Waterborne scratch-resistant coating and preparation method thereof

A scratch-resistant and coating technology, applied in the direction of coating, etc., can solve the problems of easy scratches, high prices, falling and hurting of paint films, etc., achieve strong scratch resistance and wear resistance, improve hardness and surface Effects of smoothness and compactness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

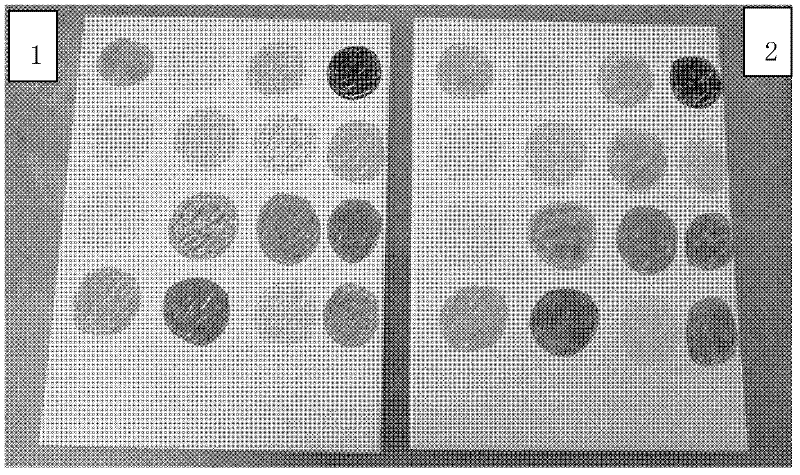

Image

Examples

Embodiment 1

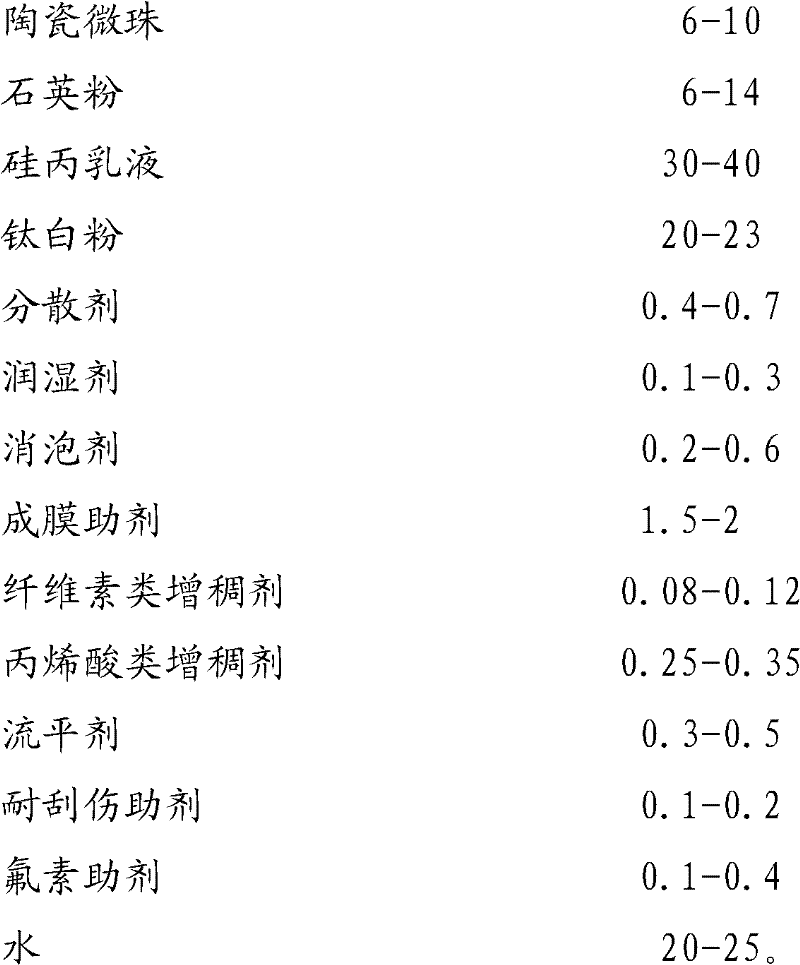

[0050] A water-based scratch-resistant coating, which is prepared from the following raw materials in parts by weight:

[0051]

[0052]

[0053] The preparation method of the water-based scratch-resistant coating of the present embodiment is as follows:

[0054] (1) Premixing: Add 17 parts by weight of water in the dispersion tank, then add the above dispersant, wetting agent, 0.2 parts by weight of defoamer, film-forming aid, antifreeze and cellulose thickener, After fully mixing evenly, a gel-like substance is formed to facilitate the dispersion of pigments and fillers. The mixing speed is controlled at 300-500rpm;

[0055] (2) Grinding and dispersing: Add titanium dioxide, ceramic microbeads, and quartz powder into the dispersing tank, beat and grind for 20 to 25 minutes at a speed of 2000 to 3000 RPM, and check that the fineness of the slurry is less than 45um. The particles are dispersed into primary particles under the high shear rate of high-speed agitation, and...

Embodiment 2

[0063] A water-based scratch-resistant coating, which is prepared from the following raw materials in parts by weight:

[0064]

[0065] The preparation method of the water-based scratch-resistant coating of the present embodiment is as follows:

[0066] (1) Premixing: Add 18 parts of water in the dispersion tank, then add the above dispersant, wetting agent, 0.1 weight part of defoamer, film-forming aid, antifreeze and cellulose thickener respectively, fully After mixing evenly, a gel-like substance will be formed to facilitate the dispersion of pigments and fillers. The mixing speed should be controlled at 300-500rpm;

[0067] (2) Grinding and dispersing: Add titanium dioxide, ceramic microbeads, and quartz powder into the dispersing tank, beat and grind for 20 to 25 minutes at a speed of 2000 to 3000 RPM, and check that the fineness of the slurry is less than 45um. The particles are dispersed into primary particles under the high shear rate of high-speed agitation, and ...

Embodiment 3

[0074] A water-based scratch-resistant coating, which is prepared from the following raw materials in parts by weight:

[0075]

[0076]

[0077] The preparation method of the water-based scratch-resistant coating of the present embodiment is as follows:

[0078] (1) Pre-mixing: add 16 parts of water in the dispersion tank, add the above dispersant, wetting agent, 0.3 parts by weight of defoamer, film-forming aid, antifreeze and cellulose thickener respectively, fully After mixing evenly, a gel-like substance will be formed to facilitate the dispersion of pigments and fillers. The mixing speed should be controlled at 300-500rpm;

[0079] (2) Grinding and dispersing: Add titanium dioxide, ceramic microbeads, and quartz powder into the dispersing tank, beat and grind for 20 to 25 minutes at a speed of 2000 to 3000 RPM, and check that the fineness of the slurry is less than 45um. The particles are dispersed into primary particles under the high shear rate of high-speed agi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com