A 750°C low-temperature carburizing process in a vacuum carburizing furnace for precision parts

A technology of vacuum carburizing and precision parts, which is applied in metal material coating process, solid-state diffusion coating, coating, etc., can solve the problems that the cost cannot be reduced, and the surface of metal parts cannot be kept clean, unable to maintain, etc., to achieve Improve the fatigue resistance, facilitate service use, and avoid the effect of secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

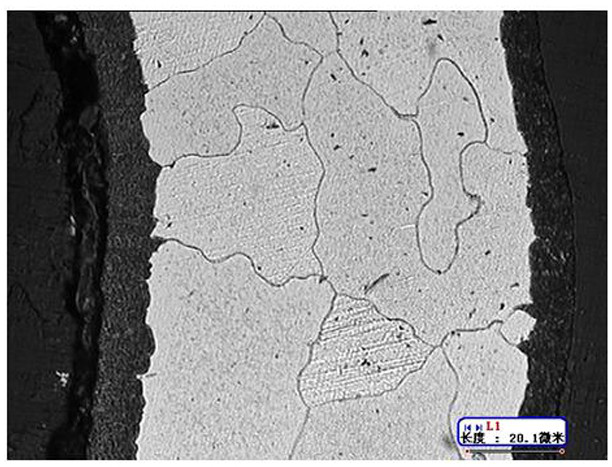

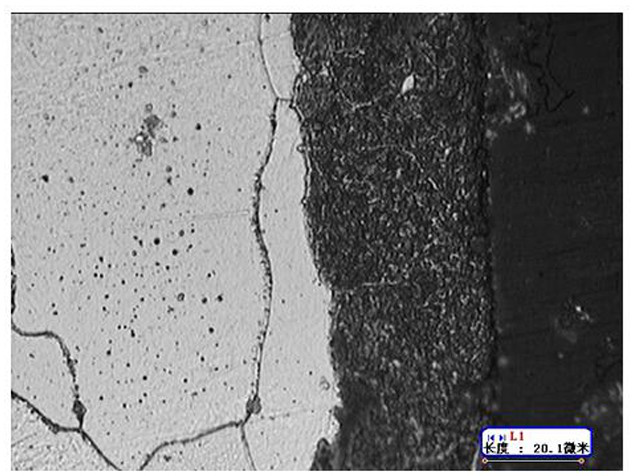

[0034] A 750°C low-temperature carburizing process in a vacuum carburizing furnace for precision parts is as follows: Step 1. First, put the metal parts in the vacuum furnace and heat the vacuum furnace to 750°C. Then, input nitrogen into the vacuum furnace until the vacuum is reached. The air pressure in the furnace reaches 100 Pa, and the vacuum furnace continues to work at a constant temperature of 750°C and a constant pressure of 100 Pa for 30 minutes before stopping the input of nitrogen into the vacuum furnace.

[0035]In one of the embodiments, in step 2, the vacuum furnace is kept warm at a constant temperature of 750°C, and then, acetylene gas is input into the vacuum furnace, and the maximum pressure of the acetylene gas is maintained at 360 Pa, so that the acetylene gas can be kept at a constant temperature. Decomposition reaction occurs with the surface of metal parts with a temperature of 750 ° C. After the decomposition reaction on the surface of metal parts, carb...

Embodiment 2

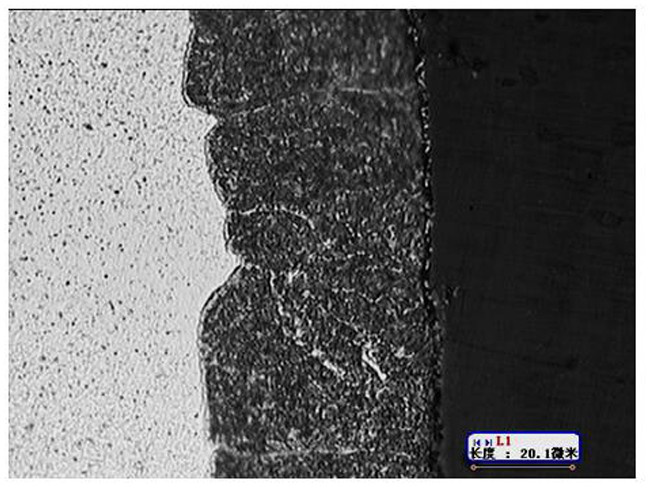

[0045] A 750°C low-temperature carburizing process for precision parts in a vacuum carburizing furnace is as follows: Step 1: First, put the metal parts in the vacuum furnace, then heat the vacuum furnace to 750°C and maintain a constant temperature state, and then, input the metal parts into the vacuum furnace Nitrogen, until the air pressure in the vacuum furnace reaches 100Pa pressure, the vacuum furnace just enters the next step operation after 30 minutes with the constant air pressure that keeps the constant temperature of 750 ℃ and 100Pa pressure.

[0046] In one of the embodiments, in step 2, the vacuum furnace is kept warm at a constant temperature of 750°C, and then, acetylene gas is input into the vacuum furnace, and the acetylene gas is input into the vacuum furnace in the form of pulses. For 2 minutes, the maximum pressure of acetylene gas input into the vacuum furnace is maintained at 360Pa; the vacuum furnace uses acetylene gas as the carburizing medium to carbu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com