Heat treatment induction quenching process for small hole

An induction hardening and process technology, applied in the field of small hole heat treatment induction hardening process, can solve the problems of complex heat treatment process, short product service life, insignificant energy saving effect, etc., achieving low cost, high production efficiency, and solving oil quenching is not hard. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An induction quenching process for small hole heat treatment, the process steps are as follows:

[0018] A. Check whether the workpiece has cracks, bruises and other defects, and install the furnace;

[0019] B. Send the workpiece into the washing machine for drying, the time is 1min;

[0020] C. Carry out induction heating, the heating time is 4s, the power of the quenching machine is set to 10%, the current is 500A, the quenching stop position is 1.00mm, the cooling position is 200mm, the speed is 500mm / min, quenching and cooling with HX-200 medium, and the spray method is used cooling down;

[0021] D. Send the quenched workpiece into the washing machine to wash and dry for 1min;

[0022] E Temper the dried workpiece immediately, set the temperature at 200°C, and hold the holding time for 2 hours;

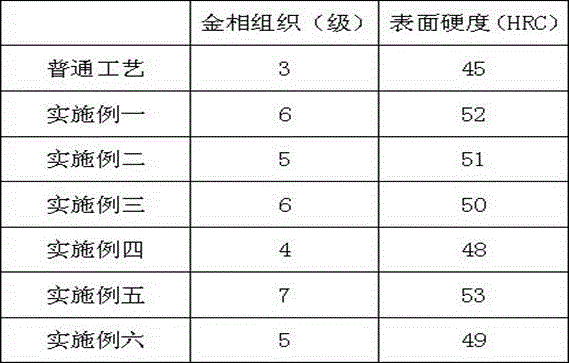

[0023] F. After cooling with cooling medium, check the metallographic structure according to the standard, and test the hardness of the product;

[0024] G. Soak the ...

Embodiment 2

[0026] An induction quenching process for small hole heat treatment, the process steps are as follows:

[0027] (A. Check whether the workpiece has cracks, bruises and other defects, and install the furnace;

[0028] B. Send the workpiece into the washing machine for drying, the time is 2min;

[0029] C. Carry out induction heating, the heating time is 6s, the power of the quenching machine is set to 10%, the current is 500A, the quenching stop position is 1.00mm, the cooling position is 200mm, the speed is 500mm / min, quenching and cooling with HX-200 medium, using spraying method cooling down;

[0030] D. Send the quenched workpiece into the cleaning machine for cleaning and drying for 2 minutes;

[0031] E Temper the dried workpiece immediately, set the temperature at 220°C, and hold the holding time for 3 hours;

[0032] F. After cooling with cooling medium, check the metallographic structure according to the standard, and test the hardness of the product;

[0033] G. S...

Embodiment 3

[0035] An induction quenching process for small hole heat treatment, the process steps are as follows:

[0036] A. Check whether the workpiece has cracks, bruises and other defects, and install the furnace;

[0037] B. Send the workpiece into the washing machine for drying, the time is 2min;

[0038] C. Carry out induction heating, the heating time is 5s, the power of the quenching machine is set to 10%, the current is 500A, the quenching stop position is 1.00mm, the cooling position is 200mm, the speed is 500mm / min, quenching and cooling with HX-200 medium, and the spray method is used cooling down;

[0039] D. Send the quenched workpiece into the washing machine to wash and dry for 1min;

[0040] E Temper the dried workpiece immediately, set the temperature at 240°C, and hold the holding time for 2.5h;

[0041] F. After cooling with cooling medium, check the metallographic structure according to the standard, and test the hardness of the product;

[0042] G. Soak the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com