Finishing-free stone-like paint and preparation method thereof

A real stone paint, cover-free technology, applied in biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve the increase in labor costs, the increase in the price of chemical raw products, the cost of raw materials, the burden of labor costs, etc. problems, to achieve the effect of cost saving, excellent storage stability and workability, and strong water whitening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

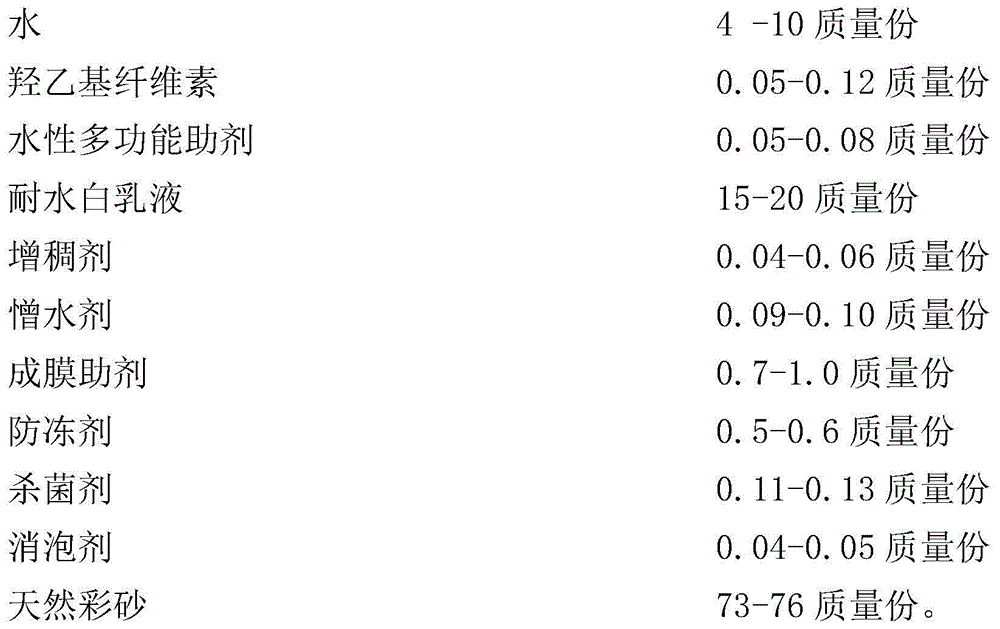

[0024] The specific embodiment of the present invention provides the face-free real stone paint, which is made of the following raw materials in weight ratio:

[0025]

[0026] The preparation method of above-mentioned top-free genuine stone paint, it comprises the following steps of carrying out in sequence:

[0027] (1) Add 4-10 parts of water into the dispersion tank, add 0.05-0.12 parts of hydroxyethyl cellulose under the stirring state of the disperser at 350-550r / min, stir for 3-5min, and stir at 350-550r / min Add 0.05-0.08 parts of water-based multifunctional additives, after adding, increase the speed to 800-1000r / min and stir for 5min-10min while stirring;

[0028] (2) Add 15-20 parts of water-resistant white emulsion, 0.04-0.06 parts of thickener, 0.09-0.10 parts of water repellent, 0.7-1.0 parts of film-forming aid, 0.5-0.6 parts of 1 part of antifreeze, 0.11-0.13 part of bactericide, 0.04-0.05 part of defoamer, and stir for 5min-10min under the stirring state of...

Embodiment 2

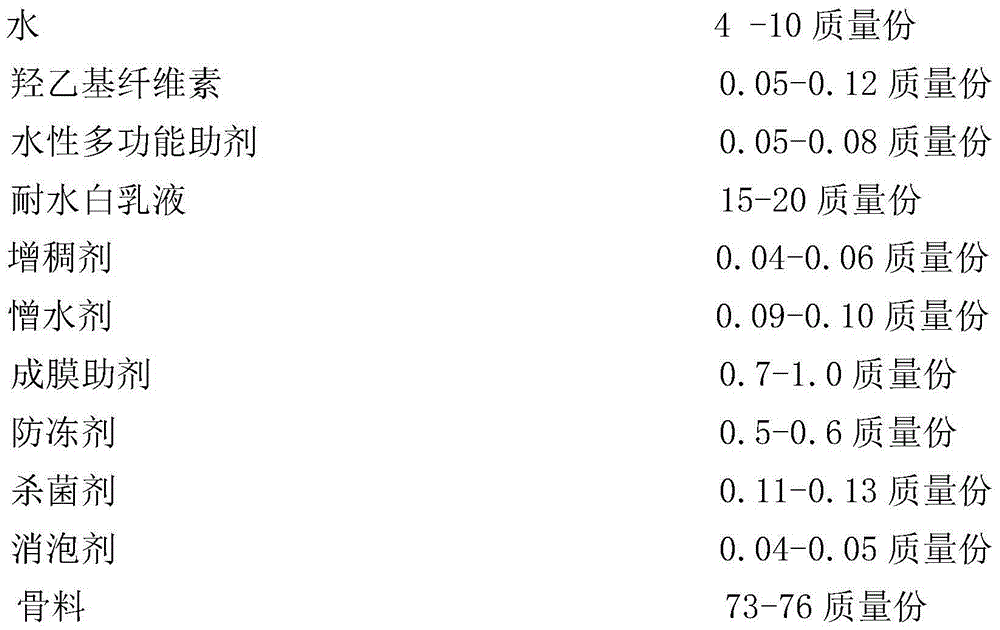

[0039] A real stone varnish without a finish, which is made of the following raw materials in proportion by weight:

[0040]

Embodiment 3

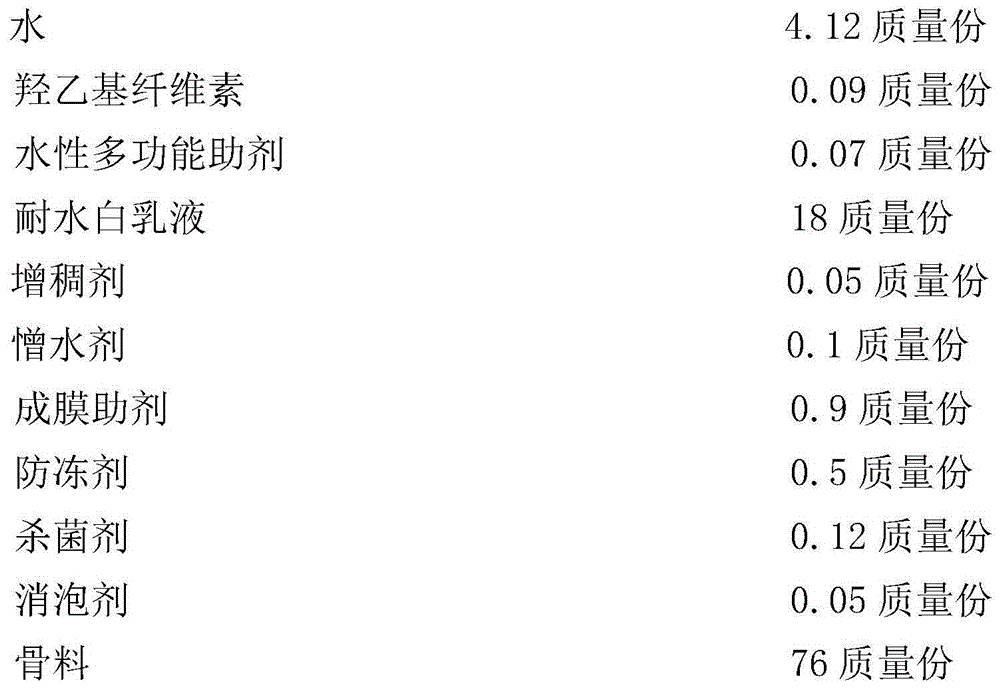

[0042] A kind of surface-free real stone paint, which is made of the following raw materials in weight ratio:

[0043]

[0044] The preparation method of the above-mentioned top-free real stone paint is the same as the step of Example 1, which is omitted here.

[0045] Raw material information adopted in the above-mentioned embodiment:

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com