Steel rail for heavy-duty railway and preparation method thereof

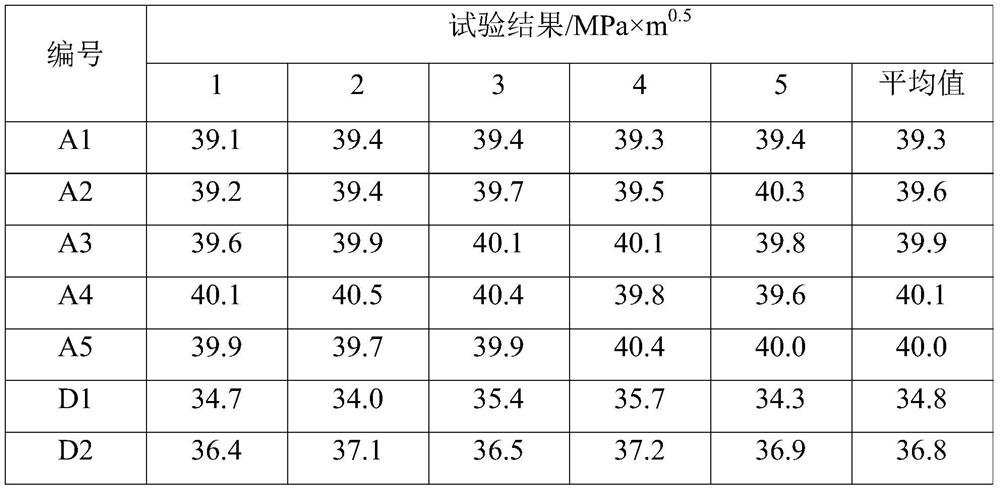

A technology for steel rails and railways, applied in the field of steel rails for heavy-duty railways and its preparation, can solve the problems of low longitudinal fracture toughness of the lower jaw, achieve excellent longitudinal fracture toughness, and improve strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] One aspect of the present invention provides a method for preparing a heavy-duty railway rail, the method comprising the following steps:

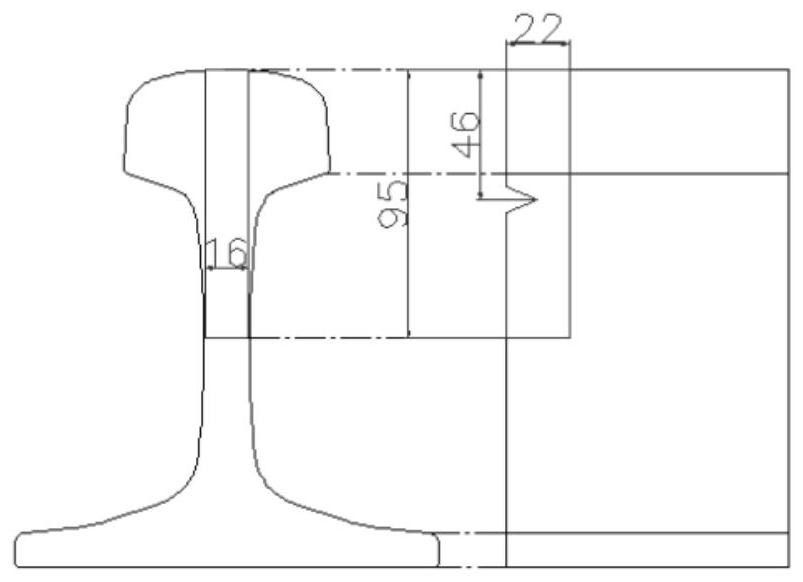

[0024] (1) hot-rolling the billet after the heat preservation treatment to obtain a waste heat rail, and performing accelerated cooling on the lower jaw part of the rail head of the waste heat rail, the cooling temperature of the accelerated cooling is 650-800 ° C, and the cooling rate of the accelerated cooling is 1.5- 2.5℃ / s, stop accelerated cooling when the temperature drops to 380-420℃;

[0025] (2) cooling the rail that stops accelerated cooling in step (1) to room temperature;

[0026] Wherein, in step (1), the steel billet contains 0.75-0.95 wt % C, 0.45-0.6 wt % Si, 0.8-1.1 wt % Mn, 0.05-0.2 wt % V, and the balance is Fe and inevitable impurities.

[0027] Carbon (C) is the most important element for obtaining good strength-toughness matching and comprehensive mechanical properties in heavy-duty railway rail steels. In o...

Embodiment 1

[0045] (1) The billet is sent to the walking furnace for heating and heat preservation, the temperature of heat preservation is 1250℃, and the time of heat preservation is 4h, and then the steel billet after heat preservation treatment is hot rolled by the universal method to obtain a unit weight of 75kg / m The waste heat rail is accelerated to cool the lower jaw part of the rail head of the waste heat rail. The start-up cooling temperature of the accelerated cooling is 677°C, the cooling rate of the accelerated cooling is 1.97°C / s, and the accelerated cooling is stopped when the temperature drops to 404°C;

[0046] (2) the rail that stops accelerated cooling in step (1) is cooled to room temperature in air to obtain rail A1;

[0047] Wherein, in step (1), the steel billet contains 0.85 wt % C, 0.57 wt % Si, 0.97 wt % Mn, 0.13 wt % V, and the balance is Fe and inevitable impurities.

Embodiment 2

[0049] (1) The billet is sent into the walking furnace for heating and heat preservation, the temperature of heat preservation is 1300℃, and the time of heat preservation is 2h, and then the steel billet after heat preservation treatment is hot rolled by the universal method to obtain a unit weight of 75kg / m The waste heat rail is accelerated to cool the lower jaw part of the rail head of the waste heat rail. The start-up cooling temperature of the accelerated cooling is 703°C, the cooling rate of the accelerated cooling is 2.21°C / s, and the accelerated cooling is stopped when the temperature drops to 398°C;

[0050] (2) the steel rail that stops accelerated cooling in step (1) is cooled to room temperature in air to obtain steel rail A2;

[0051] Wherein, in step (1), the steel billet contains 0.85 wt % C, 0.59 wt % Si, 0.96 wt % Mn, 0.15 wt % V, and the balance is Fe and inevitable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com