Superhydrophilic and underwater superoleophobic calcium carbonate hybrid membrane, preparation method and application

An underwater super-oleophobic and calcium carbonate technology, applied in chemical instruments and methods, separation methods, membranes, etc., can solve the problems of unsuccessful preparation of calcium carbonate membranes, poor stability, poor controllability, time-consuming and labor-intensive preparation, etc., to achieve Good separation effect, low adhesion, time-saving and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

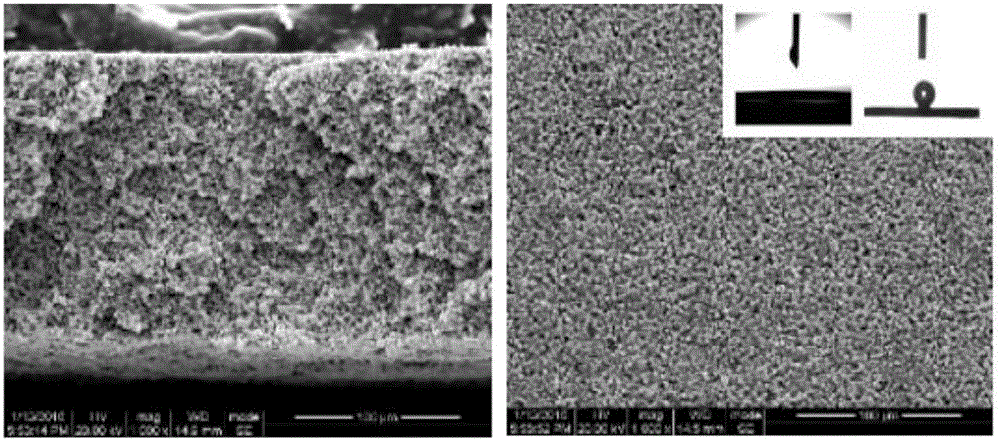

[0038] 50 g of 0.1 M CaCl 2 solution, adding 50g concentration of 0.05wt% sodium alginate solution to form calcium alginate gel; form flocculent precipitate at 1000rpm stirring speed; add 50g concentration of 0.05M Na at 1000rpm stirring speed 2 CO 3 Solution, react to obtain calcium carbonate-calcium alginate hybrid particles; vacuum filter the precipitate, and dry it at 30°C to obtain an independent calcium carbonate-calcium alginate gel hybrid film.

[0039] Calcite is the main crystal form of calcium carbonate in the film prepared under this condition. The particle size of calcium carbonate is 10-50 μm, and the pore size is 5-30 μm. The water flux is 20000±26L m -2 h -1 . The separation efficiency of oil-water emulsion is 90.00±0.09%. The tensile modulus of the film is 1.00±0.08 GPa; the flexural modulus is 1.1±0.1 GPa.

Embodiment 2

[0041] 50 g of 0.1 M CaCl 2 solution, adding 50g concentration of 0.05wt% sodium alginate solution to form calcium alginate gel; form flocculent precipitate at 10000rpm stirring speed; add 50g concentration of 0.05M Na at 15000rpm stirring speed 2 CO 3 Solution, react to obtain calcium carbonate-calcium alginate hybrid particles; vacuum filter the precipitate, and dry it at 30°C to obtain an independent calcium carbonate-calcium alginate gel hybrid film.

[0042] Calcite is the main crystal form of calcium carbonate in the film prepared under this condition. The particle size of calcium carbonate is 1-5 μm, and the pore size is 1-3 μm. The water flux is 10000±20L m -2 h -1 . The separation efficiency of oil-water emulsion is 99.00±0.05%. The tensile modulus of the film is 1.15±0.11 GPa; the flexural modulus is 1.2±0.12 GPa.

Embodiment 3

[0044] 50 g of 0.1 M CaCl 2 solution, adding 50g concentration of 0.05wt% sodium alginate solution to form calcium alginate gel; form flocculent precipitate at 15000rpm stirring speed; add 50g concentration of 0.05M Na at 30000rpm stirring speed 2 CO 3 Solution, react to obtain calcium carbonate-calcium alginate hybrid particles; vacuum filter the precipitate, and dry it at 30°C to obtain an independent calcium carbonate-calcium alginate gel hybrid film.

[0045] Calcite is the main crystal form of calcium carbonate in the film prepared under this condition. The particle size of calcium carbonate is 500nm-3μm, and the pore size is 500nm-2μm. The water flux is 7000±17L m -2 h -1 . The separation efficiency of oil-water emulsion remains above 99.99%. The tensile modulus of the film is 1.23±0.09GPa; the flexural modulus is 1.4±0.15GPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com