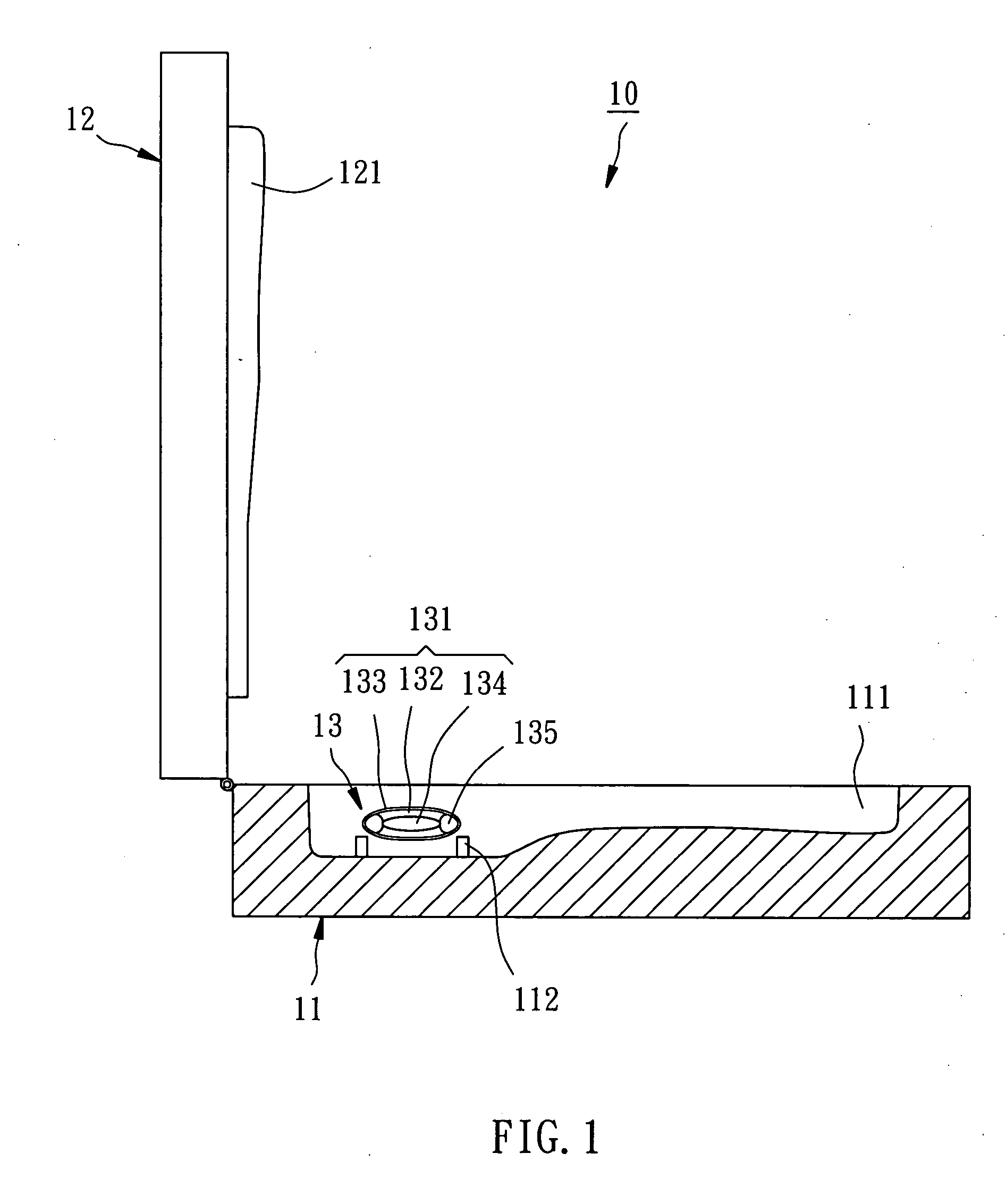

Method of making outsole

InactiveUS20060273496A1No secondary processingReduce manufacturing costSolesDomestic footwearMaterials science

A method of making an outsole includes the steps of a) preparing a mold and an insert, which mold having a cavity for molding an outsole, two through holes in communication between the cavity and the atmosphere, and a fence at a periphery of the cavity around each through hole, b) putting the insert into the cavity near the through holes, c) drawing air out of the through holes to suck the insert and to have the insert be closely attached to the fence, d) filling a molten plastic material into the cavity of the mold, and e) separating the molding thus formed from the mold after hardening of the filled plastic material so as to obtain a finished outsole.

Owner:CHEN TAY YUO +1

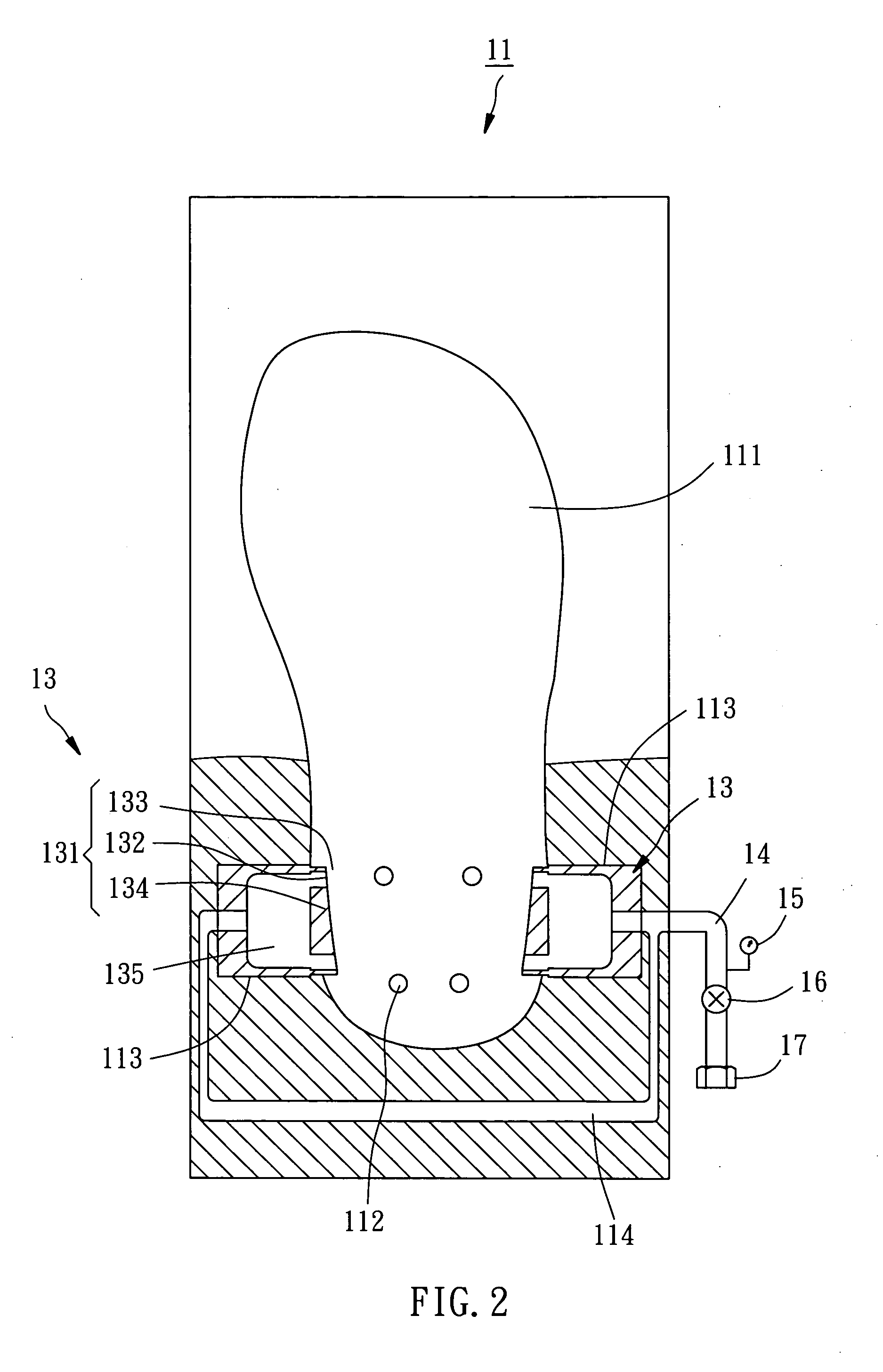

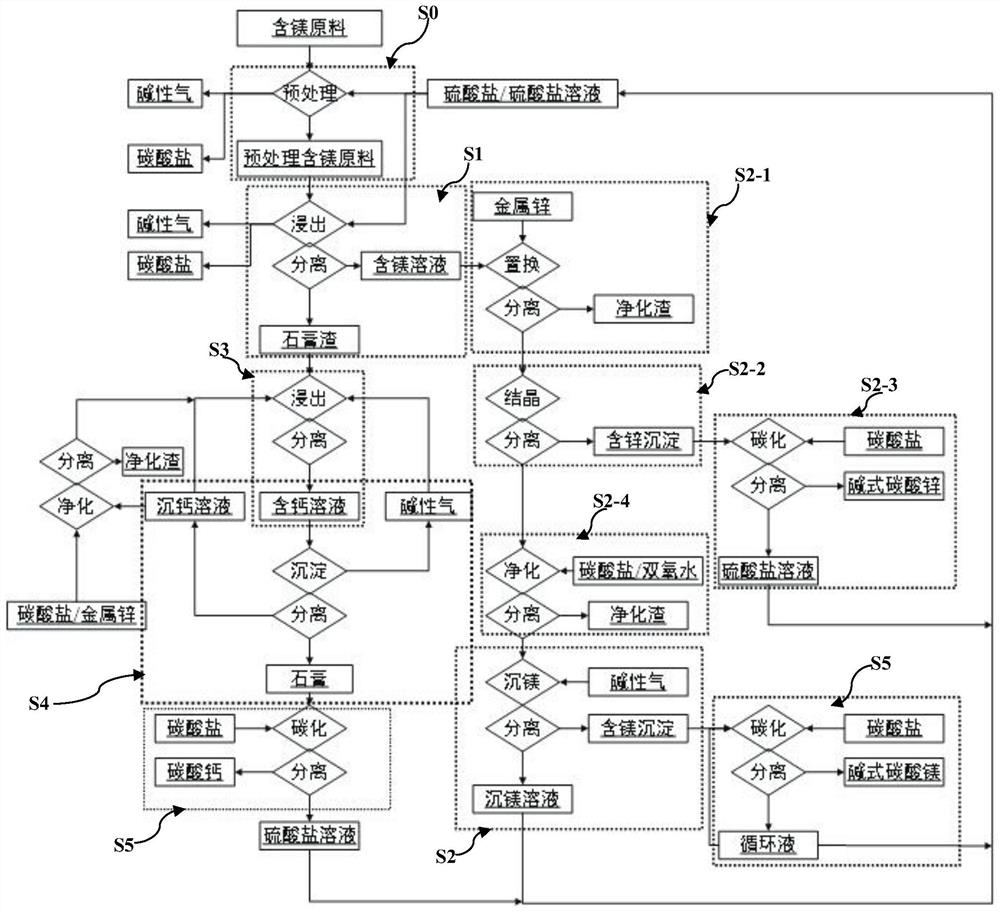

Magnesium-containing raw material recycling treatment method

ActiveCN111549239ASolve resource problemsSolve cleaning problemsProcess efficiency improvementPhysical chemistrySulphate salt

The invention relates to a magnesium-containing raw material recycling treatment method. The magnesium-containing raw material recycling treatment method comprises the steps that S1, magnesium reaction liquid containing sulfate and a magnesium cosolvent are mixed with magnesium-containing raw materials to perform reaction, the reaction system PH value is controlled to be less than 9.0, and after the reaction is finished, solid-liquid separation is performed to obtain a magnesium-containing solution A1 and calcium-containing residue B1; S2, the magnesium-containing solution A1 is reacted with aprecipitant, the reaction system PH value is controlled to be 5.5-12.0, and after the reaction is finished, the solid-liquid separation is performed to obtain a magnesium sediment solution A2 and magnesium-containing sediment B2; S3, calcium reaction liquid containing a calcium solvent, a calcium cosolvent and the sulfate is mixed with the calcium-containing residue B1 to perform the reaction, the reaction system PH value is controlled to be 5.5-12.0, and after the reaction is finished, the solid-liquid separation is performed to obtain a calcium-containing solution A3 and tail residue B3; and S4, the PH value of the calcium-containing solution A3 is adjusted to be 4.0-9.5, calcium sulfate is made to precipitate from the calcium-containing solution A3, and the solid-liquid separation is performed to obtain a calcium sediment solution A4 and calcium-containing sediment B4 containing the calcium sulfate. By means of the magnesium-containing raw material recycling treatment method, underthe condition of not consuming additional raw materials, magnesium, calcium and impurities in low-grade magnesium-containing raw materials are separated, corresponding calcium and magnesium productsare obtained, the magnesium resource recycling cost is reduced, and environmental pollution is reduced.

Owner:北京中金瑞丰环保科技有限公司

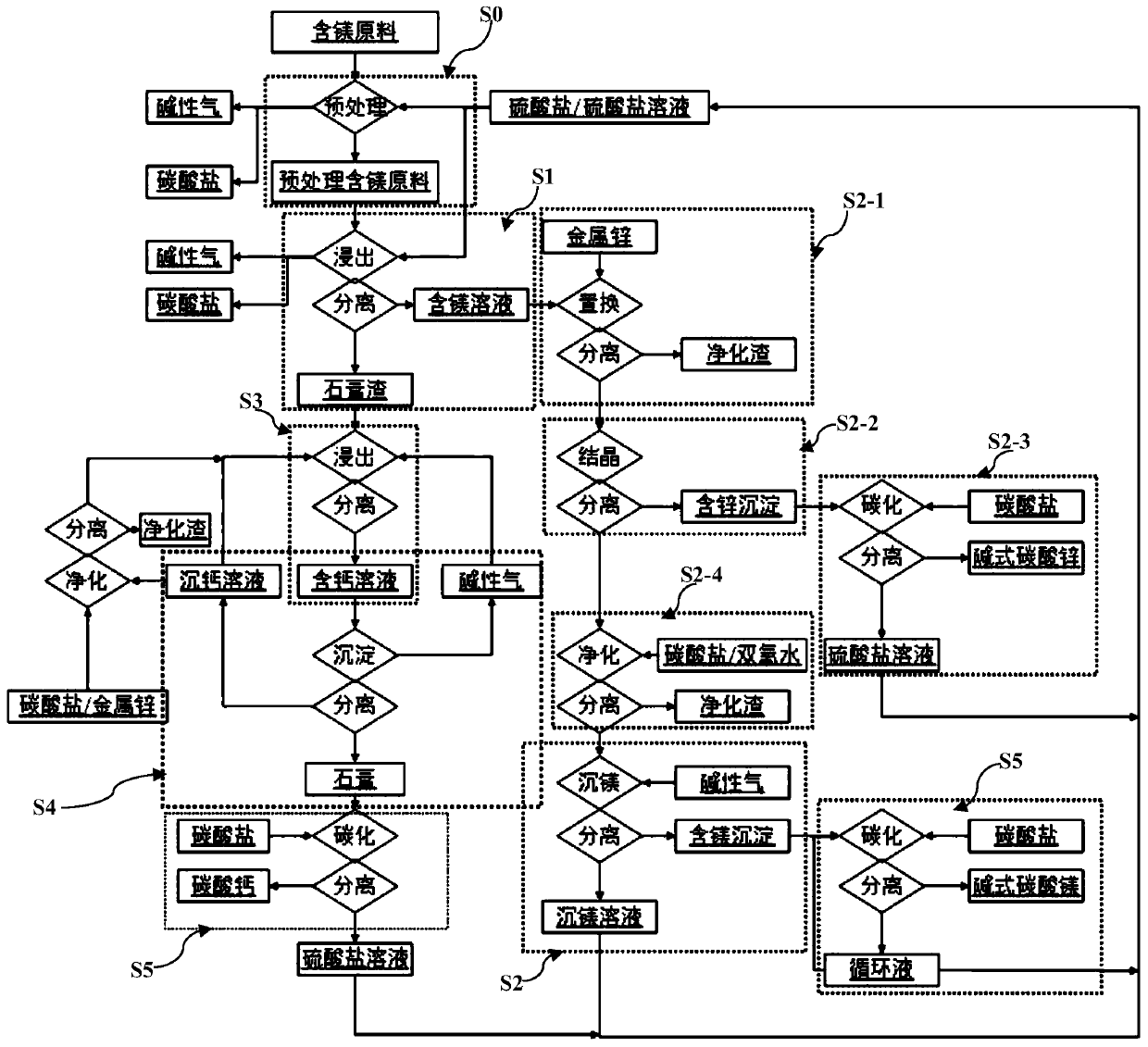

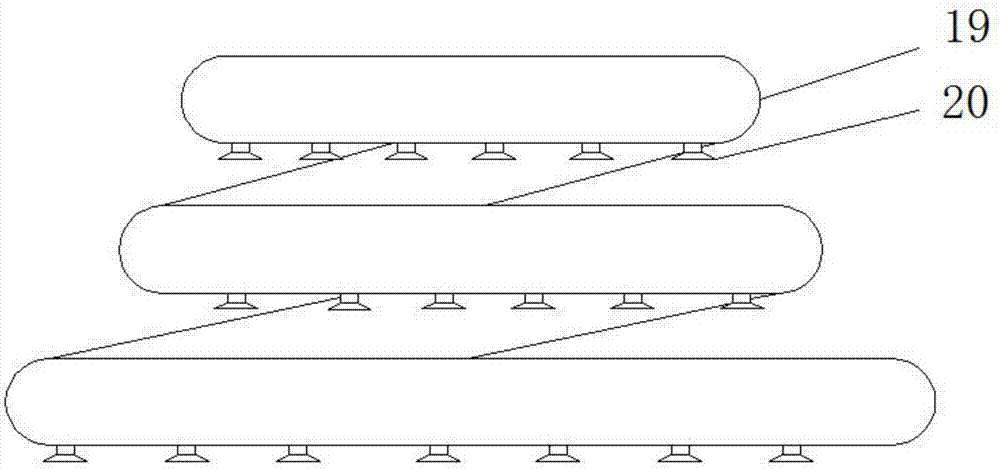

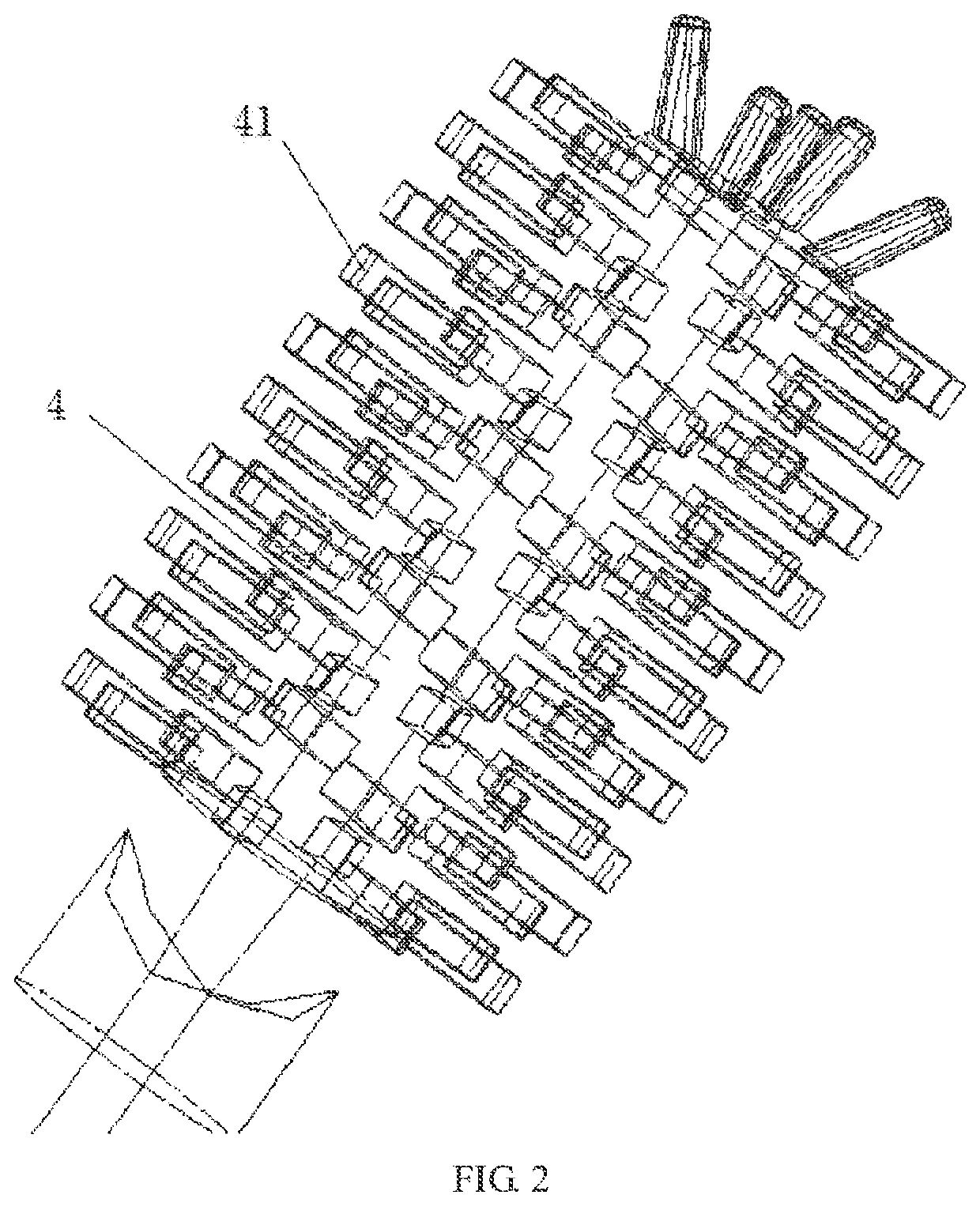

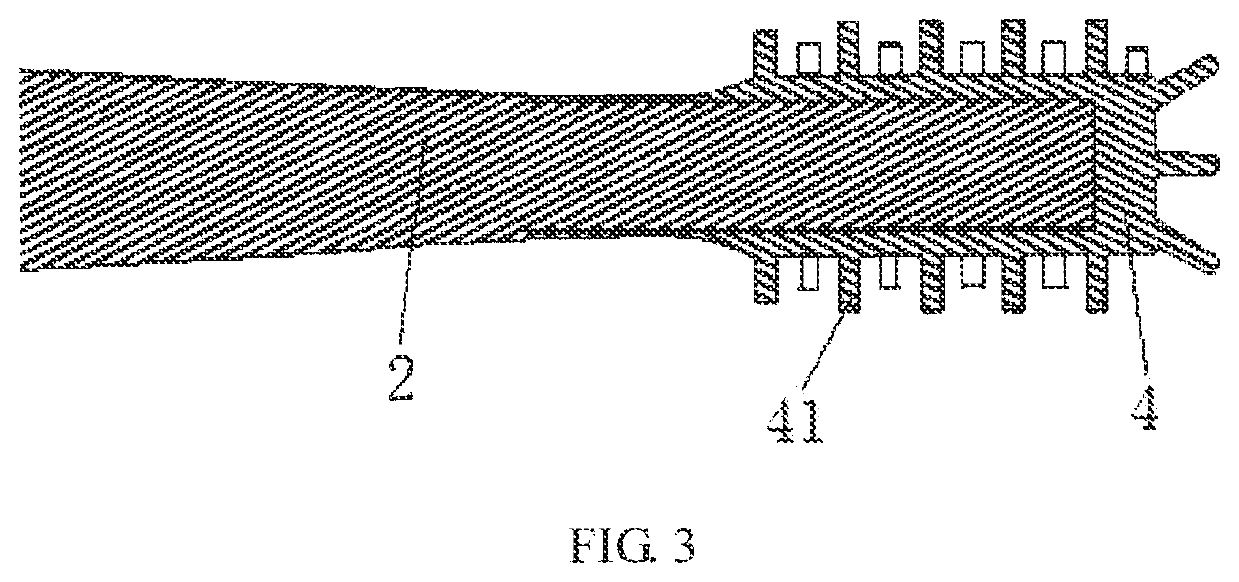

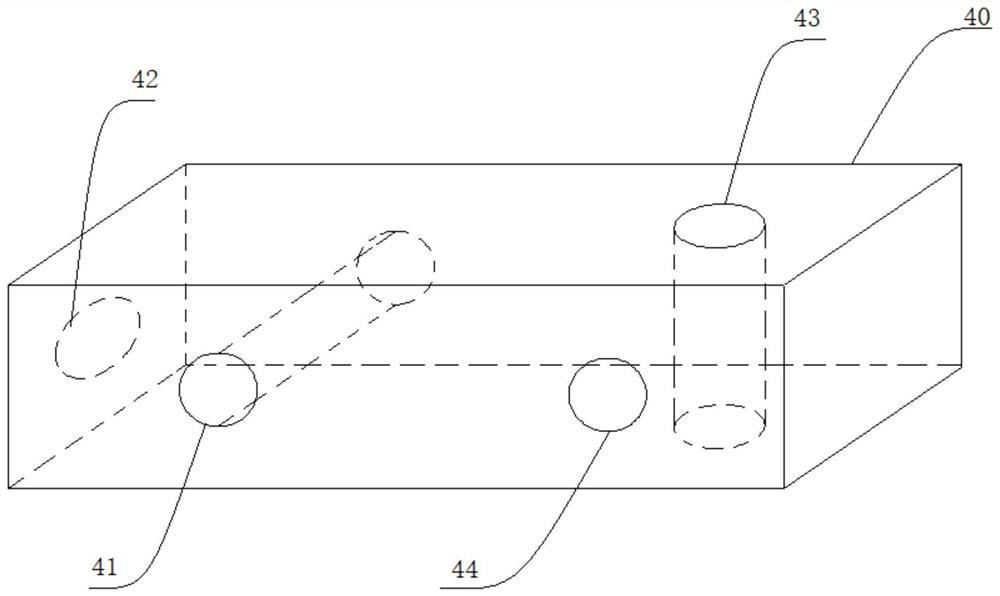

Device for directly drawing helical circular quartz tube by continuous-melt method and drawing method

ActiveCN103204621AUniform pitchQuality improvementGlass forming apparatusGlass reforming apparatusWinding machineDrive motor

The invention discloses a device for directly drawing a helical circular quartz tube by a continuous-melt method and a method for drawing the helical circular quartz tube by the device. The device comprises a rotary winding which is arranged below a discharge hole of a continuous-melt furnace; the rotary winding machine is fixed on a support plate through a support frame; a left and right movement mechanism for driving the rotary winding machine to move left and right is arranged at the lower part of the support plate; a front and back movement mechanism is arranged at the lower part of the left and right movement mechanism; the lower end of the front and back movement mechanism is arranged on a lifting mechanism; the rotary winding machine comprises a rotary drum; the rotary drum is fixed on a rotating shaft; the rotating shaft is connected with a drive motor through a drive device; a quartz tube pressing tube is arranged on the rotary drum; a quartz tube descending tractor is arranged between a discharge hole of the continuous-melt furnace and the rotary winding machine; and a quartz tube cutter is arranged between the quartz tube descending tractor and the rotary winding machine. The helical circular quartz tube is formed by molding once; secondary processing is removed; an energy source is saved; time and labor are saved; and the helical circular quartz tube is even in screw pitch and stable in quality.

Owner:LIANYUNGANG HUAYUAN QUARTZ PROD

Cold bridge-blocking composite insulation board and wallboard

InactiveCN101824877BEasy to processAvoid cold bridge phenomenonBuilding componentsButt jointEngineering

The invention discloses a cold bridge-blocking composite insulation board and a wallboard. The composite insulation board comprises an inner panel, an outer panel and a sandwich layer arranged between the two panels. Two opposite end parts at the periphery of composite insulation board are provided with rabbets for overlap joint, and the edges of the outer panels at the other two opposite sides of the composite insulation board are provided with inwards-flanged bent structures which are used for the butt joint with the corresponding composite insulation board to form grooves extending along the length directions of the edges, wherein each bent structure is provided with a bottom lower than the surface of the outer panel. By adding the bent structures for forming the joint groove during the butt joint to the rabbet-free ends based on the fact that the common composite insulation board is provided with overlapping rabbets only, the invention can effectively avoid the cold bridge phenomenon generated by the air gap existing during the anterior-posterior butt joint of the traditional composite insulation boards. Besides, the invention can effectively enhance the overall insulating property of the composite insulation board.

Owner:HENAN TIANFON ENERGY SAVING PANEL SCI & TECH

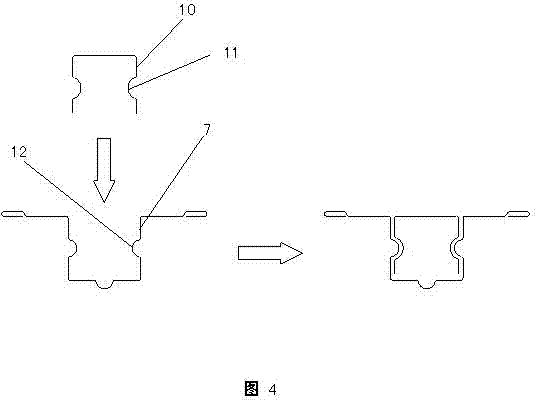

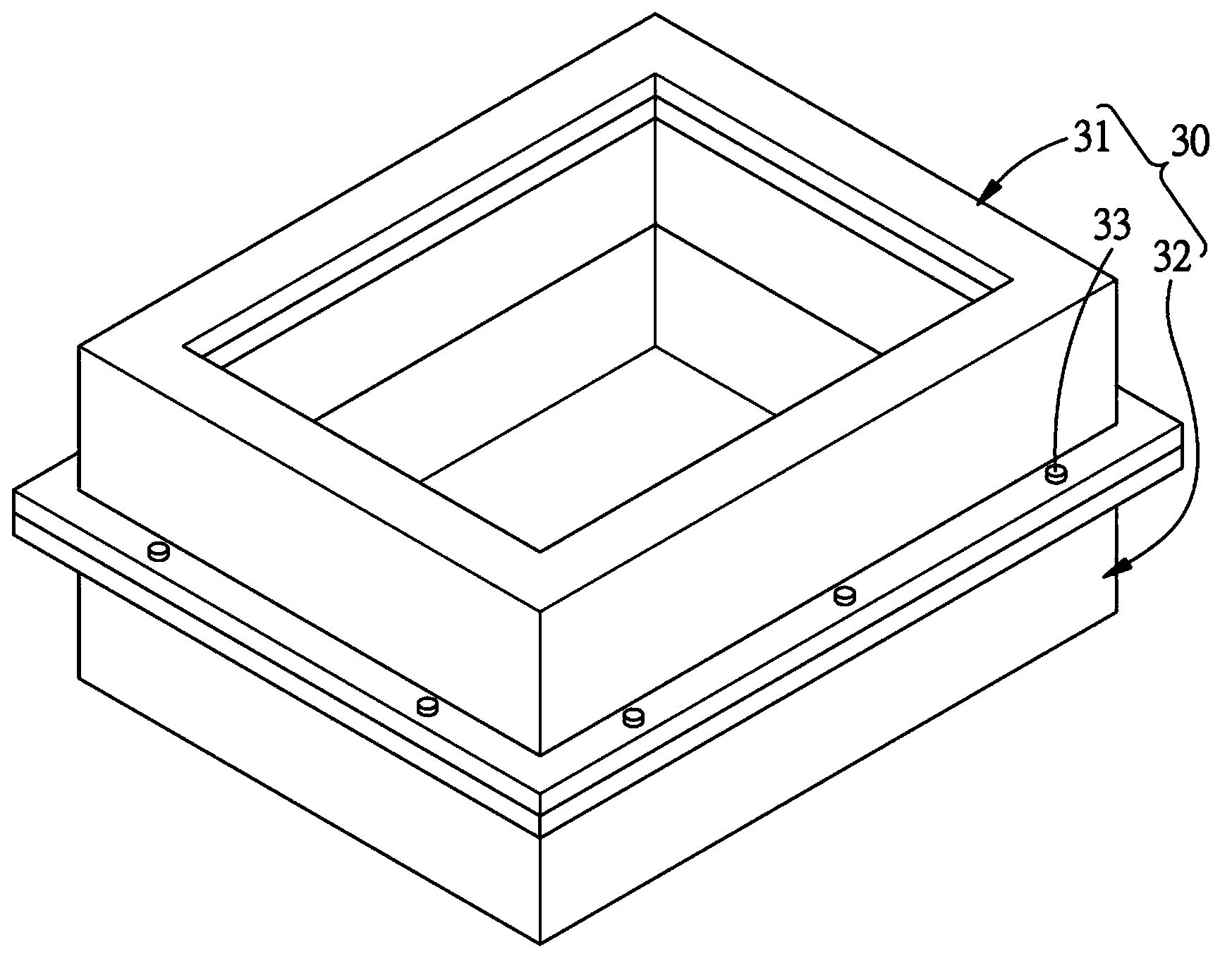

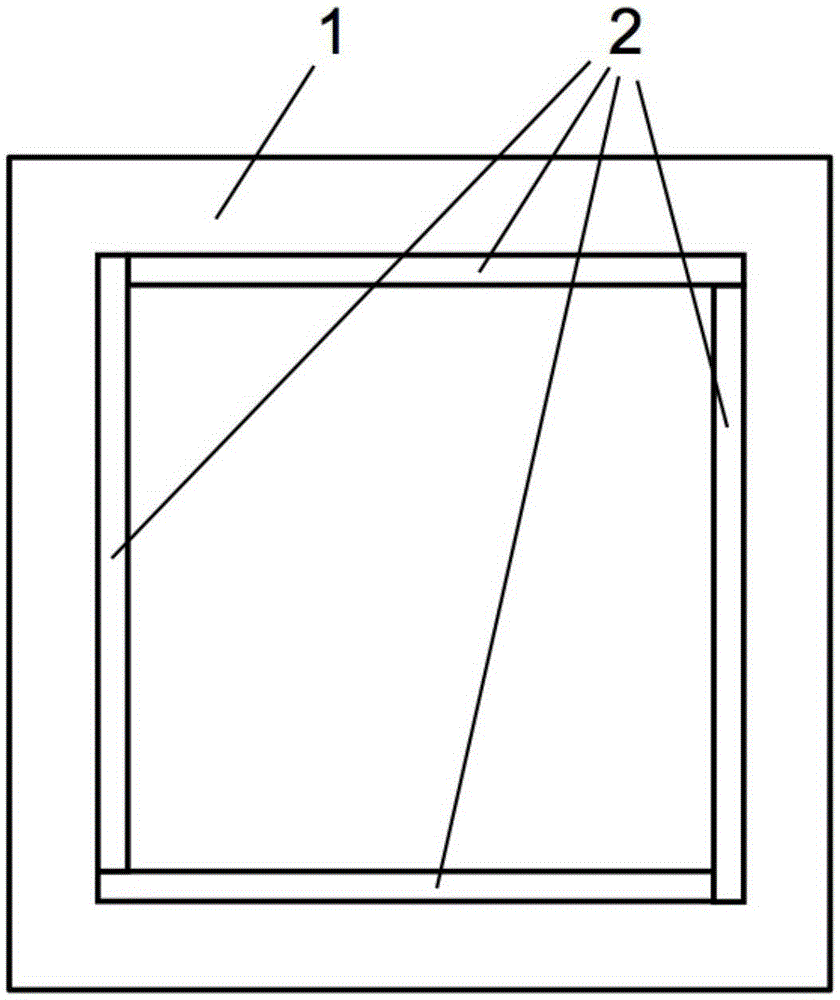

Die structure used for moulded composite fiber material die and manufacturing method thereof

InactiveCN104108188AImprove surface accuracyNo secondary processingGlass pressing apparatusGlass reforming apparatusFiberMechanical engineering

The invention discloses a die structure used for a moulded composite fiber material die and a manufacturing method thereof. The die structure mainly includes a glass-material inner die and an auxiliary fixture. The inner die includes an upper die and a lower die. An accommodating space is limited by the upper die and the lower die. The auxiliary fixture fixes the upper die with the lower die in a manner of clamping the upper die and the lower die. Because glass is a material which is easy to polish, an inner surface of the inner die is easy to be processed into a smooth surface in a manner of surface treatment, thereby enabling a product produced by the die to be high in surface precision without a secondary process.

Owner:翁庆隆

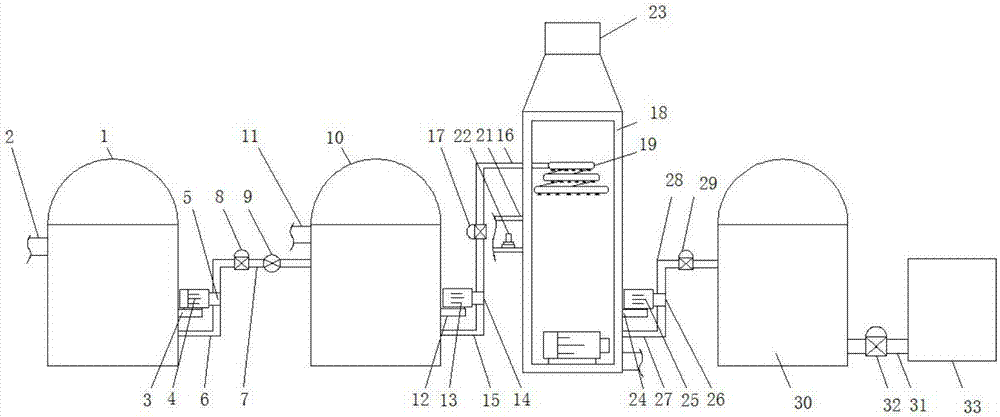

Novel flue gas desulphurization apparatus with hydrogen peroxide

PendingCN107961669AEnhance the efficiency of atomization absorptionGuaranteed desulfurization efficiencyDispersed particle separationFlue gasPhysical chemistry

The invention relates to the technical field of chemical equipment, and discloses a novel flue gas desulphurization apparatus with hydrogen peroxide. The apparatus comprises a hydrogen peroxide tank,one side of the hydrogen peroxide tank is fixedly connected with a hydrogen peroxide pipe, the other side of the hydrogen peroxide tank is fixedly connected with one side of a first support plate, thetop of the first support plate is fixedly connected with the bottom of a first centrifugal pump, one side of the first centrifugal pump far from the hydrogen peroxide tank is fixedly connected with one side of a first tee joint, and the bottom of the first tee joint is fixedly connected with one end of a first water outlet pipe. The novel flue gas desulphurization apparatus with hydrogen peroxideis provided with a spray rod which is fixedly connected with one end of a second water inlet pipe and nozzles which are fixedly connected to the surface of the spray rod, a diluted hydrogen peroxidesolution is atomized by nozzles, a lot of liquid drops of small dimensions are formed, and the liquid drops and flue gas in the absorbing tower are fully contacted, SO2 gas in the flue gas is absorbed; and at the same time, the three-layer spiral tapered spray rod can enhance efficiency of atomization absorption of the apparatus, and desulphurization efficiency is guaranteed at 95% or above.

Owner:XIANGYANG XIANTIANXIA ENVIRONMENTAL PROTECTION EQUIP

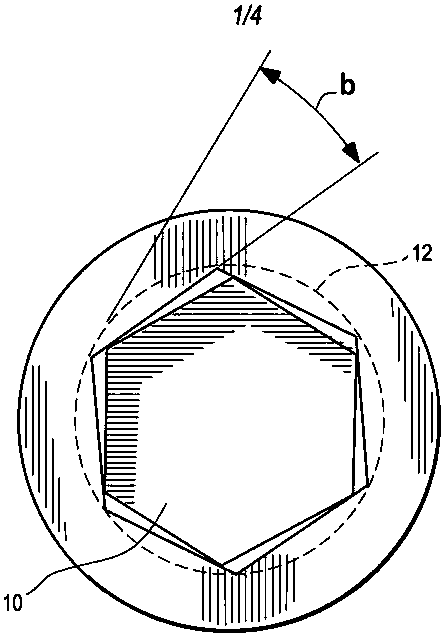

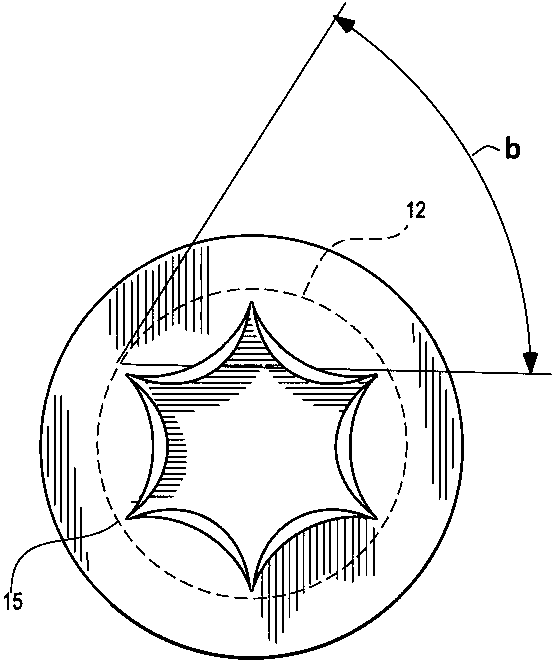

Die punch for manufacturing fasteners

The invention discloses a die punch for manufacturing fasteners. The fasteners are screwdrivers, and the die punch is a stamping die for manufacturing the screwdrivers. The punch of the die comprisesa tapered outer edge, a plurality of ribs disposed around the outer edge and a beveled surface, and the beveled surface is arranged to remove burrs. The die punch can be used for forming various slotsincluding star-shaped or plum-shaped slots. The screwdrivers are more closely inserted into slots of screws to further enable the screws to be more firmly and smoothly screwed into a workpiece, and the occurrence of shaking, vibration and tilting is reduced.

Owner:鸣达精工股份有限公司 +2

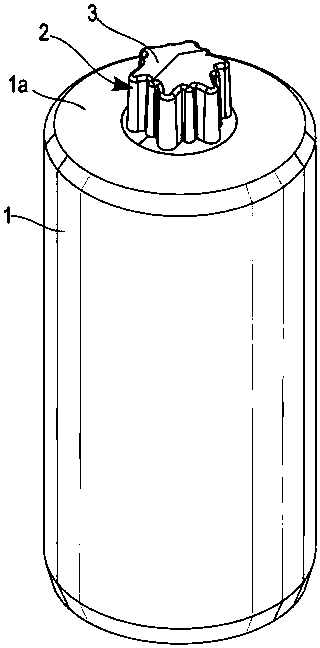

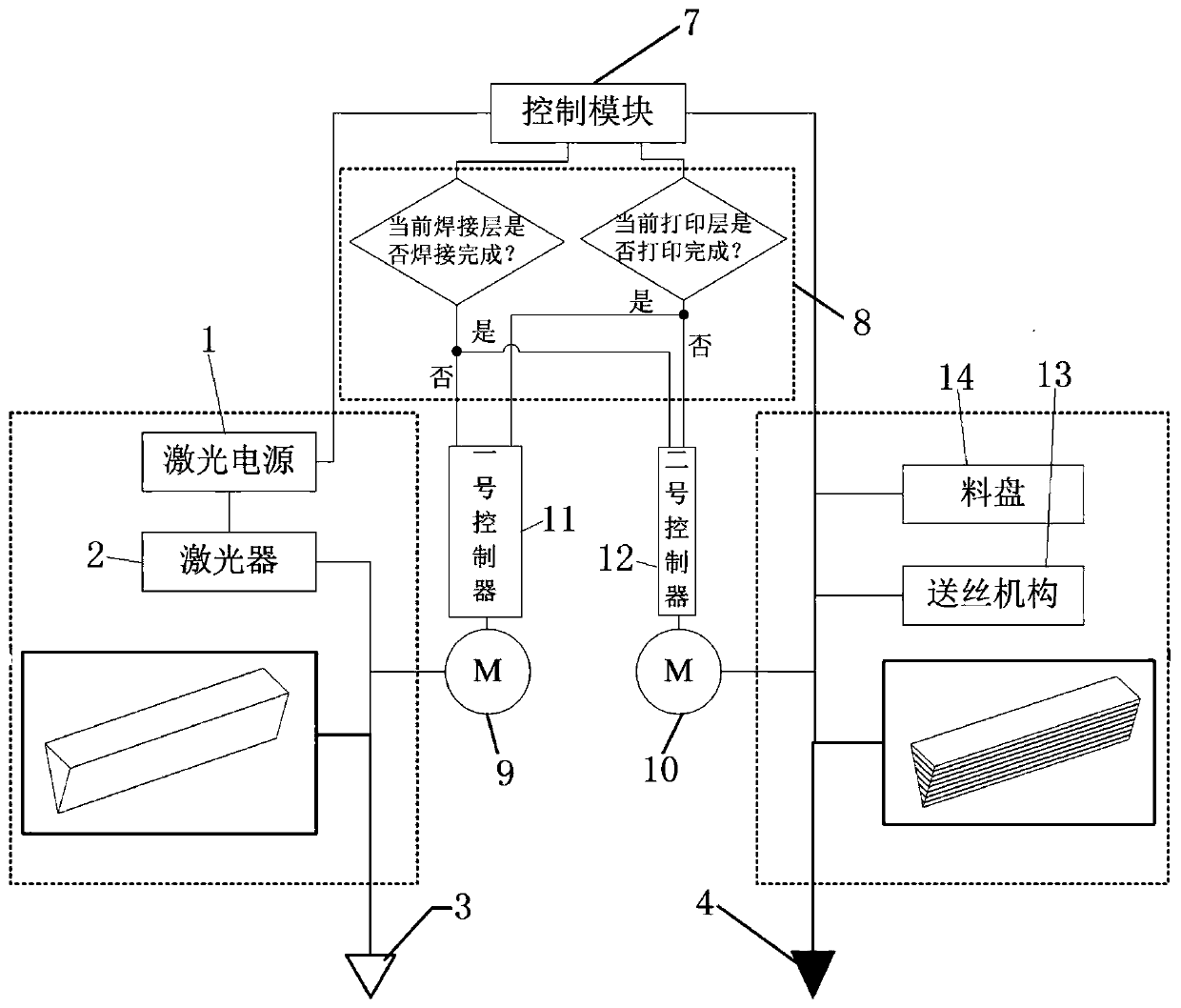

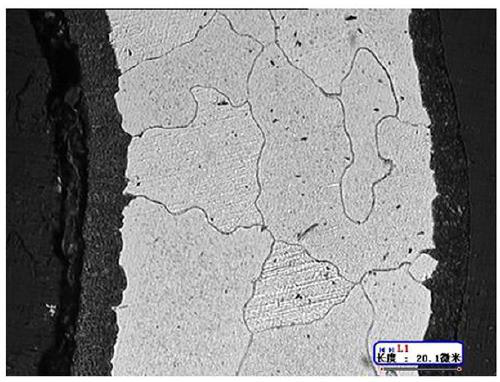

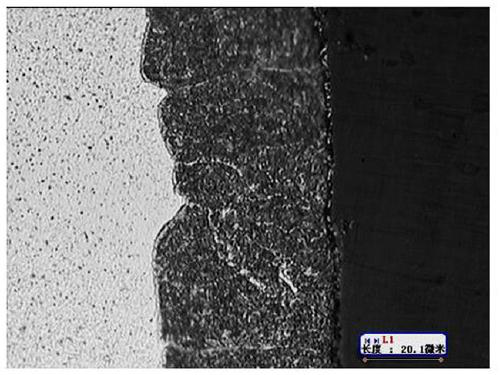

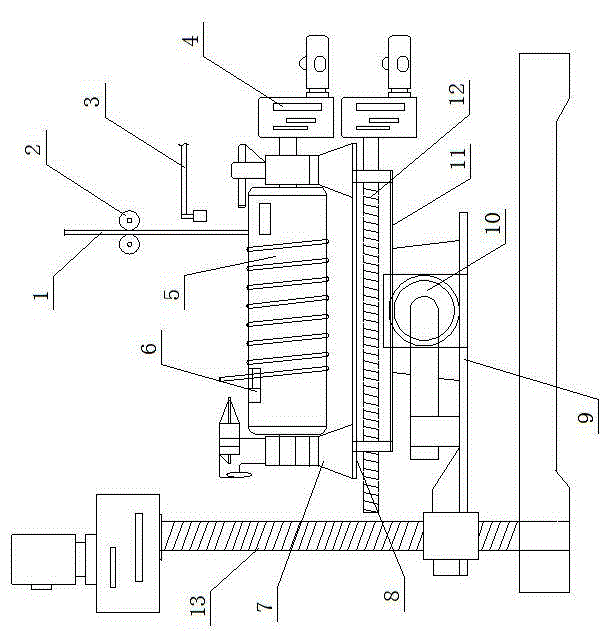

Transmission shaft torsional vibration crack welding system and method fused laser machining and 3D printing

InactiveCN110434504ANo secondary processingRealize secondary useWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneDrive shaft

The invention relates to a transmission shaft torsional vibration crack welding system and method fused with laser machining and 3D printing. The transmission shaft torsional vibration crack welding system comprises a laser machining module capable of conducting laser scanning and laser welding function switching, and a 3D printing module with a 3D printing filling solder function. According to the system, wide-depth cracks generated by torsional vibration of a transmission shaft are welded through a filling mode, and filling can realize precise machining through laser scanning and 3D printing; secondly, characteristics of laser machining are utilized, the machining belongs to non-contact point machining, the machining time is short, the cooling speed is high, the heat influence area is small, the secondary machining problem after wide-depth seam welding is eliminated, the mechanical strength of the transmission shaft after welding machining can be effectively guaranteed, and the secondary utilization of the torsional vibration damaged shaft can be realized; and finally, the system can achieve combined control of the two modules and the three functions, starting and stopping of thethree functions are completed through mode switching and control instructions, the system is simplified, and the control efficiency is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

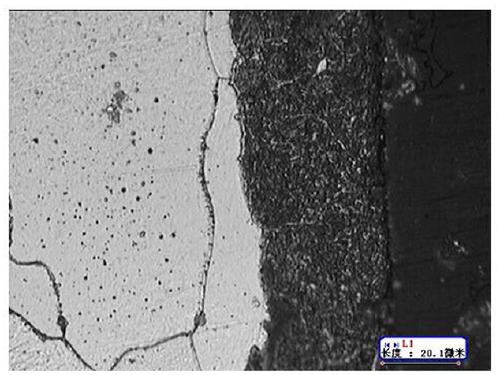

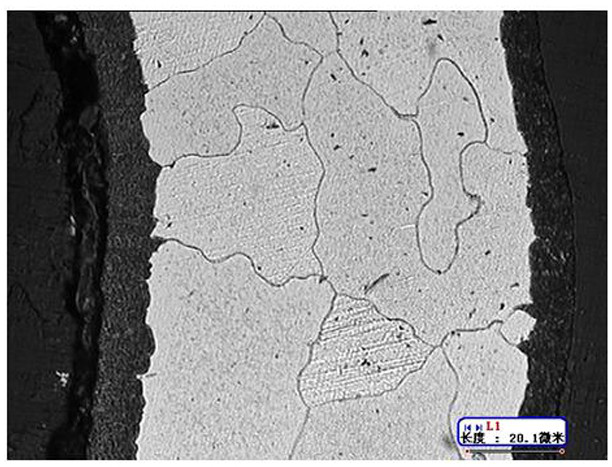

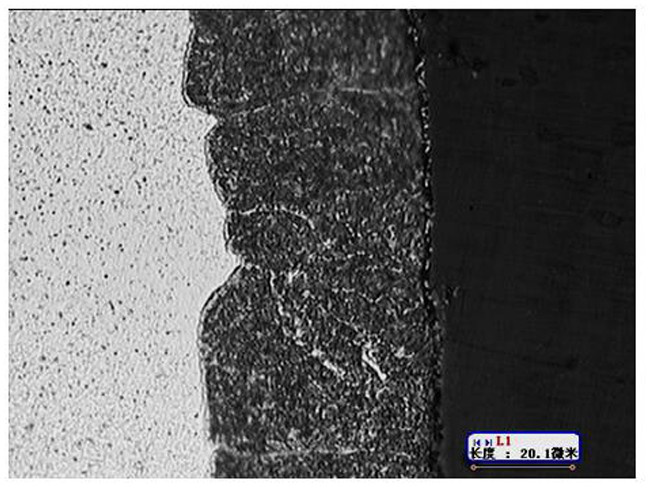

Vacuum cementation furnace 750 degrees centigrade low temperature cementation process of precision parts

ActiveCN109811295AImprove quenching hardnessThere is no breakageSolid state diffusion coatingFragilityCarbide

The invention provides a vacuum cementation furnace 750 degrees centigrade low temperature cementation process of precision parts. Cementation treatment can be carried out on metal parts at a temperature of 750 degrees centigrade; the metal parts treated by using the vacuum cementation furnace 750 degrees centigrade low temperature cementation process of the precision parts can realize uniform carburized layer, higher quenching hardness and steeper carburized layer gradient; the metal parts can realize lower fragility after annealing treatment and bending test; the bent surfaces of the metal parts have no phenomena of surface peeling, lifting and fracture; a vacuum cementation furnace using the vacuum cementation furnace 750 degrees centigrade low temperature cementation process of the precision parts does not generate intergranular oxidation in the carburizing process of the metal parts and can enhance the fatigue resistance of a workpiece material; and moreover, the surfaces of the carburized and quenched metal parts cannot generate black carbon deposit to be beneficial for follow-up electroplating processing; in addition, dotted or block-shaped carbide and residual austenite arealso not seen in the carburized layers of the produced parts; and the carburized layer and a matrix possess good bonding strength and good toughness; and the organization structure is excellent.

Owner:刘小阳

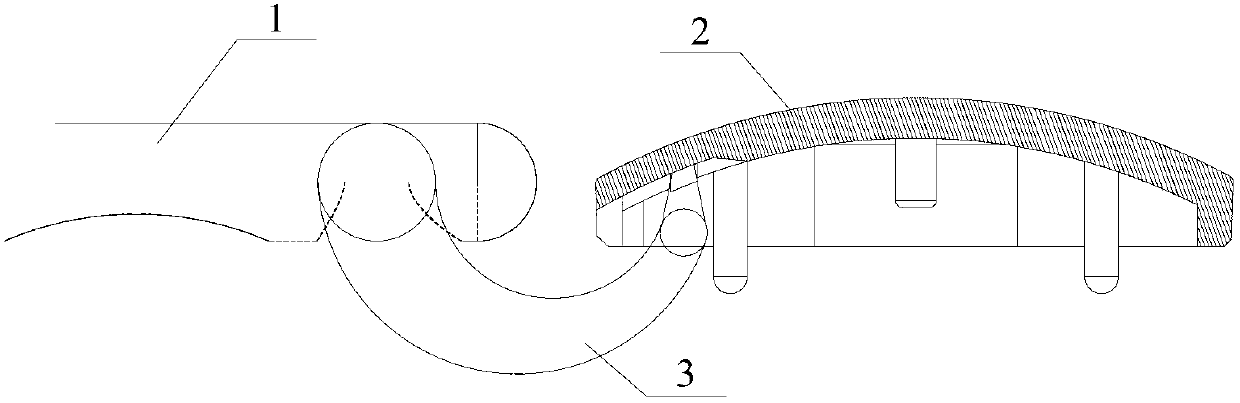

Mould with ox horn type glue-entering hole

The invention discloses a mould with an ox horn type glue-entering hole. The module comprises a pipeline for carrying out glue entering by injection molding, wherein a glue-entering hole between the pipeline and a product is folded into a camber which is downward bulged, and an outlet end of the glue-entering hole is positioned at the bottom of the product. The mould provided by the invention adopts the ox horn type glue-entering hole, a material dashing mark can not appear on the appearance of the product, the appearance surface is not provided with a glue port, and secondary processing is not needed.

Owner:KUNSHAN HAOKUN MACHINERY

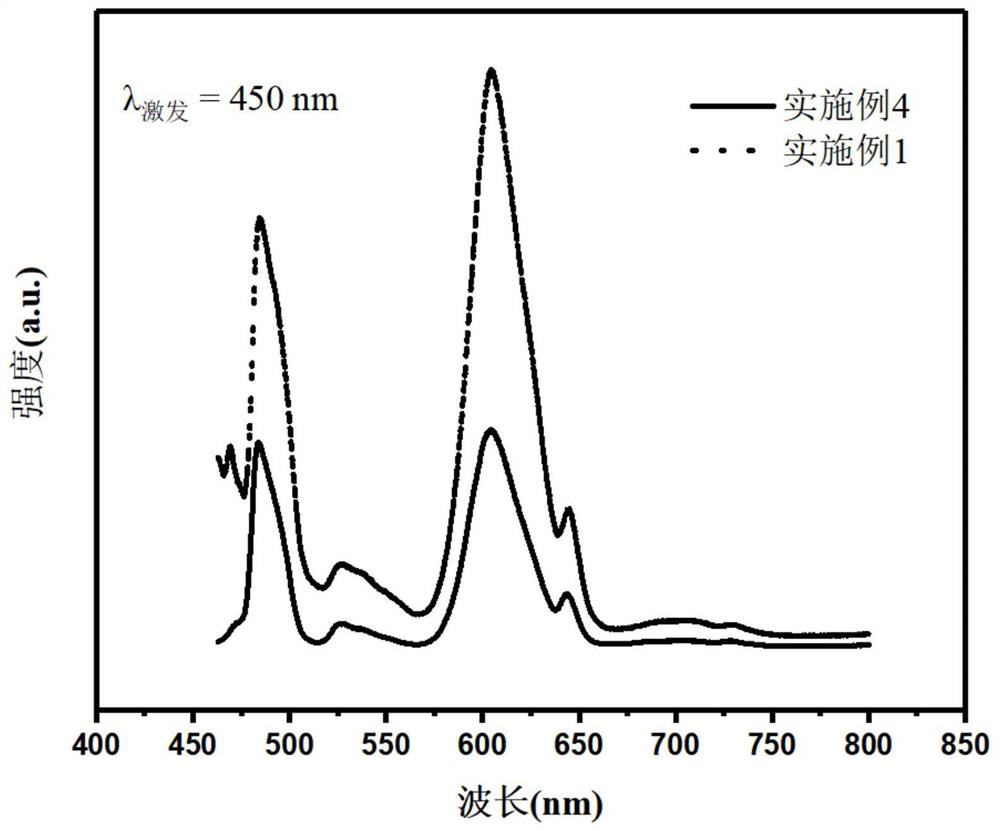

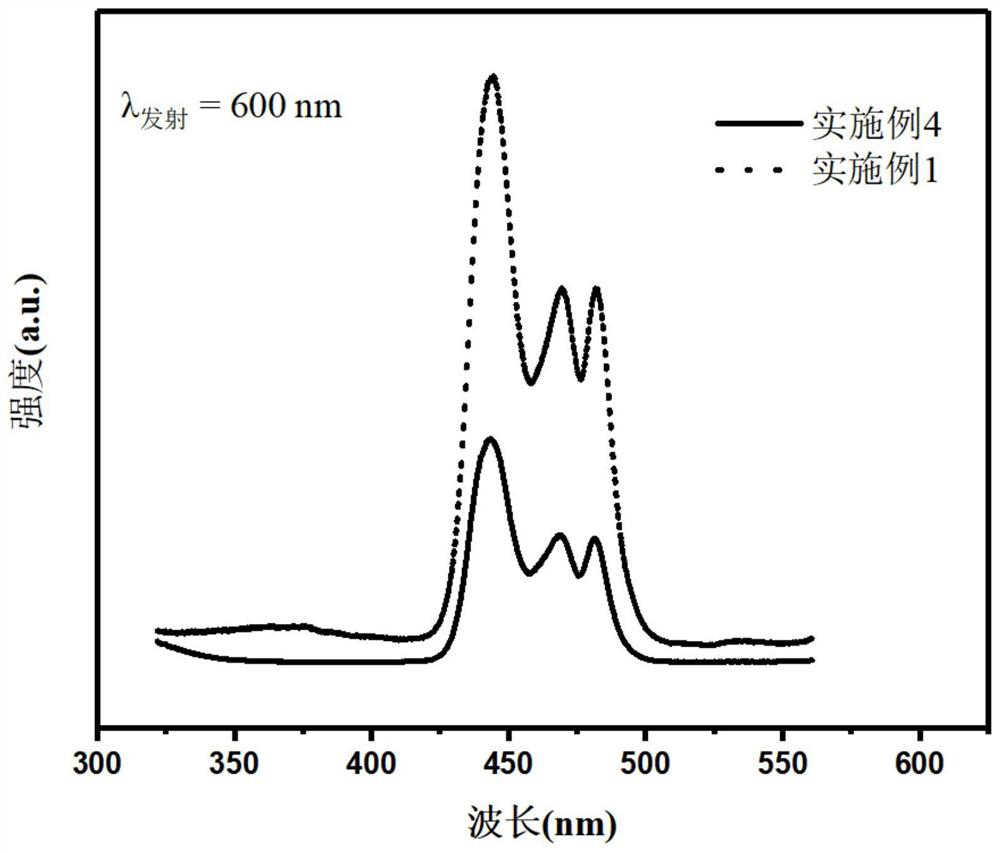

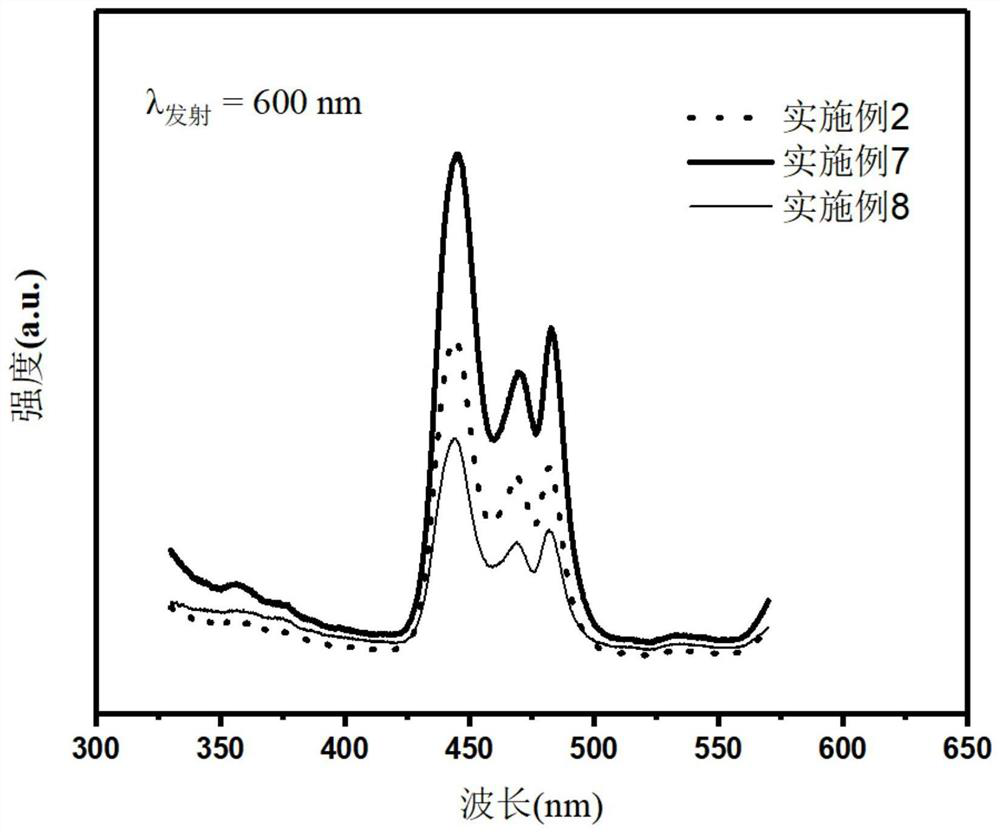

Anti-blue-light cover plate glass as well as preparation method and application thereof

PendingCN114560631AHigh strengthHigh hardnessGlass shaping apparatusIdentification meansDisplay deviceWave band

The invention provides anti-blue-light cover plate glass as well as a preparation method and application thereof. The anti-blue-light cover plate glass is prepared from the following oxides in percentage by mole: 50 to 75 percent of SiO2, 2 to 15 percent of Al2O3, 10 to 20 percent of Na2O, 5 to 15 percent of MgO, 0 to 5 percent of K2O, 0 to 6 percent of CaO and 0.01 to 1 percent of Pr < 3 + >. The anti-blue-light cover plate glass can effectively absorb blue light which is harmful to human eyes and has the wave band of 430-480 nm, has an anti-blue-light effect, can ensure that the glass has relatively high strength and hardness, and has a relatively deep surface stress layer and surface compressive stress after being chemically strengthened, so that the strength is improved, and the anti-blue-light cover plate glass has excellent mechanical properties. The preparation method is simple, does not need laminating or film coating, does not need secondary processing, is low in cost, is suitable for being used in the field of displays, and has a wide application prospect.

Owner:河北视窗玻璃有限公司 +1

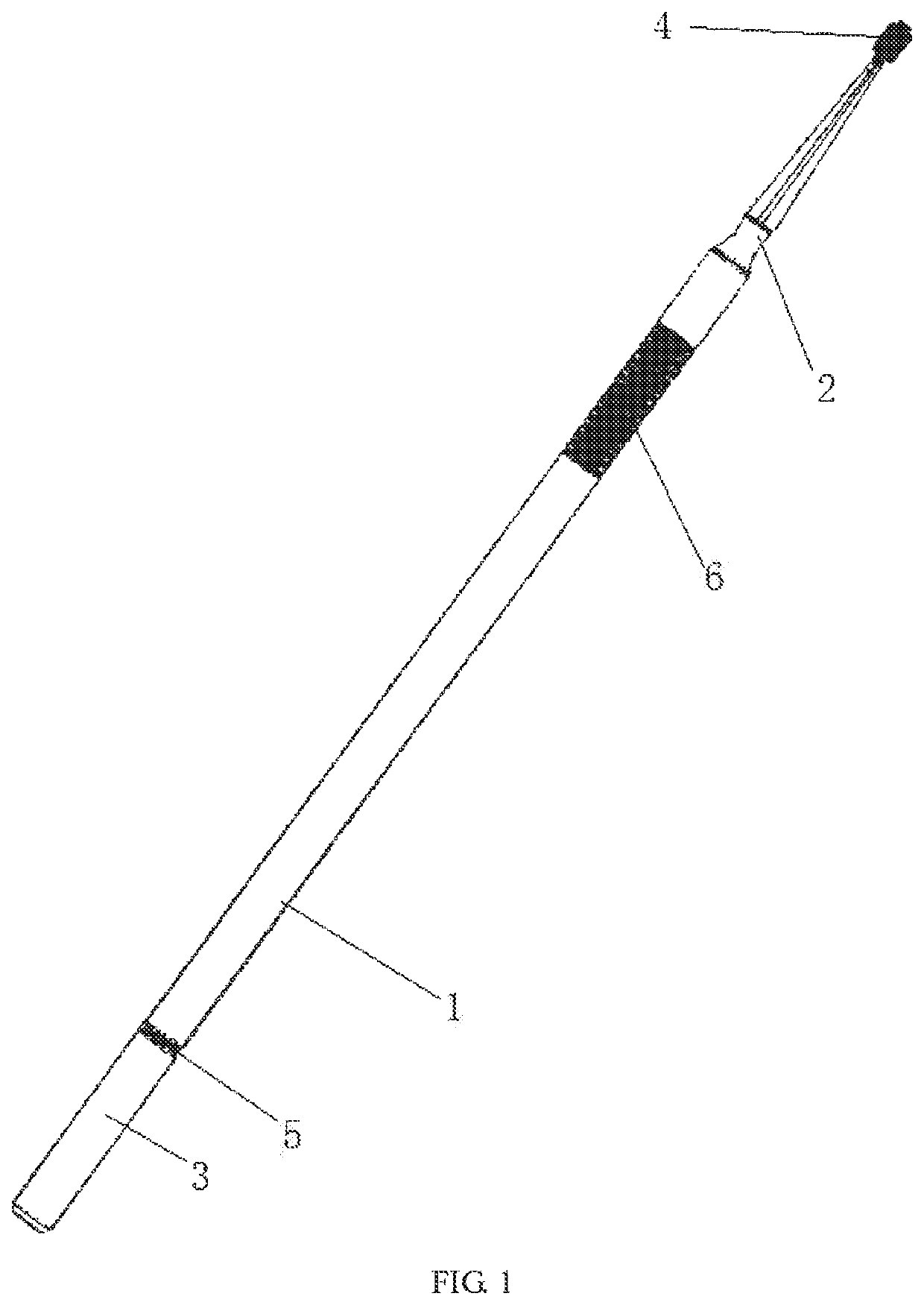

Integrally-formed flexible rubber applicator stick

ActiveUS11317704B2Simple processNot prone to losing bristles during useBrush bodiesBristleBristleEngineering

Owner:HUANGHUA PROMISEE DENTAL CO LTD

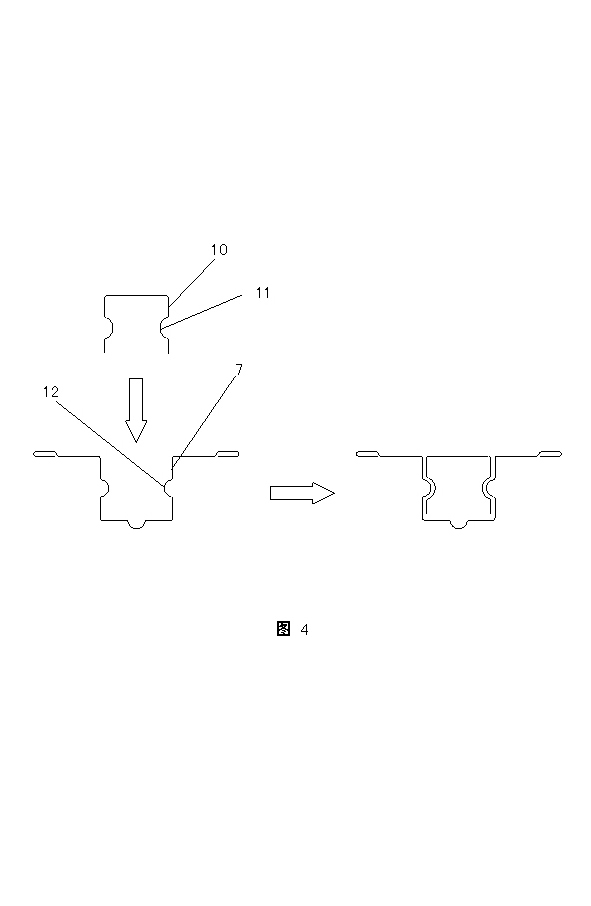

Production device and method for foam tape

PendingCN111646268ANo secondary processingArticle deliveryWebs handlingSilicone tapeManufacturing engineering

The invention relates to the field of foam tape production, and discloses a production device and method for foam tape. The production device comprises a rack; a conveying line, a first discharging shaft, a first rolling shaft and a first rolling power device are arranged on the rack; foam sleeves the first discharging shaft, and the conveying line conveys a bottom film; a die and stamping equipment are arranged above the conveying line, the stamping equipment drives the die to move up and down, and the die presses the foam on the bottom film; and the first rolling power device drives the first rolling shaft to rotate, and the first rolling shaft rolls foam waste materials pressed by the die. During using, the corresponding die can be placed below the stamping equipment according to the production specification of the foam tape, the foam of the designated specification is pressed on the bottom film through the die, thus the prepared foam tape can be directly used during using, and secondary processing is avoided.

Owner:WUXI QIANLANG TECH CO LTD

Device for directly drawing helical circular quartz tube by continuous-melt method and drawing method

ActiveCN103204621BUniform pitchQuality improvementGlass forming apparatusGlass reforming apparatusQuartzRotating drum

Disclosed are an apparatus for directly drawing a helical annular quartz tube using a continuous smelting method and a method for drawing a helical annular quartz tube using the apparatus. The apparatus comprises a rotating coiler arranged below a material outlet of a continuous smelting furnace, wherein the rotating coiler is fixed onto a support plate via a support frame, a lower part of the support plate is provided with a left / right moving mechanism driving the rotating coiler to move to the left and right, a lower part of the left / right moving mechanism is provided with a front / rear moving mechanism, and a lower end of the front / rear moving mechanism is arranged on a lifting mechanism. The rotating coiler comprises a rotating drum, wherein the rotating drum is fixed on a rotary shaft, the rotary shaft is connected to a driving electric motor via a transmission, and a quartz tube pressing plate is provided on the rotating drum. A quartz tube descent traction machine is provided between the material outlet of the continuous smelting furnace and the rotating coiler, and a quartz tube cutter is provided between the quartz tube descent traction machine and the rotating coiler.

Owner:LIANYUNGANG HUAYUAN QUARTZ PROD

Two-dimensional laser cutting pipe cutting method

ActiveCN105772950BAddress the disadvantages of limitations of useIncrease profitMetal working apparatusLaser beam welding apparatusLaser cuttingBiomedical engineering

The invention provides a cutting method for a two-dimensional laser cutting tubular product. The cutting method comprises the following steps: step 1, setting a to-be-cut path of the tubular product and dividing the to-be-cut path into three sections: a first non-edge-shared contour and an edge-shared contour located at one end and a second non-edge-shared contour located at the other end, wherein the edge-shared contour is connected to the first non-edge-shared contour and the second non-edge-shared contour; step 2, cutting the first non-edge-shared contour by using a two-dimensional cutting head; step 3, cutting the second non-edge-shared contour by using the two-dimensional cutting head; and step 4, cutting the edge-shared contour by using the two-dimensional cutting head in a one-cut ring-cutting manner. The cutting method provided by the invention cuts the tubular product by using the two-dimensional cutting head, so that an effect of three-dimensional swing angle cutting can be realized, the function of the two-dimensional cutting head is enhanced and the machining range of the two-dimensional cutting head is expanded, the actual production demand is satisfied, and the shortcoming of using limitation of the two-dimensional cutting head is overcome.

Owner:HANS LASER TECH IND GRP CO LTD +1

A kind of resource processing method of magnesium-containing raw material

ActiveCN111549239BSolve resource problemsSolve cleaning problemsProcess efficiency improvementEngineeringSulphate salt

The present invention relates to a method for recycling magnesium-containing raw materials, which comprises steps: S1: mixing and reacting a magnesium reaction solution containing sulfate and a magnesium co-solvent with magnesium-containing raw materials, controlling the pH value of the reaction system to be less than 9.0, and , solid-liquid separation to obtain magnesium-containing solution A1 and calcium-containing slag B1; S2: react magnesium-containing solution A1 with a precipitant, control the pH value of the reaction system to 5.5-12.0, after the reaction, solid-liquid separation, obtain magnesium precipitation solution A2 and Magnesium-containing precipitation B2; S3: the calcium reaction solution containing calcium solvent, calcium co-solvent and sulfate and the calcium-containing slag B1 are mixed and reacted, and the pH value of the reaction system is controlled to 5.5-12.0. After the reaction is completed, the solid-liquid separation is obtained. Calcium-containing solution A3 and tailings B3; S4: adjust the pH value of calcium-containing solution A3 to 4.0-9.5, calcium sulfate is precipitated in calcium-containing solution A3, and solid-liquid separation is obtained to obtain calcium precipitation solution A4 and calcium-containing precipitation containing calcium sulfate B4. The present invention separates magnesium and calcium from impurities in low-grade magnesium-containing raw materials without consuming additional raw materials to obtain corresponding calcium and magnesium products, reduces the cost of recycling magnesium resources, and reduces environmental pollution.

Owner:北京中金瑞丰环保科技有限公司

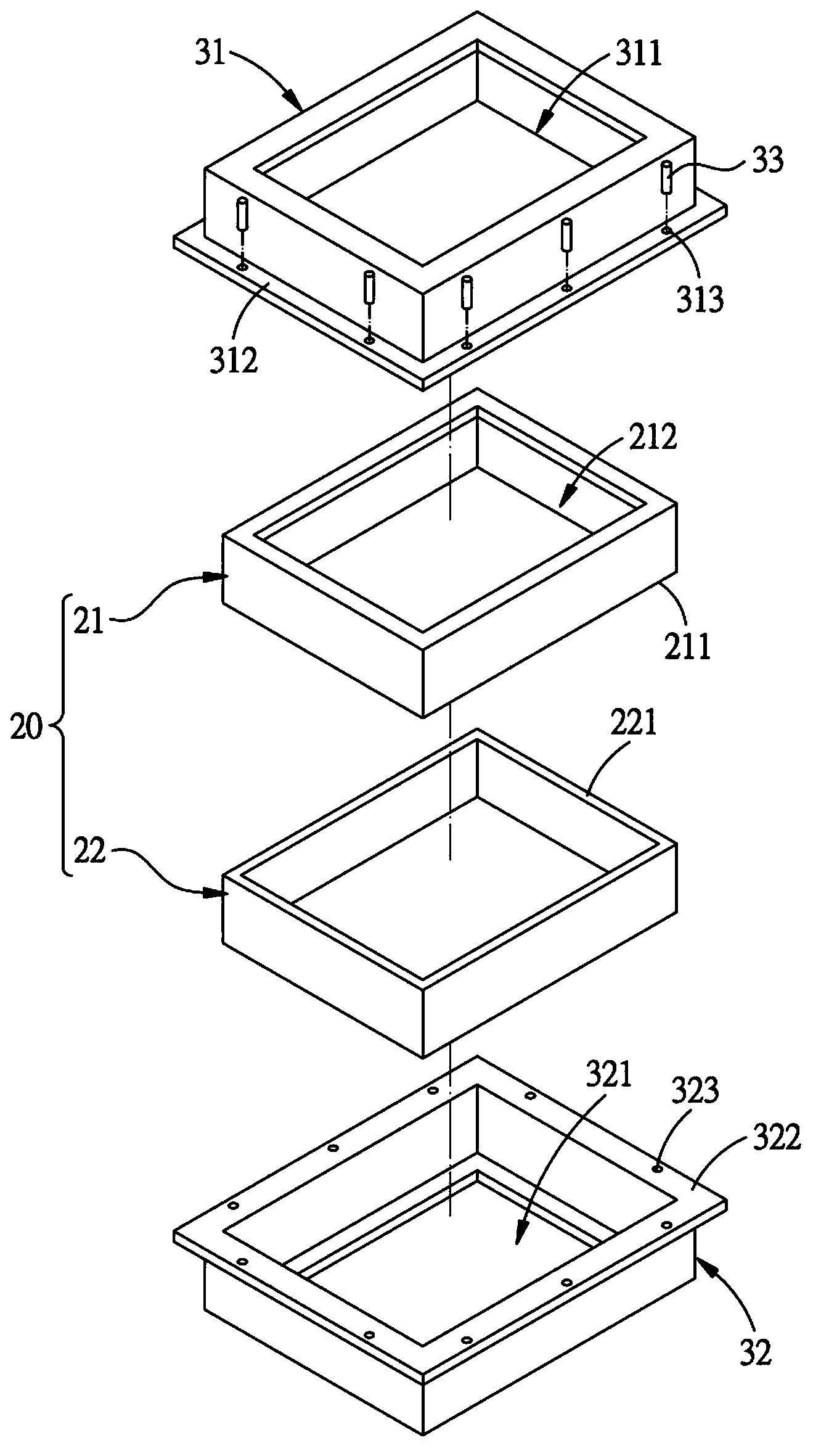

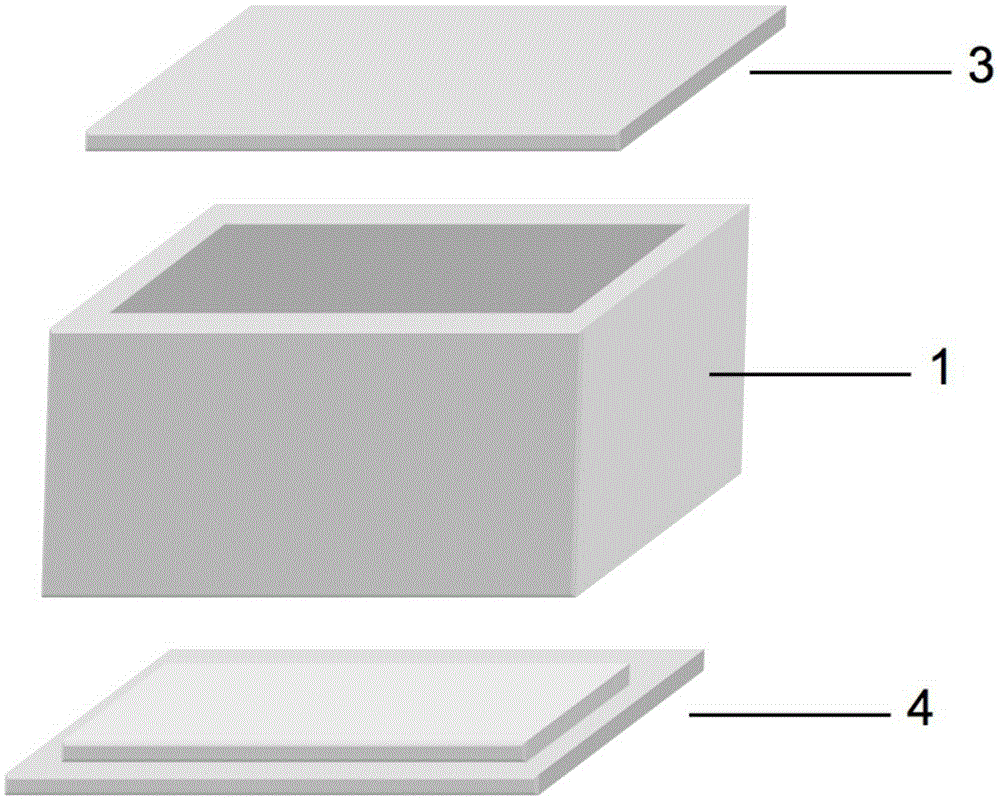

A kind of environment-friendly easy demoulding molding device and its application

ActiveCN103692685BSimple structureEasy to assemble and disassemblePressesCompression moldingEnvironmental resistance

The invention relates to an environment-friendly easily-demolded compression molding device, which comprises an outer mold 1, an assembled polytetrafluoroethylene inner lining 2, an upper cover 3, a lower cover 4, an upper sealing fin 5 and a lower sealing fin 6. The compression molding device is simple and practical in structure, and is convenient to disassemble and assemble; the surface of a molding material is not polluted, the molding material can be used repeatedly, demolding is very smooth, the molding material is smooth and flat on the surface and does not need secondary machining, machining procedures are reduced, and the aims of simplifying demolding post-treatment and improving the economic efficiency and environmental friendliness are fulfilled. When the device is applied to molding equipment for buoyancy materials, the problems of low yield, poor economic efficiency and environmental pollution existing in a buoyancy material molded by using the conventional demolding method are solved.

Owner:OCEAN UNIV OF CHINA

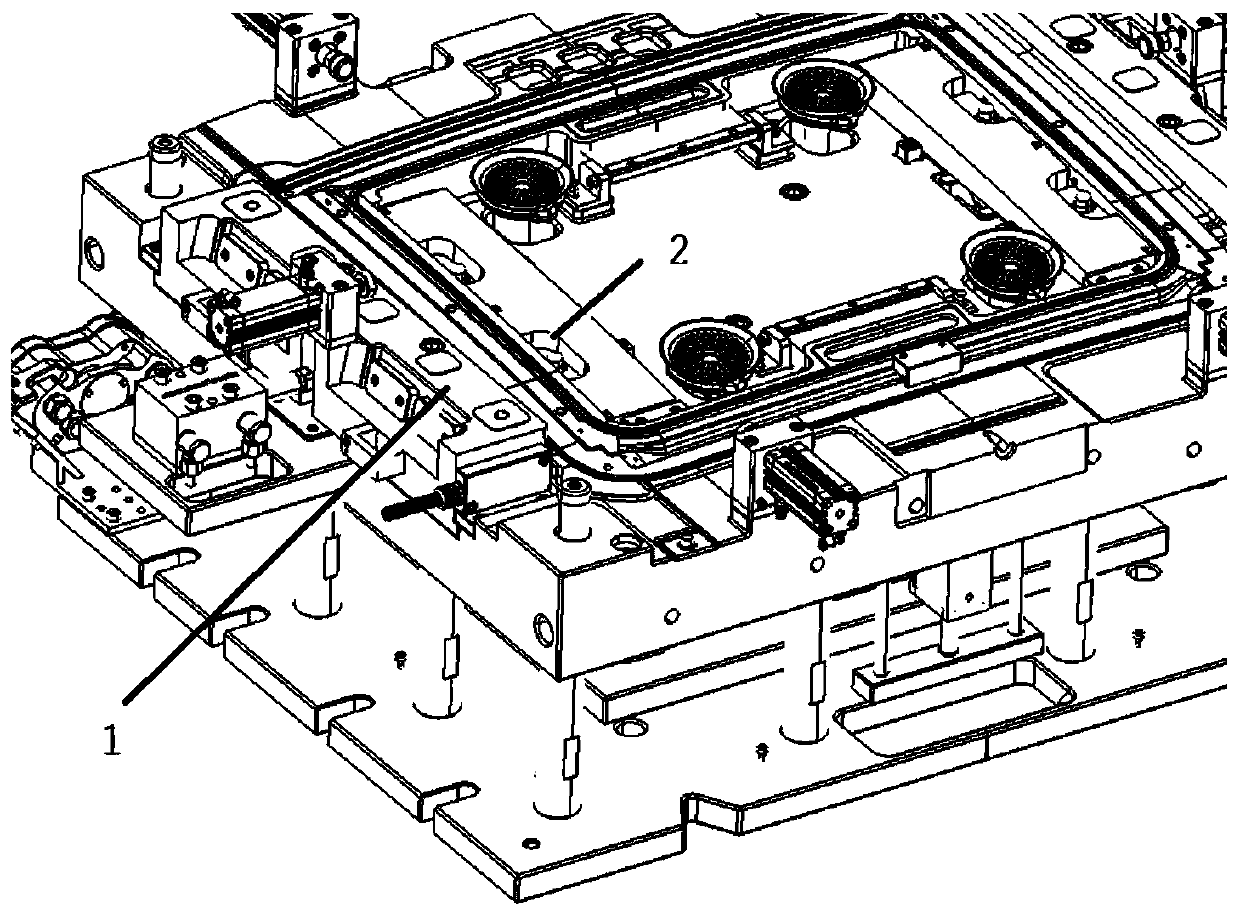

Positioning mechanism for iron parts on left and right sides of automobile sunroof products

PendingCN109986743AReduce flashingReduce grinding processDomestic articlesEngineeringMechanical engineering

The invention relates to a positioning mechanism for iron parts on left and right sides of automobile sunroof products. The positioning mechanism comprises an outer positioning assembly and an inner positioning assembly, wherein the outer positioning assembly comprises a bottom plate and a driving air cylinder, a diagonal pressing block, a guiding rail and an ejection spring, which are fixed on the bottom plate; the guiding rail is movably connected with a side pulling slider; one end of the ejection spring is connected with the side, close to an iron part, of the side pulling slider; the other end of the ejection spring abuts the iron part; the inner positioning assembly comprises a driving gas cylinder, an ejection member and a connecting rod member, which are fixed on a lower mold; a plurality of positioning pins are movably penetrated in the ejection member; the connecting rod member is used for transferring the pushing force of the driving gas cylinder to the ejection member; andone end of the positioning pin is pushed into a positioning hole or the positioning pin in the positioning hole is pulled back to ejection member through the ejection member. Compared with the prior art, the positioning mechanism saves the time of secondary ejection after ejecting and opening a clamping block, reduces the flashing phenomenon during the injection molding, and improves the product yield.

Owner:福耀玻璃(苏州)有限公司

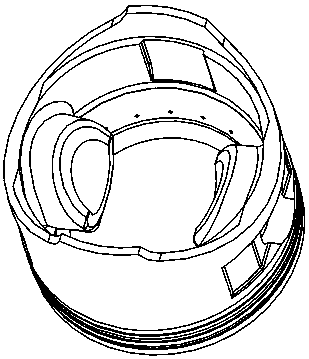

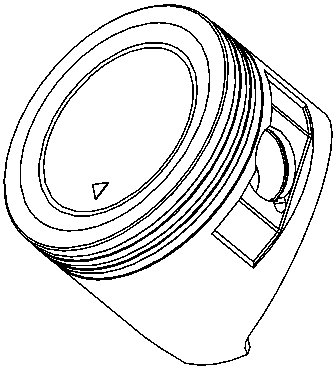

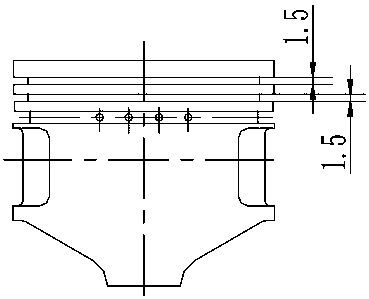

T-shaped piston on general gasoline machine

PendingCN108691685AReduce weightReduce resistancePiston ringsMachines/enginesPiston ringPressure casting

The invention discloses a T-shaped piston on a general gasoline machine. The T-shaped piston comprises a piston body which is integrally in a T shape, the piston body comprises a head portion and a skirt portion, the head portion comprises a piston ring, the top surface of the piston ring is of a flat top structure, the periphery of the piston ring is provided with at least two circular grooves which are parallelly distributed at intervals in the axial direction, the thickness of each circular groove is 1 mm, the skirt portion comprises a front arc surface, a left straight surface, a reverse arc surface and a right straight surface which are connected end to end to form a frame-shaped structure, the left straight surface and the right straight surface are provided with a left pin shaft sleeve tube and a right pin shaft sleeve tube correspondingly, the left pin shaft sleeve tube and the right pin shaft sleeve tube are designed coaxially, the front arc surface is provided with an oil return hole which is formed by integral pressure casting, and the outer walls of the front arc surface and the reverse arc surface are matched with the outer wall of the piston ring correspondingly. By means of the T-shaped piston on the general gasoline machine, the friction force is reduced, and the service life is prolonged.

Owner:TAIZHOU HUANYANG ELECTRIC & MACHINERY

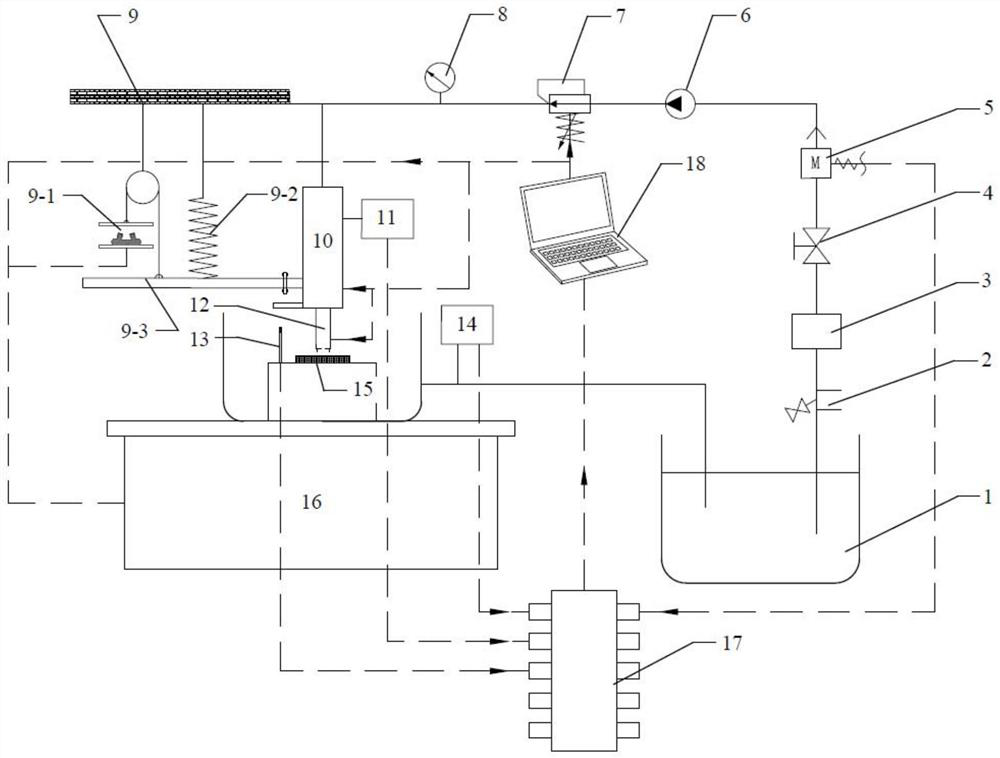

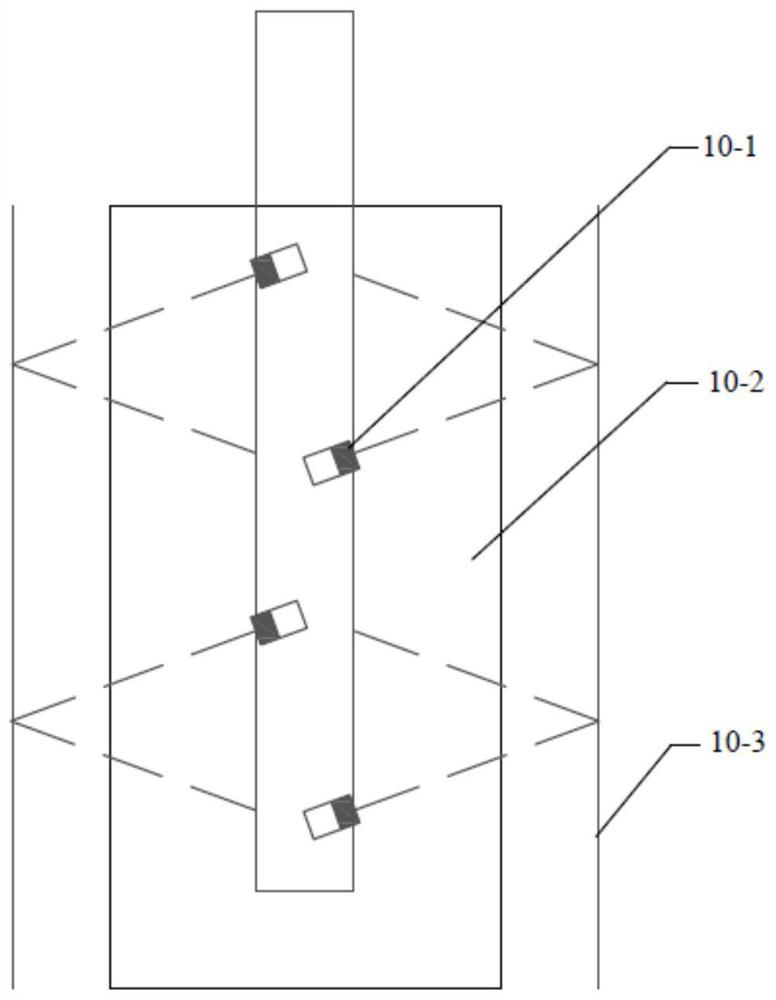

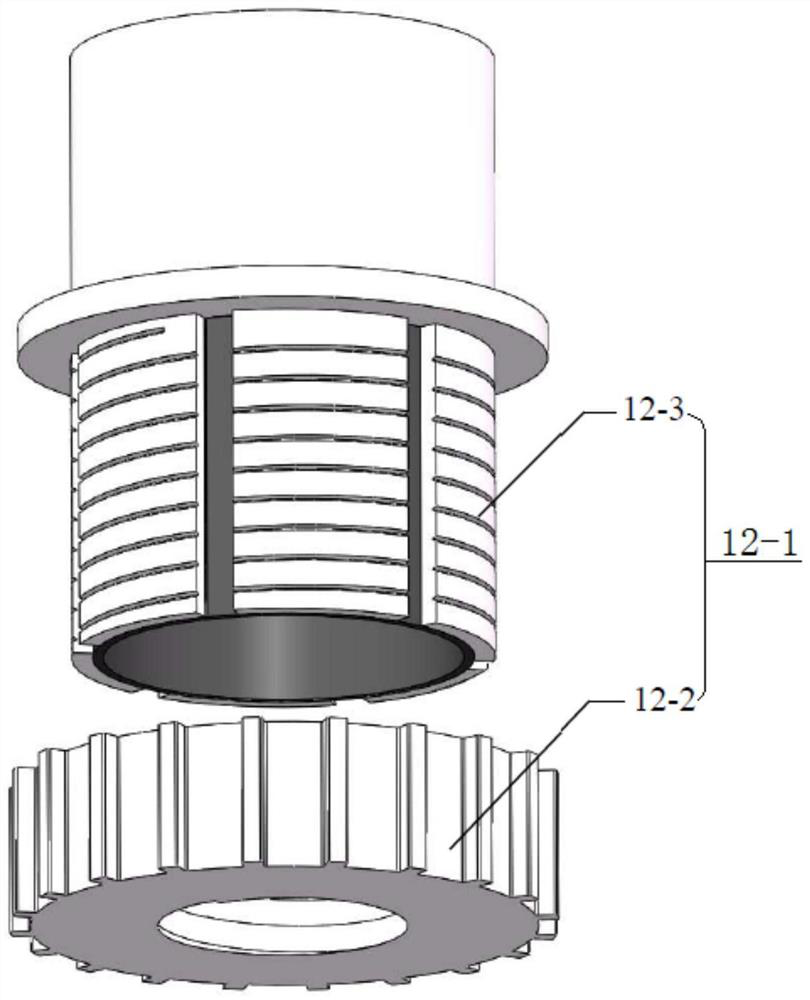

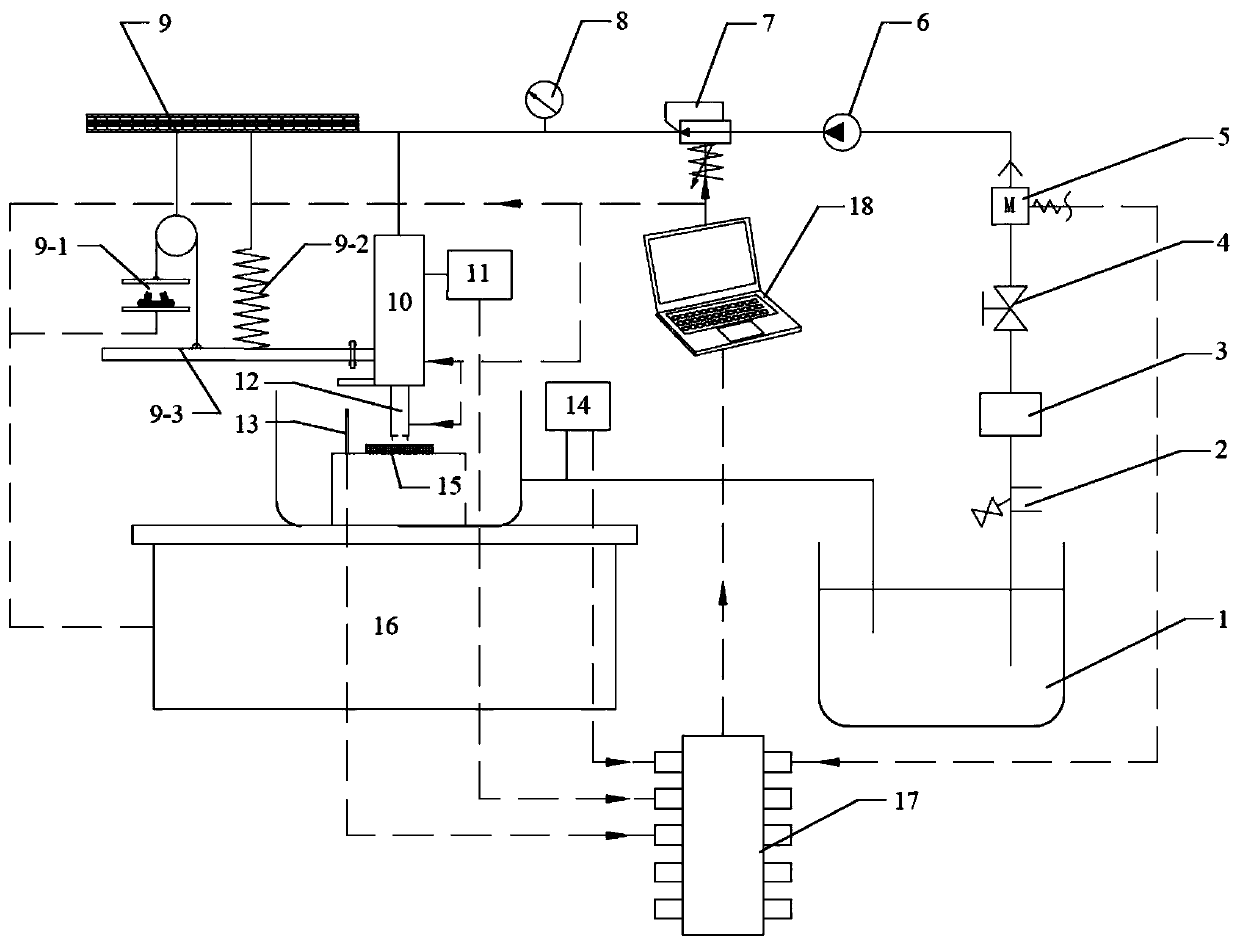

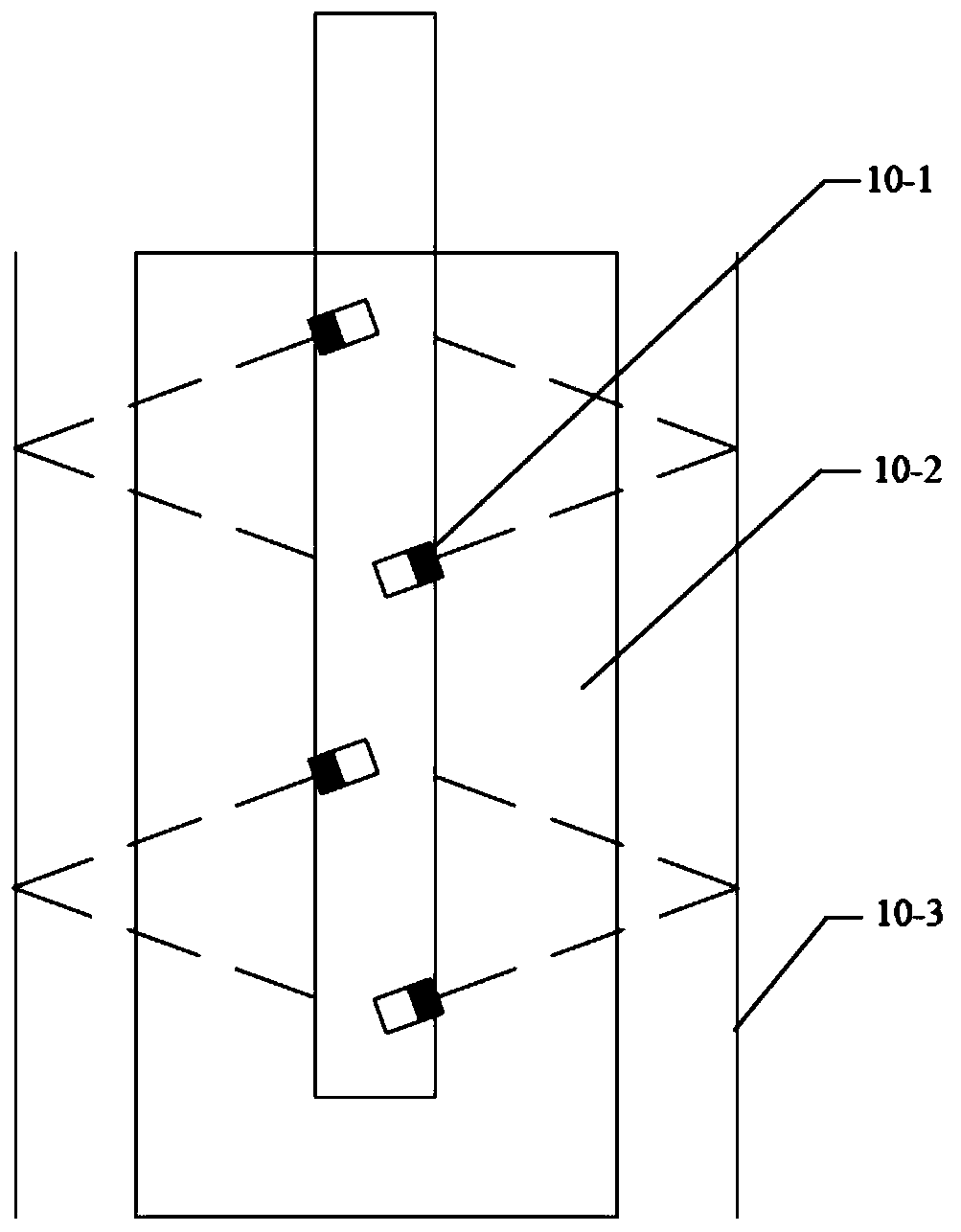

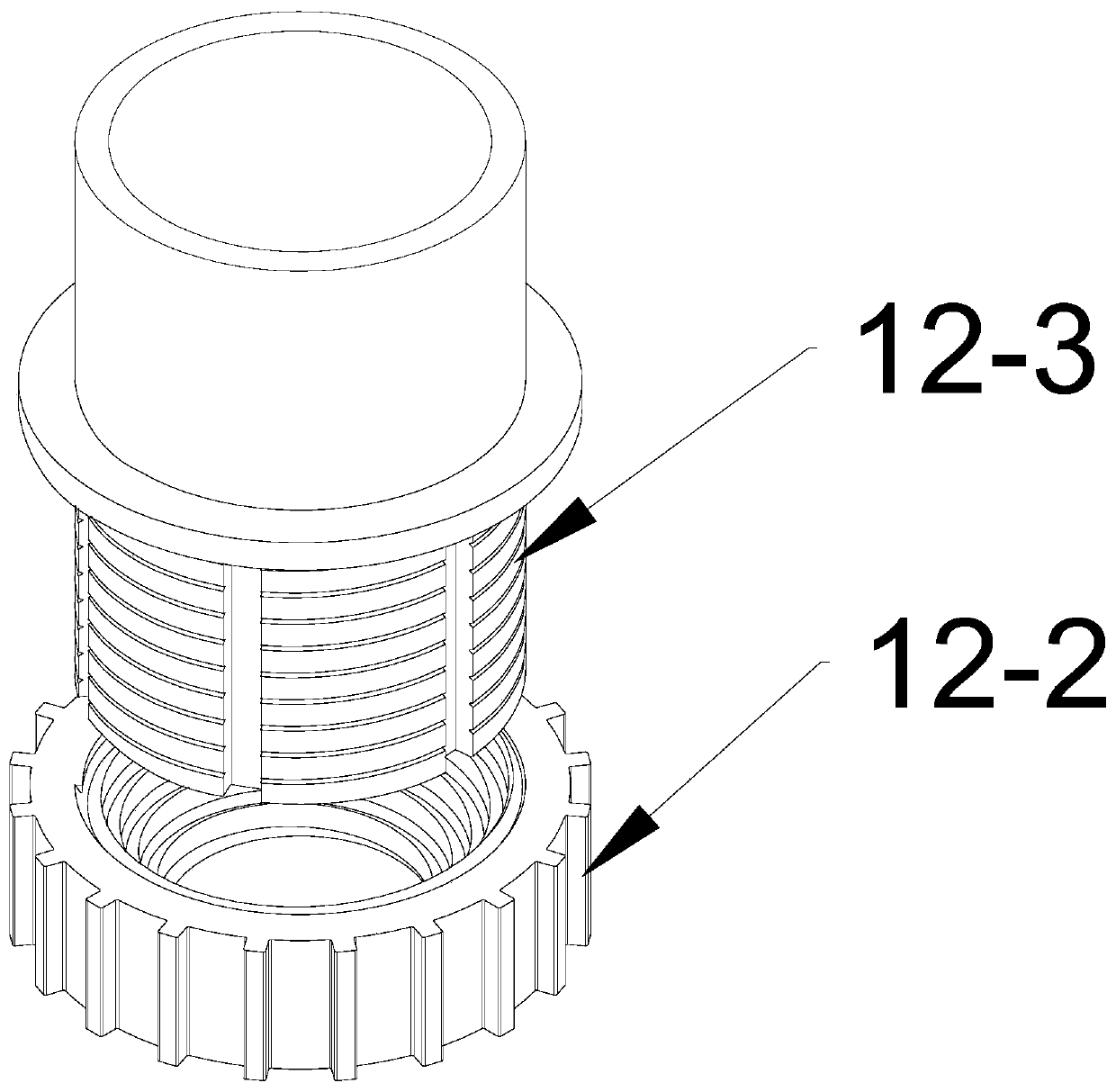

A texture processing test device based on controllable cavitation technology

ActiveCN111300273BAvoid "flapping" phenomenonNo secondary processingBlast gunsSpray nozzlesNumerical controlWater storage tank

The invention provides a texture processing test device based on controllable cavitation technology, which has the advantages of no thermal deformation, no secondary processing, no limitation of processing materials, and non-parallel contact secondary texture processing, including numerical control precision Moving platform, electromagnetic loading mechanism, water storage tank, reflective laser cavitation generator, rotary controllable diameter nozzle, texture processing monitoring and feedback control system, medium water generates a large amount of air after passing through the reflective laser cavitation generator The cavitation bubbles are transferred to the surface of the processed material through the rotary controllable nozzle, and the texture processing is carried out by using the crushing force of the cavitation bubbles. During the processing, the crushing force is controlled in real time by the texture processing monitoring and feedback control system, and at the same time The texturing at a given position of the workpiece is realized by the X‑Y direction CNC precision moving platform and the Z direction electromagnetic loading mechanism.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Texture processing test device based on controllable cavitation technology

ActiveCN111300273AAvoid "flapping" phenomenonNo secondary processingBlast gunsSpray nozzlesNumerical controlWater storage tank

The invention provides a texture processing test device based on the controllable cavitation technology. The texture processing test device has the beneficial effects that no thermal deformation exits, no secondary processing is needed, the limitation problem of a machining material is avoided, and non-parallel contact pair texture processing can be carried out. The texture processing test devicecomprises a numerical control precision moving platform, an electromagnetic loading mechanism, a water storage tank, a reflective laser-generated cavitation generator, a rotating diameter-controllablenozzle and a texture processing monitoring and feedback control system. The medium water generates a large amount of cavitation bubbles after passing through the reflective laser-generated cavitationgenerator, the cavitation bubbles are transferred to the surface of the processing material through the rotating diameter-controllable nozzle, the crushing force of the cavitation bubbles is utilizedfor texture processing, the breaking force in the machining process is controlled in real time through the texture processing monitoring and feedback control system, and meanwhile, the X-Y-directionnumerical control precision moving platform and the Z-direction electromagnetic loading mechanism achieve texturing at a given position of a workpiece.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A 750°C low-temperature carburizing process in a vacuum carburizing furnace for precision parts

ActiveCN109811295BImprove quenching hardnessThere is no breakageSolid state diffusion coatingCarbideCementation process

The vacuum carburizing furnace 750°C low-temperature carburizing process for precision parts of the present invention can realize carburizing treatment on metal parts at a temperature of 750°C, and the metal parts treated by the carburizing process can be uniform Infiltrated layer, higher quenching hardness, steeper infiltrated layer gradient and lower brittleness of metal parts after tempering and bending test, no surface peeling, peeling and fracture on the bending surface of metal parts phenomenon, the vacuum carburizing furnace using this process does not have intergranular oxidation during the carburizing process of metal parts, which can improve the fatigue resistance of the workpiece material, and the surface of the metal parts after carburizing and quenching will not produce black spots Carbon is beneficial to the subsequent electroplating process. In addition, there are no point-like or massive carbides and no residual austenite in the carburized layer of the parts produced by using it. The carburized layer and the matrix have the same Good bonding strength and good toughness, excellent organizational structure.

Owner:刘小阳

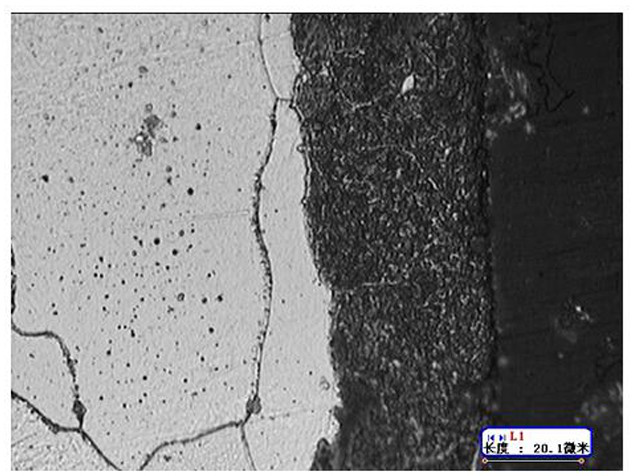

Drip tray and air conditioner

PendingCN113773605AImproved liquid repellencyGood adhesionCondensate preventionLighting and heating apparatusProcess engineeringMechanical engineering

The invention discloses a drip tray and an air conditioner, and belongs to the field of ABS plastic cleaning materials for air conditioner drip trays. The drip tray is made of a cleaning material, and raw materials for preparing the cleaning material comprise ABS plastic, a low-surface-energy material and an inorganic nano material. The mass fraction of the ABS plastic is 80%-99.9%, the mass fraction of the low surface energy material is 0.1-20%, and the mass fraction of the inorganic nano material is greater than 0. The drip tray is applied to cleaning of air conditioners, solves the problems that an existing ABS material is limited in surface energy reduction and is not thorough in cleaning when being used as a drip tray material for air conditioners, and has the characteristics of good lyophobic performance, strong self-cleaning capability, simple preparation process and easiness in industrial production.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Heat-conducting plastic cement and moulding method thereof

The invention discloses a heat-conducting plastic cement and a moulding method thereof. Nylon PA6 / PA66 is used as a base material of the heat-conducting plastic cement. The heat-conducting plastic cement is prepared by mixing aluminum nitride AlN, silicon carbide SiC, silicon trioxide Al2O3, graphite, fibrous high-thermal-conductivity carbon powder and scaly high-thermal-conductivity carbon powderwhich are used as fillers; wherein the nylon PA6 / PA66 accounts for 50 to 60wt%, the aluminum nitride AlN accounts for 3 to 5wt%, the silicon carbide SiC accounts for 4 to 6wt%, the silicon trioxide Al2O3 accounts for 5 to 8wt%, the graphite accounts for 10 to 15wt%; the fibrous high-thermal-conductivity carbon powder accounts for 6-10wt%; the scaly high-thermal-conductivity carbon powder accountsfor 6-10wt%. The moulding method of the heat-conducting plastic cement comprises the following steps: A, drying the heat-conducting plastic cement materials, wherein heating for 4-6H at the temperature of 110-130 DEG C for later use; B, by adopting following parameters, carrying out injection molding at the mold temperature of 60-100 DEG C, and the material temperature at 240-300 DEG C; the backpressure of 1-3 atmospheric pressures. Due to the application of the technical scheme, the product manufactured by the invention has the advantages of good heat-conducting property, low specific gravity and good portability; and the production period is short, insulation treatment is not needed, and the production cost is low.

Owner:苏州兆如电子有限公司

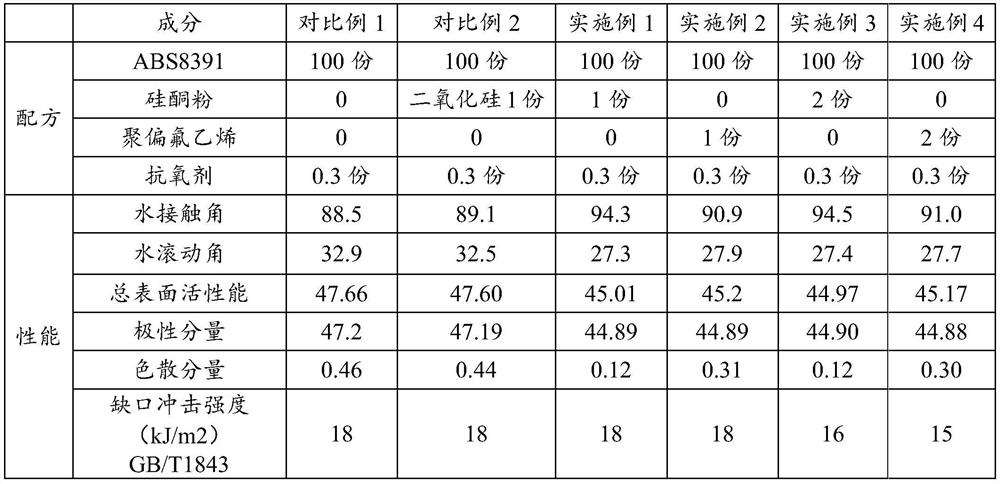

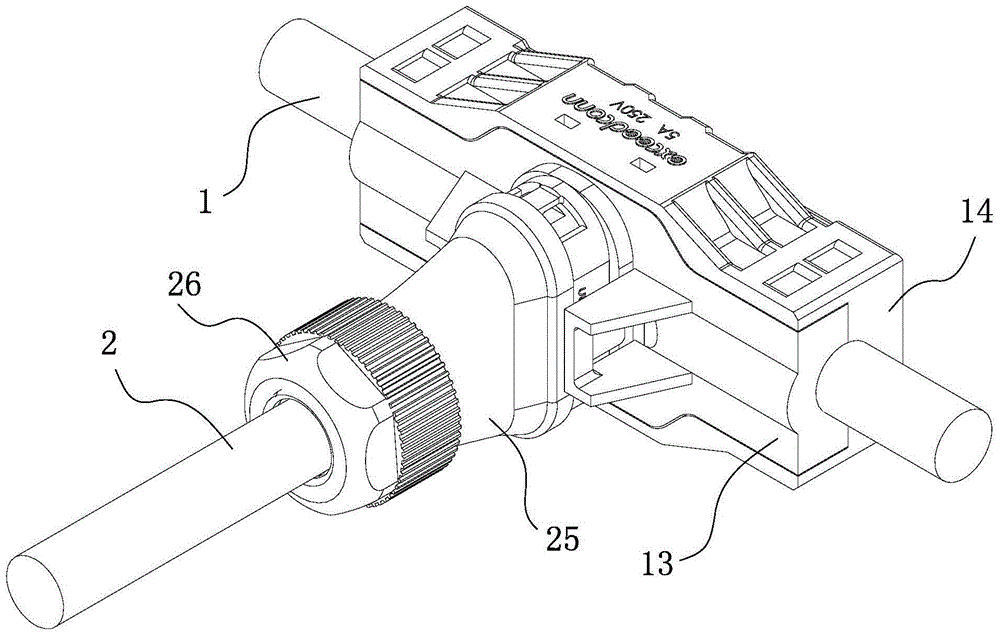

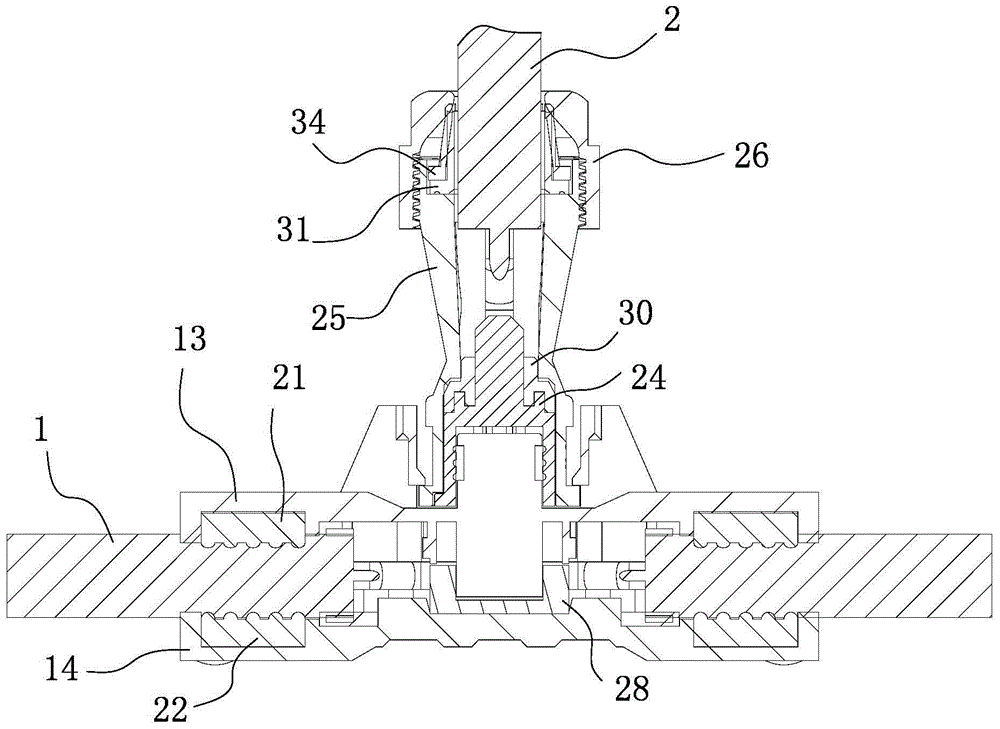

T-shaped structure connector for photovoltaic inverter

ActiveCN103811934BEasy to assembleEasy to processCoupling contact membersCouplings bases/casesTuning forkEngineering

The invention discloses a T-shaped structure connector of a photovoltaic inverter, which includes a male end and a female end. The male end is provided with a shell composed of an upper cover and a lower cover. In the cavity of the bus, the upper cover is provided with the jack corresponding to each male terminal, and the inlet, outlet and jack at both ends of the housing are respectively provided with waterproof parts; the female terminal is provided with The shell is composed of a protective cover, a main body and a nut. The main body is provided with a connection hole. The protective cover is sleeved on the outside of the female end. The nuts are threaded, and the front and rear ends of the protective cover are respectively provided with front and rear waterproof parts. The present invention constitutes the shell of the male end and the outer shell of the female end by clamping, which saves the glue-covering process, and realizes the connection of the core wire by directly plugging the tuning fork terminal with the core wire, eliminating the need for peeling and other processes, and the assembly is more efficient. Convenience and improved production efficiency.

Owner:苏州丰年科技股份有限公司

A support block material that does not crush the outer circle of the camshaft

The invention discloses a support block material which does not damage the outer circle of the camshaft. It is made of six metal materials, copper, tungsten, nickel, tin, zinc and platinum, according to the weight ratio, mixed with metal powder, molded and sintered. To form a support block with an alloy hardness of HRC 29-30, the formula weight percentage range for preparing the support block material of the present invention is: copper 50-70%, tungsten 10-30%, nickel 5-15%, tin 1-5% , 1-5% zinc, 1-5% platinum; the use of the support block material of the present invention can not only ensure the hardness requirements of the support block, but also meet the requirements of mass production, leave no traces after the workpiece is processed, and eliminate the phenomenon of crushing the workpiece .

Owner:JIANGXI TONGXIN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com