Mould with ox horn type glue-entering hole

A technology of glue feeding holes and horns is applied in the field of molds with horn-type glue feeding holes, which can solve problems such as punch marks on the surface of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

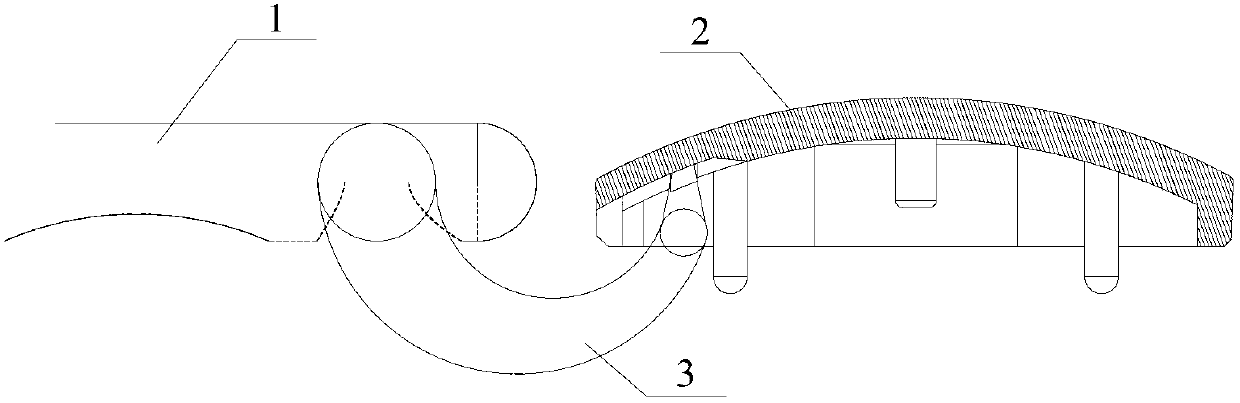

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] Such as figure 1 As shown, the mold with horn-type glue inlet provided by the present invention includes a pipe 1 for injection molding, and the glue inlet 3 between the pipe 1 and the product 2 is bent into an arc convex downward, and the glue inlet The outlet end of hole 3 is located at the bottom of product 2 .

[0010] In this embodiment, the glue inlet 3 is horn-shaped, and the size of the outlet end of the connecting product 2 is smaller than the size of the inlet end of the connecting pipe 1 .

[0011] The mold provided by the present invention adopts horn-shaped glue inlet holes 3, so that there will be no punching marks on the appearance of the product, and there is no glue opening on the appearance surface, so no secondary processing is required.

[0012] The present invention is not limited to the above-mentioned best implementation mode, and anyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com