Nodular cast iron grinding ball and preparation method thereof

A nodular cast iron and grinding ball technology, applied in the field of nodular cast iron, can solve the problems of low toughness and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A nodular cast iron grinding ball, the final chemical composition of the grinding ball includes: C: 3.65%, Si: 2.65%, Mn: 1.72%, Sn: 0.085%, Mg: 0.04%, Re: 0.026%, S : 0.03%, P: 0.04%, and the rest is Fe.

[0037] In order to obtain the above-mentioned nodular cast iron grinding balls, the manufacturing process is as follows:

[0038] (1) Smelting molten iron: Add pig iron, scrap steel, nodular iron return charge, recarburizer, ferromanganese and ferrotin into an intermediate frequency induction furnace for smelting, heat up to 1550°C, smelt to clear, and stand for 10 minutes to obtain molten iron;

[0039] (2) Spheroidization and inoculation: control the temperature of the molten iron at 1520°C, pour the molten iron into the spheroidization ladle, add silicon carbide nanomaterials with a total mass of 0.2% of the molten iron in the spheroidization ladle, and then add a covering agent to isolate the air. The cored wire is used for spheroidization and inoculation treatm...

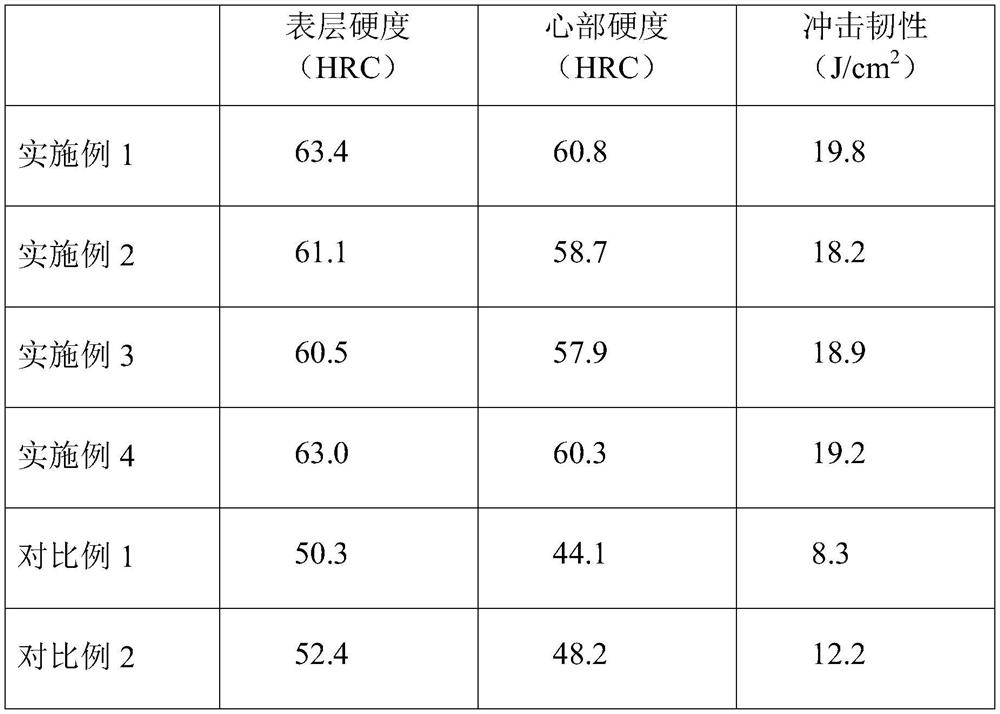

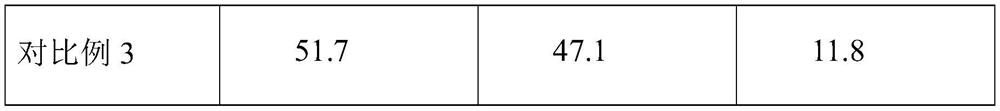

Embodiment 2-4

[0044] A nodular cast iron grinding ball, its embodiment 2-4 is basically the same as embodiment 1, the difference is that the final chemical composition of the grinding ball is different, as shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com