Drip tray and air conditioner

A water-receiving pan and cleaning material technology, which is applied in the field of polypropylene cleaning materials for air-conditioning water-receiving pans, can solve problems such as pollution of air-conditioning water-receiving pans, and achieve the effects of improved lyophobicity, easy industrial production, and good cleaning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

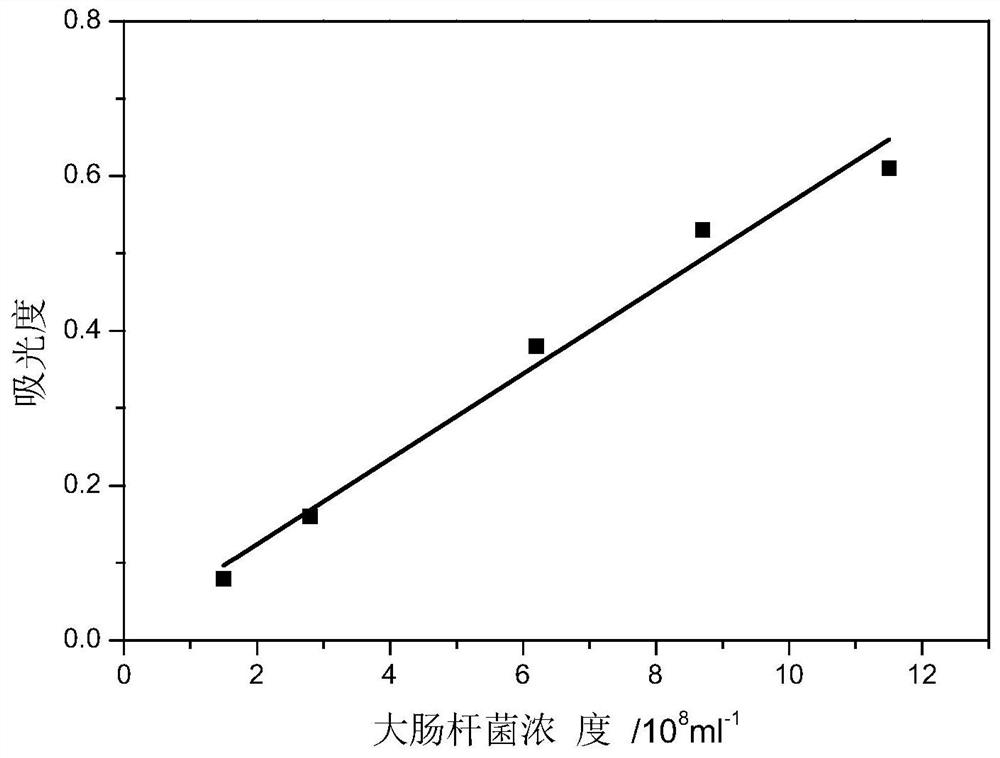

Image

Examples

preparation example Construction

[0025] In a preferred embodiment, the cleaning material is prepared by the following method: uniformly mixing the polypropylene material, low surface energy material and inorganic nanomaterial, granulating, and injection molding at 160-200°C to obtain the cleaning material. Compared with the existing preparation process of cleaning materials, the preparation equipment of cleaning materials provided by this technical solution requires less process conditions, and does not need to add new process links on the basis of the original preparation process of polypropylene plastic parts, which is conducive to the realization of Industrial production.

[0026] In a preferred embodiment, the cleaning material is prepared by the following method: Coupling the polypropylene material, the inorganic nanomaterial and the silane coupling agent, adding the low surface energy material, and mixing uniformly to produce Granules are injection molded at 160-200°C to obtain the cleaning material. ...

Embodiment 1

[0031] Mix 100 parts of polypropylene material (PP) with 7 parts of polyvinylidene fluoride evenly, and granulate. And at a processing temperature of 180° C., plastic parts are obtained by injection molding.

Embodiment 2

[0033] 100 parts of PP are coupled with 3 parts of silicon dioxide and 2 parts of methacryloxysilane, and 2 parts of polyvinylidene fluoride are added and mixed uniformly, and granulated. And at a processing temperature of 160° C., plastic parts are obtained by injection molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com