A method to improve the strong plasticity of β-type γ-tial alloy

A technology of alloying and plasticity, which is applied in the field of improving the strong plasticity of β-type γ-TiAl alloys, and can solve problems such as not reflecting the excellence of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

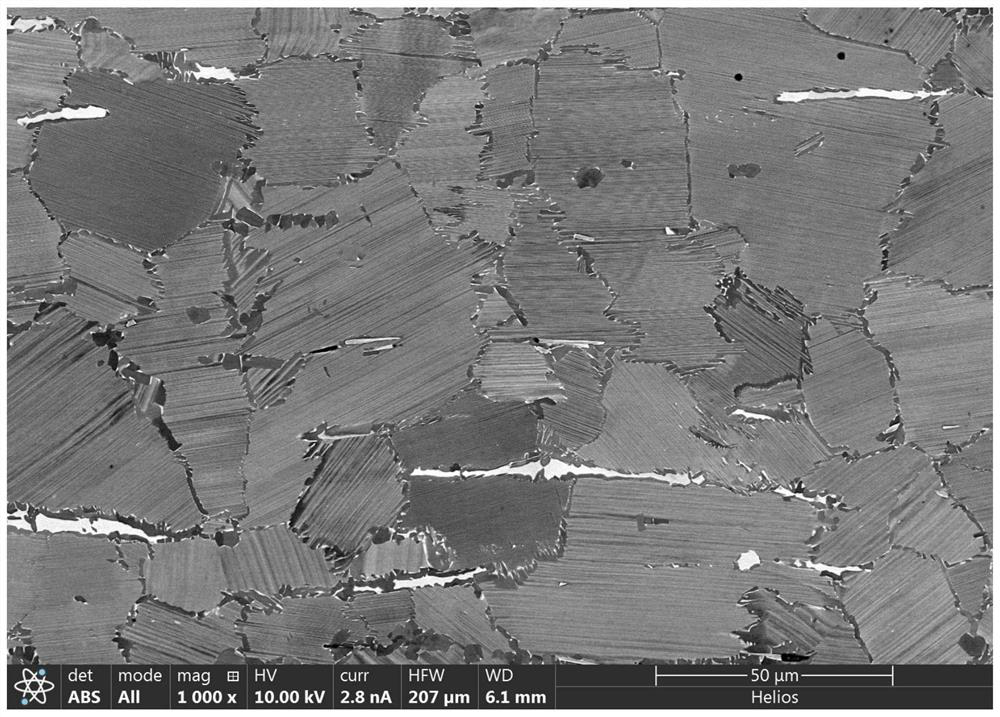

Embodiment 1

[0040] A method to obtain high-strength plasticity TNM alloy, the alloy does not exist α unidirectional region, its T γ,solv The transformation temperature is 1260°C, and the deformation is carried out near the lower limit temperature of the (α+β) phase region;

[0041] Its specific implementation steps are as follows:

[0042] Step 1, hot isostatic pressing treatment is performed on the TNM alloy cast rod to eliminate casting defects, and the hot isostatic pressing system is 1280°C / 140MPa / 4h;

[0043] Step 2, turning the hot isostatic pressed TNM alloy cast rod to remove the surface oxide layer, and then wrap it with 304 stainless steel, the thickness of the stainless steel is 10mm; use nickel foil to isolate the wrapping and TNM alloy billet ;

[0044] Step 3, heat up the box-type high-temperature heat treatment furnace to the target temperature of 1260°C at a speed of 10°C / min, and place the wrapped TNM alloy billet in the box-type high-temperature heat treatment furnace ...

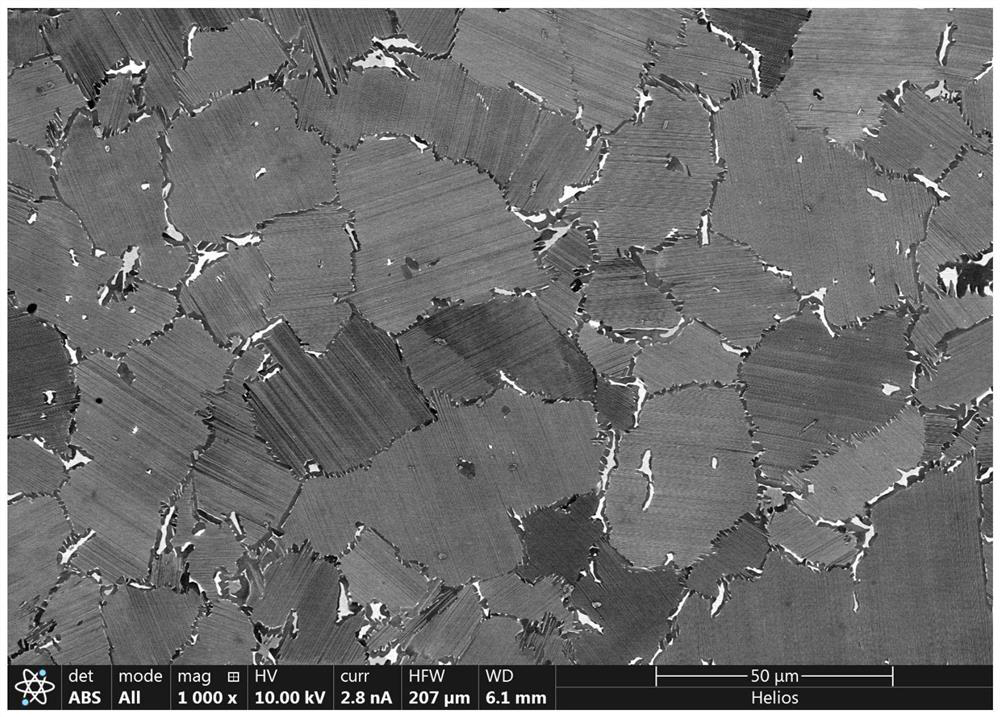

Embodiment 2

[0051] A method to obtain high-strength plasticity TNM alloy, the alloy does not exist α unidirectional region, its T γ,solv The transformation temperature is 1260°C, and the deformation is carried out near the lower limit temperature of the (α+β) phase region;

[0052] Its specific implementation steps are as follows:

[0053] Step 1, hot isostatic pressing treatment is performed on the TNM alloy cast rod to eliminate casting defects, and the hot isostatic pressing system is 1270°C / 160MPa / 4h;

[0054] Step 2, turning the hot isostatic pressed TNM alloy cast rod to remove the surface oxide layer, and then wrap it with 304 stainless steel; the thickness of the stainless steel is 11mm; the wrapping and the TNM alloy billet are separated by molybdenum foil ;

[0055] Step 3: Heat the box-type high-temperature heat treatment furnace to a target temperature of 1290°C at a rate of 10°C / min, and place the wrapped TNM alloy billet in the box-type high-temperature heat treatment furn...

Embodiment 3

[0062] It is a method to obtain high-strength plasticity TNM alloy, which does not have α-unidirectional region, and its T γ,solv The transformation temperature is 1260°C, and the deformation is carried out near the lower limit temperature of the (α+β) phase region;

[0063] Its specific implementation steps are as follows:

[0064] Step 1, hot isostatic pressing treatment is performed on the TNM alloy cast rod to eliminate casting defects, and the hot isostatic pressing system is 1300°C / 130MPa / 2h;

[0065] Step 2, turning the TNM alloy cast rod in the hot isostatic pressing state to remove the surface oxide layer, and then wrap it with 304 stainless steel; the thickness of the stainless steel is 12mm; the wrapping and the TNM alloy billet are separated by nickel foil ;

[0066] Step 3: Heat the box-type high-temperature heat treatment furnace to a target temperature of 1290°C at a rate of 10°C / min, and place the wrapped TNM alloy billet in the box-type high-temperature heat...

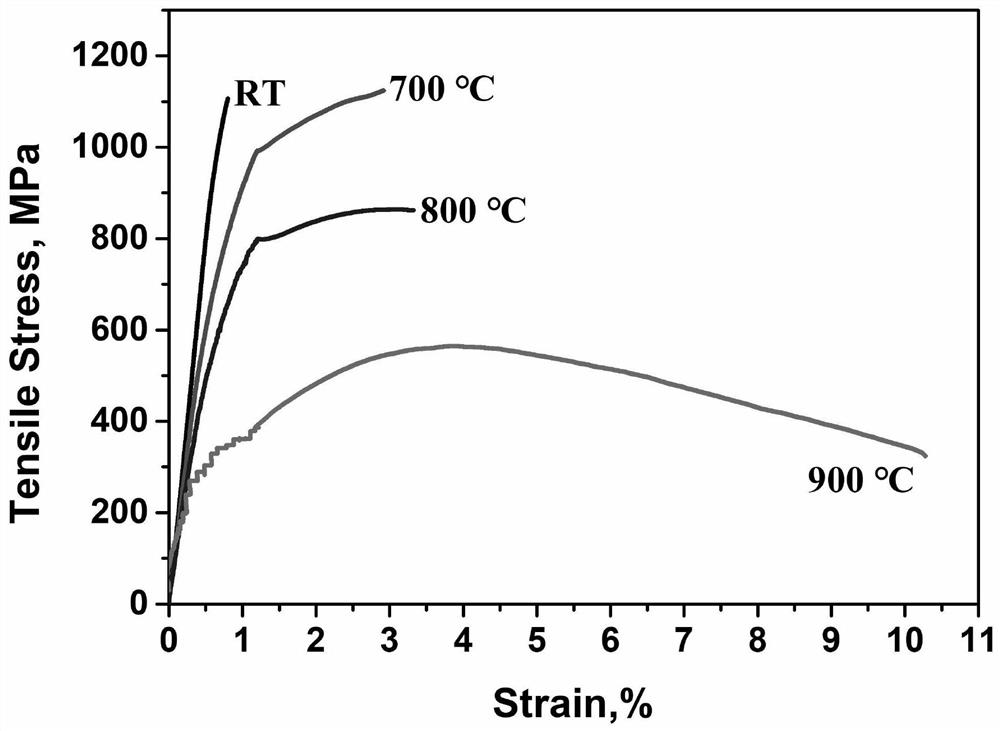

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com