Drip tray and air conditioner

A water tray and low surface energy technology, which is applied in the prevention of condensed water, space heating and ventilation details, household heating, etc., can solve the problems of incomplete cleaning and limited decline in the surface energy of ABS materials, and achieve good cleaning performance , easy industrial production, and the effect of reducing the rolling angle of water droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In a preferred embodiment, the cleaning material is prepared by the following method:

[0028]The cleaning material is obtained by uniformly mixing the ABS plastic, low surface energy material and inorganic nanometer material at 190-240° C. and injecting molding. According to the technical scheme, the cleaning material is prepared, and the cleaning material is used for blending and granulation, and injection molding is used to make the water receiving tray. Compared with the existing cleaning material preparation process, the cleaning material preparation equipment provided by this technical solution has lower requirements on the process conditions, and does not need to add new process links on the basis of the original ABS plastic preparation process, which is conducive to the realization of industrial production . The preferred temperature is 230°C. At 230°C, low surface energy substances, inorganic nanomaterials, and ABS substrates are mixed more uniformly, and the ...

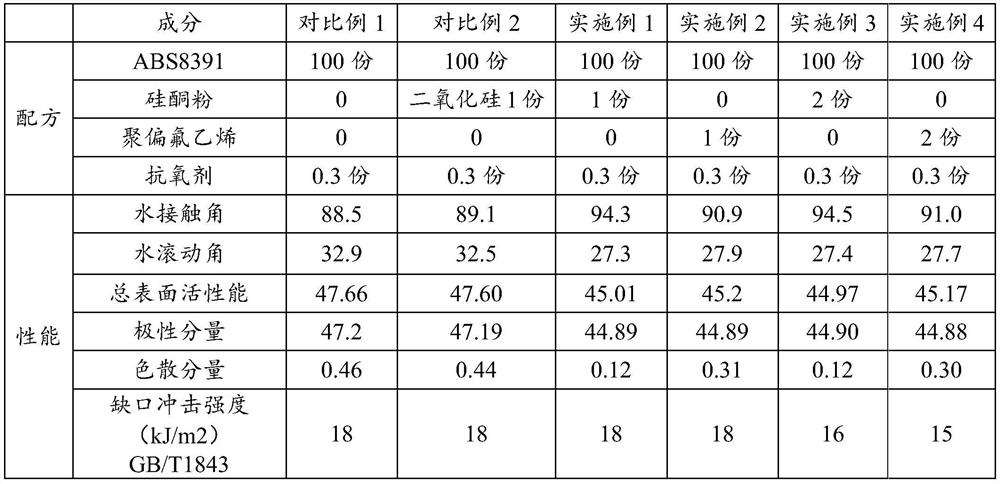

Embodiment 1

[0033] At a processing temperature of 230°C, 100 parts of ABS8391 type ABS plastics, 0.3 parts of IG-B900 type antioxidant and 1 part of RD-500 low surface energy material silicone powder (belonging to fluorine-containing compounds, It is a lyophobic material prepared by inorganic particles and low surface energy materials) mixed evenly, and the sample is obtained after injection molding.

Embodiment 2

[0035] At a processing temperature of 230°C, 100 parts of ABS plastic of ABS8391 type, 0.3 part of IG-B900 type antioxidant and 1 part of 720 type vinylidene fluoride purchased from Arkema were injection molded to obtain samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com