Riser-free gating system for upper flanges used for compressor and production technique of upper flanges

A riser pouring and compressor technology, which is applied in the field of casting processing, can solve the problems of not meeting the high quality and high performance of products, moving the hot node of castings outward, and unsatisfactory feeding effect, so as to improve the CE value and reduce the liquidus line. Temperature, the effect of increasing the expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

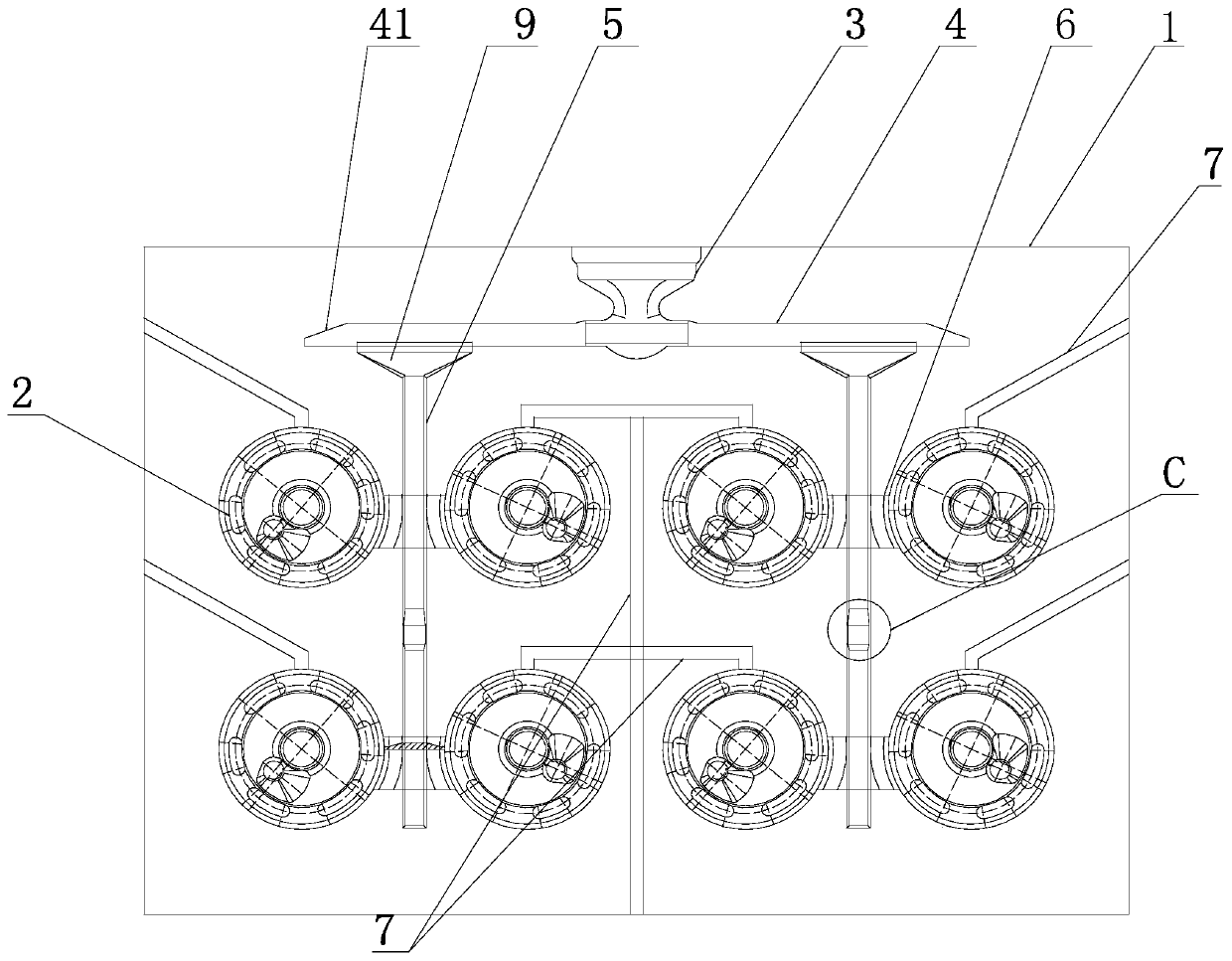

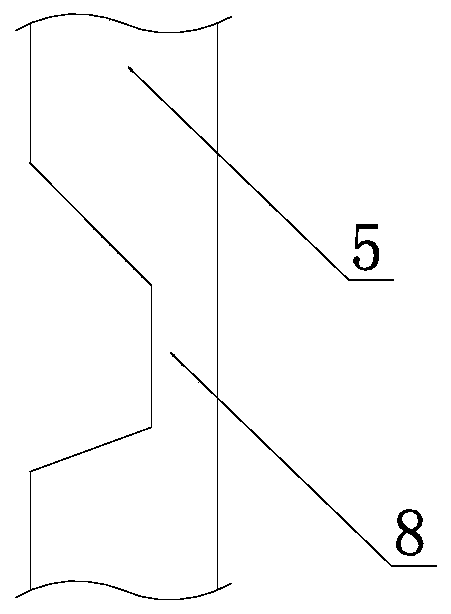

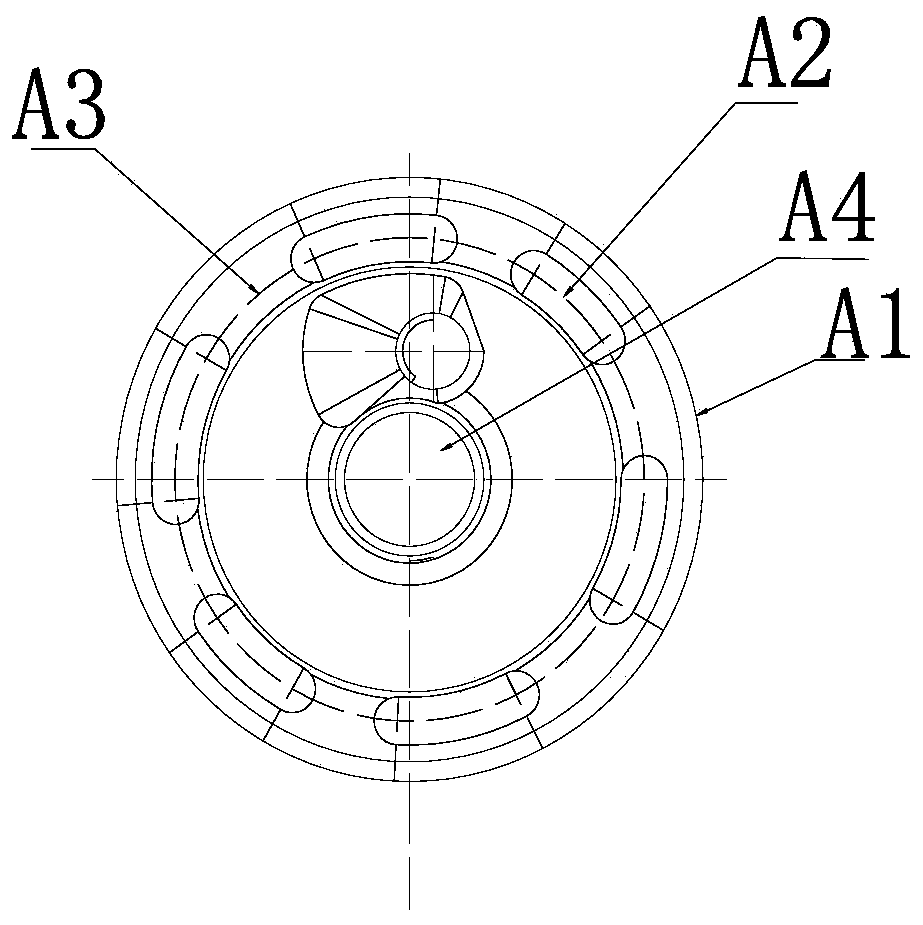

[0038] see Figure 1~5 , a riser-free casting system for the upper flange of a compressor, comprising a sand mold 1, the sand mold 1 is provided with a plurality of cavities 2 matching the shape of the upper flange A, and the sand mold 1 is provided with The sprue cup 3, the runner 4, the vertical sprue 5, and the ingate 6 connected in sequence, the ingate 6 communicates with the cavity 2; the ingate 6 is a wedge-shaped sheet structure, for details, please refer to Figure 5 , Figure 5 is a section along the direction of liquid flow; the cavity 2 is connected with an exhaust bar 7; the vertical sprue 5 is provided with a decompression groove 8; The spoke grooves corresponding to the spokes A3; at least one spoke groove is directly opposite to the ingate 6; the decompression groove 8 is located between the two rows of cavities 2 arranged up and down.

[0039]In this embodiment, the ingate 6 is a wedge-shaped sheet structure, so that the molten iron flows into the casting cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com