Die structure used for moulded composite fiber material die and manufacturing method thereof

A composite fiber and mold technology, applied in the field of mold structure, can solve the problems of complex and time-consuming processing, uneven detailed structure, and difficult polishing of the surface of the mold cavity, and achieves the effect of no secondary processing and high surface precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

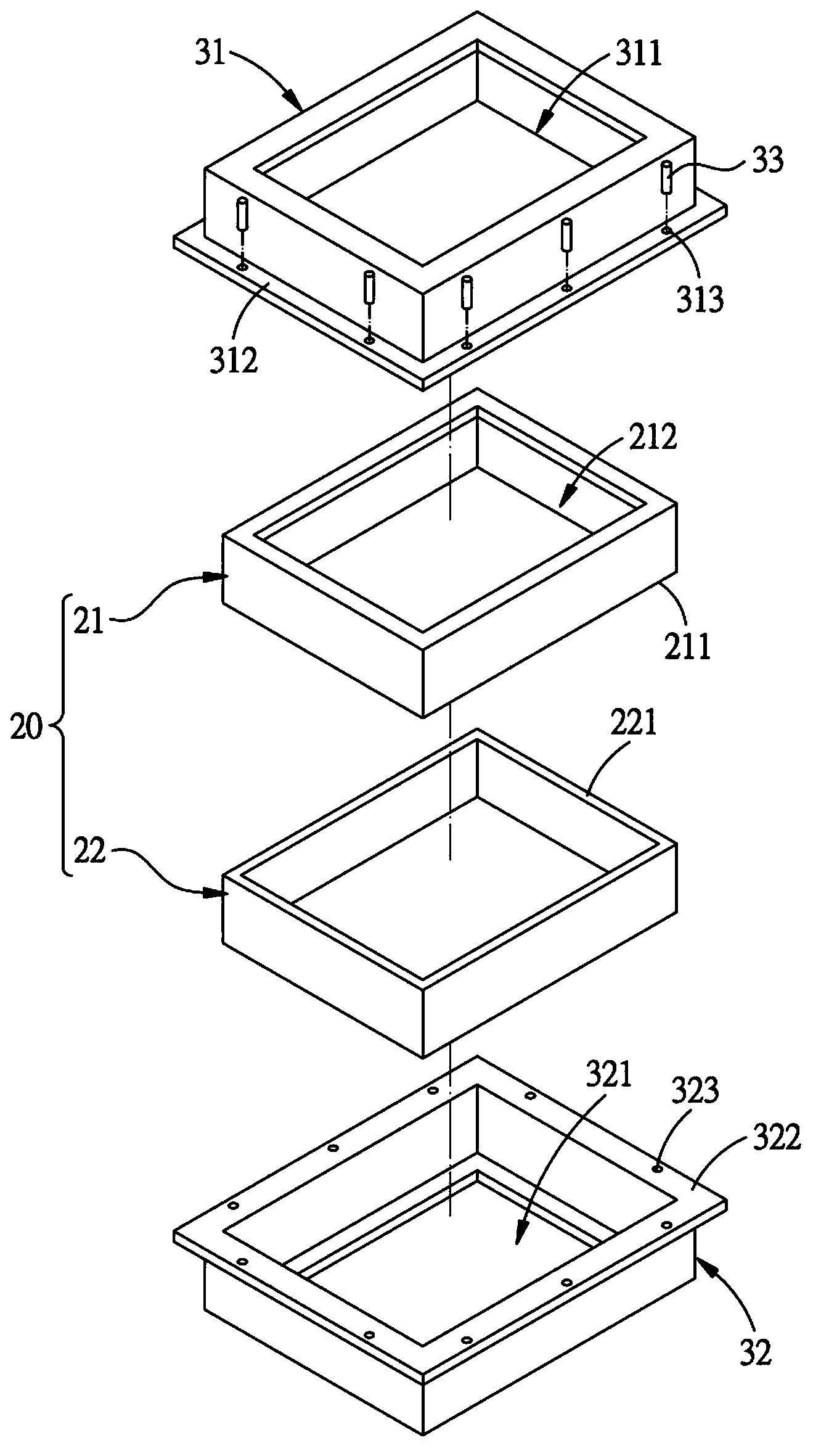

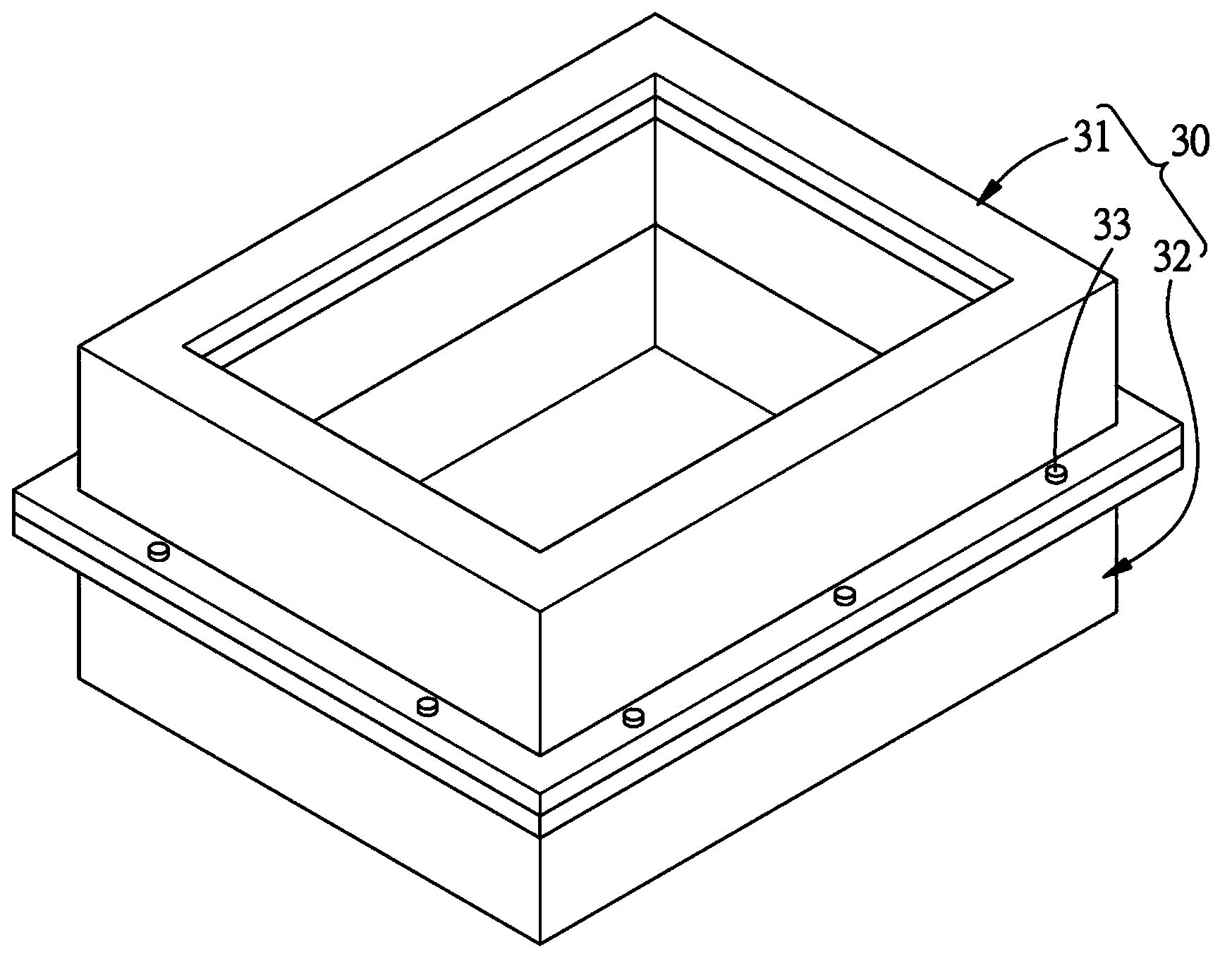

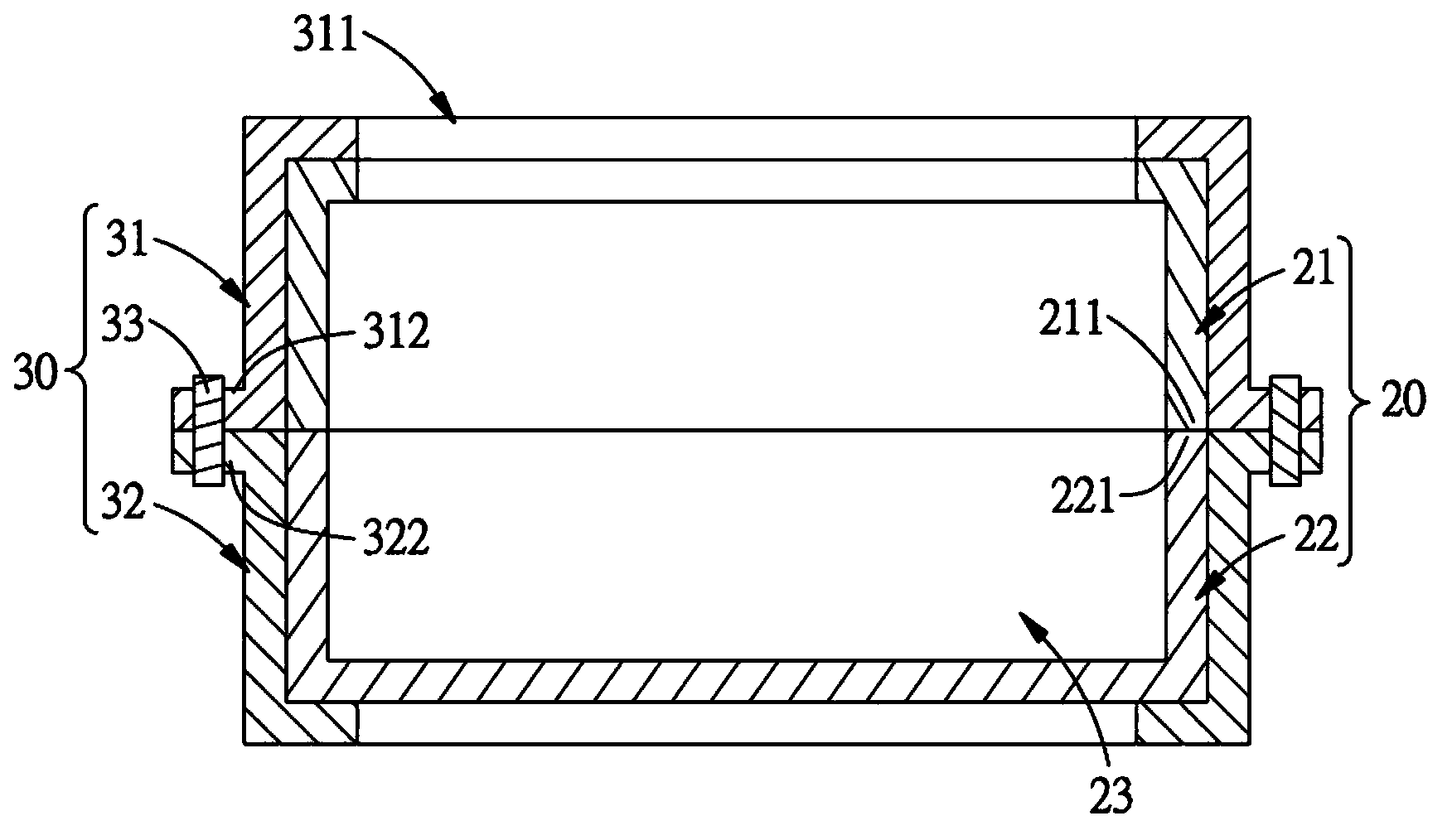

[0037] The preferred embodiment of the mold structure for forming composite fiber material molds of the present invention is as follows Figure 1 to Figure 3 As shown, the composite fiber material can be carbon fiber, glass fiber, basalt fiber, mineral fiber, boron fiber, Kevlar fiber or other man-made fibers. The mold structure includes: an inner mold 20 and an auxiliary fixture 30, wherein:

[0038] The inner mold 20 is made of glass material, and its inner surface is a smooth surface. The inner mold 20 includes an upper mold 21 and a lower mold 22. The periphery of the upper mold 21 has a first flange 211. There is a second flange 221 on the periphery of the mold 22, and the contour of the first flange 211 corresponds to the contour of the second flange 221, so that the upper mold 21 is closely attached to the lower mold by the first flange 211. 22 of the second flange 221, and make the upper mold 21 and the lower mold 22 jointly define an accommodating space 23, the accomm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com