Drain Pipe Elbow Mold

A drainage pipe and mold technology, which is applied in the field of injection mold manufacturing, can solve problems such as injury to operators and easy damage, and achieve the effects of convenient maintenance, improved strength, and reduced flash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

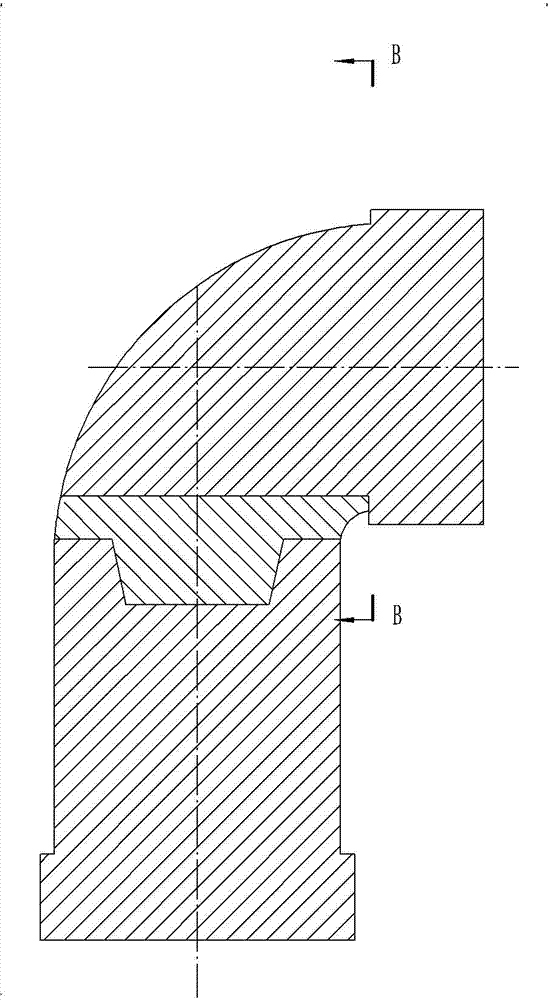

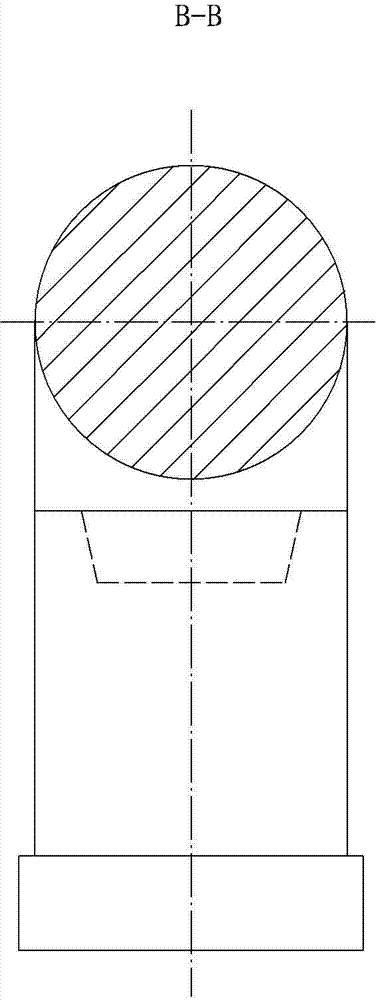

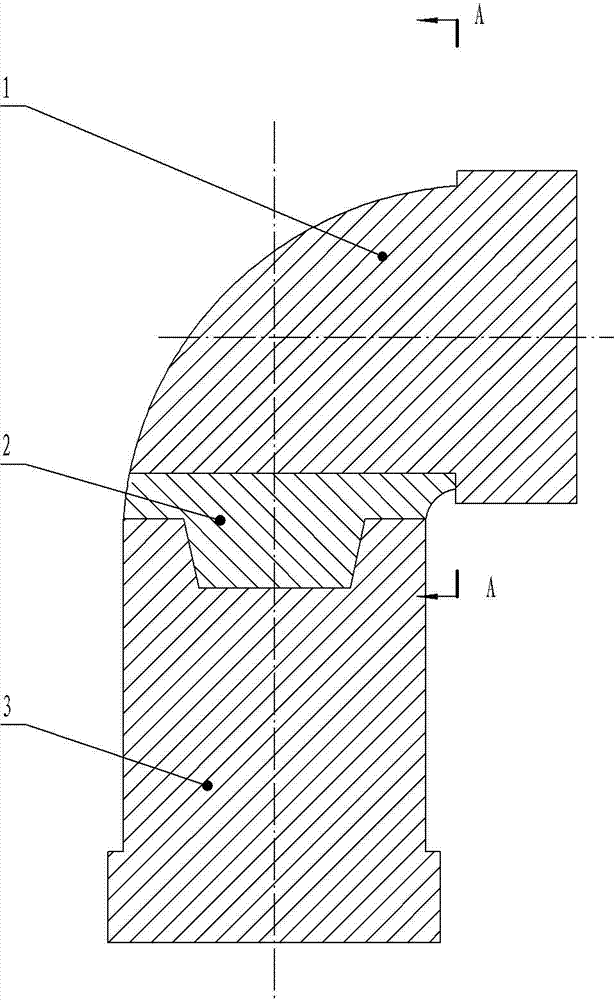

[0016] Embodiment 1 includes a fixed module A 3 composed of two cylinders with a large outer end and a smaller inner end. One outer end is a cylinder, the outer side of the inner end is a ring body with a torus and the outer side is a plug with a cylindrical surface. The fixed module B 1 composed of the composite part is equipped with a movable module 2 between the fixed module A 3 and the fixed module B 1, and the movable module 2 and the fixed module A 3 are joined by a tapered socket and a tapered plug. The connection between the module 2 and the fixed module B 1 is to insert the plug portion on the fixed module B 1 into the groove bottom surface of the movable module 2 which is a cylindrical groove, and the diameter of the groove bottom surface of the movable module 2 is smaller than that of the fixed module B 1 The diameter of the torus of the ring body is 5.5 mm, and the connection between the torus of the ring body of the fixed module B 1 and the cylindrical surface of t...

Embodiment 2

[0017] Embodiment 2 This embodiment is identical to Embodiment 1 except that the diameter of the bottom surface of the groove of the movable module 2 is smaller than the diameter of the annulus of the annulus of the fixed module B 1 by 3 mm, and the remaining parts are identical, and will not be repeated.

Embodiment 3

[0018] Embodiment 3 This embodiment is identical to Embodiment 1 except that the diameter of the bottom surface of the groove of the movable module 2 is smaller than the diameter of the annulus of the ring body of the fixed module B 1 by 8 mm, and the remaining parts are identical, and will not be repeated.

[0019] When closing the mold, the torus of the ring body of the fixed module B1 is engaged with the groove whose bottom surface of the groove of the movable module 2 is cylindrical, because the diameter of the bottom surface of the groove of the movable module 2 is smaller than the torus of the ring body of the fixed module B1 The diameter of the ring, the top of the groove edge of the groove of the movable module 2 will not form a sharp edge, but form two platforms, so that the contact between the fixed module B1 and the movable module 2 is changed from the original line contact to the present surface contact. Contact, the contact area between the two has increased, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com