Positioning mechanism for iron parts on left and right sides of automobile sunroof products

A technology for left and right side, car sunroofs, applied in household components, applications, household appliances, etc., can solve the problems of difficult flash cleaning process, waste of mold opening time, lengthened overall production process, etc., to improve labor efficiency and yield , Guarantee the specific position and angle, and reduce the effect of the secondary rework process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

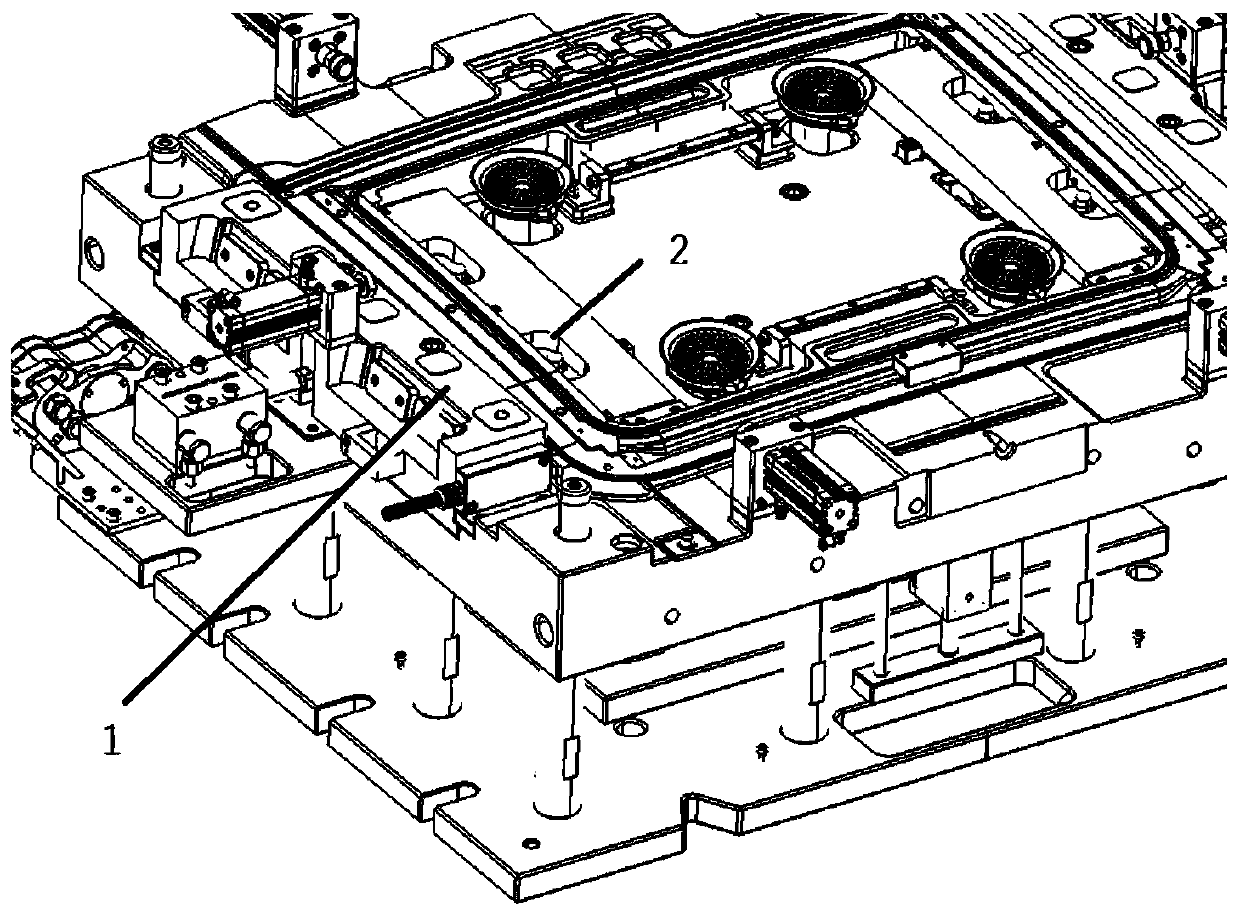

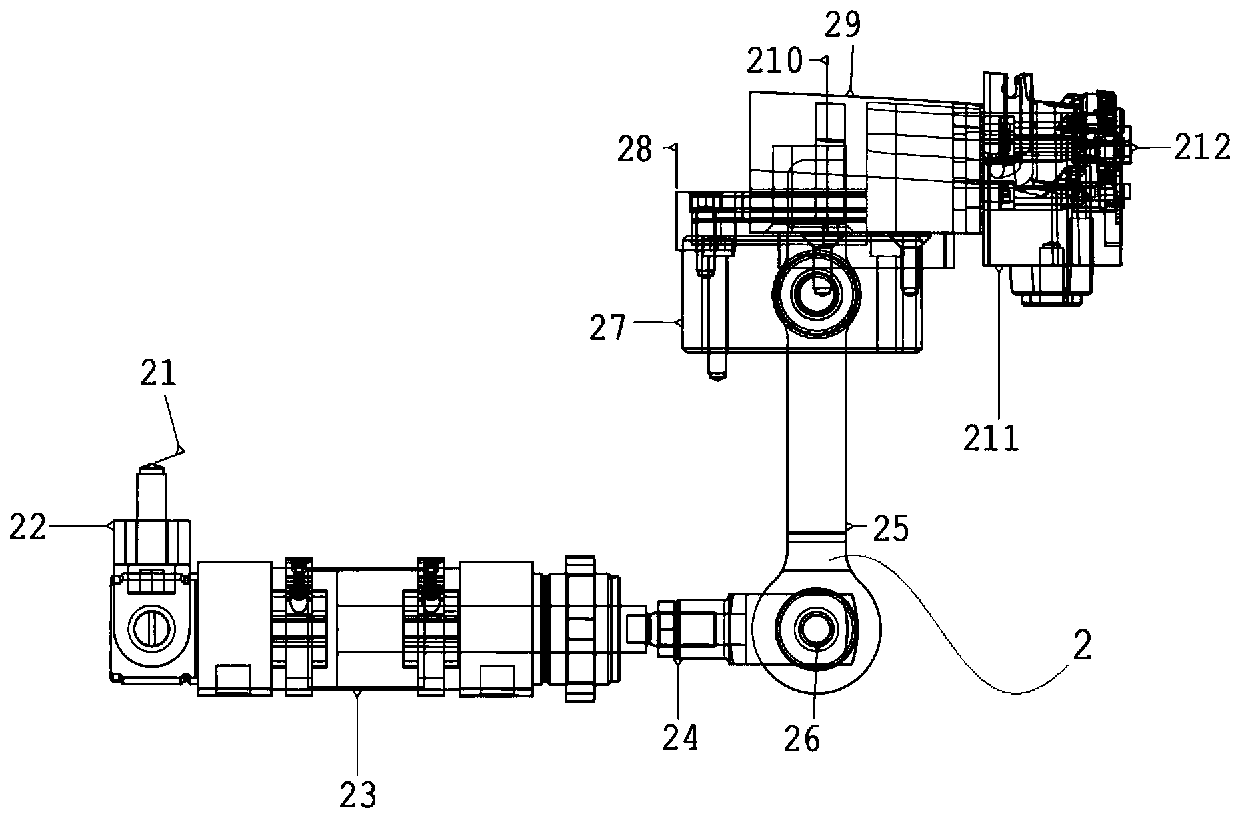

[0023] A positioning mechanism for iron parts on the left and right sides of a car sunroof product, used for positioning the iron parts in the injection molding process, including: an outer positioning component 1 and an inner positioning component 2 .

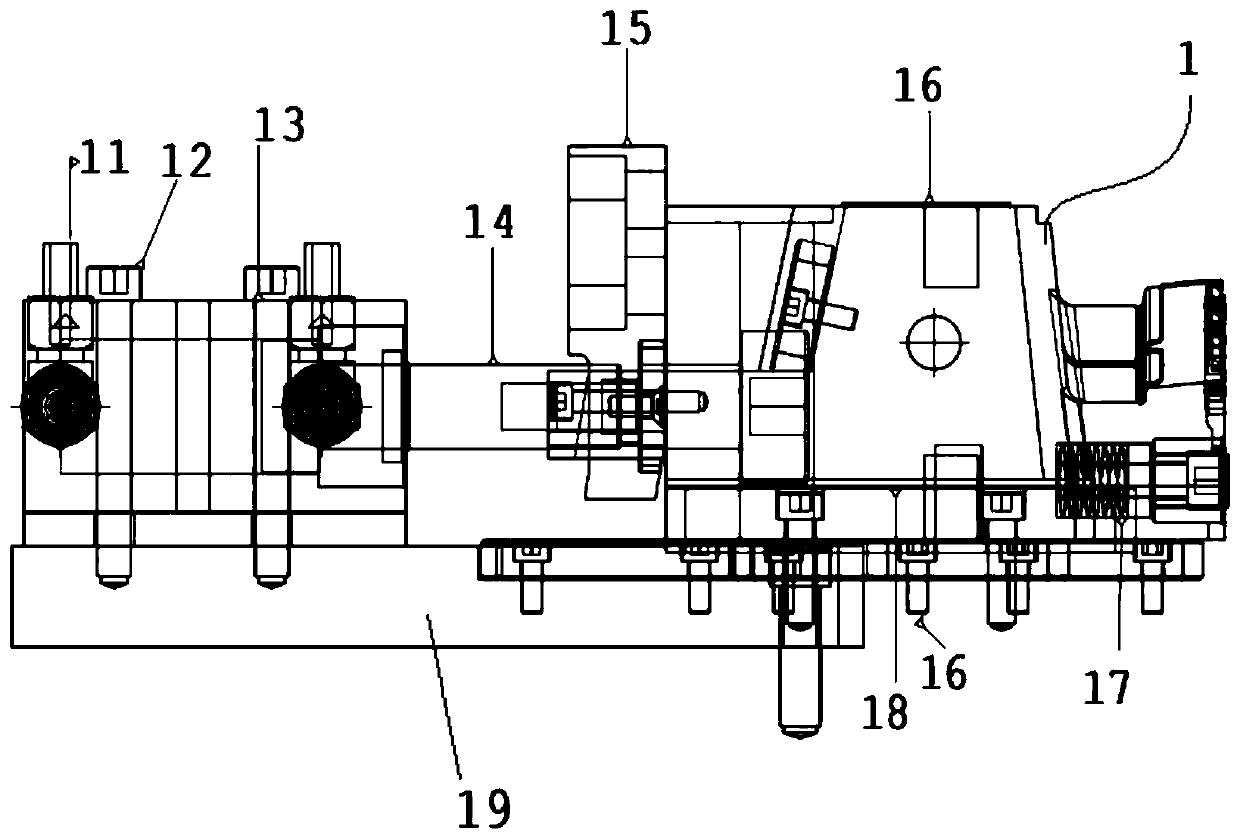

[0024] Wherein the outer positioning assembly 1 is located on the outer wall of the mold and is attached to one side of the iron piece, including a base plate 19 and a drive cylinder 13 fixed on the base plate 19, an oblique pressure block 15, a guide rail 18, and a ejection spring 17. The bottom plate 19 is fixed on the lower mold, the oblique pressure block 15 is used to cooperate with the slider located on the upper mold and clamp the upper and lower molds, and the guide rail 18 is movably connected with a side pull slider 16, One end of the ejection spring 17 is connected to the side of the side pull slider 16 near the iron piece, and the other end of the ejection spring 17 is against the iron piece. Vertically, the push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com