Method for increasing hardness of large high-grade gray-cast-iron diesel engine body

A high-grade, gray cast iron technology, applied in the field of casting technology, can solve the problems of lower product qualification rate, lower body quality, body cracking, etc., and achieve the effect of improving body qualification rate, improving body quality, and reducing casting stress and brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

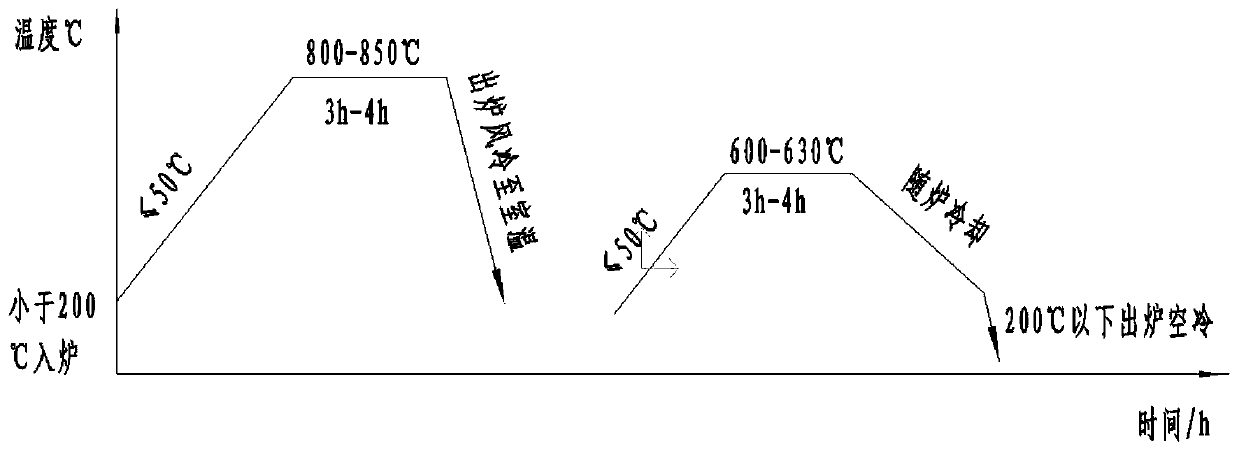

Image

Examples

Embodiment 1

[0025] Embodiment 1: The method for improving the hardness of a large-scale high-grade gray cast iron diesel engine body body includes the following steps;

[0026] Step 1: Ingredients: Determine the chemical composition of the furnace ingredients according to the principle of high carbon equivalent, high carbon and low silicon, wherein the weight percentage of each chemical component is: C: 3.0-3.5, Si: 1.5-2.5, Mn: 0.7 ~1.00, P: <0.1, S: <0.15, Sn: 0.060~0.080, the rest is Fe, and the carbon equivalent is in the range of 3.6~4.0;

[0027] Step 2: Smelting the raw materials configured in step 1, wherein, on the premise that the total amount of Si is guaranteed to be constant, add Si in two times. Volume reduced by 0.5%;

[0028] Step 3: Inoculation treatment: adopt the inoculation method of pouring into the front of the furnace, and add an inoculant during the process of pouring the molten iron into the ladle for inoculation treatment. The inoculant used in the front of the ...

Embodiment 2

[0039] Embodiment 2: This embodiment is based on Embodiment 1. In the above step six, for the large-scale high-grade gray cast iron diesel engine body, the air-cooled fan is used for cooling, and the specific fan uses two power 2.2 KW、18700m 3 An axial-flow fan with an air volume per hour and a speed of 1440 rpm. The fan can be placed in a position that can cover the body and ensure that the air around the body is unobstructed, simplifying the structure of the air-cooling process.

[0040] In the present invention, the machine body first obtains a certain range of body hardness in the cast state, and then obtains a higher body hardness in the normalizing state, thereby ensuring that the body of a large-scale high-grade gray cast iron diesel engine can meet the hardness requirements and avoid gray cast iron. Airframe heat treatment cracking risk and other quality issues, improve the quality of the body, improve the pass rate of the body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com