Vacuum gel casting device

A gel injection molding and vacuum technology, applied in the direction of supply devices, auxiliary molding equipment, ceramic molding machines, etc., can solve the problems of high requirements for the workshop, large space occupation, and difficult removal of air bubbles, so as to improve the efficiency of grouting, The effect of high slurry efficiency and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

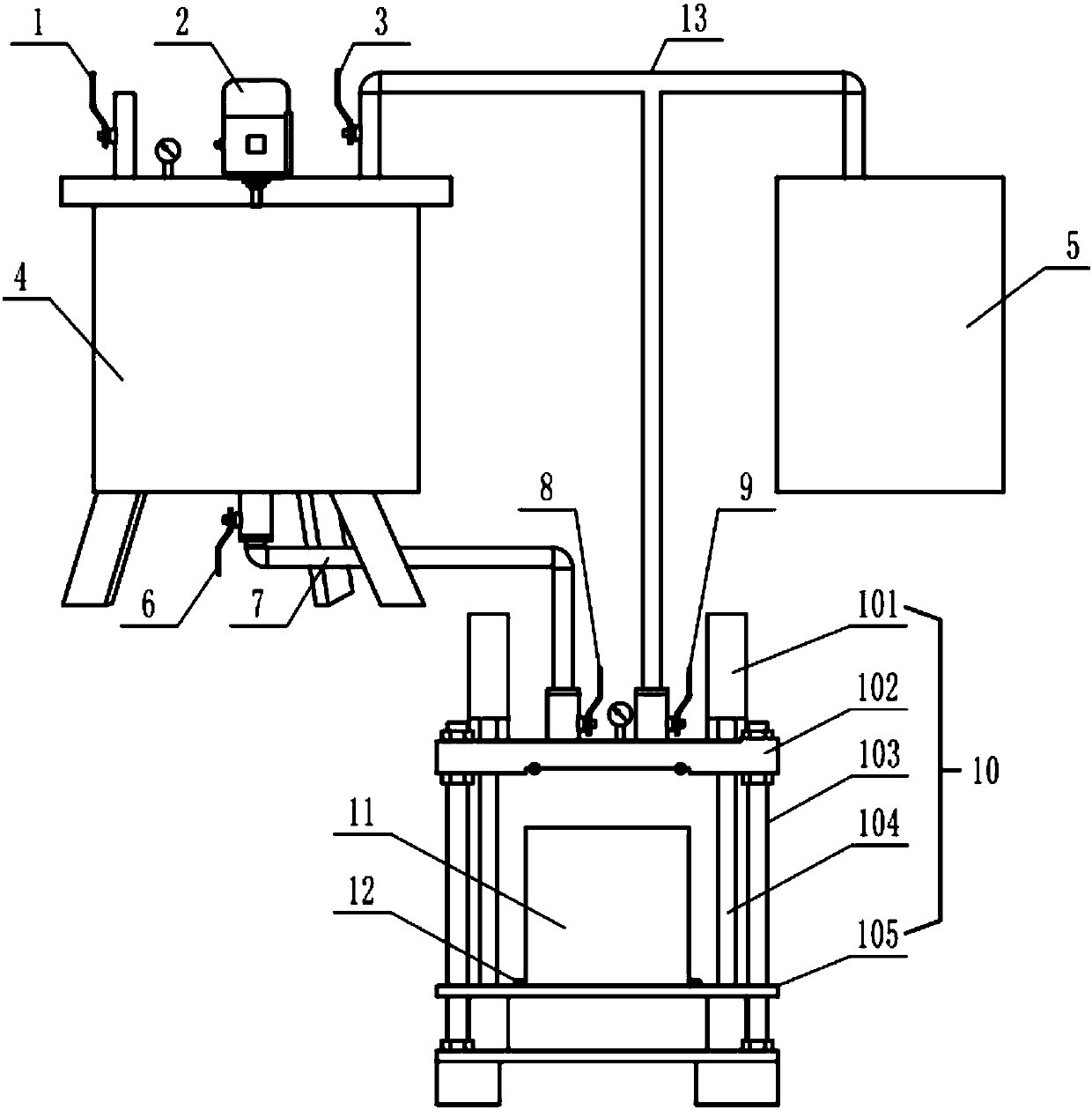

[0027] figure 1 It is a structural schematic diagram of the vacuum gel injection molding device of the first embodiment of the present invention. The vacuum gel injection molding device includes a vacuum mixing tank 4 and a vacuum pump 5, the top of the vacuum mixing tank 4 is provided with a stirring motor 2, and the injection molding device also includes an injection molding tank 10, and the injection molding tank 10 includes a tank body 103 , the inside of the tank body 103 is provided with a lifting platform 105, and the lifting platform 105 is provided with a positioning block 12, which is used to limit the position of the grouting mold 11, so that it is aligned with the corresponding position of the end cover 102; the top of the tank body 103 is provided with an end cover 102, the upper part of the end cover 102 is provided with a lifting cylinder 101, the lifting cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com