T-shaped piston on general gasoline machine

A general-purpose gasoline engine and piston technology, applied to pistons, piston rings, mechanical equipment, etc., can solve problems such as bad emissions, high frictional resistance, CH dead angle, etc., and achieve the effect of tight air leakage, small frictional resistance, and optimized emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

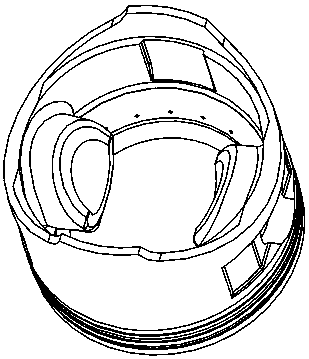

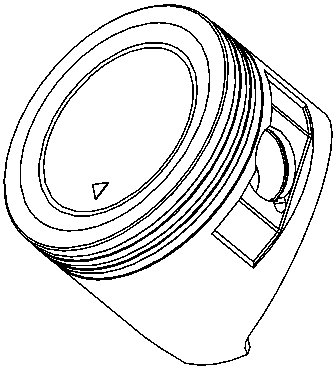

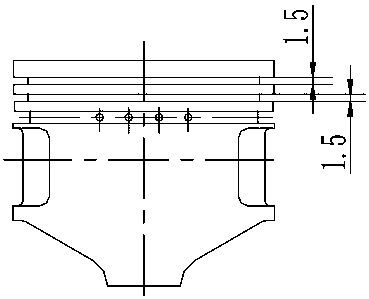

[0020] see Figure 4 to Figure 6 , the present invention provides a T-shaped piston on a general-purpose gasoline engine, including a piston body, the piston body is in the shape of a "T" as a whole, the piston body includes a head 1 and a skirt 2, and the head 1 includes a piston ring 3, The top surface of the piston ring 3 is a flat top structure, and the outer circumference of the piston ring 3 is provided with at least two annular grooves 4 spaced in parallel along the axial direction; the thickness of the annular groove 4 is 1 mm; the skirt 2 Including positive circular arc surface 5, left straight surface 6, reverse arc surface 7 and right straight surface 8 connected end to end to form a frame structure, left pin sleeve 9, right The pin sleeve 10, the left pin sleeve 9 and the right pin sleeve 10 are coaxially designed; the positive arc surface 5 is provided with an integral die-casting oil return hole 11; the positive arc surface 5, The outer walls of the anti-arc sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com