Patents

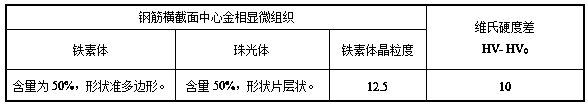

Literature

58results about How to "Increased pearlite content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

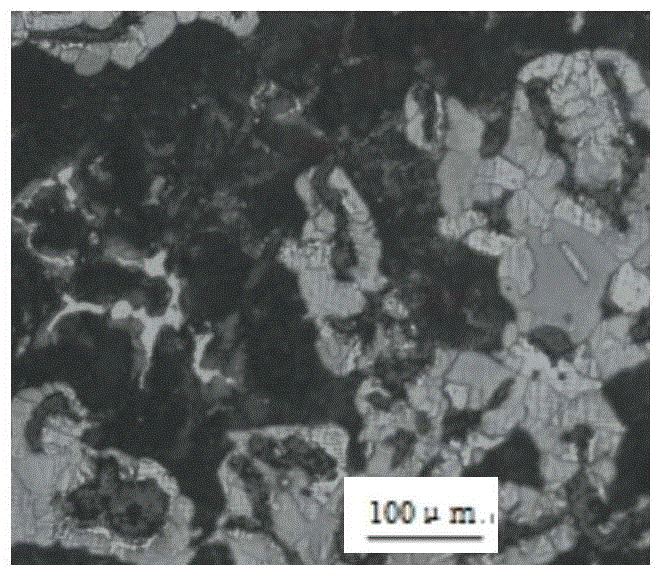

Alloy vermicular graphite cast iron for railway vehicle brake disc and smelting method of alloy vermicular graphite cast iron

The invention relates to alloy vermicular graphite cast iron for a railway vehicle brake disc and a smelting method of the alloy vermicular graphite cast iron. The vermicular graphite cast iron is composed of, by mass, 3.3%-3.5% of C, 2.3%-2.5% of Si, 0.4%-0.7% of Mn, 0.6%-1.0% of Cu, 0.2%-0.6% of Mo, 0.6%-1.0% of Ni, 0-0.07% of P, 0-0.02% of S and the balance Fe. The vermicular graphite rate of the vermicular graphite cast iron brake disc is higher than or equal to 75% and the pearlite content is 50% to 60%. According to the alloy vermicular graphite cast iron for the railway vehicle brake disc and the smelting method of the alloy vermicular graphite cast iron, the stress threshold value when a disc body is cracked and extended due to thermal stress concentration can be increased, and the mechanical property of the railway vehicle brake disc is improved.

Owner:CHANGZHOU LANGRUI CASTING +1

Tin and niobium composite alloying gray pig iron and production process thereof

The invention discloses tin and niobium composite alloying gray pig iron which comprises the following elements in percentage by weight: 3.5-4.0% of C, 1.8-2.8% of Si, 0.6-1.0% of Mn, 0.02-0.08% of P, 0.02-0.10% of S, 0.02-0.10% of Sn, 0.07-0.40% of Nb and the balance of Fe. According to performance requirements, one or more following elements can be added: 0.3-0.8% of Cu, 0.2-0.7% of Cr, 0.2-2.0% of Ni, 0.2-1.0% of Mo, 0.01-0.07% of V and 0.01-0.07% of Ti. According to the gray pig iron, Sn and Nb alloys are compositely added, so that graphite and pearlite in the cast iron are remarkably refined, and the content of the pearlite is increased to over 98%, thereby remarkably improving the hardness, compressive strength and elasticity modulus of the cast iron. The tin and niobium composite alloying gray pig iron can be used for brake discs, air cylinder covers of engines and piston rings of top grade automobiles and is stable in performance and low in cost.

Owner:SICHUAN UNIV

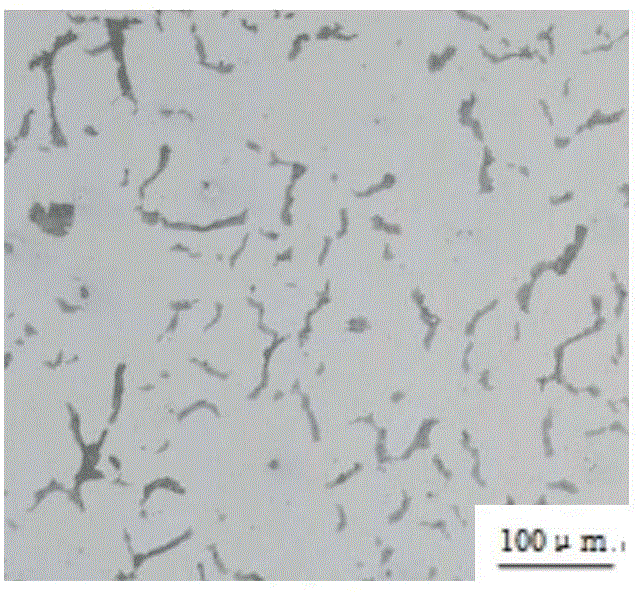

Production method of spheroidal graphite cast iron for hydraulic parts and prepared spheroidal graphite cast iron

ActiveCN102534352AGood heredityAdjust carbon contentProcess efficiency improvementSteelmakingHardness

The invention relates to a production method of spheroidal graphite cast iron for hydraulic parts and prepared spheroidal graphite cast iron. The production method comprises the following steps of a material proportioning procedure, a charging melting procedure and a nodulizing inoculation procedure. In the material proportioning process of the material proportioning procedure, the adopted raw materials by weight part comprise 25-35 parts of pig iron for steelmaking, 33-43 parts of steel scrap, 26.5-36.5 parts of scrap return, 0.3-0.5 part of red copper and 0.5-2.5 parts of carburizing agent.A completely new formula is adopted. As a defined amount of red copper is added in ferritic nodular iron, a matrix structure can be added with 20-40 percent of pearlite content, the hardness can be increased by 8-10 percent, the tensile strength can be increased by 9-11 percent, the yield strength can be increased by 8-10 percent, and the elongation can be reduced by 20-30 percent. The too-soft defect of the ferritic nodular iron in the machining process can be obviously overcome, and the machining performance is increased.

Owner:SHANDONG CHANGLIN MACHINERY GRP

Vanadium-titanium gray cast iron and production technique thereof

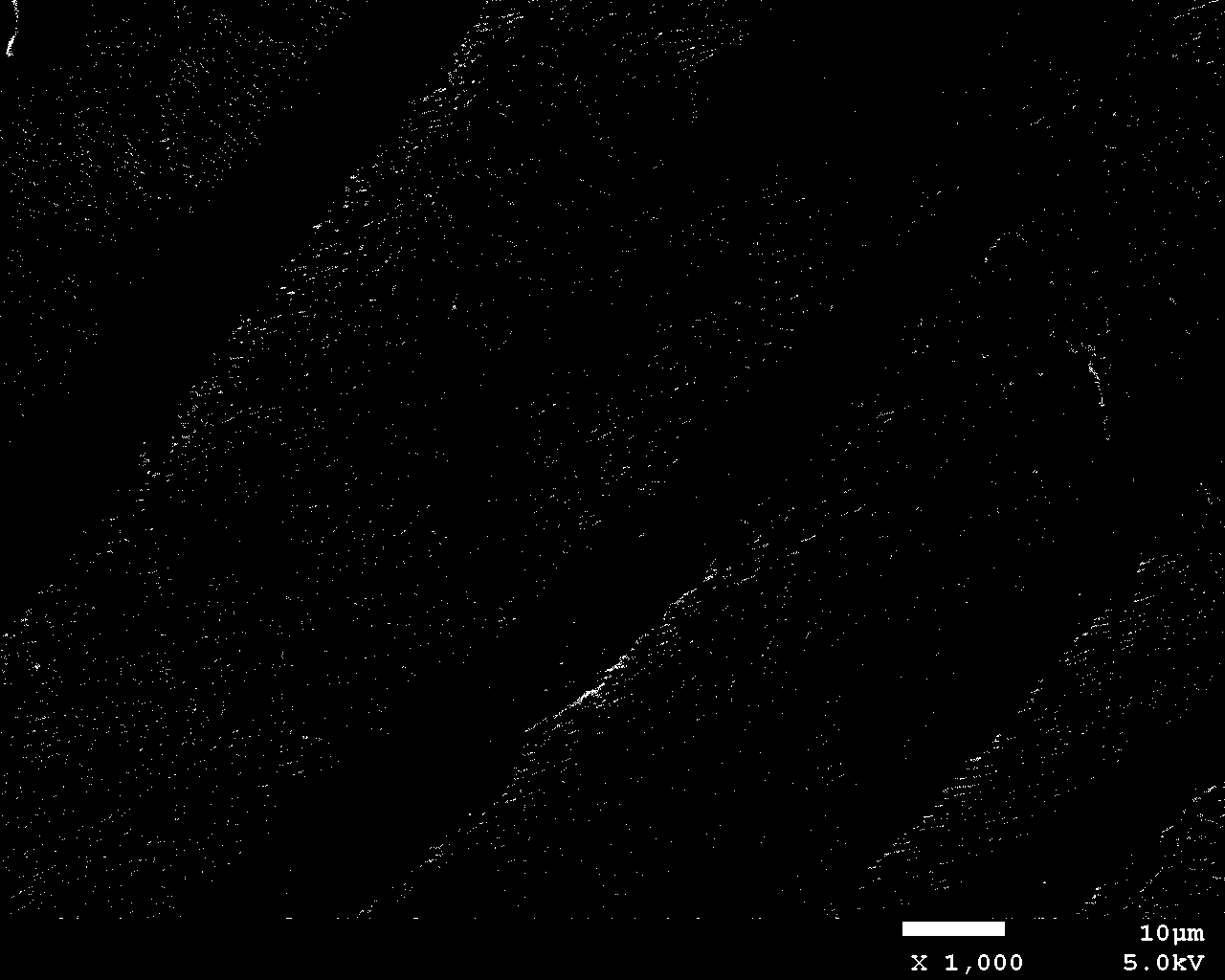

The invention particularly relates to a vanadium-titanium gray cast iron and a production technique thereof. The vanadium-titanium gray cast iron contains 3.2-3.6% of C, 1.6-1.9% of Si, 0.7-0.9% of Mn, 0-0.10% of P, 0.07-0.12% of S, 0.15-0.20% of V, 0.07-0.12% of Ti, 0.25-0.35% of Cr, and the balance of Fe and other minor elements and inevitable impurities. The vanadium-titanium gray cast iron has the advantages of high tensile strength, favorable heat resistance and favorable wear resistance; and the type-A graphite content in the metallurgical structure is higher than 85%, the graphite length is Grade 3-5, the pearlite content in the matrix structure is greater than or equal to 98%, and the total content of carbides and iron phosphide eutectic is less than or equal to 2%.Late inoculation treatment is adopted to enhance the inoculation effect, improve the graphite form, eliminate the carbides and ferrite and increase the pearlite content. By using cheap vanadium-titanium pig iron as the raw material and avoiding adding noble alloys, the vanadium-titanium gray cast iron has the advantages of low cost and high performance.

Owner:陈国

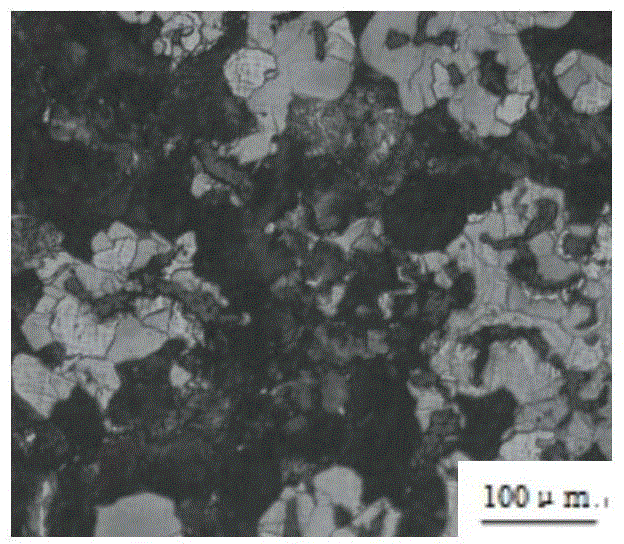

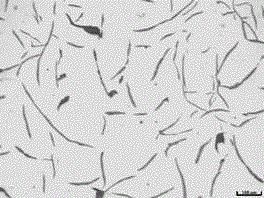

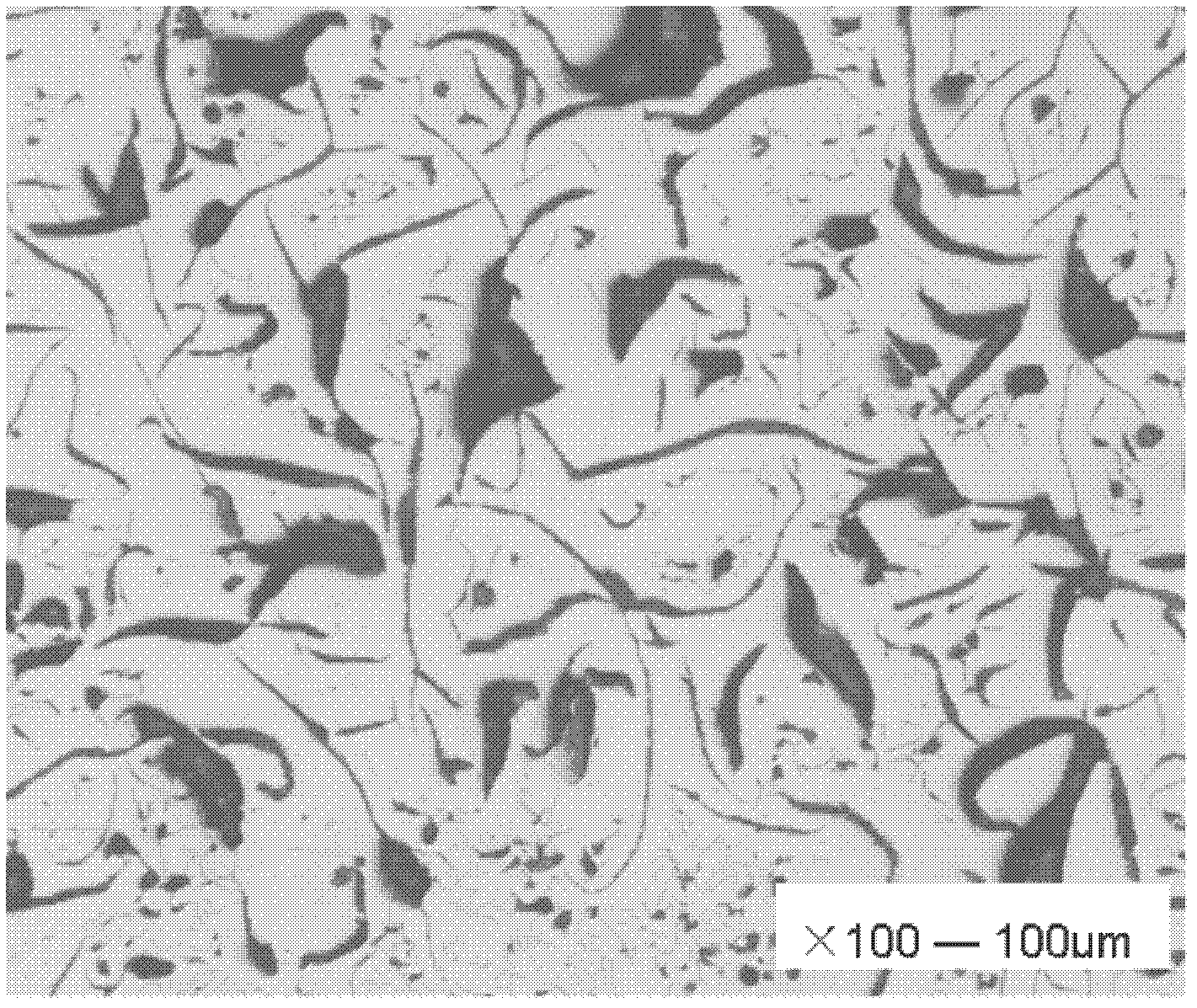

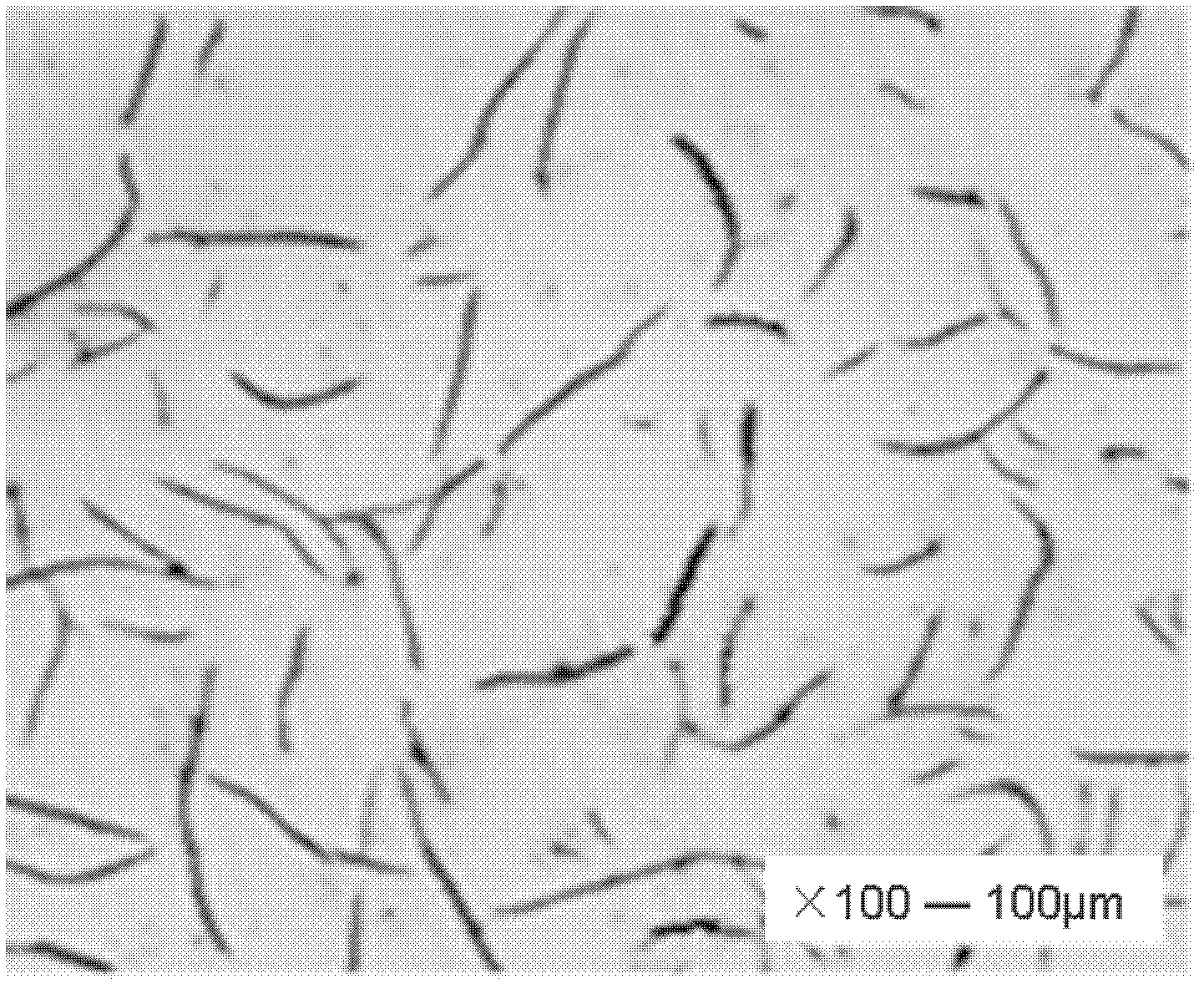

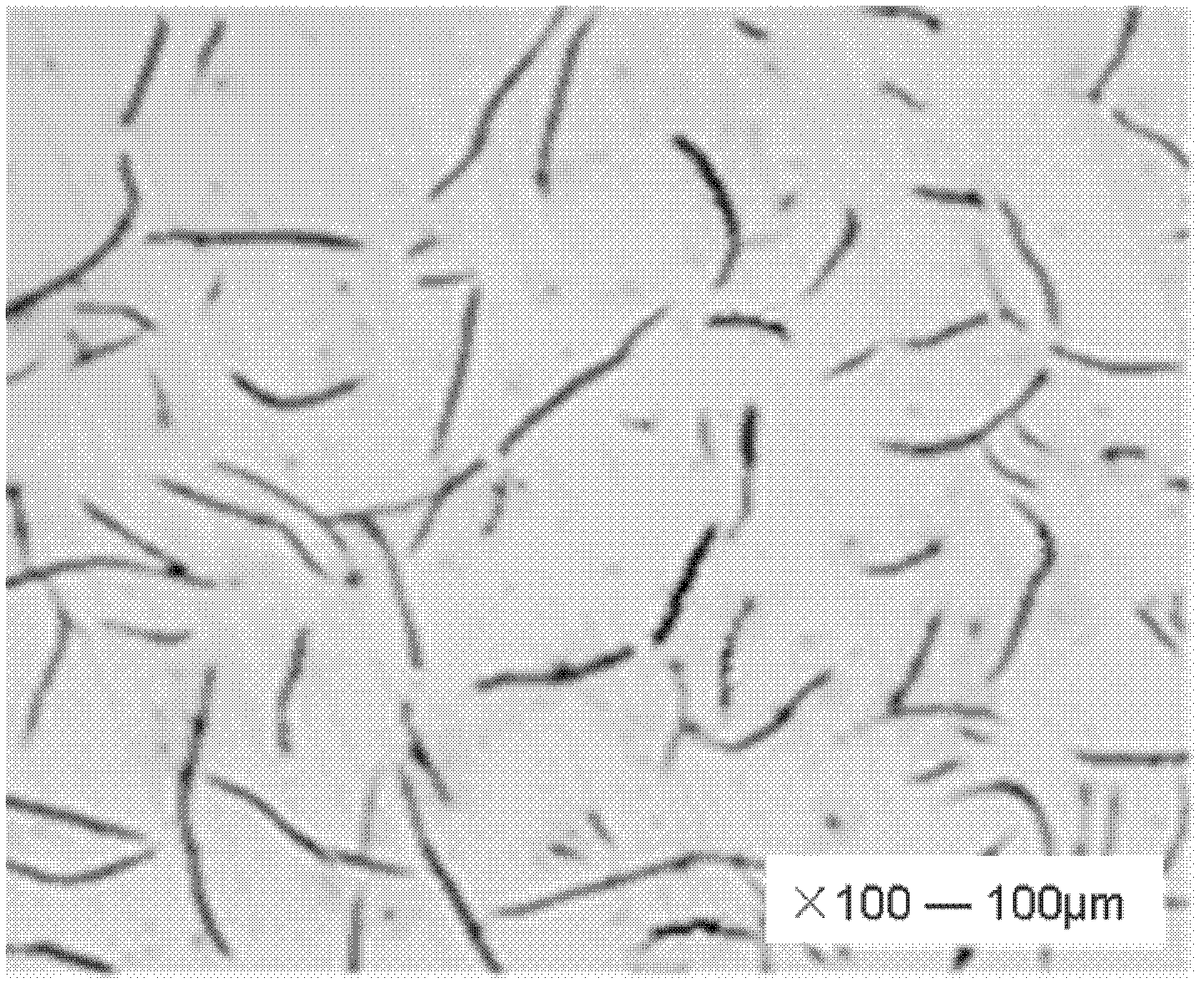

As-cast high pearlite quantity and high vermicular rate vermicular graphite cast iron and preparation method thereof

ActiveCN108624807AEvenly distributedSimple preparation processProcess efficiency improvementCrack resistanceCreep rate

The invention discloses as-cast high pearlite quantity and high vermicular rate vermicular graphite cast iron and a preparation method thereof. The vermicular graphite cast iron is prepared from the following components by weight percent: 3.5-3.8% of C, 2.2-2.4% of Si, 0.8-1% of Mn, 0.2-0.4% of Cu, 0-0.4% of Mo, 0.08-0.1% of Sn, 0.2-0.4% of Cr, 0.2-0.5% of Ni, 0.05-0.1% of Nb, less than or equal to 0.06% of S, less than or equal to 0 .06% of P, and the balance of Fe and impurities introduced by raw materials. The vermicular graphite cast iron with a high creep rate (90-98%) is obtained by using an Mg-RE creeping method for controlling; furthermore, by means of micro-regulation of multiple alloy elements, the vermicular graphite cast iron with a high high pearlite quantity (90%-100%) can bestably obtained; the tensile strength of the vermicular graphite cast iron is greater than or equal to 500MPa, the elongation of the vermicular graphite cast iron is greater than or equal to 1.5%, Brinell hardness of the vermicular graphite cast iron is 230-260HBW, and the microhardness of pearlite is 300-320HV. The vermicular graphite cast iron provided by the invention has the characteristics of being good in mechanical properties, thermal fatigue resistance, thermal crack resistance and wear resistance under the extremely harsh working conditions; the preparation method is simple in control method and can stably produce castings with excellent comprehensive performance, thus being suitable for industrial mass production.

Owner:西安洪盛冶金科技有限公司

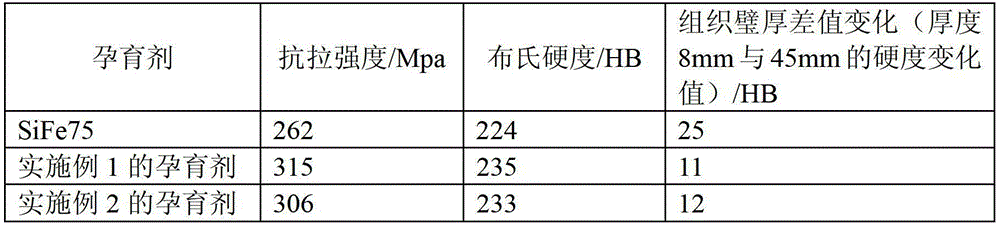

High-intensity gray pig iron inoculator and preparation method thereof

The invention discloses a high-intensity gray pig iron inoculator and a preparation method thereof and belongs to the technical field of casting. The high-intensity gray pig iron inoculator comprises the following chemical components in percentage by weight: 65 to 72 percent of Si, 0.5 to 1.2 percent of Al, 0.5 to 1.5 percent of Zr, 0.6 to 1.8 percent of RE, 4.0 to 6.0 percent of Mn, 0.4 to 1.2 percent of Sn (or 0.1 to 0.4 percent of Sb), less than 0.2 of C, less than 0.02 of S, less than 0.05 of P, and the balance of iron and unavoidable impurities. The inoculator can obviously reduce chilling tendency, refine graphite and reduce wall thickness and sensitivity of tissues and obviously increase pearlite content, so that tensile strength of gray pig iron is improved. For base iron with the same components, compared with a common 75 silicon iron inoculator, the high-intensity gray pig iron inoculator has the advantage that the tensile strength of cast iron applying the high-intensity gray pig iron inoculator can be improved by 30 to 60MPa.

Owner:SHANDONG HUIFENG CASTING TECH

Gray cast iron and preparation method thereof

The invention discloses gray cast iron and a preparation method thereof, and belongs to the field of metal casting. The gray cast iron and the preparation method solve the technical problems that existing gray cast iron is high in production cost and insufficient in performance. According to the gray cast iron and the preparation method, precious metal such as copper, molybdenum, nickel and vanadium is not added, strength and hardness of castings are improved through chromium and antimony, the manufacturing cost is reduced, and performance of the gray cast iron can be improved by conducting microalloying on antimony and chromium together.

Owner:浙江杭机铸造有限公司

Production method of cast-state ductile iron QT800-5 by using fired mold precision casting

InactiveCN108796355AIncreased pearlite contentImprove mechanical propertiesFoundry mouldsFoundry coresManganeseCopper

The invention discloses a production method of a cast-state ductile iron QT800-5 by using fired mold precision casting. The method comprises the following steps of fired mold precision casting of shell and shell making, molten iron smelting, spheroidizing treatment, inoculation treatment, mold shell casting and module cooling so as to obtain the QT800-5, wherein the requirements that the tensile strength Rm is larger than or equal to 800 MPa and the elongation percentage after fracture A is larger than or equal to 5% can be met. The production method of cast-state ductile iron QT800-5 by usingthe fired mold precision casting has the beneficial effects that low-cost copper and manganese are added to improve a pearlite content in a cast-state ductile iron matrix, the structure is strengthened and refined, the mechanical property of a material is improved, the cost can be effectively reduced, and the cast-state heat-free treatment is realized; and meanwhile, deformation is avoided afterthe heat treatment of a casting is avoided.

Owner:DONGFENG PRECISION CASTING CO LTD

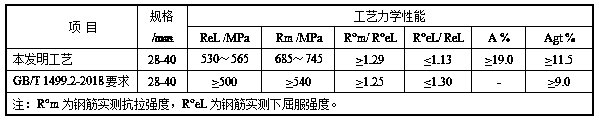

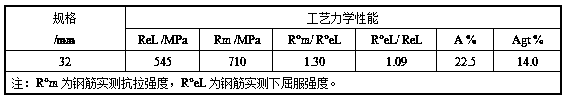

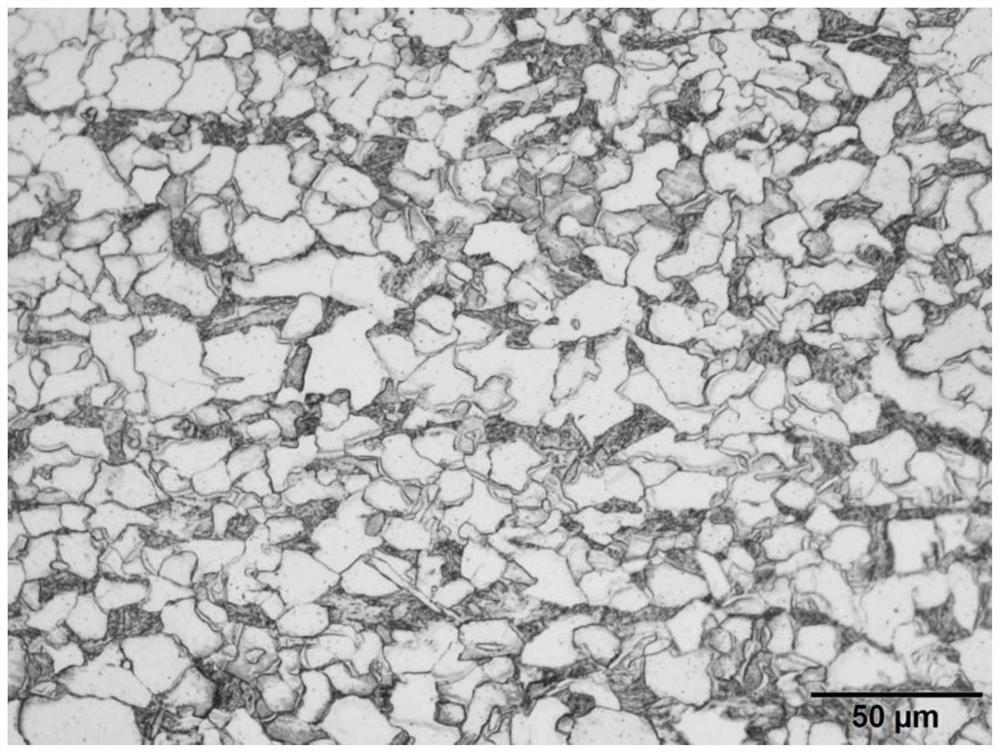

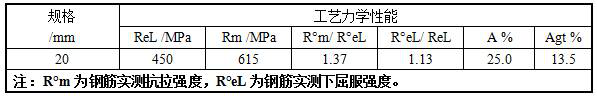

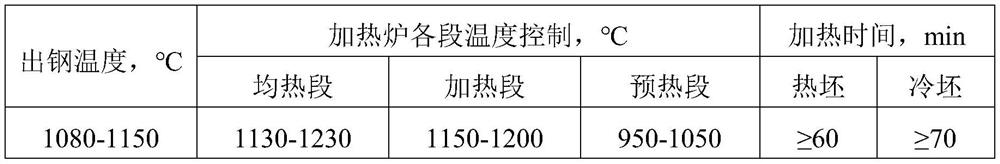

Vanadium-chromium microalloying large-specification 500MPa ultra-fine grain corrosion-resisting anti-seismic steel bar and preparation method thereof

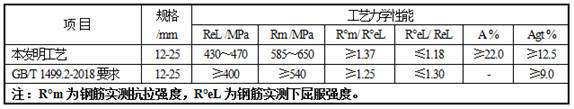

ActiveCN111519099AImprove precipitation strengthening effectImprove plastic toughnessProcess efficiency improvementAlloyRebar

The invention discloses a vanadium-chromium microalloying large-specification 500MPa ultra-fine grain corrosion-resisting anti-seismic steel bar and a preparation method thereof. The steel bar comprises, by weight percent, 0.21-0.25wt% of C, 0.45-0.55wt% of Si, 1.25-1.40wt% of Mn, 0.30-0.35wt% of Cr, 0.065-0.080wt% of V, not larger than 0.040wt% of S, not larger than 0.045wt% of P, not larger than0.0070wt% of O, 0.0165-0.0200wt% of N and the balance Fe and inevitable impurities. The preparation method of the steel bar comprises the procedures of molten steel smelting, deoxidization alloying,LF furnace refining, casting, steel blank heating and controlled rolling and controlled cooling. A certain amount of vanadium-containing pig iron is added into a tapping steel ladle to replace the expensive vanadium alloy, the V content of molten steel is increased, and the adding quantity of the vanadium alloy is reduced; in the deoxidization alloying process, a small quantity of silicon-nitrogenalloy is added, the nitrogen content in the molten steel is increased, and the proportion value of V / N in the steel is reduced, transferring of V from the solid solution state to a carbonitride precipitated phase in the rolling process is promoted, and the precipitation strength effect of the steel is obviously improved; and the preparation method is low in production cost and high in process applicability and controllability.

Owner:WUKUN STEEL

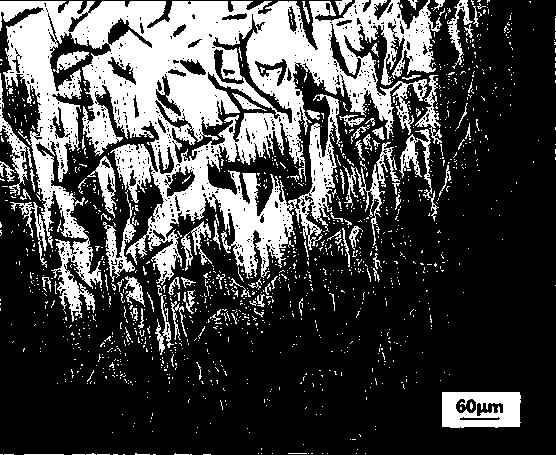

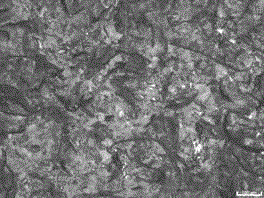

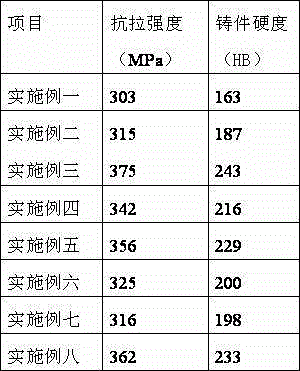

Production process of high-strength alloyed gray iron hydraulic valve body part

ActiveCN105401065AIncreased pearlite contentSolve the problem of low hardness in thick and large sectionsProcess efficiency improvementElectric furnacePearliteScrap

The invention discloses a production process of a high-strength alloyed gray iron hydraulic valve body part. The production process comprises the following steps: adding a scrap steel, a pig iron, foundry returns and a carburant to a medium-frequency induction furnace and turning on the furnace for smelting; after the materials in the furnace are melted down, adding alloy particles and continuing to heat for 4-8 minutes by controlling a temperature within a range of 1560-1600 DEG C, wherein the alloy particles comprise three elements, namely copper, chromium and tin; taking liquid iron from the furnace by using a sampling spoon, and detecting the content of each element in the liquid iron through a metal element analyzer; carrying out drossing and pouring after the liquid iron is cooled, keeping a pouring temperature within the range of 1320-1360 DEG C and pouring the liquid iron into a cavity of the hydraulic valve body part; and forming a final casting. According to the production process of the high-strength alloyed gray iron hydraulic valve body part, the brand-new alloy is added, such that the content of a pearlite can be increased and the graphite can be refined; as a result, the problems of thick and large section and low hardness, and low pearlite content of the hydraulic part are effectively solved, and the tensile strength of the hydraulic valve body part and the hardness of the casting are improved.

Owner:西峡飞龙特种铸造有限公司

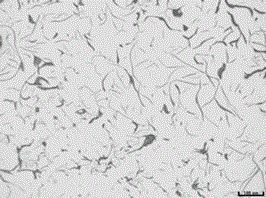

High-thermal-conductivity vermicular graphite cast iron diesel engine cylinder body material and preparation method thereof

InactiveCN105483515ARefinement pitchImprove mechanical propertiesCylinder headsCylindersThermal conductivityCast iron

The invention discloses a high-thermal-conductivity vermicular graphite cast iron diesel engine cylinder body material and a preparation method thereof. The high-thermal-conductivity vermicular graphite cast iron diesel engine cylinder body material consists of the following components in percentage by mass: 3.3-3.7% of C, 2.4-2.8% of Si, 0.5-0.7% of Mn, 0.4-0.6% of Cu, 0.3-0.5% of Cr, 0.2-0.35% of Mo, 0.1-0.3% of Sn, 0.2-0.4% of Ag, 0.05-0.15% of Sb, 0.04-0.07% of Sm, 0.03-0.04% of Ho, 0.02-0.03% of Yb, 0.04-0.05% of P, 0.02-0.03% of S and the balance of Fe. The vermicular graphite cast iron prepared by the preparation method has high strength, good toughness, a high heat conduction coefficient, good heat resistance, and fatigue resistance, and is durable in use.

Owner:FANCHANG COUNTY HENGXIN AUTO PARTS

Hydraulic part servo valve body material formula and preparation process thereof

PendingCN103966499AReduce the amount of C and SiPrevent pitting and small holesFoundry mouldsFoundry coresLiquid stateGraphite

The invention discloses a hydraulic part servo valve body material formula and a preparation process thereof. The method comprises the following steps of: (1) smelting by adopting an electric furnace, adding 15-25 parts (in parts by weight) of raw iron, 40-60 parts of waste steel and 20-40 parts of foundry returns into the electric furnace for melting; (2) adding Sn in the electric furnace after melting; (3) continuously adding ferrochrome into the electric furnace; (4) then, continuously adding copper; (5) then carrying out inoculation treatment in three steps; (6) pouring liquid-state cast iron into a casting mould cavity of a sand mould to form hydraulic part servo valve body blank. According to the invention, formation of thick sheet-shaped graphite can be prevented, hard spot shaped small holes can be prevented, and mechanical performances of cast iron can be improved.

Owner:SHANDONG CHANGLIN MACHINERY GRP

Manufacturing method of vermicular graphite cast-iron brake drum

The invention belongs to the field of mechanical part machining and manufacturing and particularly relates to a manufacturing method of a vermicular graphite cast-iron brake drum. The manufacturing method is characterized in that vermiculizer containing 12-13% of Ce is used, molten iron processing temperature is 1480-1500 DEG C, and spheroidizing is performed by a pouring process. The vermicular graphite cast-iron brake drum manufactured by the method is excellent in mechanical performance, high in flexural fatigue performance and thermal fatigue performance, high in pearlite content, excellent in wear resistance, low in cost, and the like.

Owner:QINGTE GRP

Low-alloy, high-strength and high-weather-resistance structural steel for highway guardrails and preparation method thereof

ActiveCN112647018AIncreased compactness of the rust layerImprove weather resistanceTemperature control deviceFurnace typesPearliteWeather resistance

The invention relates to the field of production and manufacturing of structural steel for highway guardrails, in particular to low-alloy, high-strength and high-weather-resistance structural steel for highway guardrails and a preparation method of the low-alloy, high-strength and high-weather-resistance structural steel. The low-alloy, high-strength and high-weather-resistance structural steel comprises, by mass, less than or equal to 0.12% of C; less than or equal to 0.65% of Si; less than or equal to 1.20% of Mn; 0.07-0.12% of P; less than or equal to0.030% of S; 0.20-0.55% of Cu; 0.30-1.25% of Cr; 0.12-0.65% of Ni; less than or equal to0.03% of Nb; less than or equal to 0.05% of Al, and the balance Fe. On the basis of existing low-alloy high-strength weather-resistant steel, the compactness of a rust layer is improved by optimizing the P element, and then the weather resistance of the structural steel is improved; the Cr content, the rust layer compactness and the pearlite content are improved, and the weather resistance and the mechanical property of the structural steel are improved; and the Nb element is increased, the grain size of the steel is refined, and the comprehensive mechanical property of the material is improved. The structural steel can meet the requirements of road guardrails on weather resistance and strength performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

High nitrogen-vanadium microalloying large-scale anti-seismic reinforcing steel bar preparation method

ActiveCN111020393AImprove precipitation strengthening effectHigh tensile strengthFurnace typesManufacturing convertersSteelmakingRebar

The invention discloses a high nitrogen-vanadium microalloying large-scale anti-seismic reinforcing steel bar preparation method. In the steelmaking converter steel tapping process and the ladle furnace (LF) refining process, a certain amount of vanadium pig iron is added to replace an expensive vanadium alloy, so that the molten steel V content is increased; and in the steelmaking deoxidation alloying process, a high nitrogen-vanadium alloy and appropriate amount of silicon-nitrogen alloys are added, and molten steel is subjected to LF refining and nitrogen-blowing treatment, so that the nitrogen content in the molten steel is increased, a V / N matching ratio in steel is remarkably reduced, and a steel precipitation strength effect is remarkably improved. According to the high nitrogen-vanadium microalloying large-scale anti-seismic reinforcing steel bar preparation method provided by the invention, through the integrated innovation of chemical composition design, converter smelting, deoxidation alloying, LF refining, continuous casting, a rolled steel heating schedule, rolling temperature and a controlled cooling technology, a produced reinforcing steel bar has the advantages of excellent and stable process mechanical property, fine and uniform microscopic structure, good ductility and toughness, low strain timeliness, excellent anti-seismic property and the like, the production cost is reduced, the anti-seismic property is improved, and the market competitiveness of products is improved.

Owner:WUKUN STEEL

Fusible chaplet for thin-walled iron casting, application method and combined core

PendingCN109277538AImprove mechanical propertiesImprove fusion effectFoundry mouldsFoundry coresRound barThin walled

A fusible chaplet for a thin-walled iron casting comprises an inner copper body and an outer tin layer wrapping the exterior of the copper body. The inner copper body is made of copper, and the outertin layer is made of tin; the inner copper body comprises a binding post, and an upper supporting seat and a lower supporting seat which are vertically connected to the two ends of the binding post; acombined core comprises an upper water jacket core, round bar cores and chaplets, and one upper water jacket core is provided; a plurality of round bar cores and chaplets are provided, and the roundbar cores correspond to the chaplets one by one; the top surface of the upper water jacket core is provided with a plurality of core units arranged continuously, and one round bar core is arranged above each core unit correspondingly; and one chaplet is arranged between each round bar core and each core unit. According to the design, not only can the more complete fusion between the chaplets and the casting be ensured, but also impurities are not introduced; and the anti-oxidation effect is better.

Owner:DONGFENG COMML VEHICLE CO LTD

Nitrogen-rich microalloy fine grain HRB400E straight aseismic steel bar and preparation method thereof

ActiveCN113981311AImprove acceleration performanceImprove plastic toughnessTemperature control deviceManufacturing convertersAlloyNitrogen rich

The invention discloses a nitrogen-rich microalloy fine grain HRB400E straight aseismic steel bar and a preparation method thereof. The steel bar is prepared from the following chemical components in parts by weight: 0.21 to 0.25 weight percent of C, 0.42 to 0.55 weight percent of Si, 1.38 to 1.50 weight percent of Mn, 0.012 to 0.020 weight percent of V, less than or equal to 0.045 weight percent of S, less than or equal to 0.045 weight percent of P, 0.0090 to 0.0115 weight percent of N and the balance of Fe and inevitable impurities. The steel bar is prepared through the following steps of molten steel smelting, deoxidation alloying, molten steel argon station refining, molten steel casting, steel billet heating and steel billet controlled rolling and controlled cooling in sequence. The process disclosed by the invention has the characteristics of low production cost, high process applicability, high controllability and the like, and various strengthening effects such as precipitation strengthening, fine grain strengthening and the like are fully exerted by integrating and innovating chemical component design, converter smelting, a deoxidation alloying structure, continuous casting, a steel rolling heating schedule, rolling temperature and a controlled cooling process; and the produced reinforcing steel bar has the advantages of excellent and stable process mechanical properties, fine and uniform microscopic structure, good plasticity and toughness, excellent anti-seismic property and the like.

Owner:WUKUN STEEL

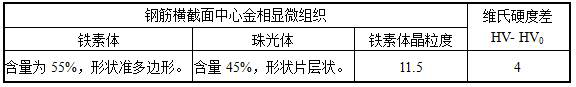

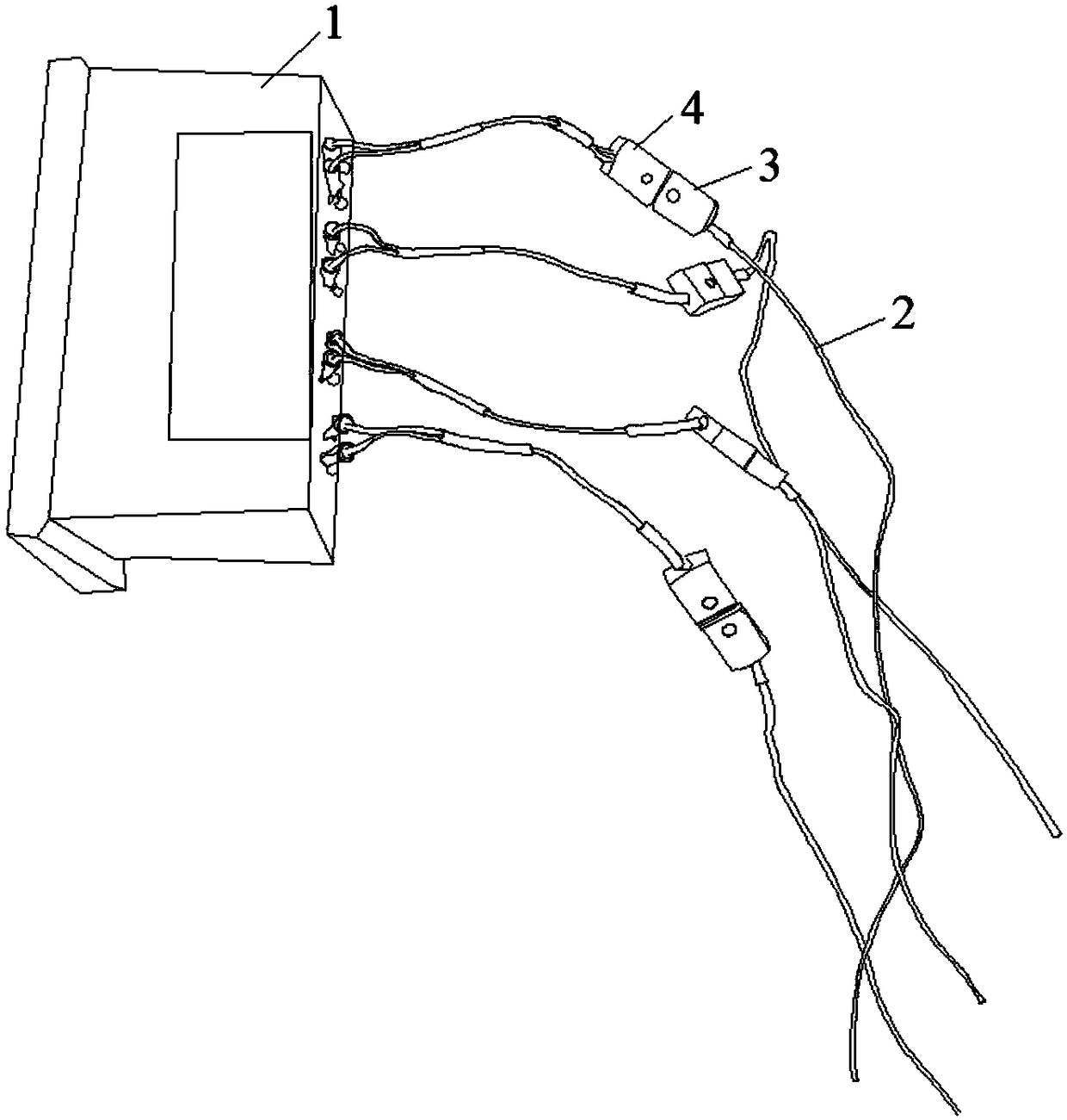

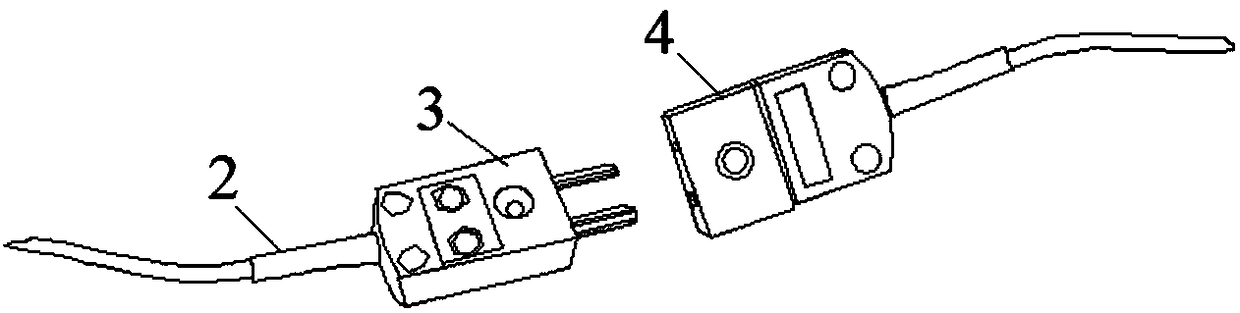

Internal temperature monitoring device and monitoring method for heavy casting in cooling process

InactiveCN108380855AImprove cooling effectControl deformationCasting parameters measurement/indication devicesStress ProblemThermocouple

The invention discloses an internal temperature monitoring device for a heavy casting in the cooling process. The internal temperature monitoring device for the heavy casting in the cooling process comprises a temperature controller, a thermocouple arranged at the temperature measuring point and a compensating wire which is connected with the thermocouple and the temperature controller, and the thermocouple is pre-buried in molding sand in a sand box. According to the internal temperature monitoring device for the heavy casting in the cooling process, the thermocouple and external equipment are used for measuring the temperature of the heavy casting in the cooling process, the temperature change of the casting in the cooling process is known, the reasonable taking time of the casting is determined, and therefore the deformation and stress problems of the casting can be effectively controlled, and the turnover efficiency of the production sand box is improved. The invention further discloses an internal temperature monitoring method for the heavy casting in the cooling process.

Owner:WUHU RUYHOO CASTING

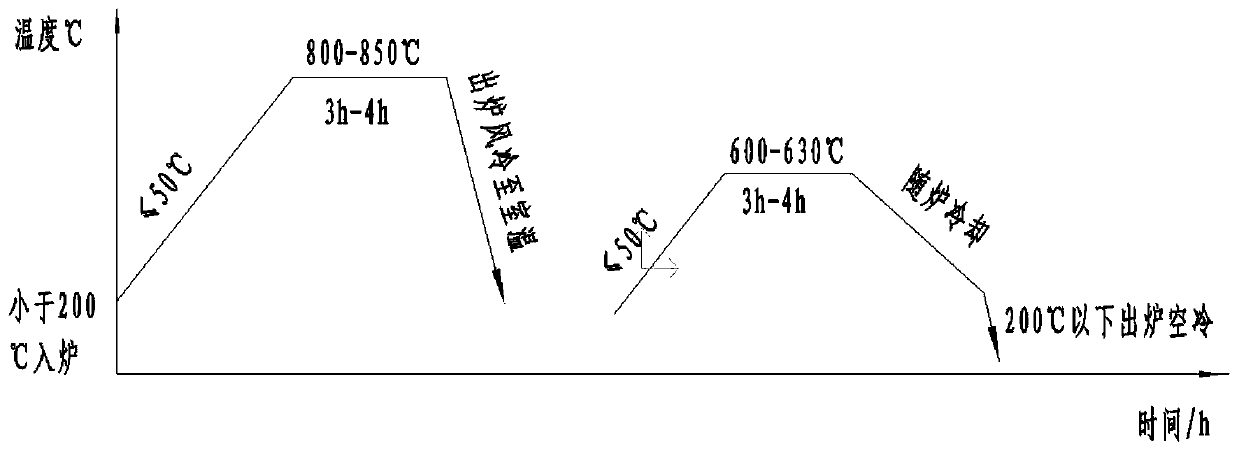

Method for increasing hardness of large high-grade gray-cast-iron diesel engine body

InactiveCN111304522AReduce stressReduce brittlenessFurnace typesHeat treatment process controlDieselingGraphite

The invention provides a method for increasing the hardness of a large high-grade gray-cast-iron diesel engine body. According to the casting process, under the condition of selecting a high carbon equivalent, high carbon and low silicon, and multi-stage enhanced inoculation treatment, the microscopic structure and performance of cast iron are improved through as-cast inoculation, the generation of undercooled graphite and free cementite is reduced, molten iron is promoted to be solidified according to stable-system co-crystallization, the casting stress and brittleness of gray cast iron are reduced, the body obtains a body hardness in a certain range under an as-cast condition, and then a high body hardness is obtained through a normalized state, so that the quality problems of heat treatment cracking risk and the like of the gray-cast-iron body can also be avoided on the premise of ensuring that the large high-grade gray-cast-iron diesel engine body achieves a hardness requirement, the quality of the body is improved, and the qualification rate of the body is increased.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

Special cleansing agent for short-flow high-strength cast iron and manufacturing process thereof

InactiveCN102586666ASignificant technological progressSolve the mechanical propertiesRare earthCast iron

The invention relates to a special cleansing agent for short-flow high-strength cast iron and a manufacturing process thereof, belonging to the technical field of cast iron production flow. The cleansing agent consists of the following components in parts by weight: 6-18 parts of rare earth oxide, 29-49 parts of calcium oxide, 19-29 parts of aluminum oxide and 4-8 parts of carbon. The cleansing agent is manufactured by the following steps of: based on rare-earth selected mineral powder, high-purity calcium oxide powder, bauxite powder and coke powder as raw materials, adding a fluxing agent, roasting a mixture of the raw materials and the fluxing agent at high temperature, and electrically melting and spraying the mixture to obtain the special cleansing agent. The special cleansing agent disclosed by the invention can change conditions of thermodynamics and dynamics of a metallurgical reaction of blast-furnace molten iron, and eliminates or restrains a hereditary defect of vicious expansion of thick graphite of the blast-furnace molten iron so as to form a comprehensive strengthening effect with an inoculant; and high-strength cast iron mainly comprising A-type graphite and havingmore than 95% of pearlite and 250-350MPa of tensile strength can be obtained.

Owner:QINGZHOU HAOZHANG CASTING

A pump casing, pump seat, impeller or pump cover ductile iron casting and its casting process used in the petroleum industry

InactiveCN103352161BIncreased pearlite contentImprove wear resistanceProcess efficiency improvementManganeseDuctile iron

The invention discloses a ductile iron casting and the casting process thereof. The ductile iron casting comprises the following components according to weight percent: 3.5 to 3.7 percent of carbon, 2.0 to 2.4 percent of silicone, 0.4 to 0.8 percent of manganese, 0.04 or less than 0.4 percent of sulfur, 0.06 or less than 0.06 percent of phosphorus and 0.15 to 0.25 percent of chromium, and the rest is Fe. The preparing process of the ductile iron casting comprises the steps of smelting, balling, breeding, molding and detecting. According to the invention, chemical composition of casting is improved, the chromium is used for replacing precious metal copper and tin, the content of pearlite is also increased, the wearing resistance of the casting is improved, heat treatment is not required, that the requirements of a special petroleum pump for petroleum enterprises are met is detected, due to the improvement to matching components, the smelting and casting process of the invention is enabled to be more reasonable, the smelting cost is lower, the self feeding capacity of the casting is excellent, and dense tissue can be obtained easily after cooling.

Owner:SICHUAN XIANGYE MASCH CASTING CO LTD

Nucleating agent for cast iron

The invention discloses a nucleating agent for cast iron and relates to the field of metal materials. The nucleating agent comprises, by weight, 50%-63% of Si, 15%-20% of Ga, 1.5%-2.5% of Al, 0.2%-0.8% of RE, 2.0%-3.0% of Mg, 0.2%-0.8% of Sn and the balance Fe and inevitable microelements. The nucleating agent can promote nucleation of graphite and improve the inoculation effect; the chilling tendency of the cast iron is obviously reduced; and the refining property of the graphite is better. It is shown through practice that the pearlite content of the inoculated cast iron is obviously increased, and therefore the tensile strength of gray cast iron is improved.

Owner:潘桂枝

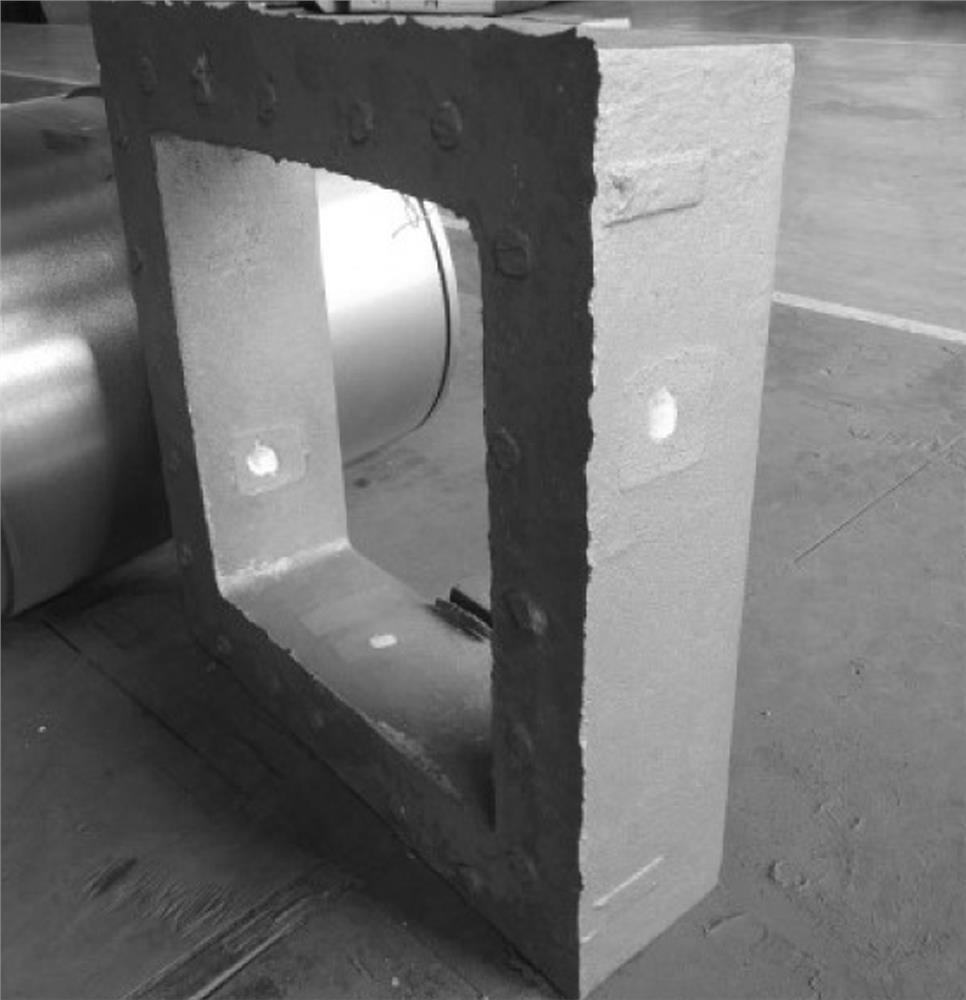

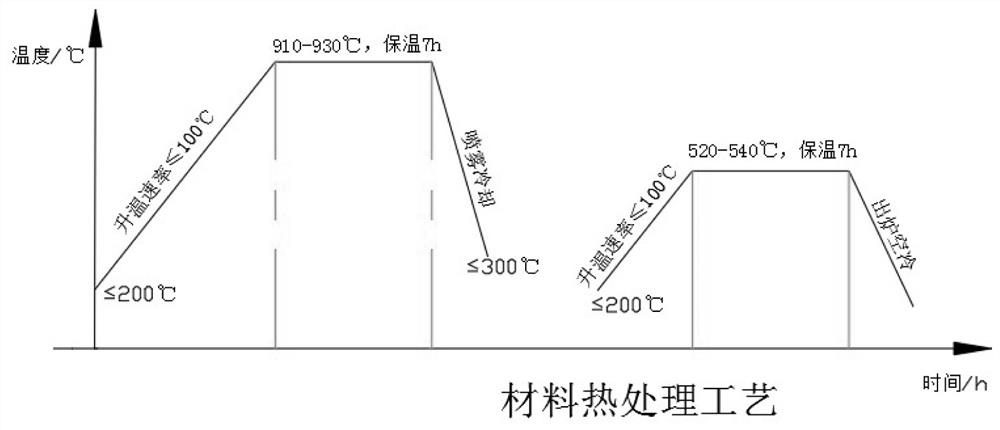

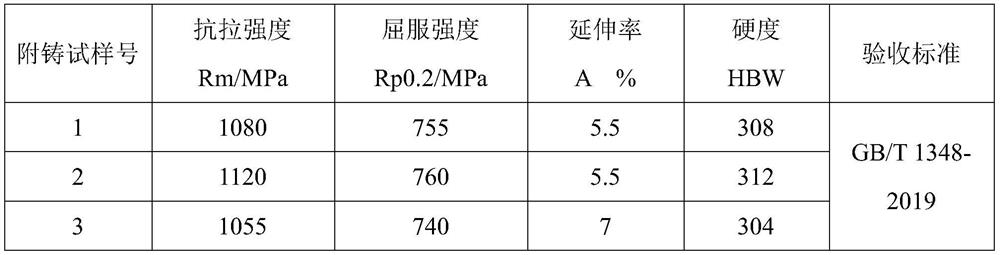

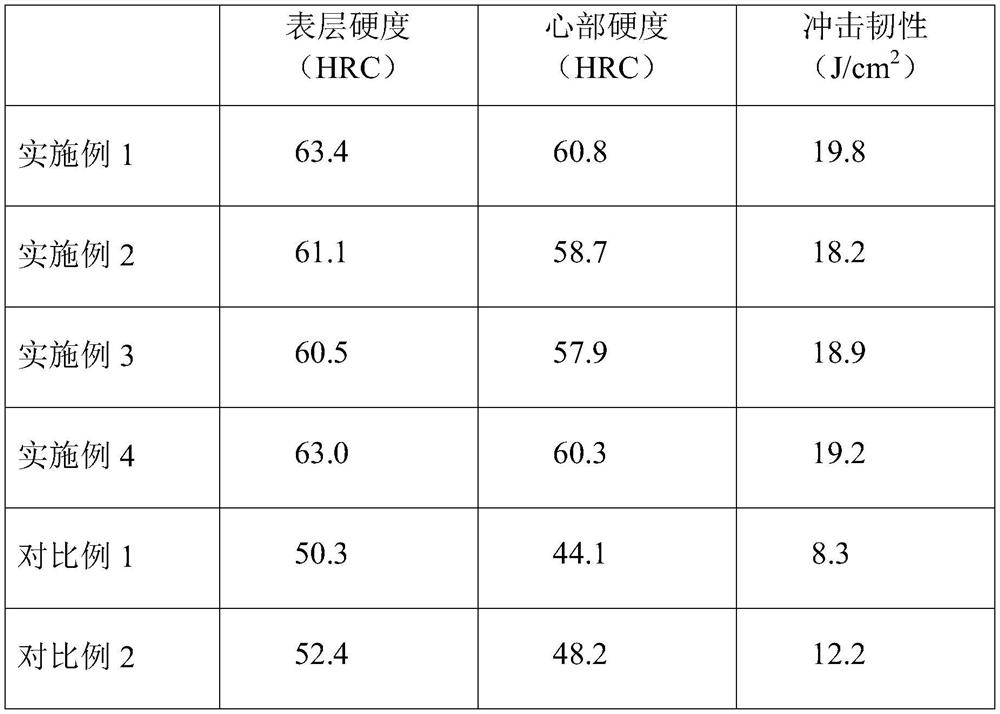

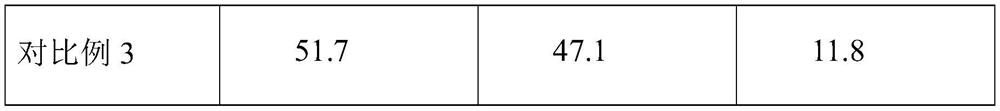

High-strength and high-toughness thick-wall nodular cast iron material and casting method thereof

The invention provides a high-strength and high-toughness thick-wall nodular cast iron material and a casting method thereof. Raw iron liquid of the material comprises, by mass, 3.5%-3.8% of C, 0.3%-0.60% of Si, smaller than 0.4% of Mn, smaller than 0.06% of P, smaller than 0.05% of S, 0.4%-0.7% of Cr and the balance Fe and inevitable impurities. The casting material subjected to spheroidizing inoculation comprises the following chemical components in percentage by mass: 3.5%-3.8% of C, 1.6%-2.2% of Si, less than 0.4% of Mn, less than 0.06% of P, less than 0.05% of S, 0.4%-0.7% of Cr, 0.5%-0.8% of Cu, 0.04%-0.06% of Mg and 0.01%-0.04% of RE. The casting method comprises the following steps of melting raw materials into molten iron, preparing a nodulizing agent, a nucleating agent, a deslagging agent and Cu in a casting ladle, then discharging, treating the molten iron by adopting a pouring method and a flow following mode, casting after slagging off, and finally carrying out normalizing and tempering heat treatment to obtain the high-strength and high-toughness thick-wall nodular cast iron material, wherein the wall thickness of the material is greater than 100mm, the tensile strength is greater than or equal to 1000MPA, the elongation is greater than or equal to 4%, and the HBW is greater than or equal to 300.

Owner:YICHANG MARINE DIESEL ENGINE

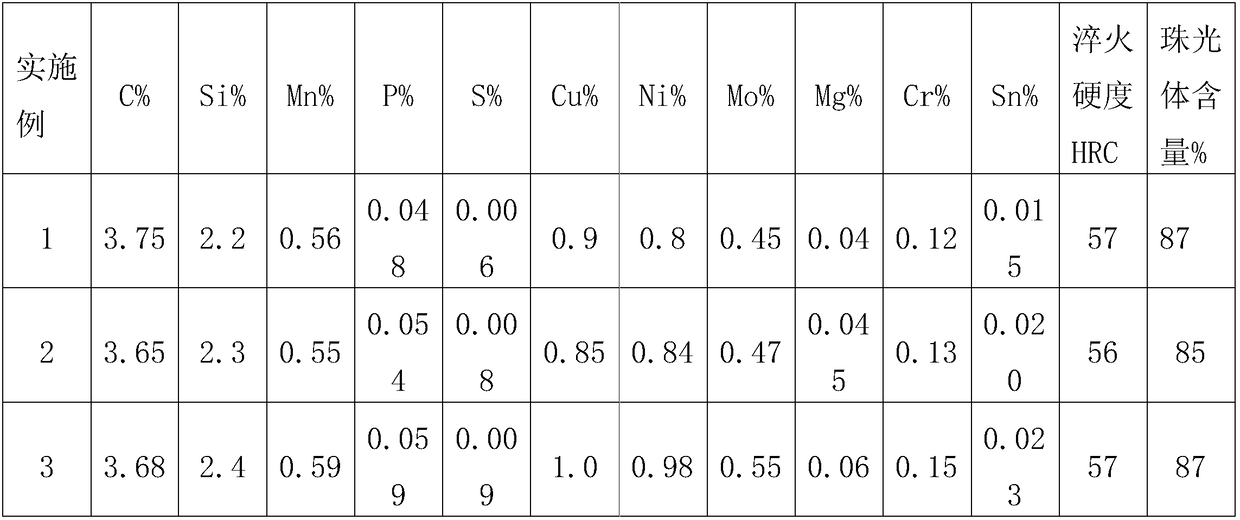

GGG70L nodular cast iron and preparation method thereof

The invention discloses GGG70L nodular cast iron and a preparation method thereof, and belongs to the technical field of cast iron production. The GGG70L nodular cast iron comprises the following chemical components of, by weight, 3.4-3.8% of C, 2.0-2.4% of Si, 0.5-0.6% of Mn, 0.06% of P or the less, 0.01% of S or the less, 0.45-0.55% of Mo, 0.9-1.0% of Cu, 0.9-1.0% of Ni, 0.04-0.06% of Mg, 0.015-0.025% of Sn, 0.1-0.15% of Cr and the balance Fe. The GGG70L nodular cast iron is added according to the existing alloy ratio, when a casting is more than 8 tons, the content of pearlite in the core can also reach 85% or more, and it is guaranteed that the hardness of the quenched casting is larger than 55 HRC.

Owner:HEBEI SHUOKAI CASTING

Casting process for clutch pressure disc

The invention belongs to the technical field of casting processes for pressure discs, and particularly relates to a casting process for a clutch pressure disc. The casting process comprises the steps of molten iron preparation, molten iron standing and casting forming. Compared with the prior art, the casting process has the advantages that: pearlite content of a cast piece is increased, so that the metallographic structure and mechanical properties of the cast piece can meet requirements so as to perform nondestructive examination on the cast piece; examination requirements of radiographic inspection I-grade, ultrasonic flaw detection I-grade and magnetic powder inspection I-grade are met; the clutch pressure disc is manufactured through a casting method and a casting device; and a metal usage rate is increased by 40% or more, and working efficiency is improved by about 60%.

Owner:HEFEI CITY TENVER PRECISION CASTING

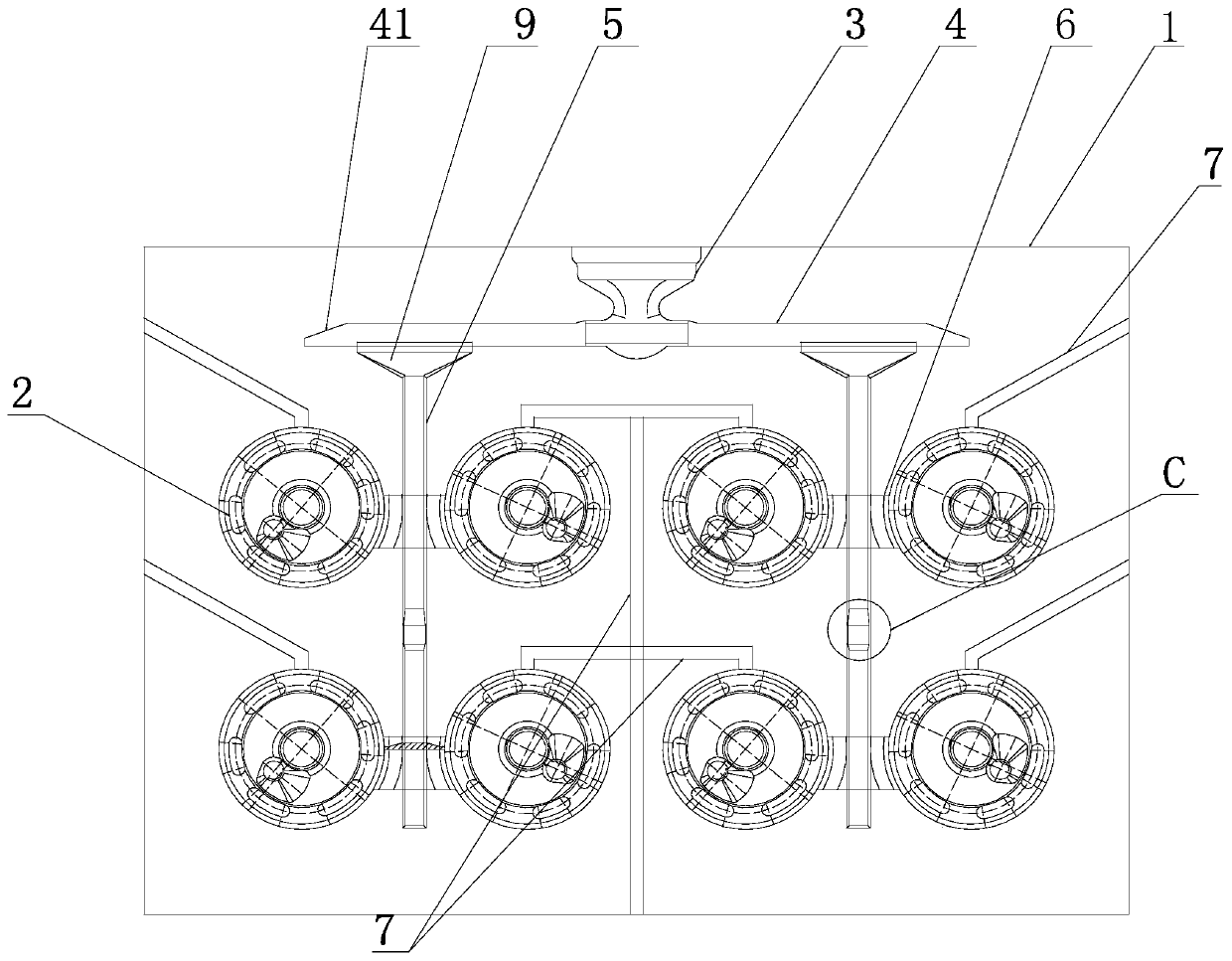

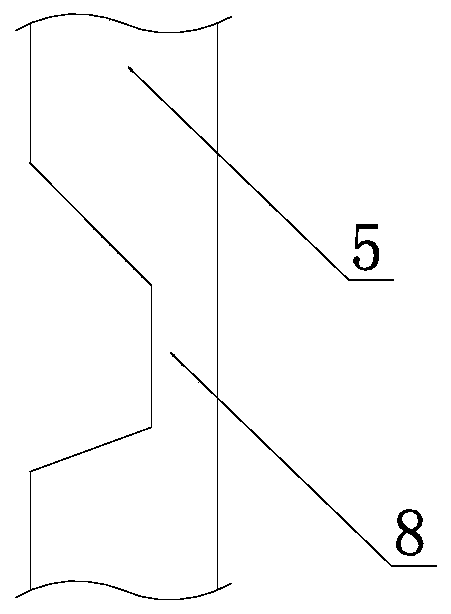

Riser-free gating system for upper flanges used for compressor and production technique of upper flanges

PendingCN110711847ASmooth inflowReduce the injection rateFoundry mouldsFoundry coresCasting moldMachining

The invention belongs to the field of gating machining, and discloses a riser-free pouring system for upper flanges used for a compressor; the riser-free gating system comprises a sand mould casting mould; multiple cavities matched with the shapes of the upper flanges are formed in the sand mould casting mould; a sprue cup, a cross runner, vertical runners and inner sprues which are sequentially connected are arranged in the sand mould casting mould; the inner sprues communicate with the cavities; each inner sprue is of a wedge-shaped sheet structure; exhausting bars are connected to the cavities; a decompression groove is formed in each vertical runner; multiple spoke grooves corresponding to spokes of the upper flange are formed in the cavities; at least one spoke groove faces to the corresponding inner sprue; and the decompression grooves are located between the two rows of cavities which are arranged up and down. According to the system, positions of hot spot circles can be controlled, so that molten iron mould filling is stable, and turbulence is avoided; meanwhile, the invention further provides a production technique; and comprehensive improvement of product quality is realized by improving a formula.

Owner:肇庆精通机械有限公司

Nodular cast iron grinding ball and preparation method thereof

The invention provides a nodular cast iron grinding ball and a preparation method thereof. The grinding ball comprises the following chemical components in percentage by mass: 3.6%-3.7% of C, 2.5%-2.8% of Si, 1.6%-1.8% of Mn, 0.07%-0.1% of Sn, 0.03%-0.05% of Mg, 0.02%-0.03% of Re, less than or equal to 0.06% of S, less than or equal to 0.1% of P and the balance of Fe. According to the spheroidal graphite cast iron grinding ball and the preparation method thereof provided by the invention, the grinding ball overcomes the defects of high hardness and low toughness of a spheroidal graphite cast iron grinding ball in the prior art, and has certain hardness and high wear resistance while having high toughness.

Owner:宁国东方碾磨材料股份有限公司

Anti-seismic reinforcing steel bar and preparation method thereof

The invention relates to the technical field of ferrous metallurgy, in particular to an anti-seismic reinforcing steel bar and a preparation method thereof.The anti-seismic reinforcing steel bar comprises, by weight, 0.20%-0.25% of C, 0.65%-0.80% of Si, 1.35%-1.60% of Mn, 0.090%-0.110% of V, 0.20%-0.30% of Cr, larger than or equal to 0.0180% of N, smaller than or equal to 0.035% of P, smaller than or equal to 0.035% of S, smaller than or equal to 0.55% of Ceq and the balance Fe and inevitable impurities. The beneficial influence of the specification effect of the small-specification HRB600E anti-seismic steel bar on the strength performance is fully considered, the C content is properly reduced and controlled to be 0.20%-0.25%, Ceq is smaller than or equal to 0.55%, the requirements for the C content and the carbon equivalent of the 500 MPa-grade steel bar in the GB / T 1499.2-2018 standard are met, the continuous casting rejudgment of the 500 MPa-grade steel bar can be achieved on a production organization, the production efficiency is not affected, the production organization is facilitated, and waste judgment loss is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

A kind of low-alloy high-strength high-weathering structural steel for highway guardrail and preparation method thereof

ActiveCN112647018BGood weather resistanceImprove mechanical propertiesTemperature control deviceFurnace typesAlloyPearlite

The invention relates to the field of manufacturing structural steel for highway guardrails, in particular to a low-alloy, high-strength, high-weathering structural steel for highway guardrails and a preparation method thereof. In terms of mass percentage, the chemical composition of structural steel is: C≤0.12%; Si≤0.65%; Mn≤1.20%; P: 0.07~0.12%; S≤0.030%; Cu: 0.20~0.55%; Cr: 0.30~1.25 %; Ni: 0.12~0.65%; Nb≤0.03%; Al≤0.05%, Fe is the balance. On the basis of the existing low-alloy high-strength weather-resistant steel, the present invention improves the compactness of the rust layer by optimizing the P element, thereby improving the weather-resistant performance of the structural steel; increasing the Cr content, increasing the compactness of the rust layer and the pearlite content, and improving the structure The weather resistance and mechanical properties of steel; increase the Nb element, refine the grain size of steel, and improve the comprehensive mechanical properties of materials. The invention can meet the requirements of the road guardrail on weather resistance and strength performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Compound rare earth nucleating agent for nodular cast iron and preparation method of compound rare earth nucleating agent

The invention discloses a compound rare earth nucleating agent for nodular cast iron and a preparation method of the compound rare earth nucleating agent. The compound rare earth nucleating agent is prepared from, by weight percent, 2.5% to 3.2% of copper, 12% to 18% of tin, 8.0% to 15% of antimony, 1.8% to 3.5% of manganese, 3.0% to 4.0% of aluminum, 3.5% to 4.2% of magnesium, 5.5% to 6.2% of calcium, 4.4% to 5.2% of cerium, 0.85% to 1.2% of lanthanum, 2.2% to 3.0% of rhenium, 0.75% to 1.25% of strontium and the balance iron. Compared with the prior art, the compound rare earth nucleating agent has the beneficial effects that the compound rare earth nucleating agent can promote nucleation of graphite, enhance the nucleating effect and remarkably reduce the chilling tendency of the cast iron, and the graphite refining performance is better; and the content of pearlite in the nucleated nodular cast iron is remarkably increased, and therefore the tensile strength of the nodular cast iron is improved.

Owner:TONGLING ANDONG CAST STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com