Anti-seismic reinforcing steel bar and preparation method thereof

A technology of seismic reinforcement and tensile strength, applied in the field of iron and steel metallurgy, can solve the problems of continuous casting, difficult 500MPa grade reinforcement, low strength-to-yield ratio, etc., and achieves the effect of improving hardenability, improving strength performance, and saving alloy resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

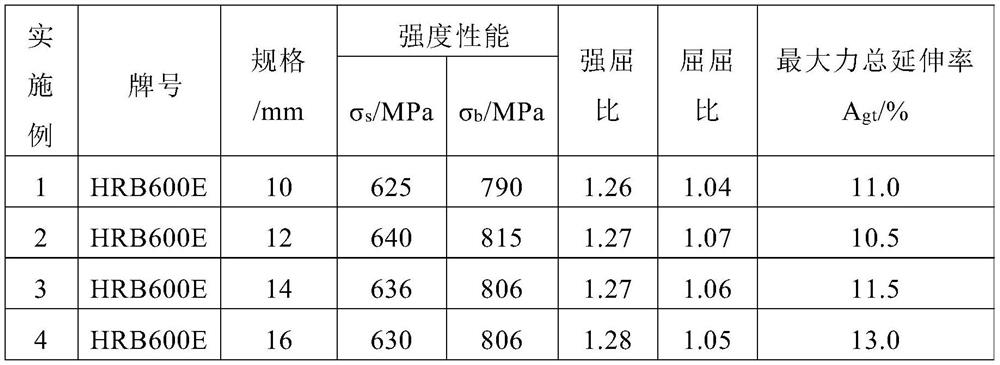

Embodiment 1

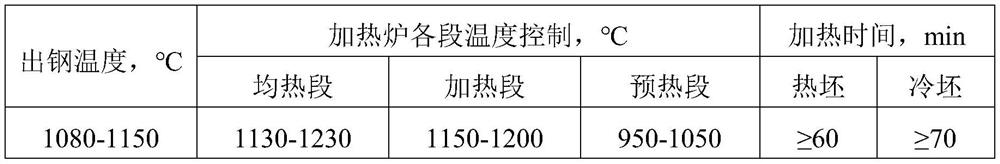

[0048] The invention provides a small-sized HRB600E earthquake-resistant steel bar. The production includes the following processes of reblowing converter smelting, LF refining, continuous casting and rolling. in:

[0049] In the converter smelting process, silicon manganese, ferrosilicon, high chromium ferro, vanadium nitrogen alloy are added in sequence when the molten steel reaches 1 / 4, and the addition is completed when the molten steel reaches 3 / 4. The smelting process adopts high-strength supplementary blowing, and the control end point [C] is 0.14%, [P] is 0.025%, [S] is 0.011%, and the chemical composition of molten steel in this process is controlled as follows: C: 0.23%, Si: 0.68%, Mn: 1.43%, V: 0.096%, Cr: 0.22%, N: 0.0206%, P: 0.025%, S: 0.011%, Ceq: 0.53%, the rest is Fe and unavoidable impurities;

[0050] In the LF refining process: after the temperature of the ingredients is suitable, the "soft blowing" operation is carried out, and the soft blowing time is 10...

Embodiment 2

[0054] The invention provides a small-sized HRB600E earthquake-resistant steel bar. The production includes the following processes of reblowing converter smelting, LF refining, continuous casting and rolling. in:

[0055] In the converter smelting process, silicon manganese, ferrosilicon, high chromium ferro, vanadium nitrogen alloy are added in sequence when the molten steel reaches 1 / 4, and the addition is completed when the molten steel reaches 3 / 4. The smelting process adopts high-strength supplementary blowing, and the control end point [C] is 0.12%, [P] is 0.019%, [S] is 0.013%, and the chemical composition of molten steel in this process is controlled as follows: C: 0.24%, Si: 0.70%, Mn: 1.38%, V: 0.100%, Cr: 0.24%, N: 0.022%, P: 0.019%, S: 0.013%, Ceq: 0.54%, the rest is Fe and unavoidable impurities;

[0056] In the LF refining process: after the temperature of the ingredients is suitable, the "soft blowing" operation is carried out, and the soft blowing time is 11 ...

Embodiment 3

[0060] The invention provides a small-sized HRB600E earthquake-resistant steel bar. The production includes the following processes of reblowing converter smelting, LF refining, continuous casting and rolling. in:

[0061] In the converter smelting process, silicon manganese, ferrosilicon, high chromium ferro, vanadium nitrogen alloy are added in sequence when the molten steel reaches 1 / 4, and the addition is completed when the molten steel reaches 3 / 4. The smelting process adopts high-strength supplementary blowing, the control end point [C] is 0.12%, [P] is 0.020%, [S] is 0.010%, and the chemical composition of molten steel in this process is controlled as follows: C: 0.24%, Si: 0.75%, Mn: 1.40%, V: 0.103%, Cr: 0.26%, N: 0.021%, P: 0.020%, S: 0.010%, Ceq: 0.55%, the rest is Fe and unavoidable impurities;

[0062] In the LF refining process: after the temperature of the ingredients is suitable, the "soft blowing" operation is carried out, and the soft blowing time is 10 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strong bend ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com