Patents

Literature

31results about How to "Improve injection molding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED (Light Emitting Diode) integrated structure, manufacturing method, lamp, display screen, backlight device, projecting device and injection mould of forming plastic part

InactiveCN101963295AReduce distanceRealize high-definition image displayPlanar light sourcesPoint-like light sourceLuminous fluxLight-emitting diode

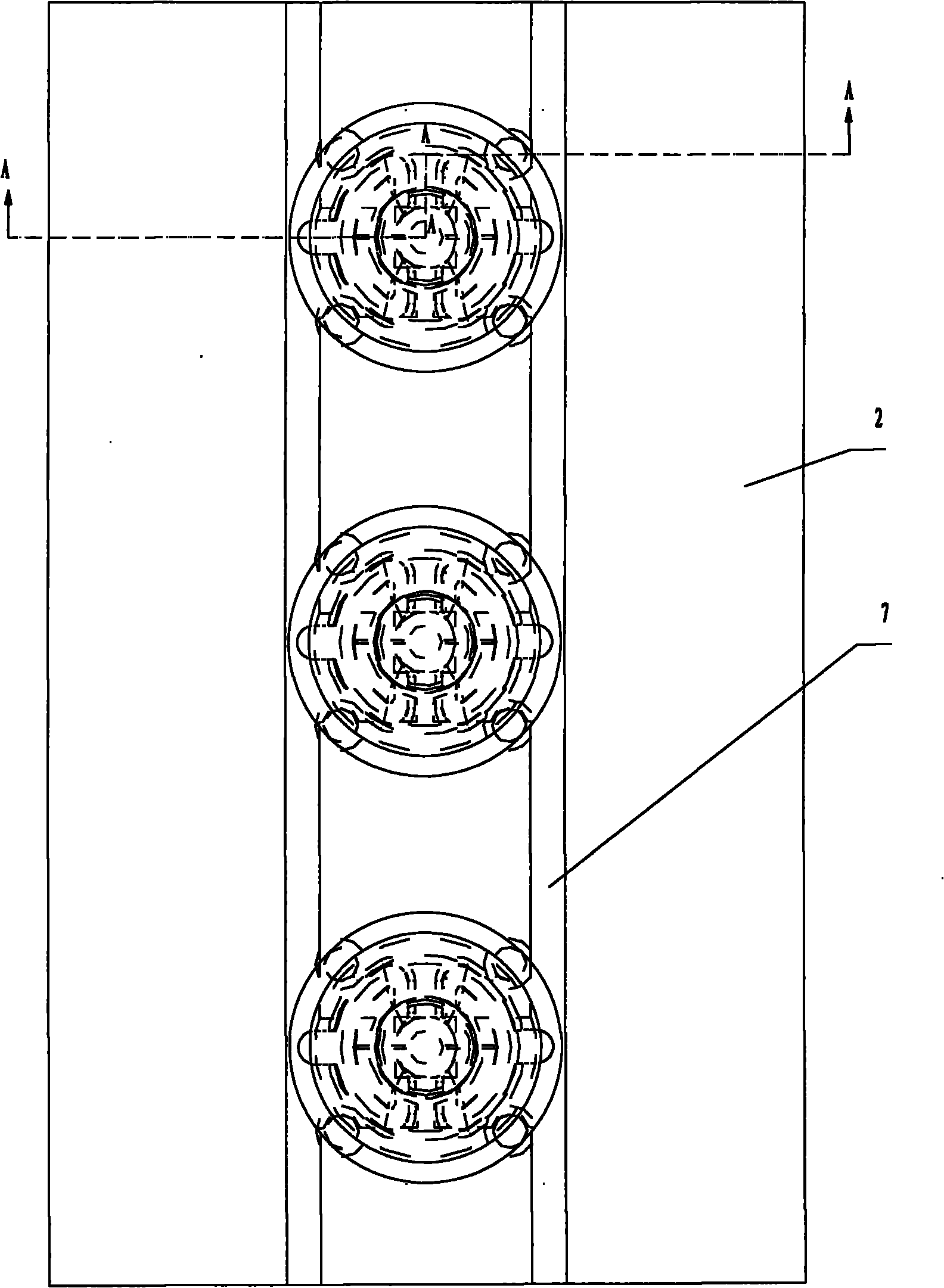

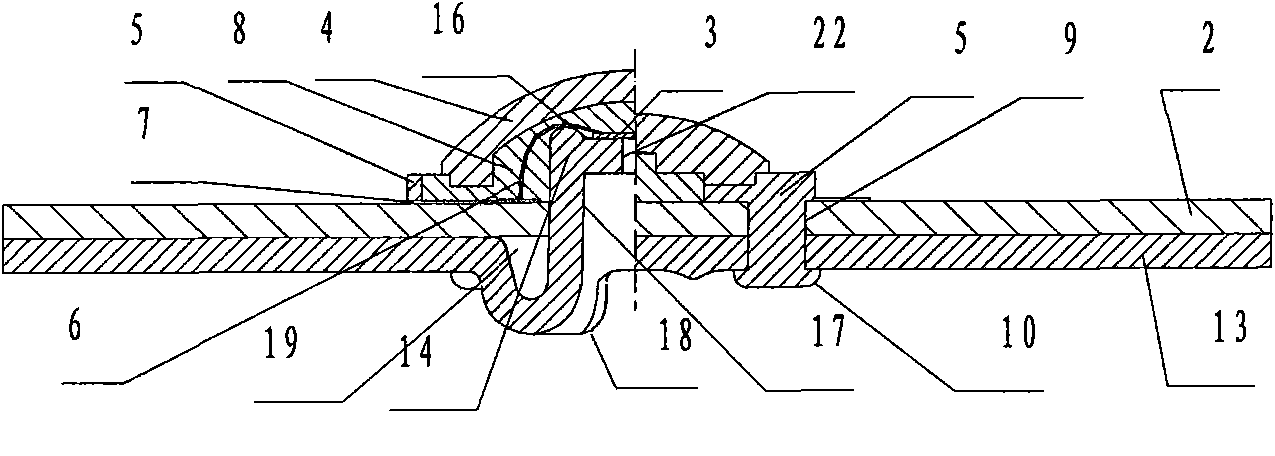

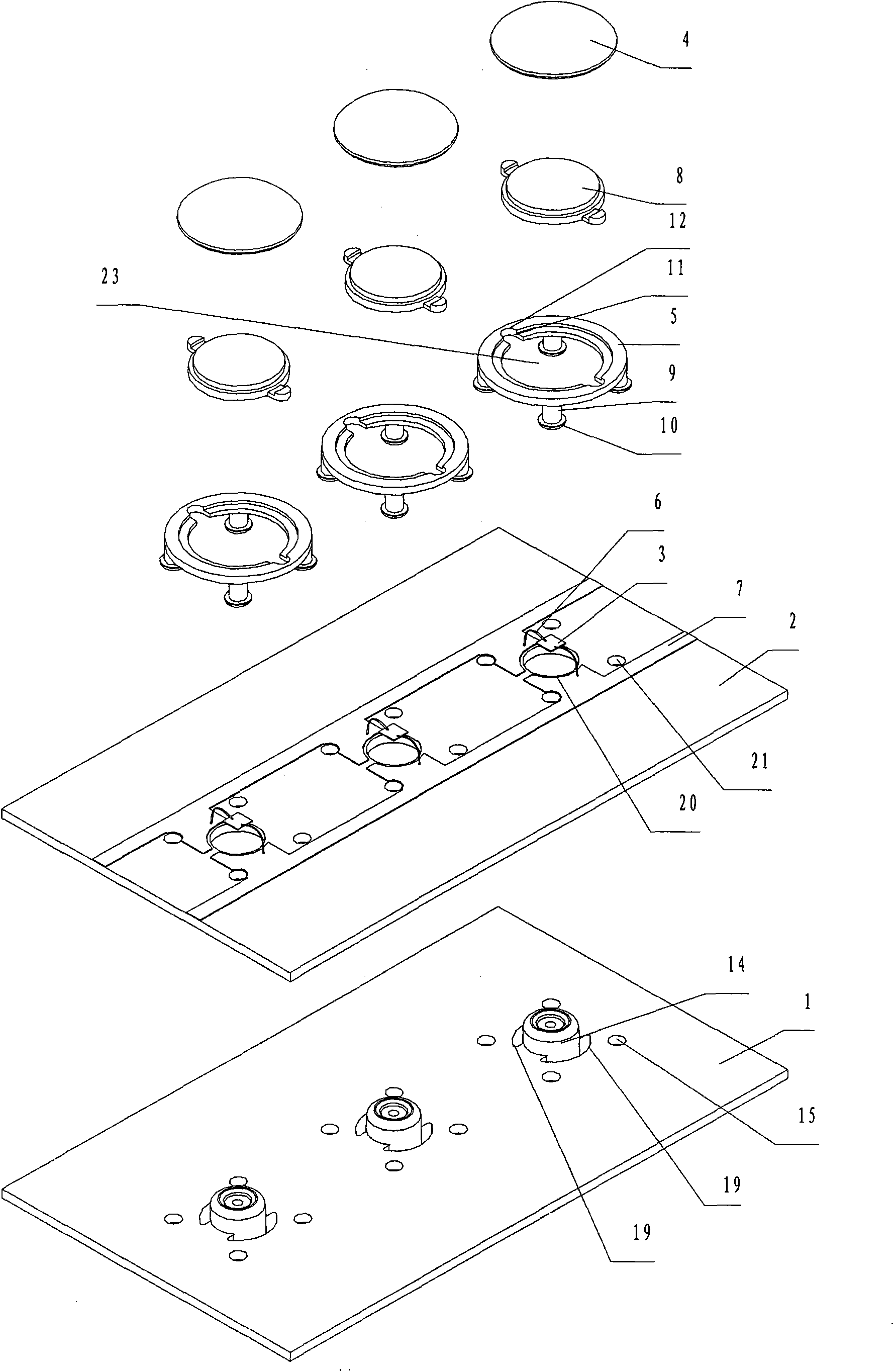

The invention relates to an LED (Light Emitting Diode) integrated structure comprising a radiating base plate, an LED chip, a lens, a plastic piece of a positioning lens or a forming lens, a conducting wire and a layout circuit conducting layer, wherein two or more than two chip fixing lug bosses which are integrally formed with the radiating base plate are arranged on the radiating base plate, a first through hole of the positioning lens or the forming lens is arranged on the plastic piece of the positioning lens or the forming lens, the chip fixing lug bosses are arranged in the first through hole, the layout circuit conducting layer is extended between the inside wall of the first through hole and the outside walls of the chip fixing lug bosses, one end of the conducting wire is electrically connected with the LED chip, and the other end of the conducting wire is electrically connected with the layout circuit conducting layer which is extended between the inside wall of the first through hole and the outside walls of the chip fixing lug bosses. The LED integrated structure has the advantages of low thermal resistance of an intermediate link, good heat radiating performance, accurate position relation of the lens and the chip, high luminous flux, simple structure, simple assembly, good radiating effect and good optical effect.

Owner:杨东佐

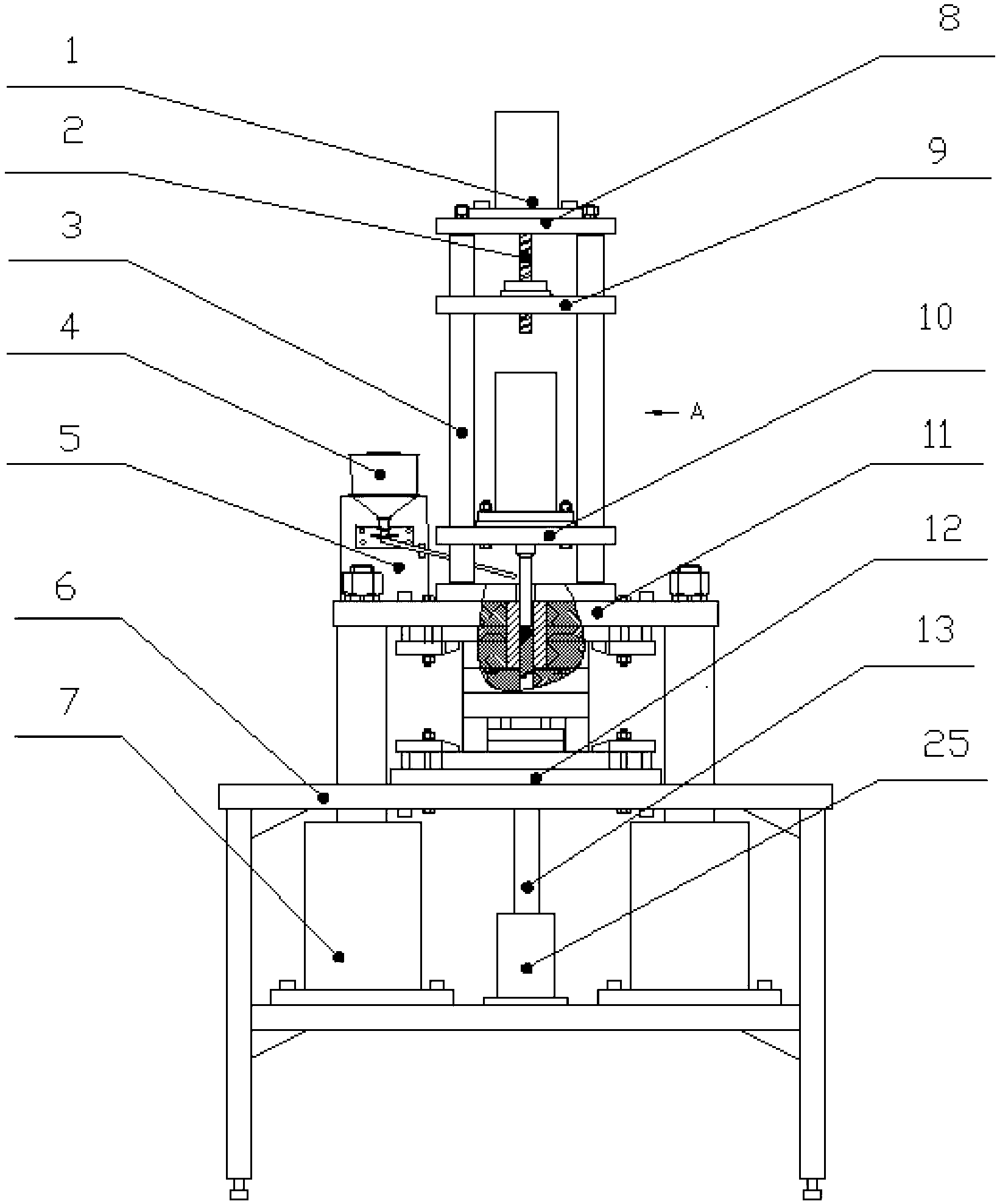

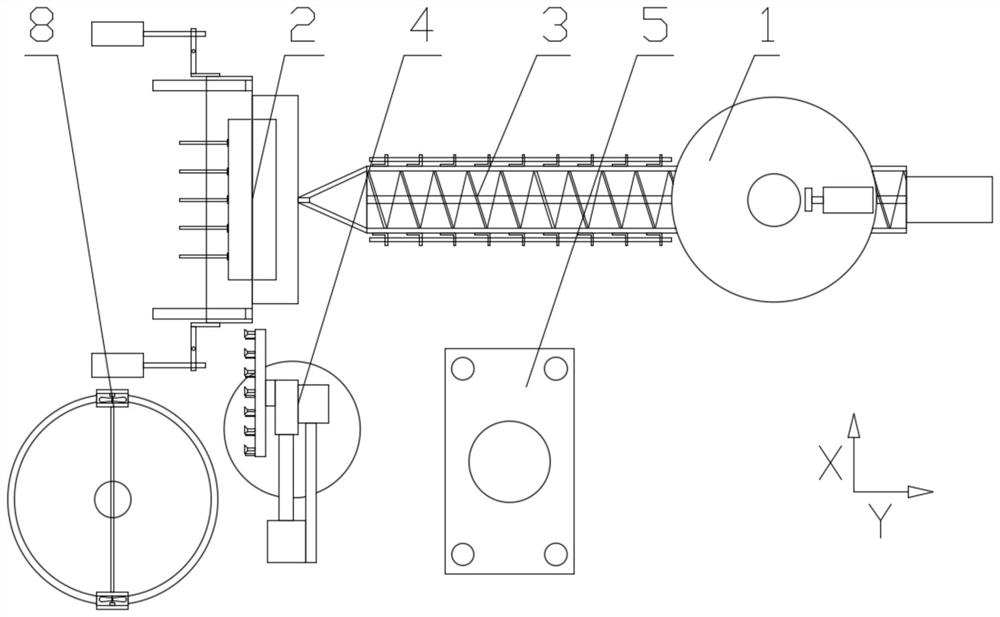

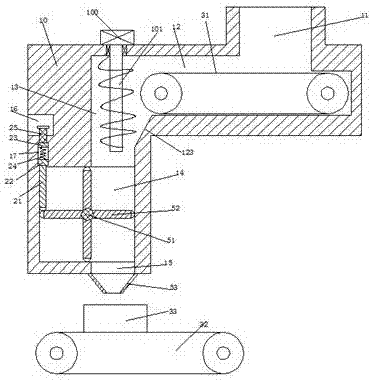

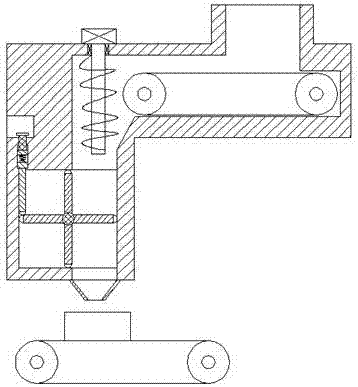

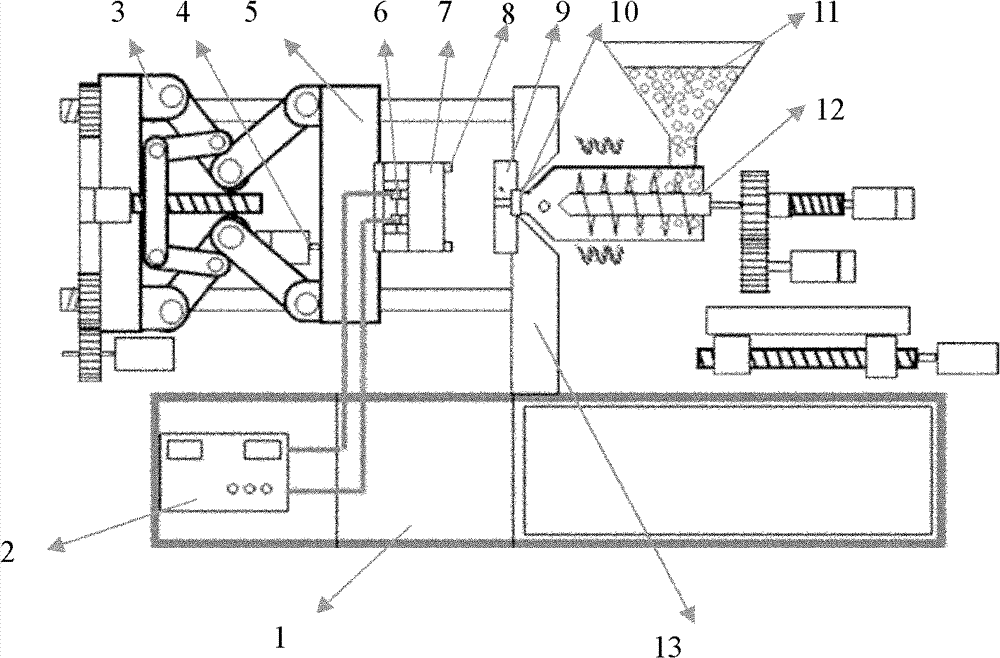

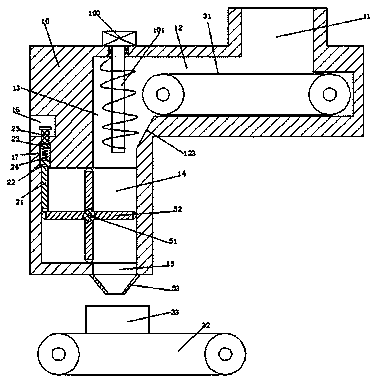

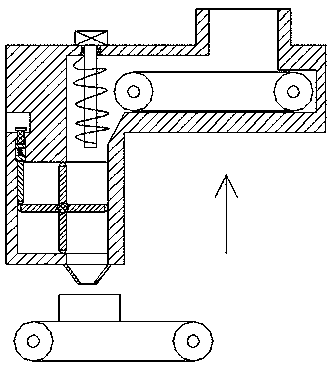

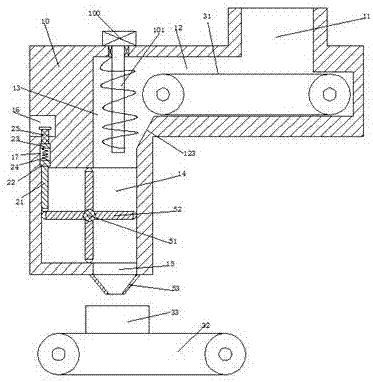

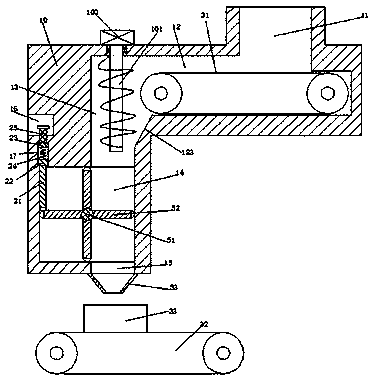

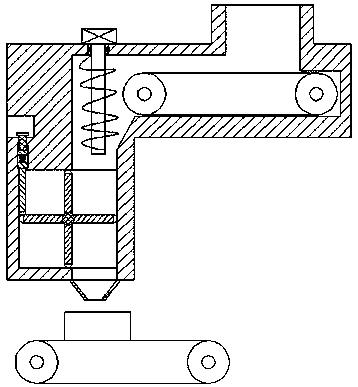

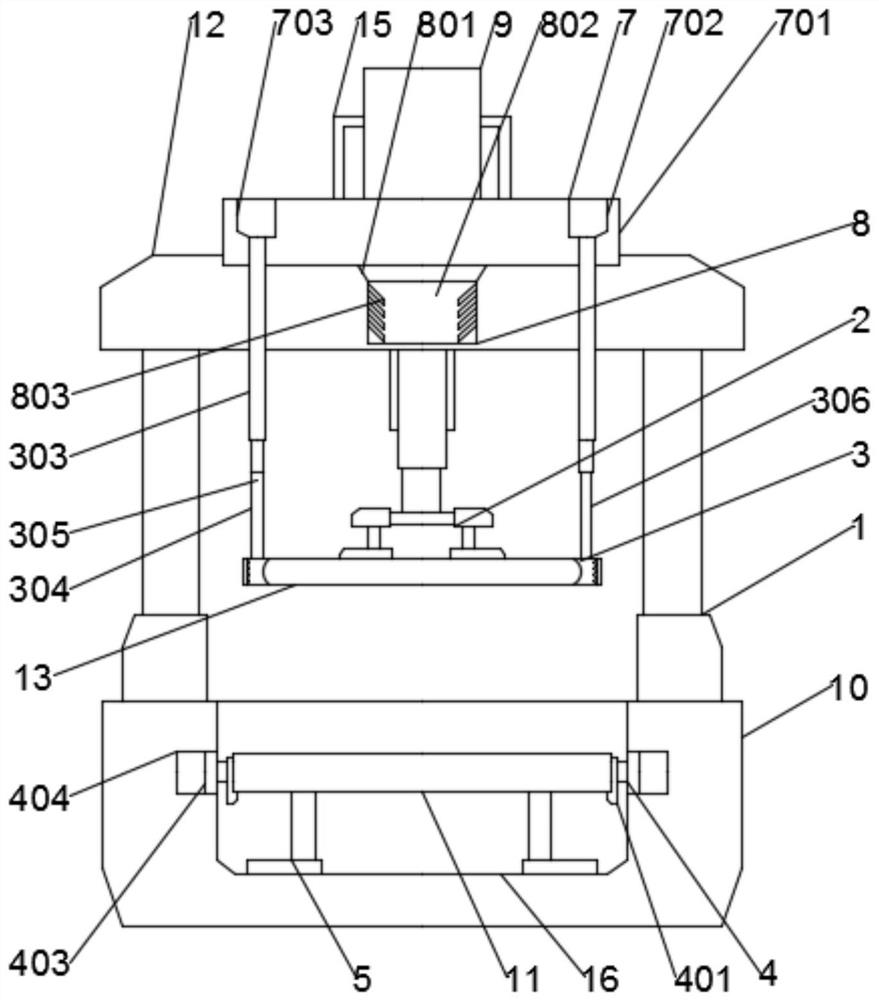

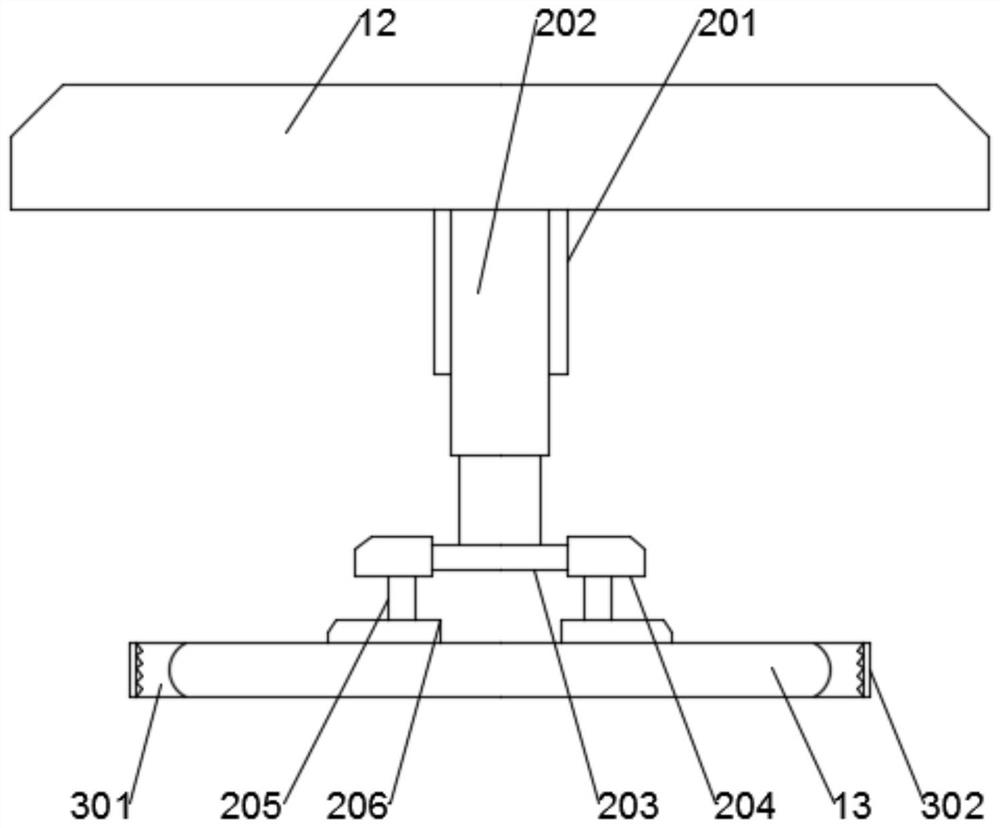

Screw-free ultrasonic microinjection molding device for molten and plasticized polymer and molding method

The invention discloses a screw-free ultrasonic microinjection molding device for a molten and plasticized polymer and a molding method. An injection part comprises an injection motor, a lead screw, an injection push plate and a connecting rod; an ultrasonic vibration system comprises an ultrasonic generator, an energy converter, an amplitude-change pole and a tool head; an injection module is provided with a plasticizing hole, a sub-runner and a mould cavity; a feeding system comprises a hopper and a support; and a mould closing and ejecting system comprises a mould closing hydraulic cylinder, an ejecting hydraulic cylinder, an upper mould fixing plate, a lower mould fixing plate and an ejector rod. A solid polymer is molten into a liquid under the action of frication thermogenesis and viscoelasticity thermogenesis applied into the polymer particle process through ultrasonic vibration, and meanwhile, ultrasonic waves play a cavitation role in the polymer liquid, so that the apparent viscosity is reduced, the phenomenon of short shot or insufficient filling in the machining process is overcome, the injection molding of a small plastic device can be well realized, the energy consumption is reduced, the difficulty in controlling the process is lowered, the economic efficiency of the device is increased, and the production cost is reduced.

Owner:CENT SOUTH UNIV

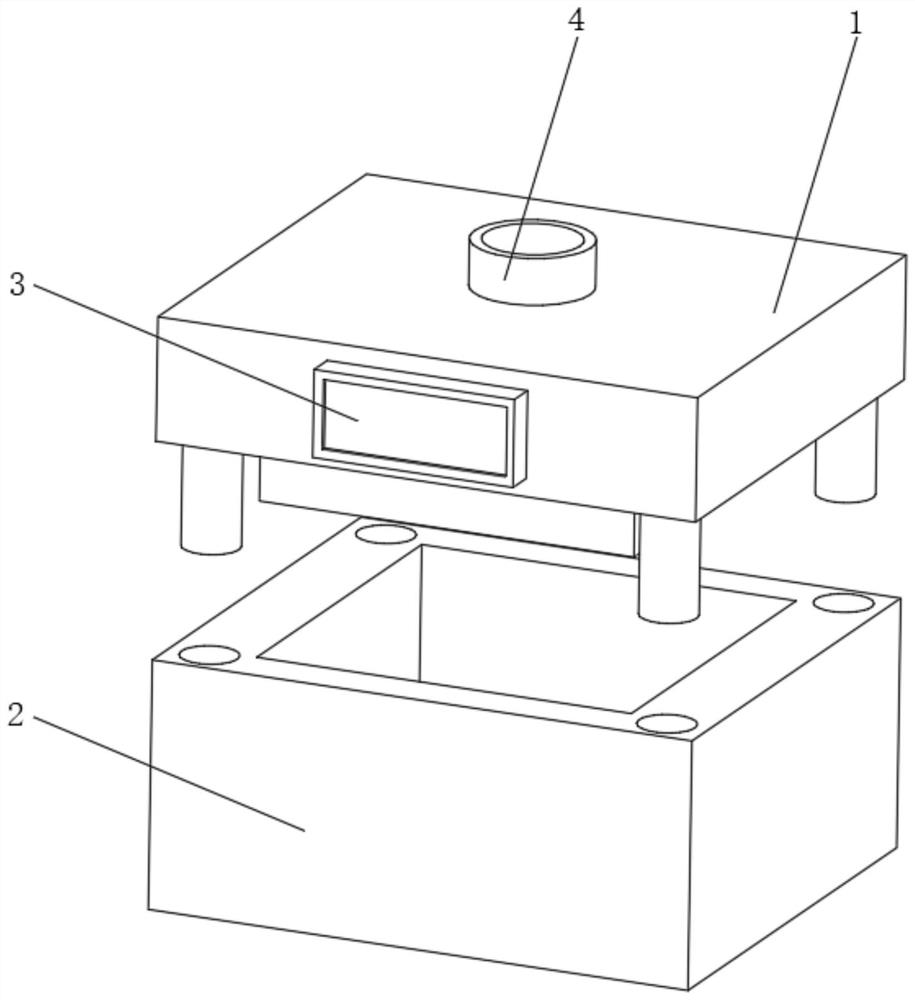

Injection mould for studying tool box stationery series

The invention discloses an injection mould for studying tool box stationery series, and particularly relates to the technical field of moulds. The injection mould for the studying tool box stationeryseries comprises a lower mould seat. An upper mould seat is arranged at the top of the lower mould seat, a first groove is formed in the top end of the lower mould seat, a clamping groove is formed inthe middle of the first groove, an injection mould plate is movably connected into the clamping groove, and a first clamping block is movably connected between the inner wall of the first groove andthe injection mould plate. According to the injection mould for the studying tool box stationery series, the clamping groove is connected with the injection mould plate in a clamped mode, the injection mould plate is fixed through the first clamping block, the mould plate is conveniently replaced, the mould manufacturing cost is lowered, the motor rotates and is connected with a connecting threaded rod in a transmission mode through a conveyor belt, thus two moving sleeves move oppositely, a pulling rod slides in a sliding sleeve, the upper mould seat is pulled to slide on the outer side of the sliding rod, the lower mould seat and the upper mould seat conveniently work in a corresponding mode, the production efficiency is improved, a raised block is matched with a second groove, a limiting pin and a limiting hole are matched, the raised block, the second groove, the limiting pin and the limiting hole are matched with a buffering cushion to reduce vibration, the upper mould seat is stabilized advantageously, mould crushing is avoided, and the injection quality is improved.

Owner:福建省靖虹模具科技有限公司

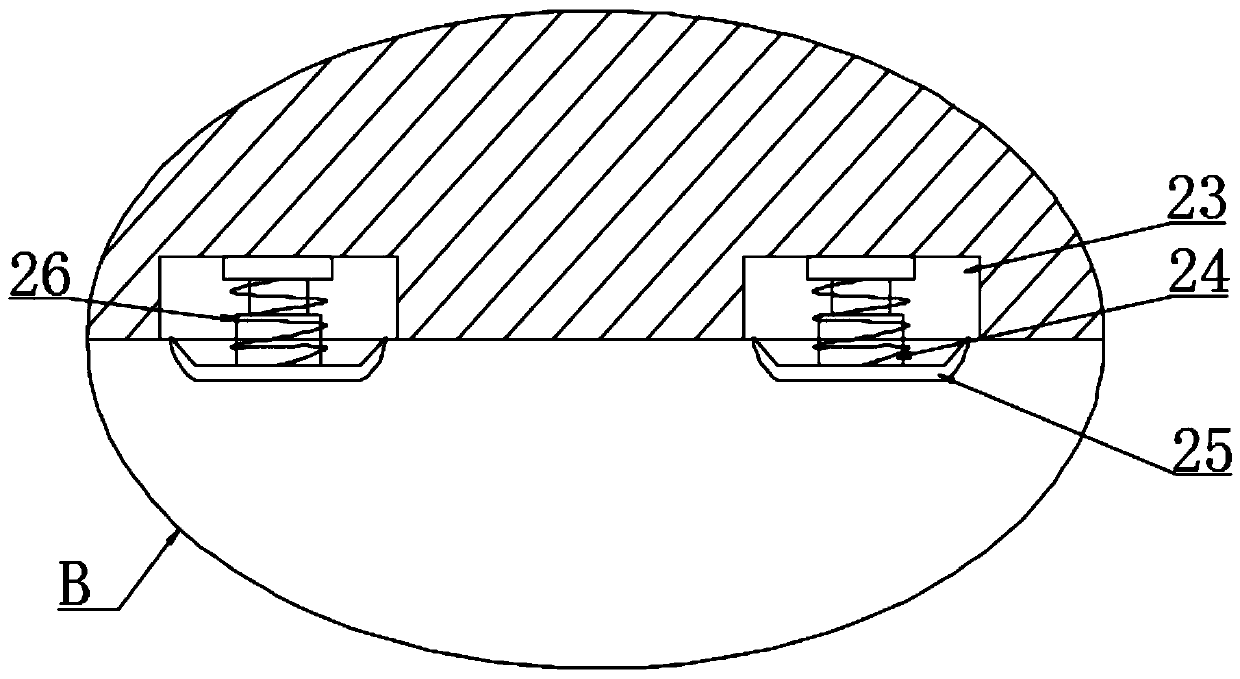

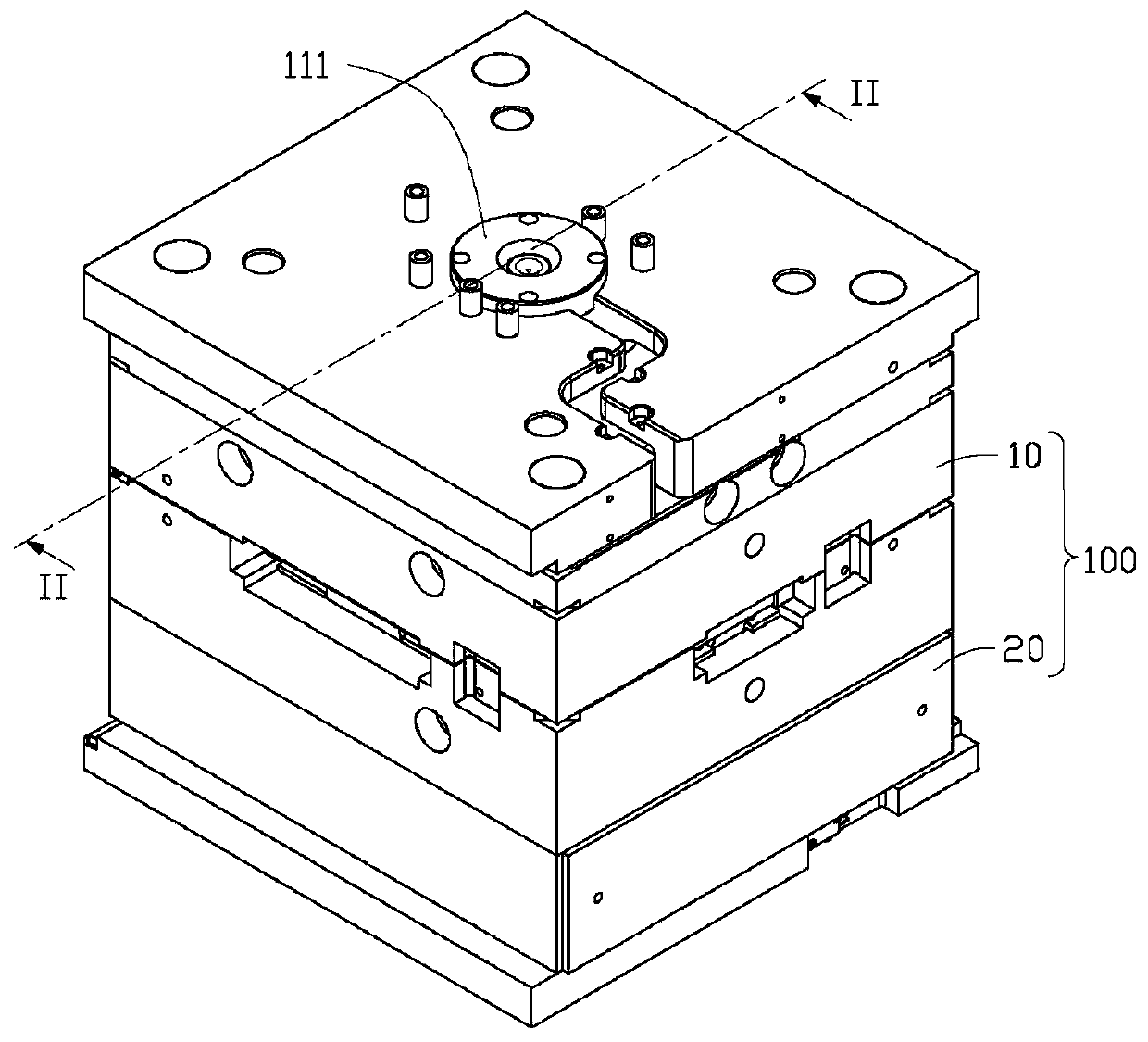

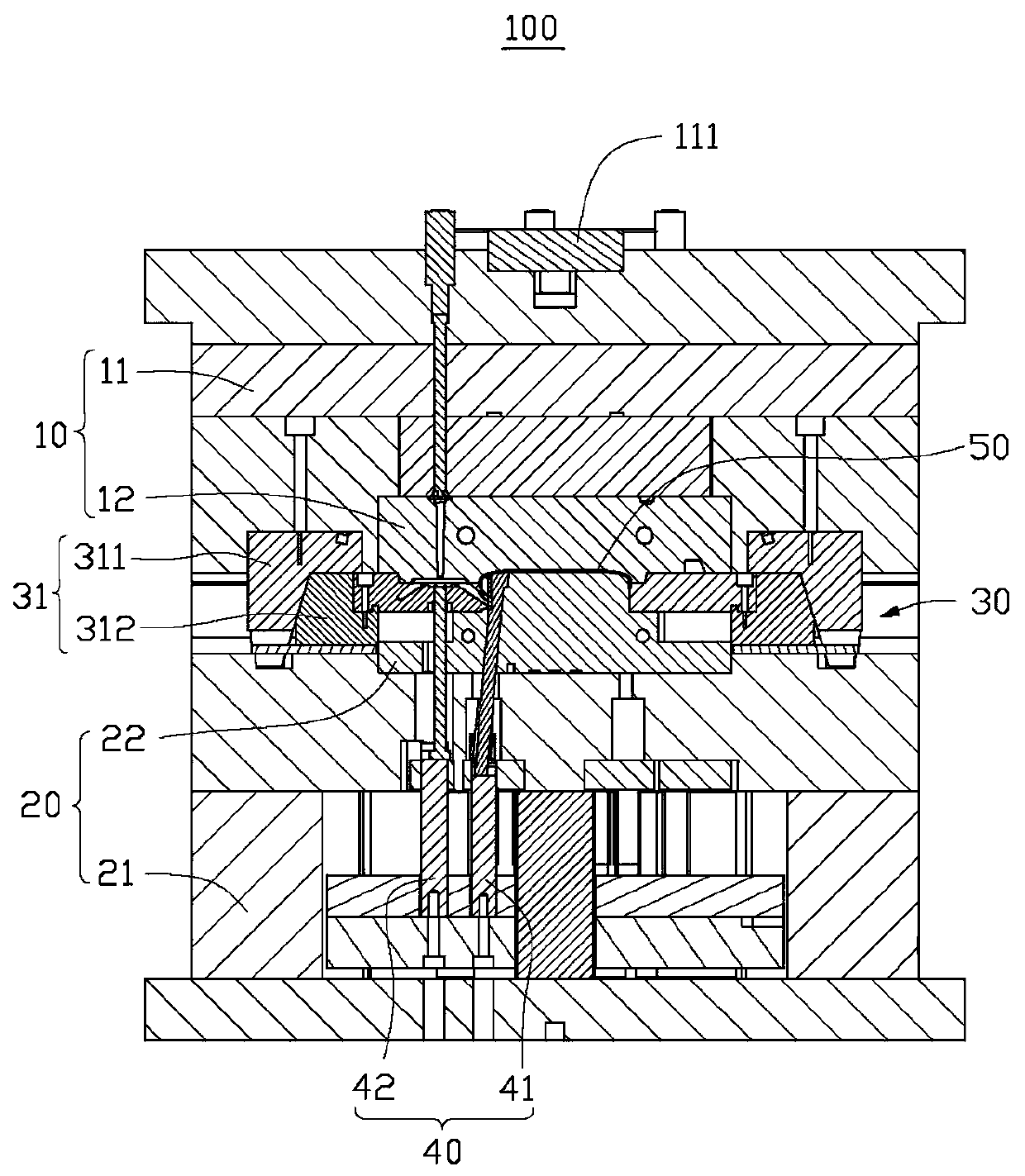

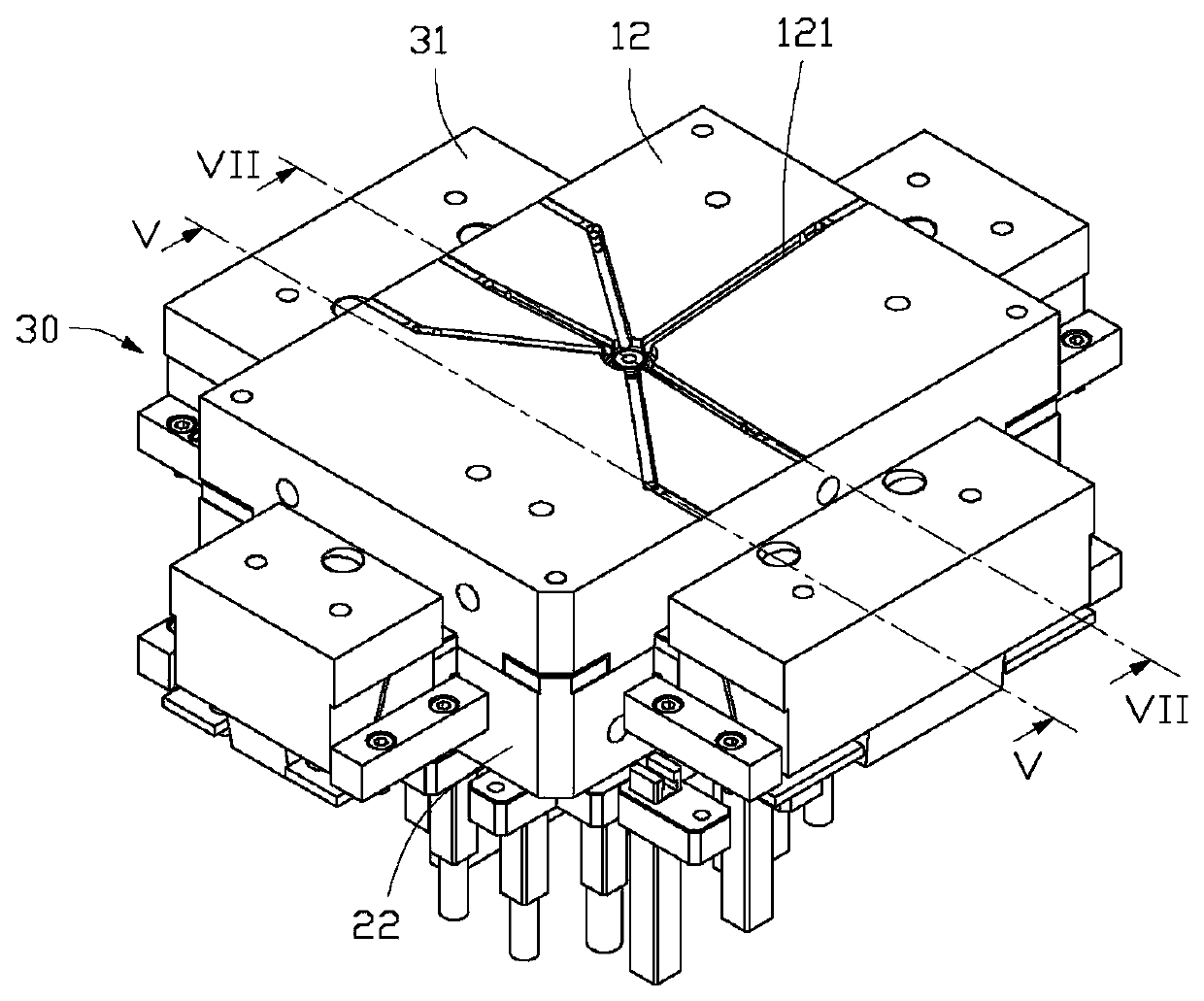

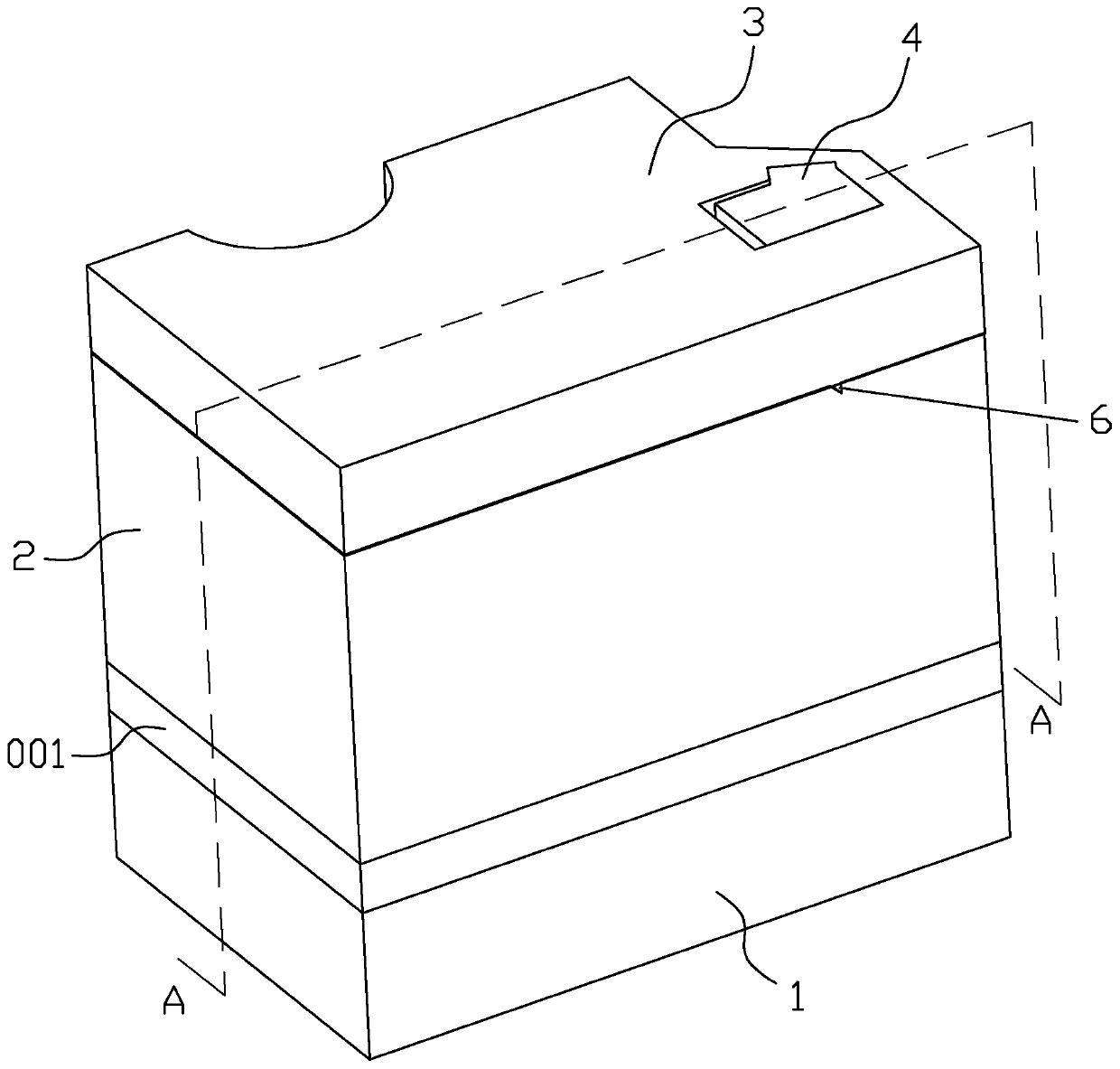

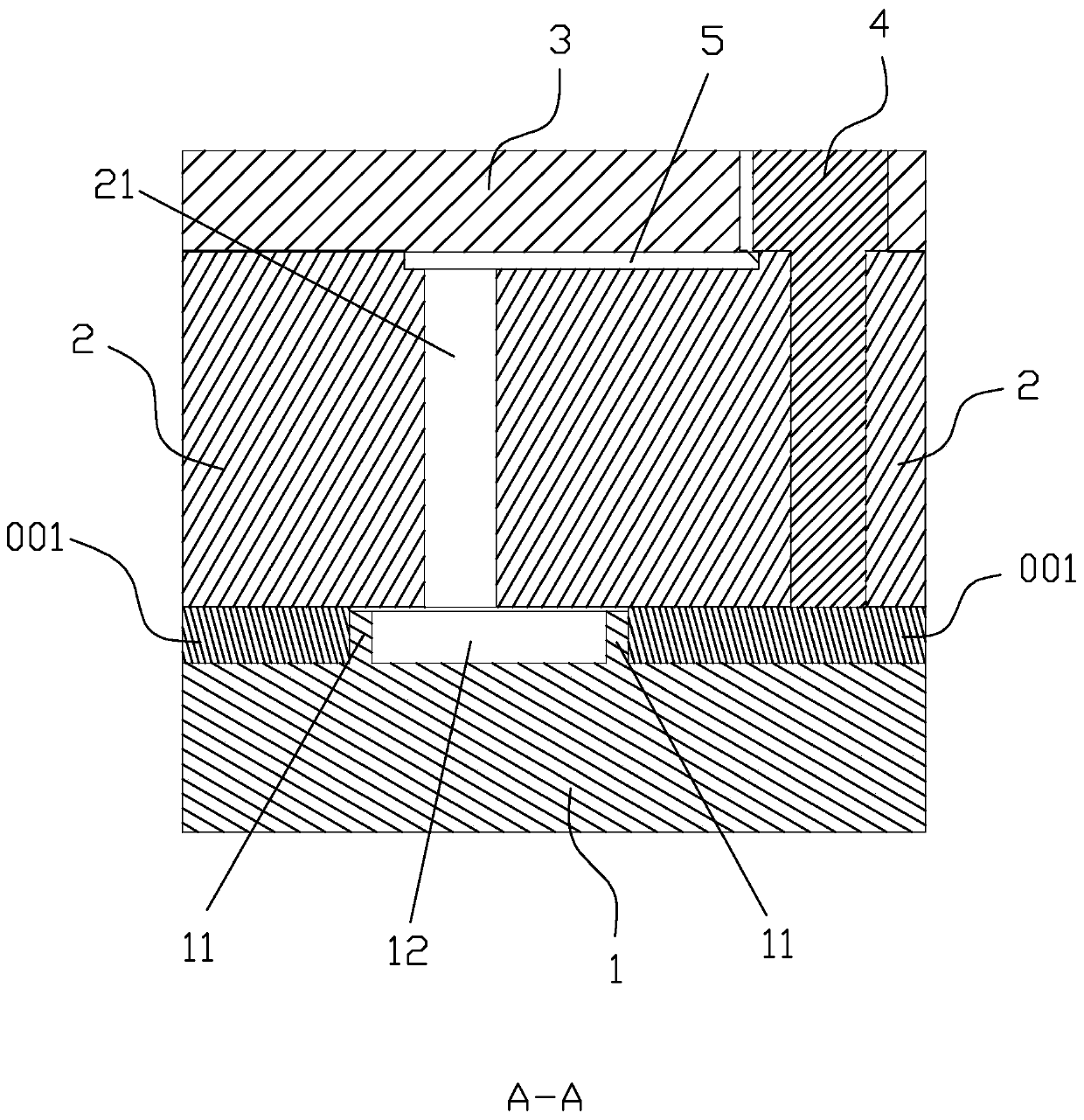

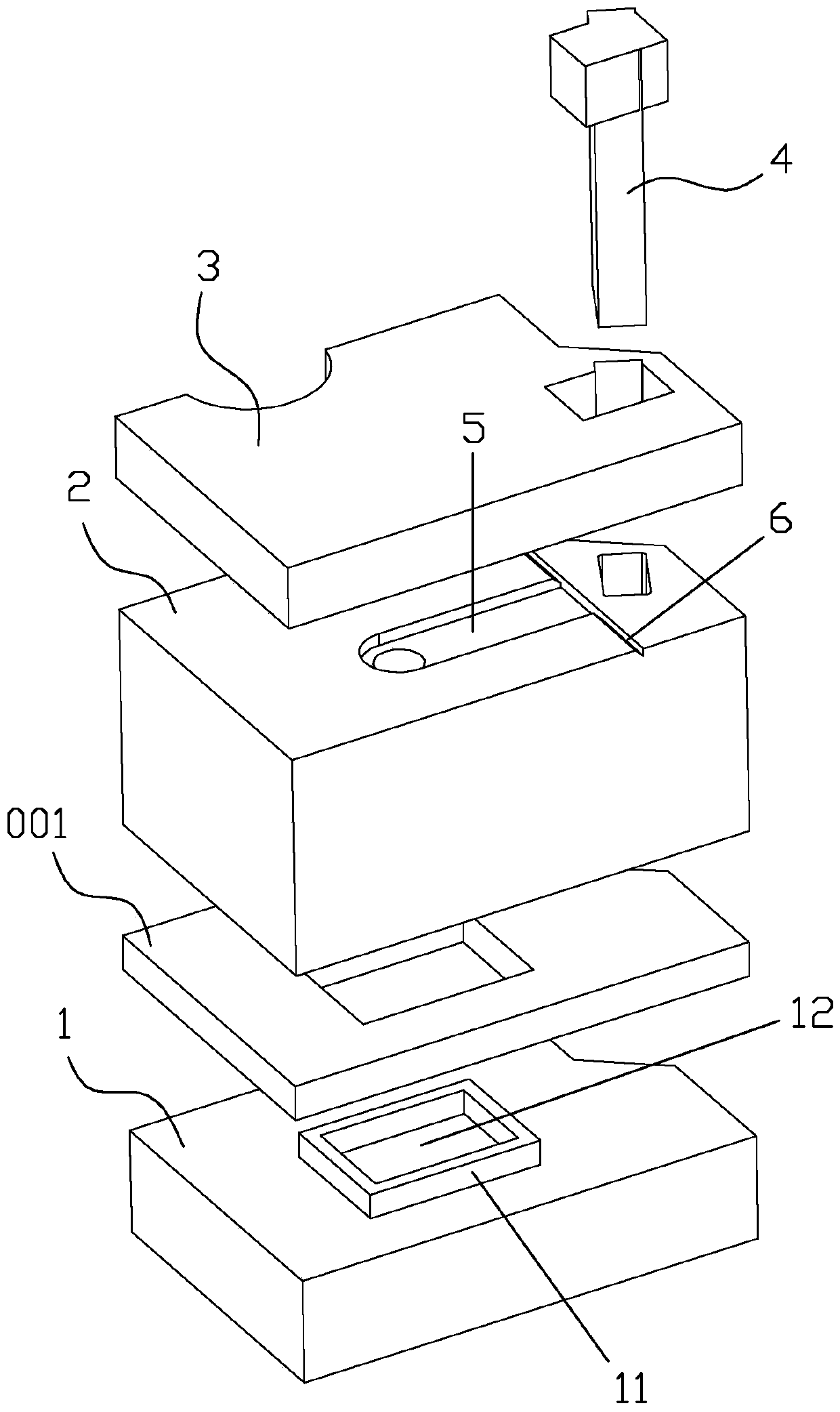

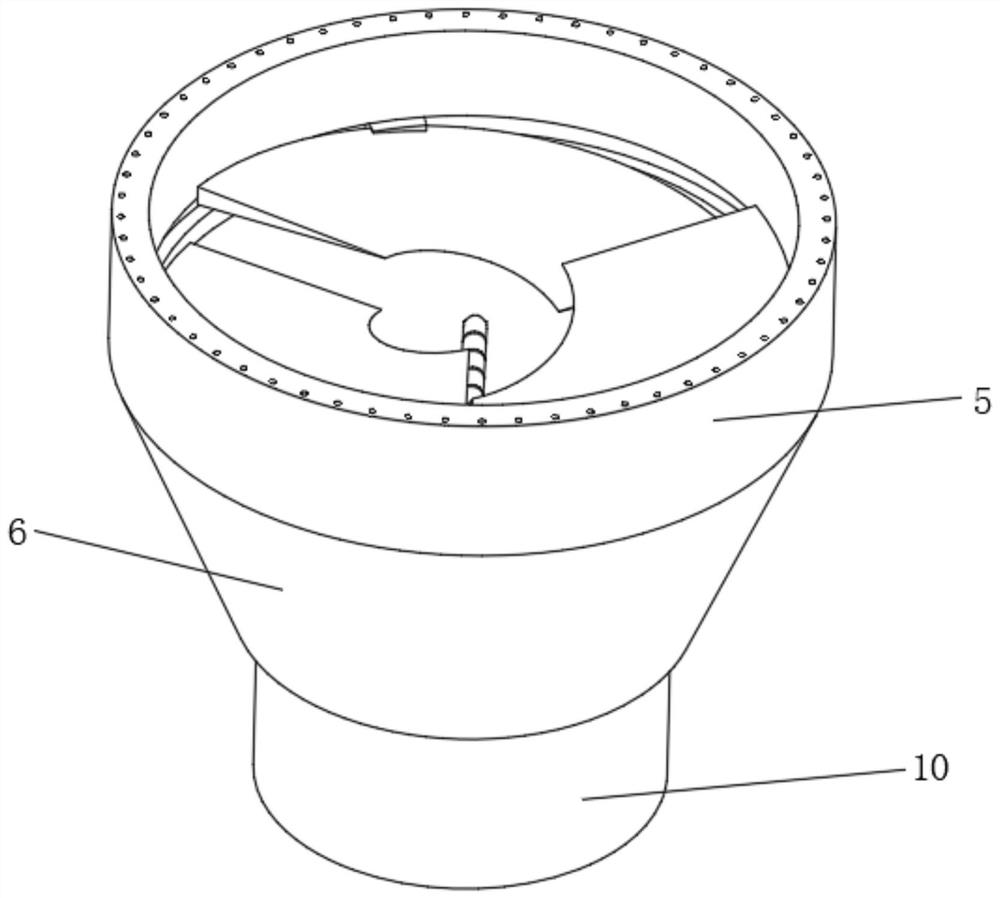

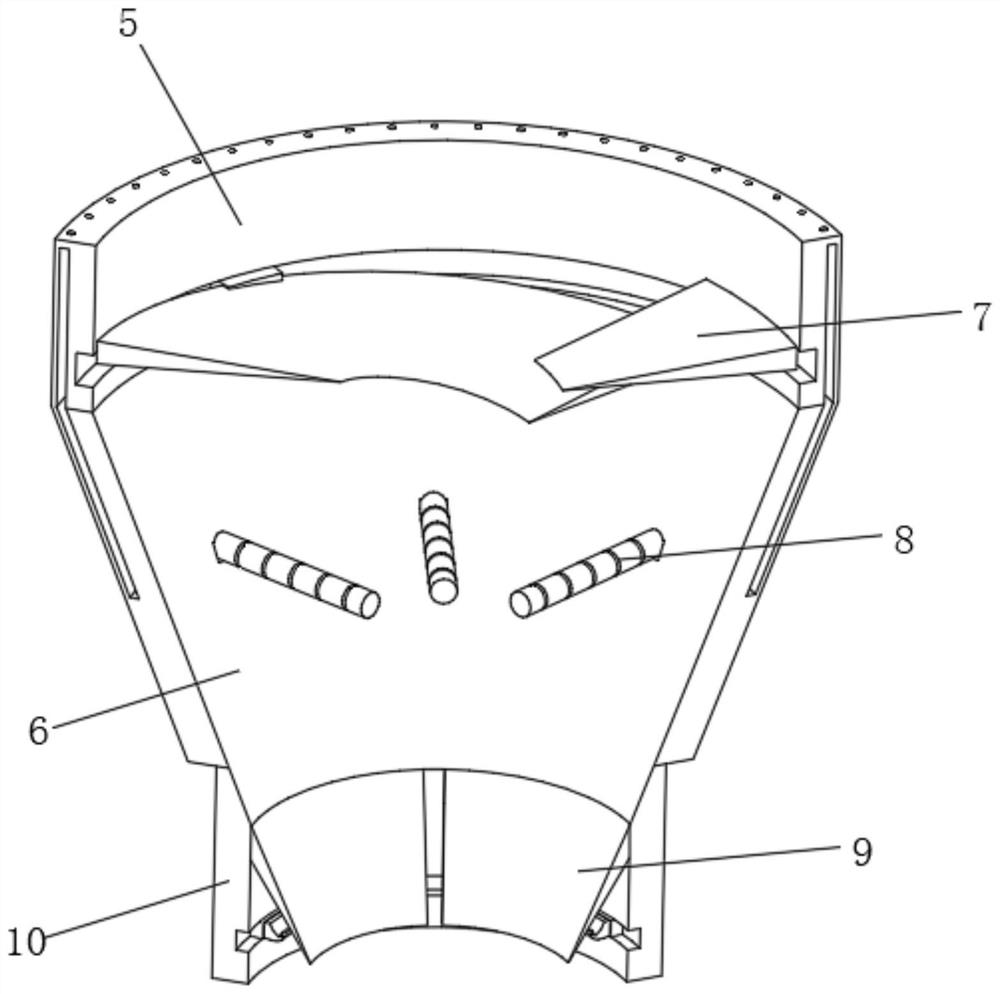

injection mold

InactiveCN106273257BImprove injection molding qualityImprove yieldInjection mouldingMaterials science

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

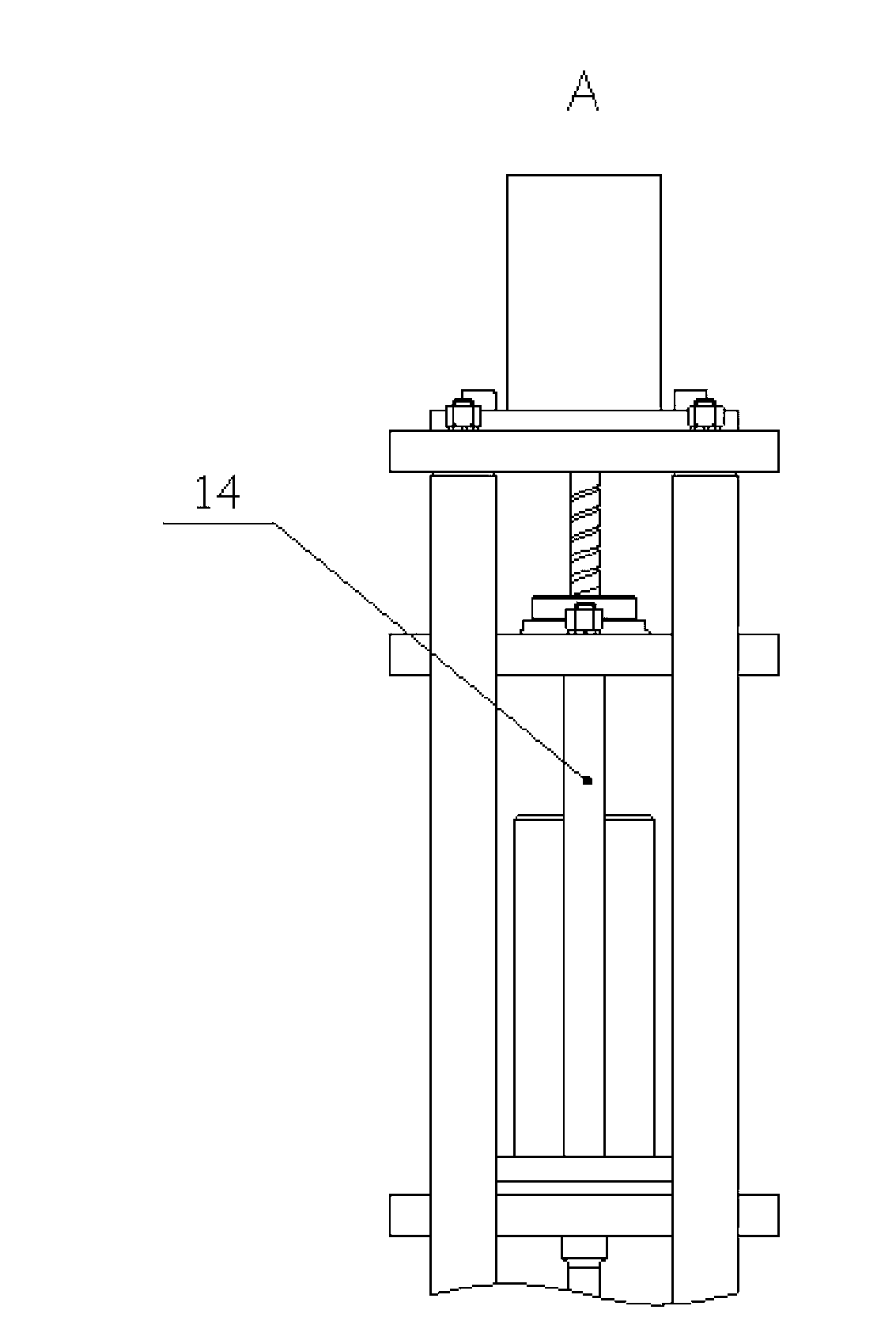

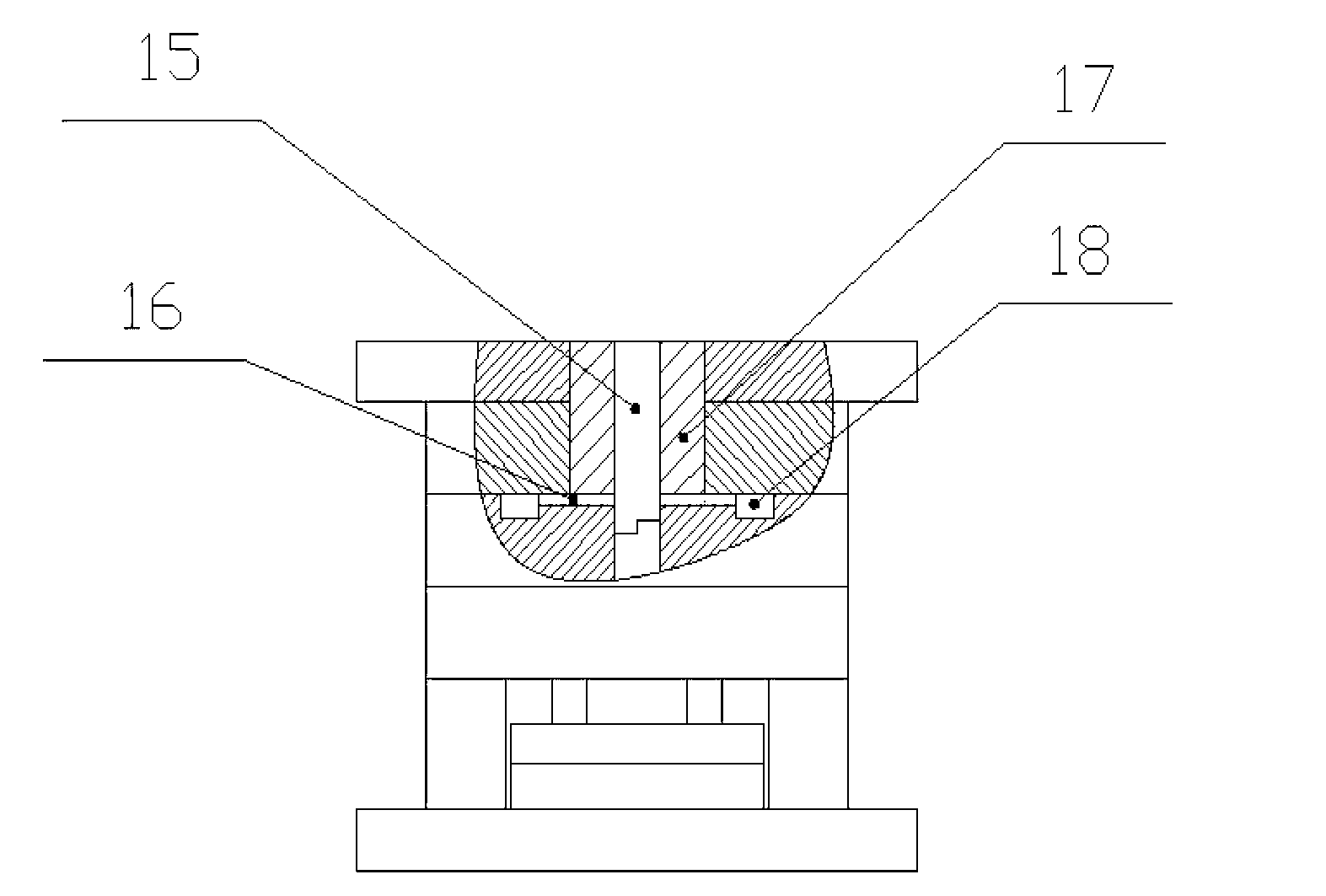

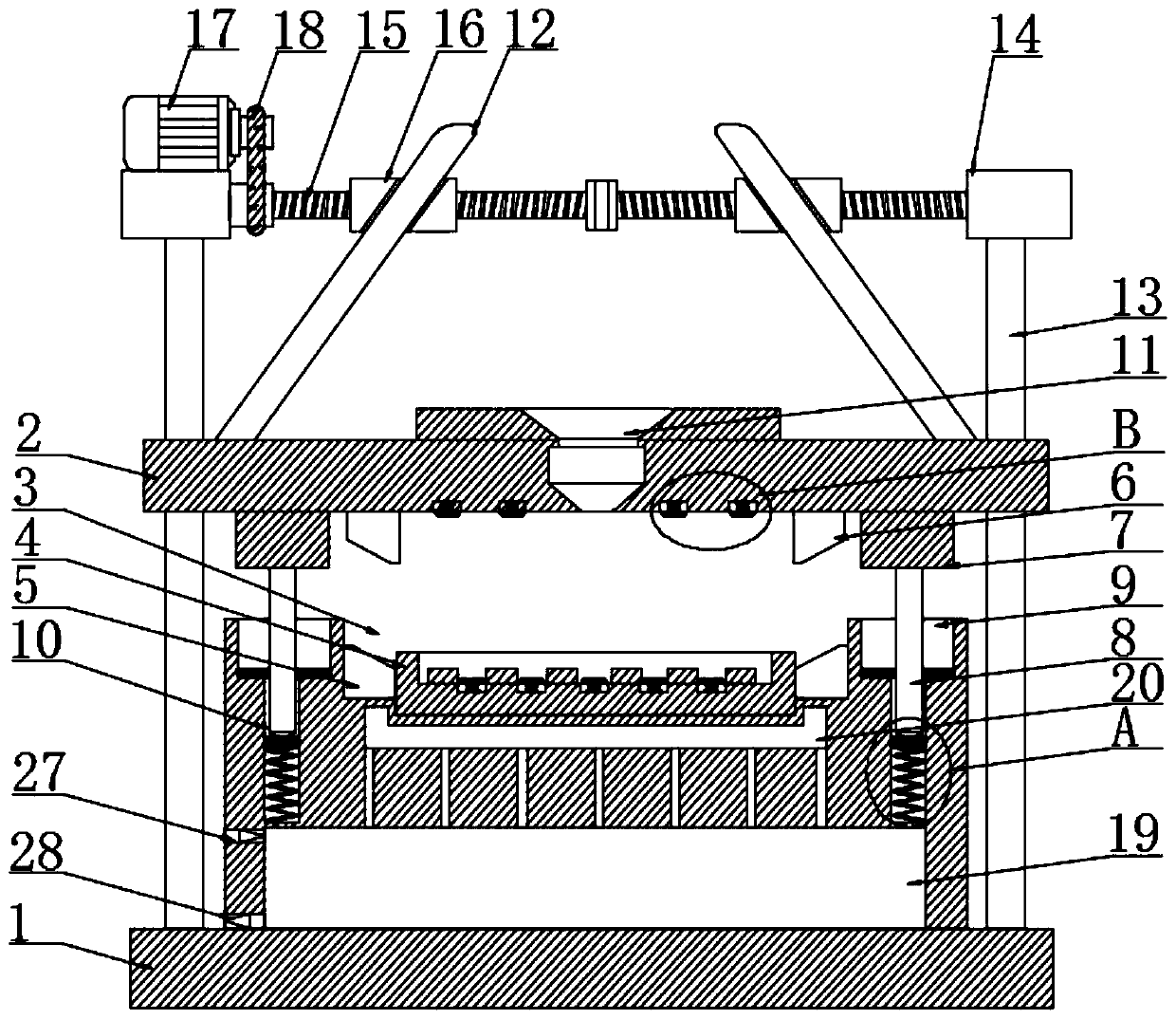

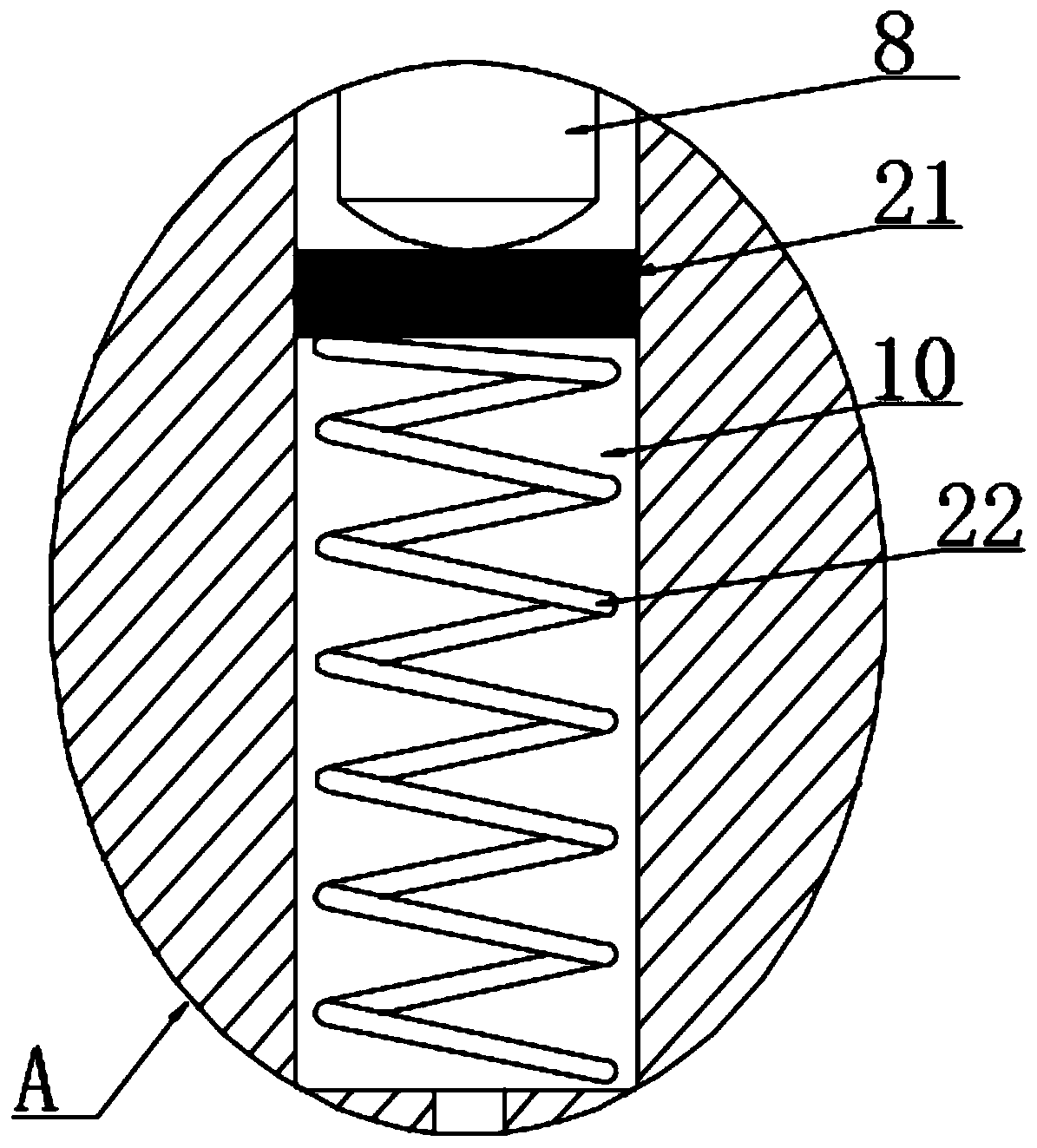

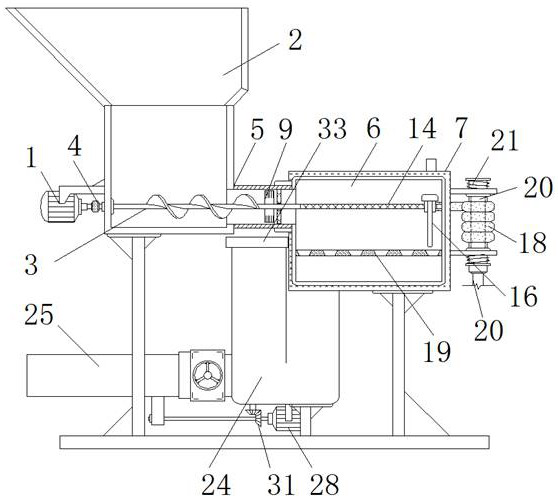

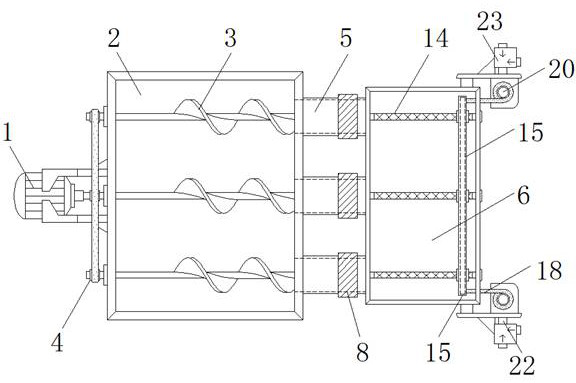

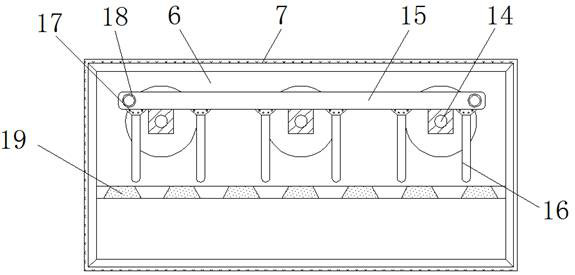

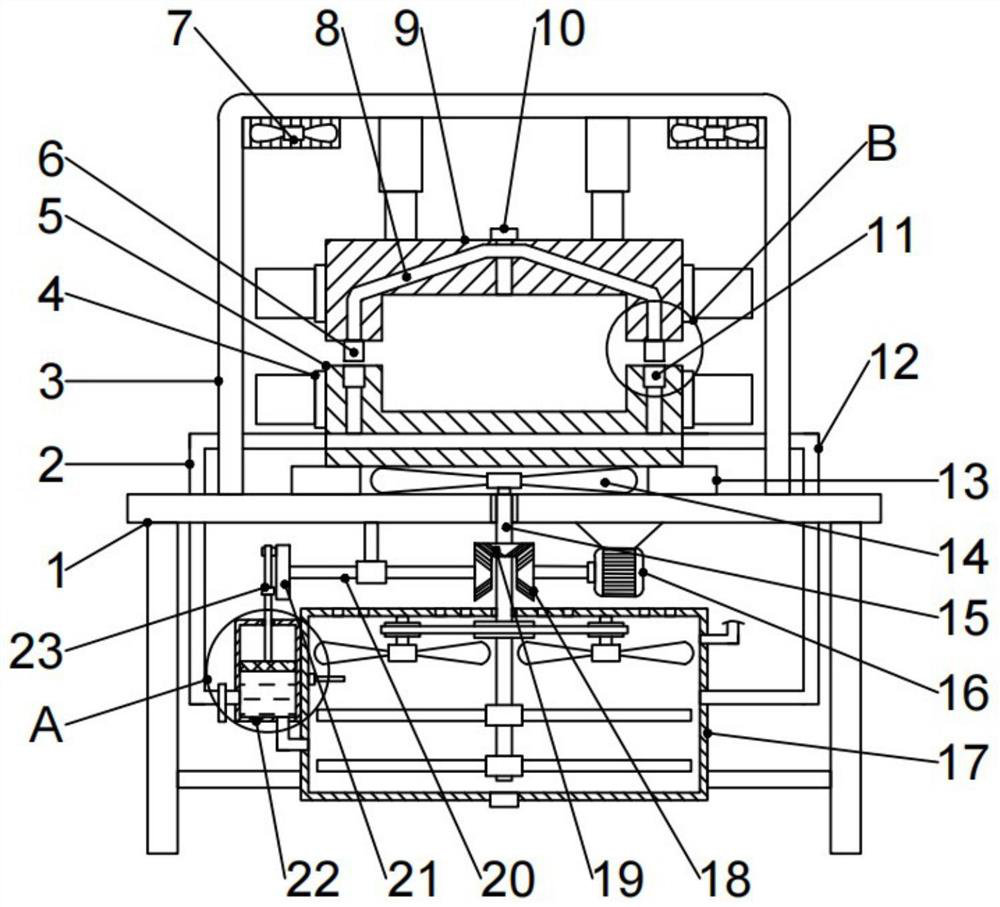

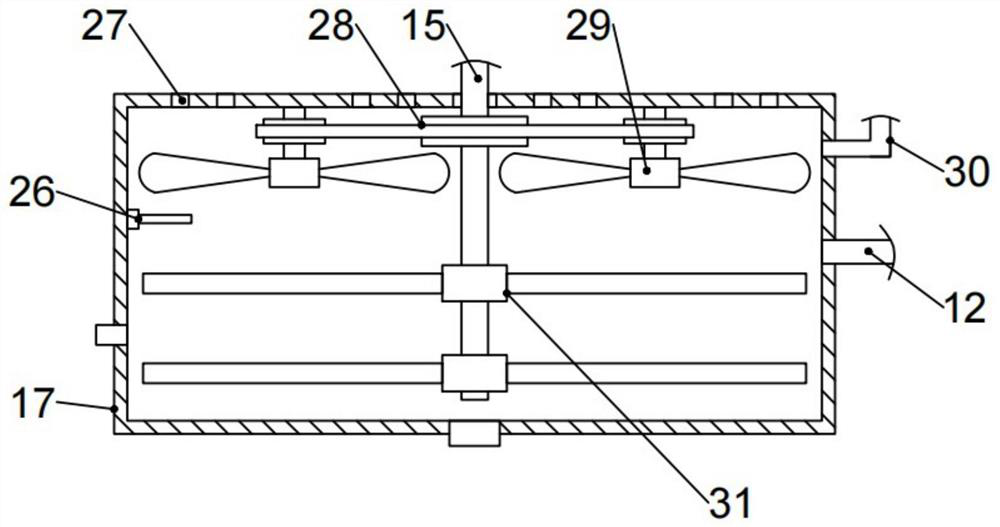

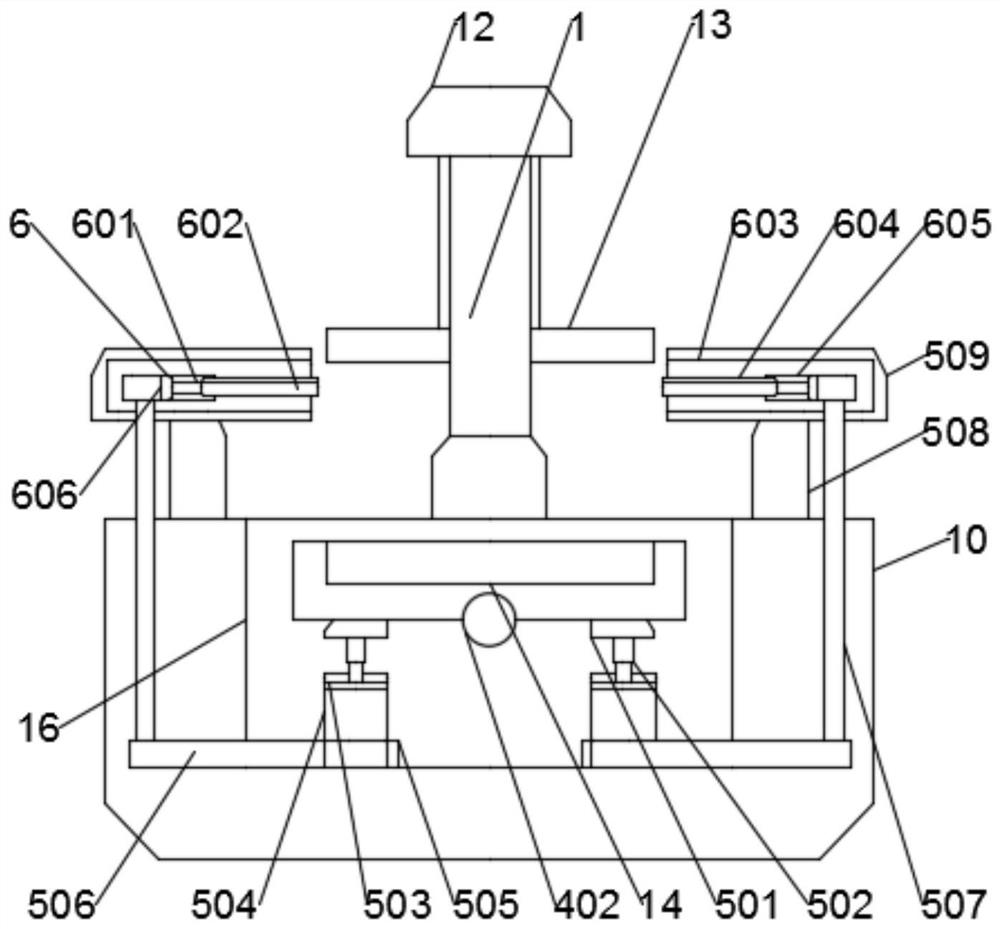

Intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine

The invention discloses an intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine. The intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine comprises a first motor, a material containing tank, a heating cavity and a material storage cavity, wherein the first motor is fixedly installed at the bottom of the left side of the material containing tank, and a conveying auger shaft is rotatably installed in the material containing tank; and an output shaft of the first motor is fixedly connected with the end of the middle conveying auger shaft in the material containing tank, the heating cavity is connected to the bottom of the other side of the material containing tank through a communicating pipe in a penetrating manner, a reciprocating lead screw is fixedly connected to the portion, located at the end of the conveying auger shaft, of the communicating pipe, and a threaded hose is connected to the edge of the end of the inner hollow rod in a penetrating manner. According to the intermittent multi-adaptive-specification plastic part anti-deformation injection molding machine, the injection molding frequency can be changed according to different specifications of injection molding parts, and meanwhile, the melting efficiency and stability of injection molding raw materials can be improved, subsequent injection molding machining is facilitated, the injection molding quality is improved, and molding deformation damage to the injection molding parts is effectively reduced.

Owner:赵秉辉

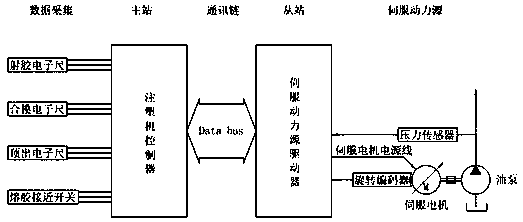

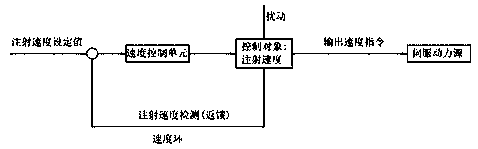

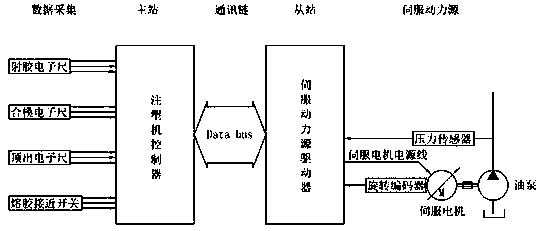

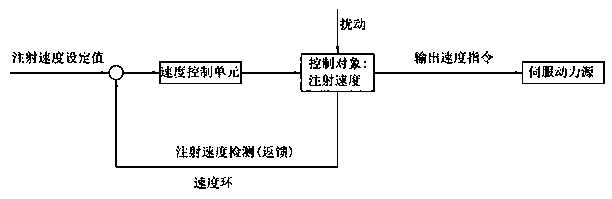

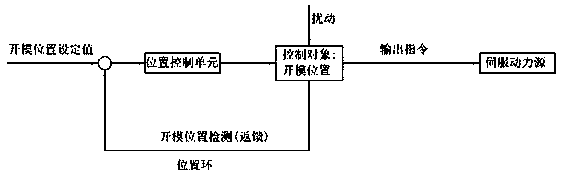

Full closed-loop high-precision high-energy-saving injection molding control system

The invention discloses a full closed-loop high-precision high-energy-saving injection molding control system comprising a glue injection electronic ruler, a die assembly electronic ruler, an ejectionelectronic ruler, a melting glue proximity switch, an injection molding machine controller and a servo power source drive. The glue injection electronic ruler, the die assembly electronic ruler, theejection electronic ruler and the melting glue proximity switch are all connected with the injection molding machine controller. The injection molding machine controller is in communication connectionwith the servo power source drive. A pressure sensor, a rotary encoder, a servo motor and an oil pump are connected to the servo power source drive. The ejection electronic ruler further comprises anejection position controller and an ejection force controller. A servo power source is arranged in the servo power source drive. Through the full closed-loop high-precision high-energy-saving injection molding control system, control precision of an injection molding system is improved greatly, injection molding forming quality of products is improved, and actual practical needs are met.

Owner:中山广美机械设备有限公司

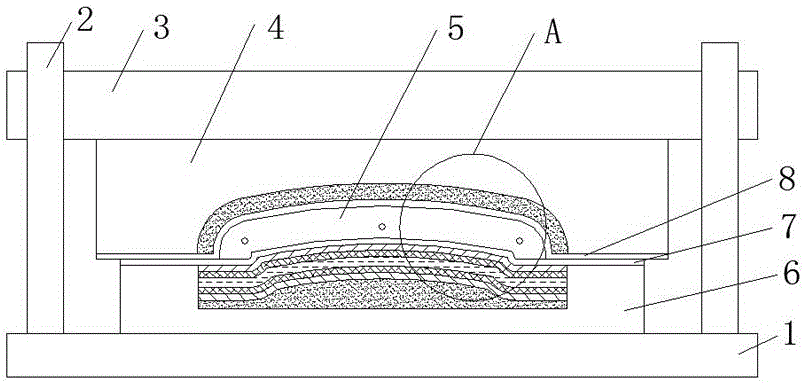

Simply and conveniently formed wear-proof heel lift and preparation method thereof

InactiveCN107043532AEvenly dispersedImprove injection molding qualityHeelsTop-piecesArray data structureEngineering

The invention discloses a simply and conveniently formed wear-proof heel lift. The heel lift comprises shoe nails and a substrate which are integrated through injection molding, wherein a wear-proof layer is arranged on the grounding outer surface of the substrate. The simply and conveniently formed wear-proof heel lift is prepared from the following components in parts by weight: 35-55 parts of polyamide resin, polysulfone, a nonionic surfactant, acyl-containing ether, an aramid fiber, glass fiber, a silane coupling agent and thienyl-containing poly-alpha-olefin. The heel lift has the advantages and beneficial technical effects that by utilizing a once injection molding manner, the heel lift is convenient to prepare, high in production efficiency and low in cost; heel lift nails are nonmetallic and light, so that the strength, tenacity and comfort level are increased, and the heel lift nails can be recycled after being abandoned; and the energy conservation and the environment protection are achieved, and the integral cost is low.

Owner:佛山星期六科技研发有限公司 +1

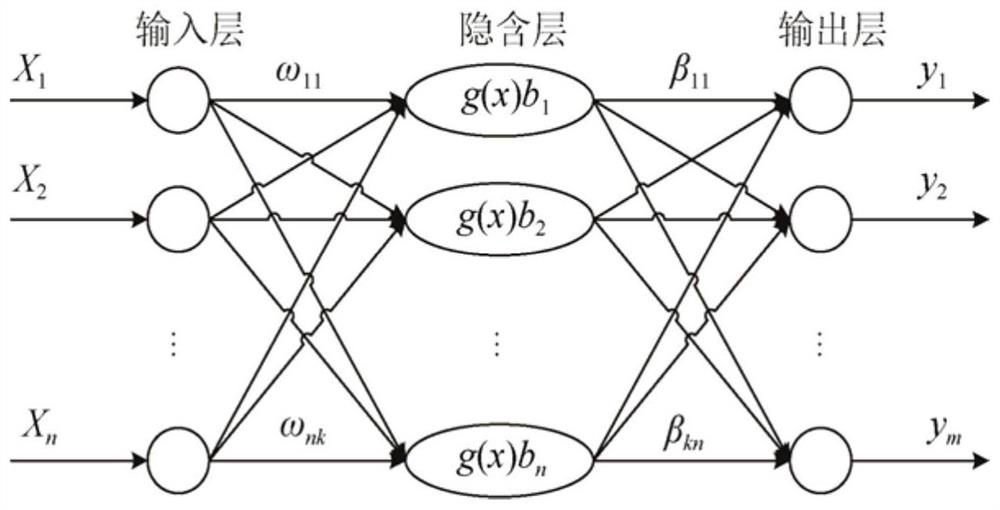

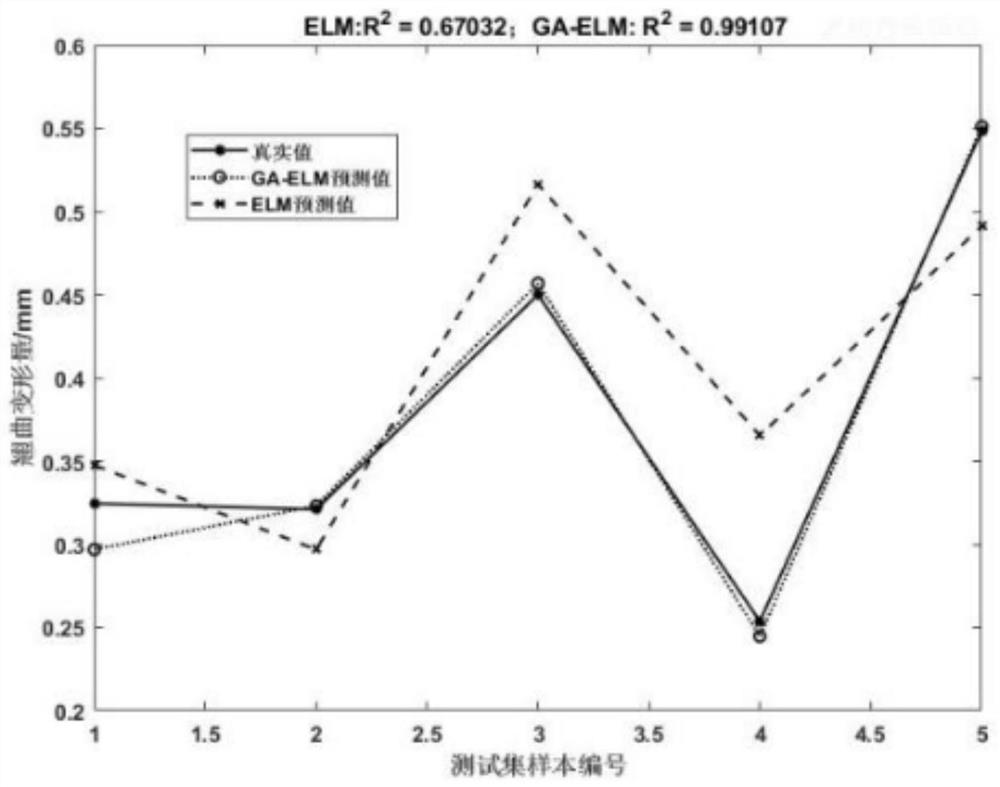

Injection molding part mold parameter optimization method based on GA-ELM-GA

InactiveCN113103535AReduce mistakesVerify reliabilityDesign optimisation/simulationSpecial data processing applicationsGenetics algorithmsStructural engineering

The invention discloses an injection molding part mold parameter optimization method based on a GA-ELM-GA (Genetic Algorithm-Extreme Learning Model-Genetic Algorithm). The method specifically comprises the following steps that the influence degree of process parameters on the buckling deformation of a plastic part is found out through orthogonal experimental design and range analysis, and a nonlinear function relationship between the buckling deformation and injection molding process parameters is fitted by utilizing an ELM model optimized by a genetic algorithm; and finally, a genetic algorithm is adopted to optimize the extremum of the GA-ELM network model after fitting, small buckling deformation is found out, and the actual buckling deformation problem of air conditioner support injection molding is solved to a certain extent.

Owner:GUIZHOU UNIV

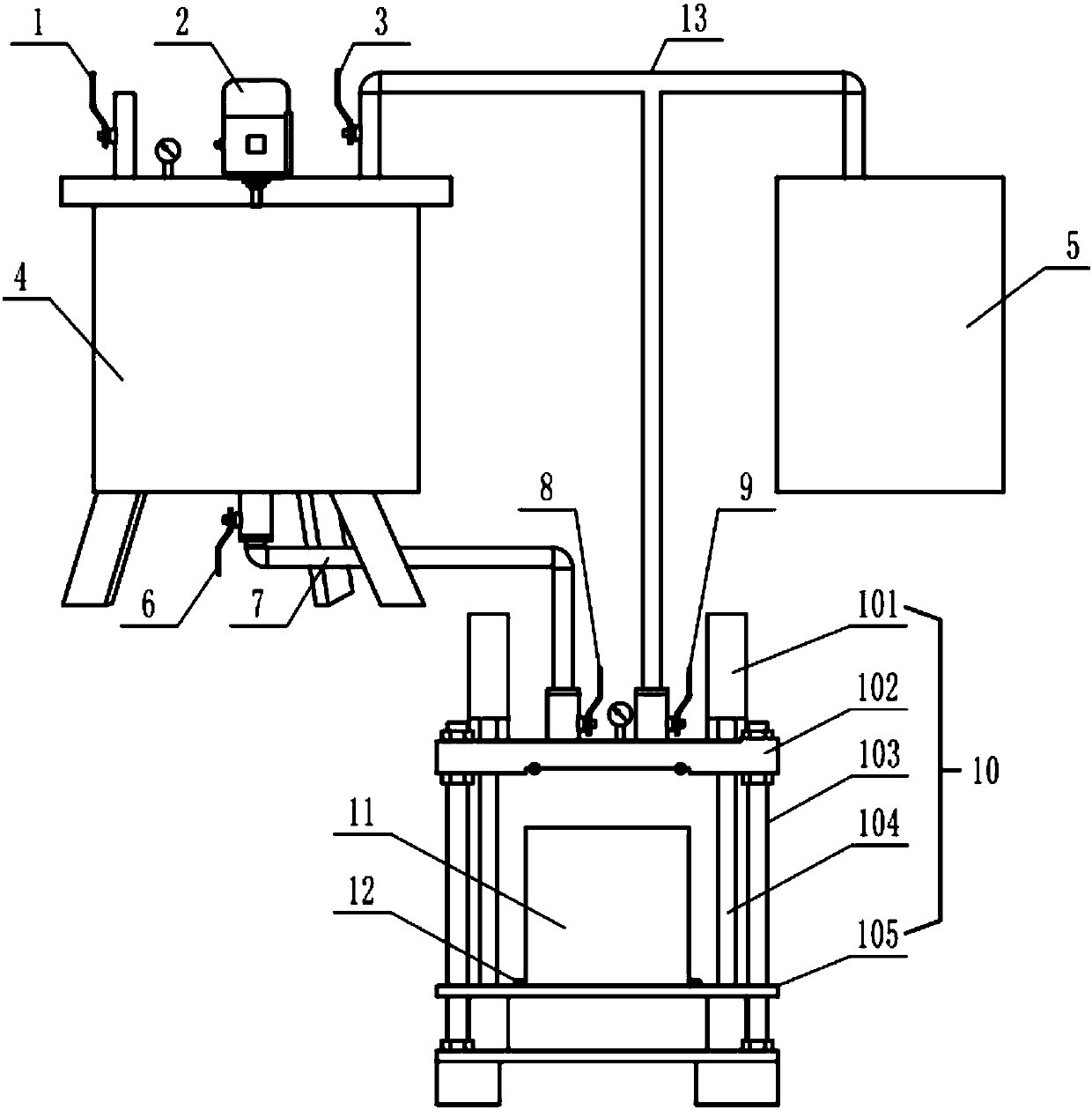

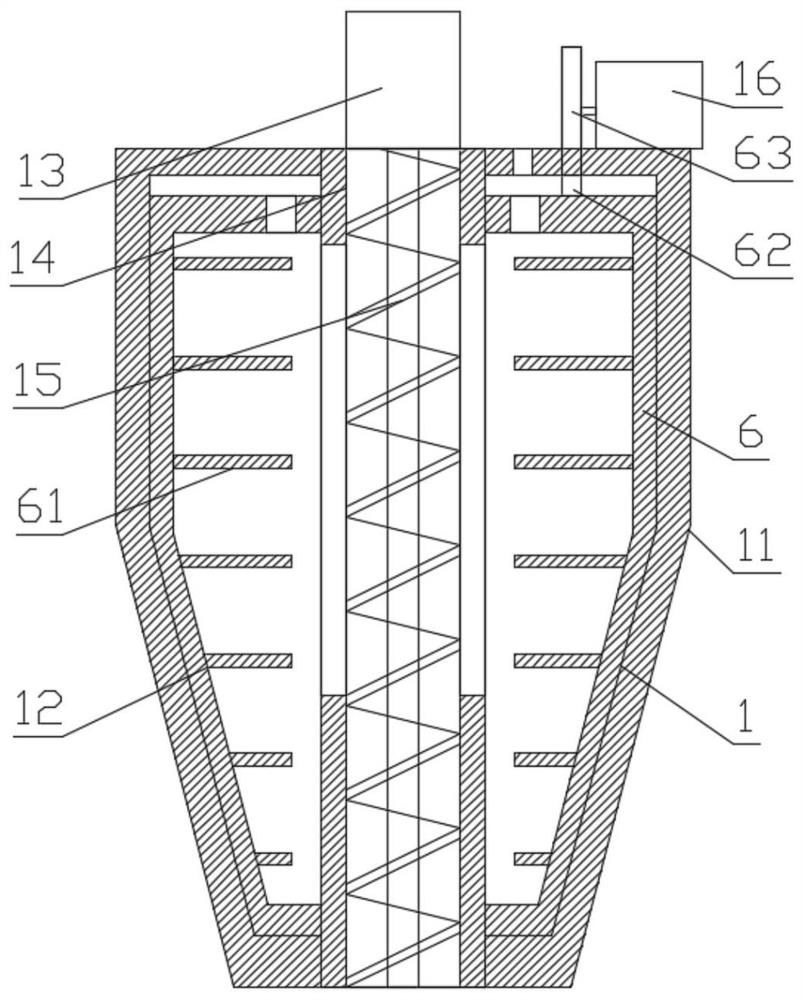

Vacuum gel casting device

InactiveCN108015882ASimple structureSmall footprintFeeding arrangmentsAuxillary shaping apparatusMold fillingPulp and paper industry

The invention relates to a vacuum gel casting device. The vacuum gel casting device comprises a vacuum stirring bucket, a vacuum pump and a casting tank. A stirring motor is arranged on the upper portion of the vacuum stirring bucket. The casting tank comprises a tank body. A lifting platform is arranged in the tank body. An end cover is arranged at the top of the tank body. Lifting air cylindersare arranged on the upper portion of the end cover and are connected with the lifting platform through guide columns arranged in the tank body. The vacuum stirring bucket and the casting tank are connected with the vacuum pump through vacuumizing pipes. The vacuum stirring bucket is connected with the end cover through a flow guide pipe, and a discharging control valve is arranged at the joint ofthe vacuum stirring bucket and the flow guide pipe. The height of the bottom of the vacuum stirring bucket is larger than the height of the end cover. The vacuum gel casting device is simple in structure, small in occupied space, convenient to operate, high in grouting efficiency and high in casting quality, a manufactured blank is full in mold filling, uniform and free of bubbles, and the requirement for close-size prefabricated members in the precision machine production process can be met.

Owner:HUNAN HANGTIAN CHENGYUAN PRECISION MACHINERY

Full-closed-loop high-precision high-energy-saving injection molding machine control system

PendingCN111002550AHigh control precisionImprove injection molding qualityProcess engineeringHigh energy

The invention discloses a full-closed-loop high-precision high-energy-saving injection molding machine control system, which comprises a glue injection electronic ruler, a mold closing electronic ruler, an ejection electronic ruler, a melt glue proximity switch, an injection molding machine controller, a servo power source driver and a servo power source, wherein the glue injection electronic ruler, the mold closing electronic ruler, the ejection electronic ruler and the melt glue proximity switch are all connected with an injection molding machine; the glue injection electronic ruler, the mold closing electronic ruler and the ejection electronic ruler can detect and feed back the position and the speed of the injection molding machine mechanism in real time, the melt glue proximity switchcan detect and feed back the rotating speed of a melt glue screw in real time, and all the units form a hardware part of the full-closed-loop high-precision high-energy-saving injection molding machine control system. According to the invention, a full-closed-loop control system is adopted, and the control precision of the injection molding system is greatly improved. The adoption of the full-closed-loop control system realizes high energy conservation and reduces the economic cost of actual production; and the intelligent, unmanned and highly-automatic flexible systematization of a modern industrial automatic production line is met.

Owner:中山广美机械设备有限公司

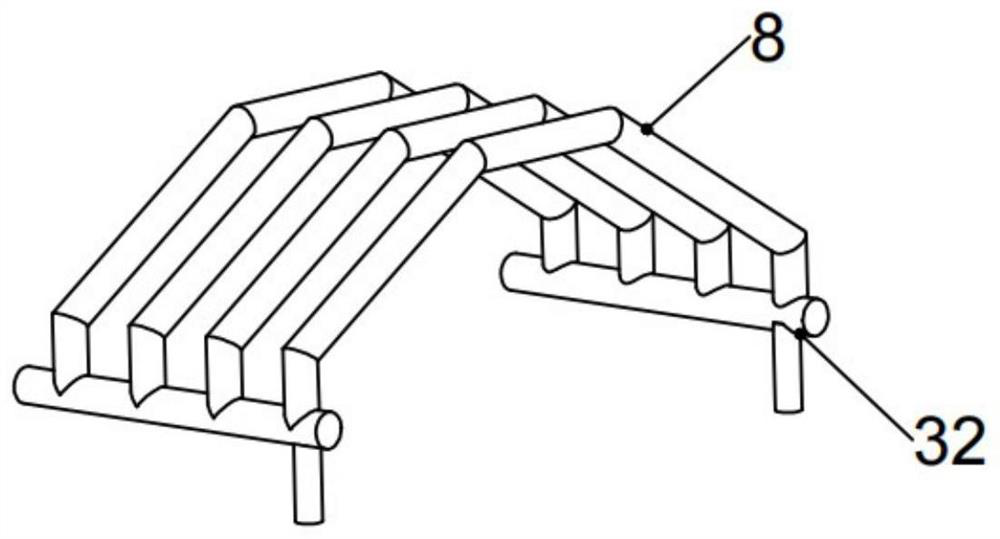

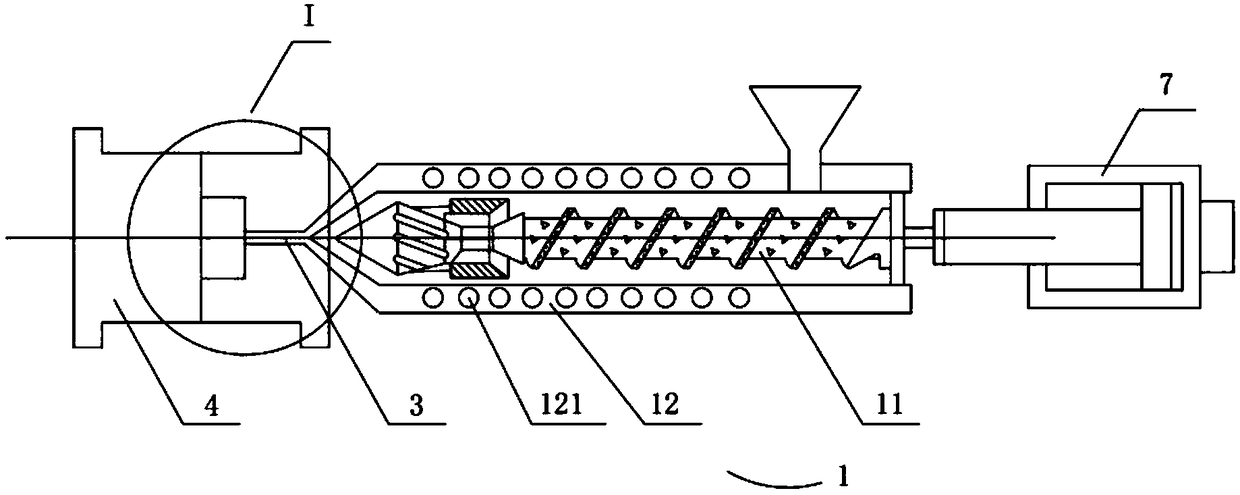

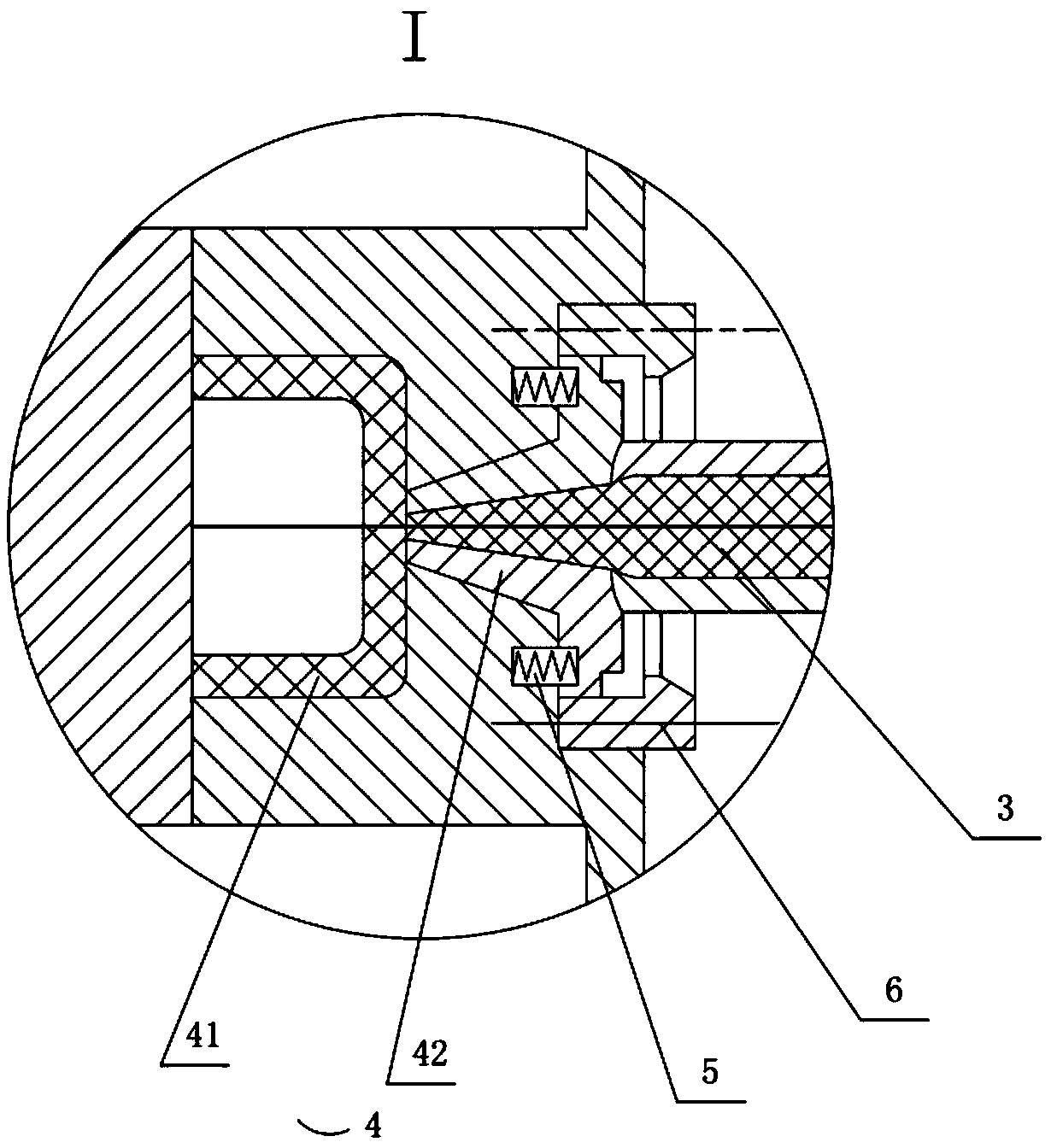

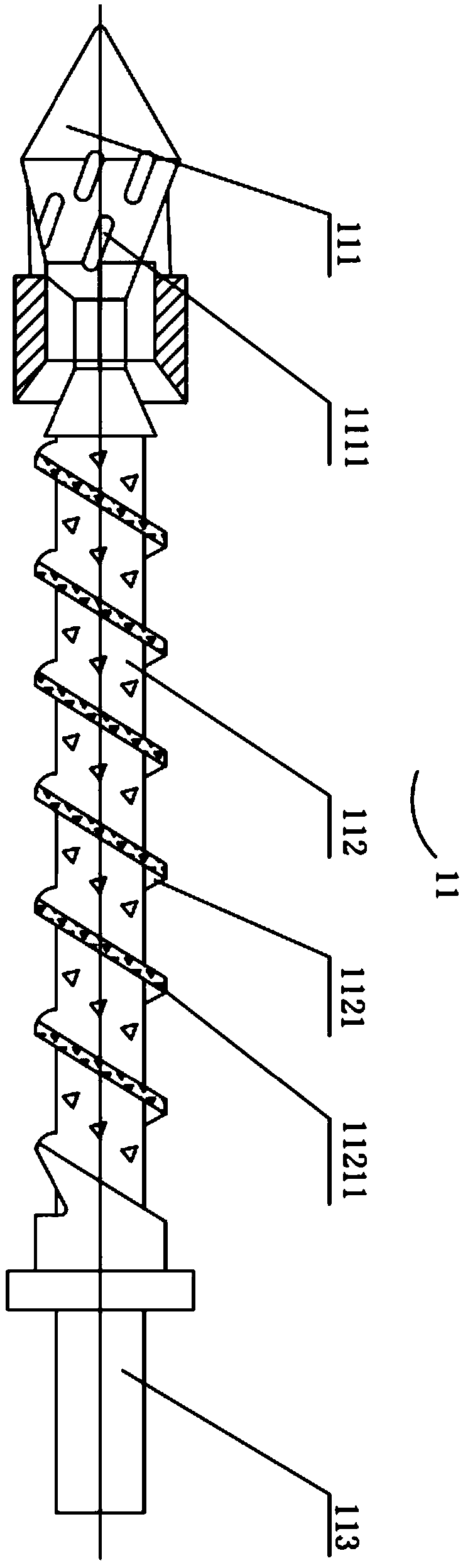

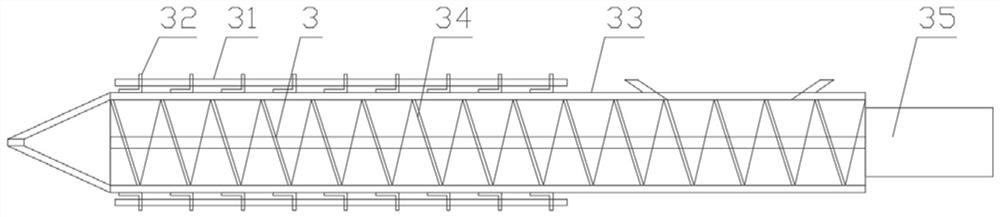

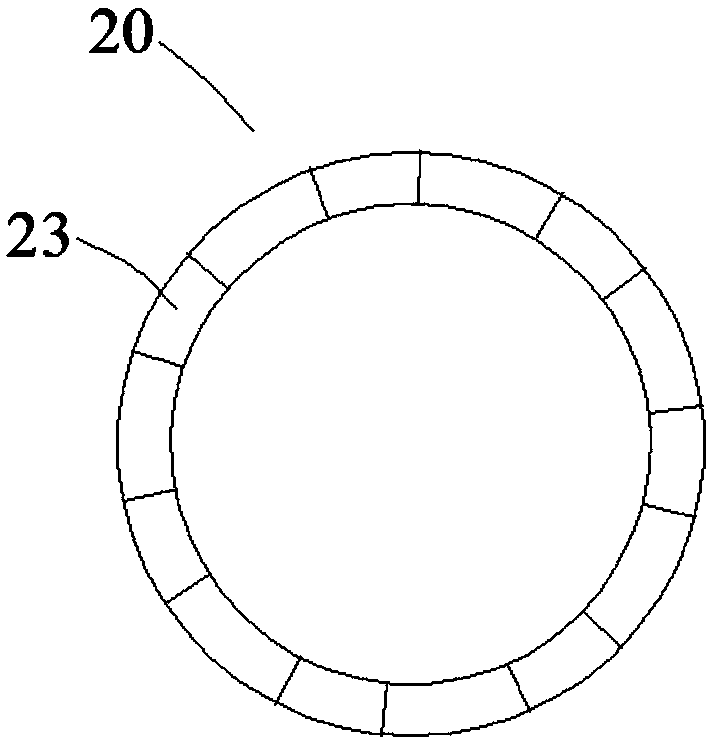

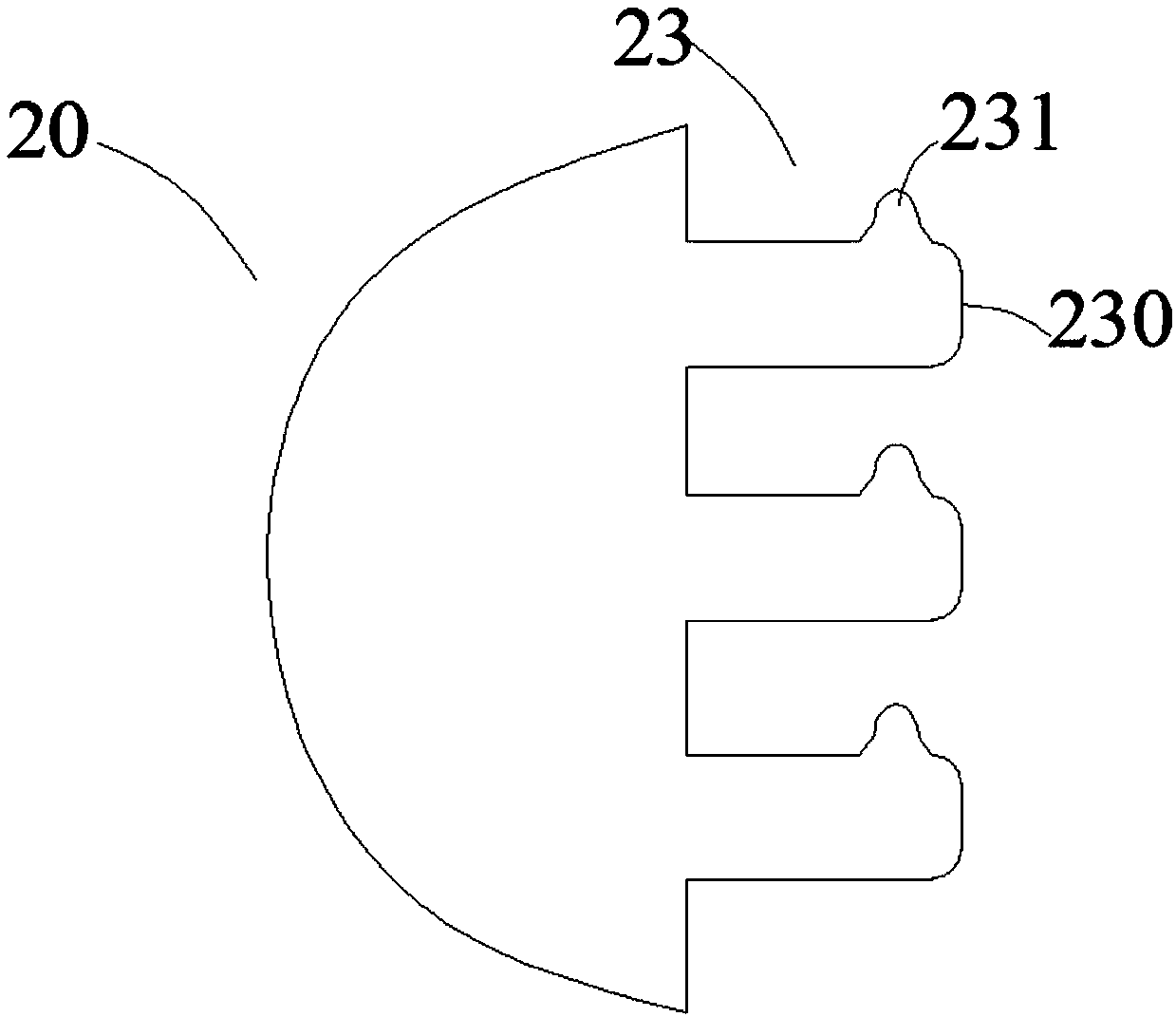

Injection molding machine and plasticizing component thereof

InactiveCN104669564AImprove the mixing effectImprove injection molding qualityEngineeringRubber material

The invention provides an injection molding machine and a plasticizing component thereof. The plasticizing component is provided with a central axis and comprises a screw and a feed cylinder, which are matched with each other, wherein a composite mixing head is arranged at the top end of the screw and comprises a mixing part and a shunting part; the mixing part is used for being matched with the inner wall of the feed cylinder to form a plurality of rubber passing channels; each rubber passing channel can allow melted rubber materials to pass and effectively prevent unmelted particles from passing; the shunting part further extends forward from the front end of the mixing part and is used for being matched with the inner wall of the feed cylinder to form a plurality of shunting channels so that the melted rubber materials are further shunted and mixed. The mixing effects and the injection molding quality can be improved by adopting the injection molding machine and the plasticizing component.

Owner:佛山市顺德区震德塑料机械有限公司

Injection mold with rapid discharging function

PendingCN113059771AHeat dissipation fastImprove cooling effectLighting and heating apparatusCooling fluid circulationThermodynamicsEngineering

The invention belongs to the technical field of injection molds, and provides an injection mold with a rapid discharging function. The injection mold with the rapid discharging function comprises a base and a mold main body located on the base, wherein the mold main body comprises a lower mold and an upper mold, and an injection molding opening is further formed in the upper mold; a liquid cooling mechanism connected with the mold main body, wherein the liquid cooling mechanism comprises a circulating pipe assembly and a cooling assembly, and the circulating pipe assembly is connected with the cooling assembly and used for cooling the mold main body; and an auxiliary cooling mechanism connected with the mold main body, wherein the auxiliary cooling mechanism comprises at least one group of heat conduction pieces, and the heat conduction pieces are connected with the mold main body and are used for carrying out auxiliary heat dissipation on the mold main body. The injection mold is novel in structure, and through cooperative use of the liquid cooling mechanism and the auxiliary cooling mechanism, the heat dissipation performance of the injection mold is effectively improved.

Owner:深圳市恒大伟业塑胶有限公司

Injection control system for injection molding machine and control method

InactiveCN108621375AImprove heat conduction speedImprove thermal conductivityControl systemSpray nozzle

The invention relates to the technical field of injection molding machines, in particular to an injection control system for an injection molding machine. The system comprises a plasticization device,a screw rod driving device, an injection device and a spray nozzle pressure detection device, wherein the plasticization device comprises a screw rod and a material tube; the screw rod is arranged inthe material tube; the material tube is of a hollow structure; a heating coil is arranged in the hollow structure; the screw rod driving device provides driving power for the screw rod; the injectiondevice comprises a spray nozzle; the spray nozzle comprises a connecting part and a built-in part; the connecting part is connected with the material tube; the built-in part extends into a main flowpassage of a mold; the main flow passage and the mold are connected through a spring; the main flow passage moves along with the spray nozzle; the spray nozzle is used for spraying melt into a mold cavity; the spray nozzle pressure detection device is used for detecting the spray nozzle pressure change. The injection control system has the advantages that the structure is simple; a main flow passage cup moves along with the spray nozzle; the problem of influencing injection molding quality due to plastic curing in a cold material well can be solved.

Owner:琮伟机械(昆山)有限公司

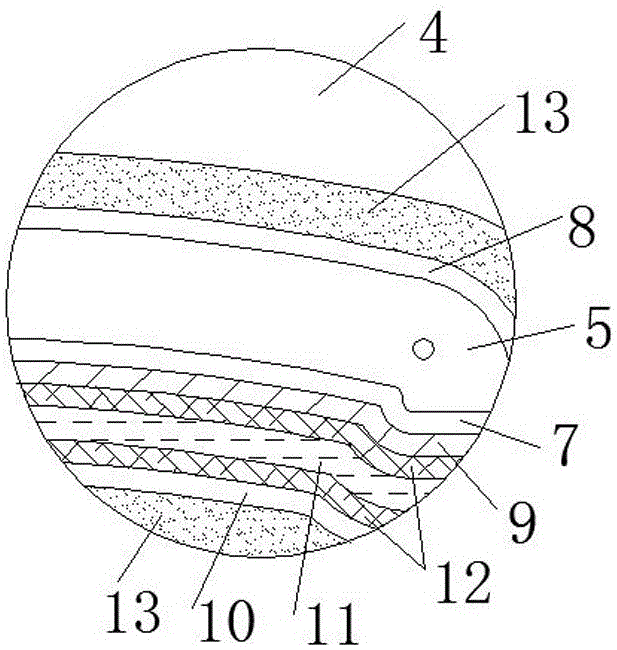

Mold

InactiveCN109774079AEliminate the phenomenon of trapped gasImprove injection molding qualityInjection mouldingMaterials science

The invention provides a mold comprising a first mold core and a second mold core. A glue sealing surrounding wall is arranged on one side of a mold closing surface of the first mold core, an exhaustpassage is arranged on the second mold core, and the exhaust passage and the glue sealing surrounding wall are correspondingly arranged. When injection mold closing is performed, a cavity is formed between the first mold core and the second mold core, an exhaust cavity is formed between the glue sealing surrounding wall and the second mold core, the glue sealing surrounding wall isolates molten plastic in the cavity outside the exhaust cavity, a gap for leading air in the cavity into the exhaust cavity is arranged between the end face of the glue sealing surrounding wall and the second mold core, and the exhaust passage allows air in the exhaust cavity to flow outside the second mold core. The glue sealing surrounding wall can prevent the molten plastic from entering the exhaust cavity, the air in the cavity enters the exhaust cavity from the gap between the glue sealing surrounding wall and the second mold core, then the air is discharged outside the second mold core from the exhaustcavity through the exhaust passage, the air trapping phenomenon in the injection mold is prevented, and the injection molding quality of the product is improved.

Owner:AAC PRECISE MFG TECH CHANGZHOU

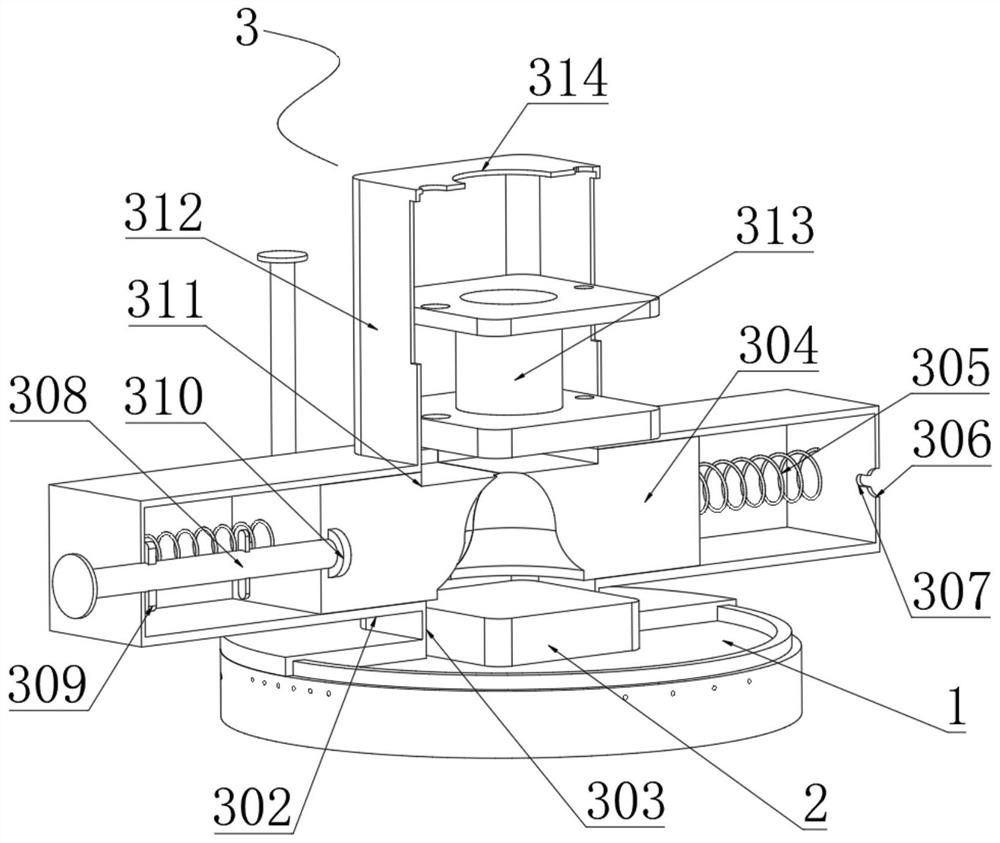

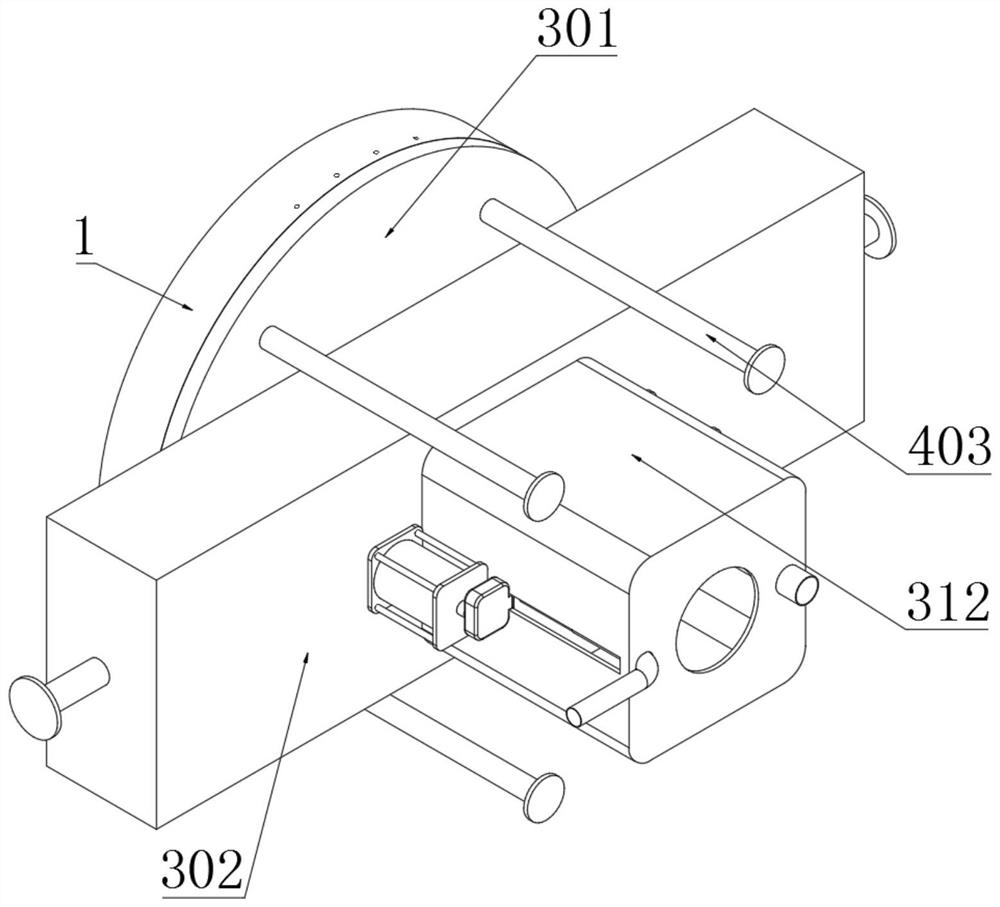

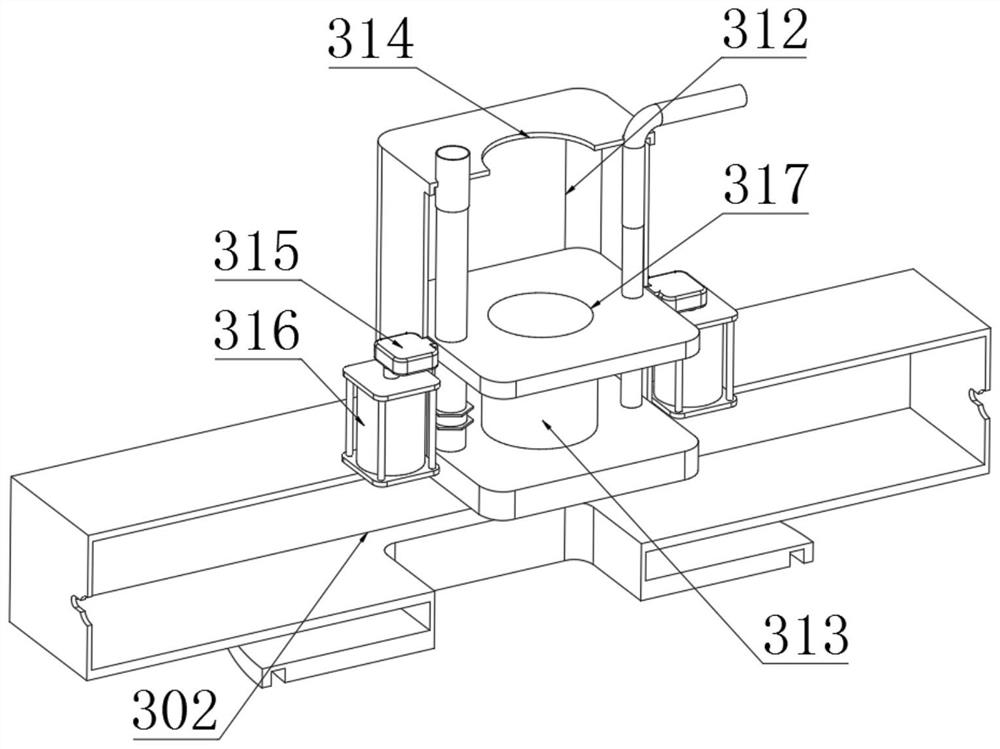

Full-automatic forming equipment for electronic component shell

PendingCN113306083AImprove injection molding qualityEasy to absorb partsDomestic articlesPhysicsMoving parts

The invention relates to full-automatic forming equipment for an electronic element shell. The full-automatic forming equipment is characterized by comprising a material mixing mechanism for mixing materials, a mold mechanism for part forming, an injection molding mechanism for injecting a mixture into the mold mechanism, a clamping mechanism for clamping and moving parts and a punching mechanism for shearing the parts; the material mixing mechanism communicates with an inlet of the injection molding mechanism; the mold mechanism communicates with an outlet of the injection molding mechanism; and the clamping mechanism is arranged between the mold mechanism and the punching mechanism. The problems that in an existing scheme, the injection molding efficiency of products is low, and the shearing effect is poor are solved.

Owner:无锡威孚工程塑料有限公司

Injection mold for flame retardant housing of data interaction device

InactiveCN106042282AImprove injection molding qualityGuaranteed melting effectInteraction deviceEngineering

The invention belongs to the technical field of communication equipment manufacturing, and discloses an injection mold for a flame-retardant shell of data interaction equipment, which solves the problem of poor injection molding quality of the existing shell made of flame-retardant plastics. The invention comprises a fixed mold installation plate and a fixed mold, the fixed mold is installed above the fixed mold installation plate, guide columns are arranged around the fixed mold installation plate, and the upper end of the guide column is covered with a movable mold installation plate A movable mold is installed under the movable mold mounting plate, the movable mold includes a movable mold cavity, the fixed mold includes a fixed mold cavity, and the movable mold cavity and the fixed film cavity together form a pouring cavity, and the pouring The mold cavity is connected with a pouring channel, the fixed mold includes a mold core and a template provided with a fixed mold cavity, a heating device is arranged between the mold core and the template, and the heating device includes an outer cylinder and an inner cylinder, and the inner cylinder It is fixedly connected with the template, a vacuum steam chamber is formed between the inner cylinder and the outer cylinder, and a liquid-absorbing core is arranged on the inner wall of the steam chamber.

Owner:CHENGDU KECHUANGGU TECH CO LTD

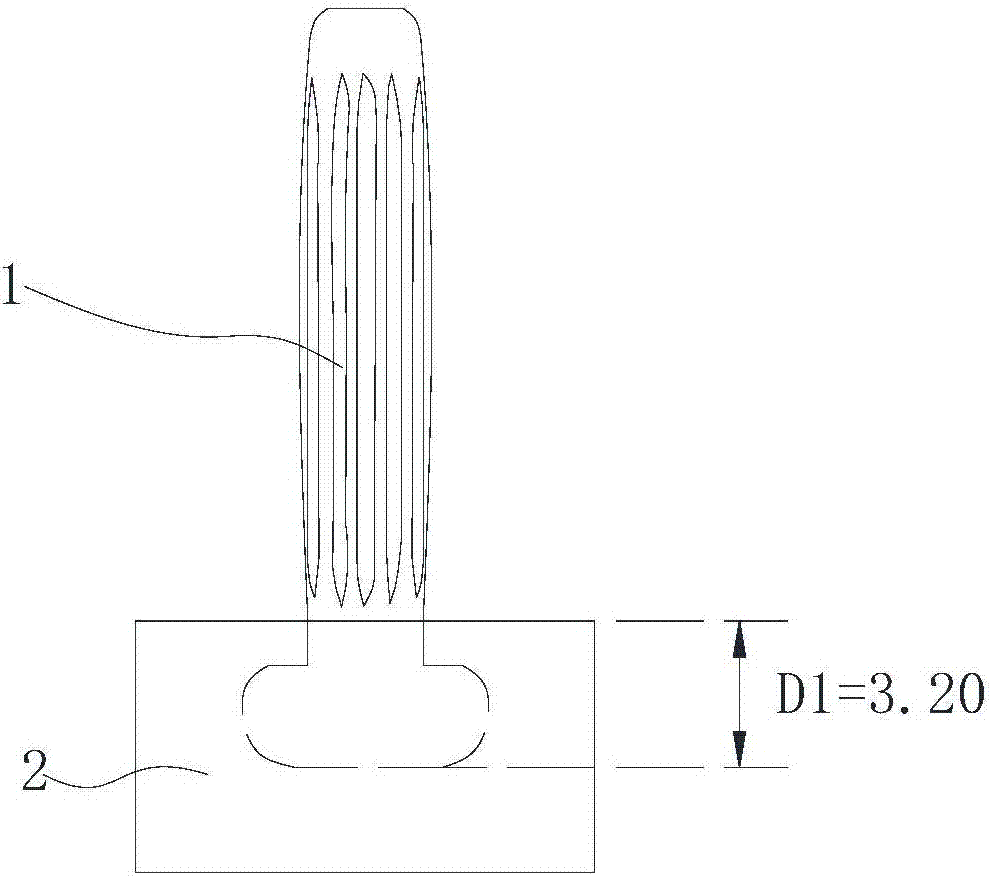

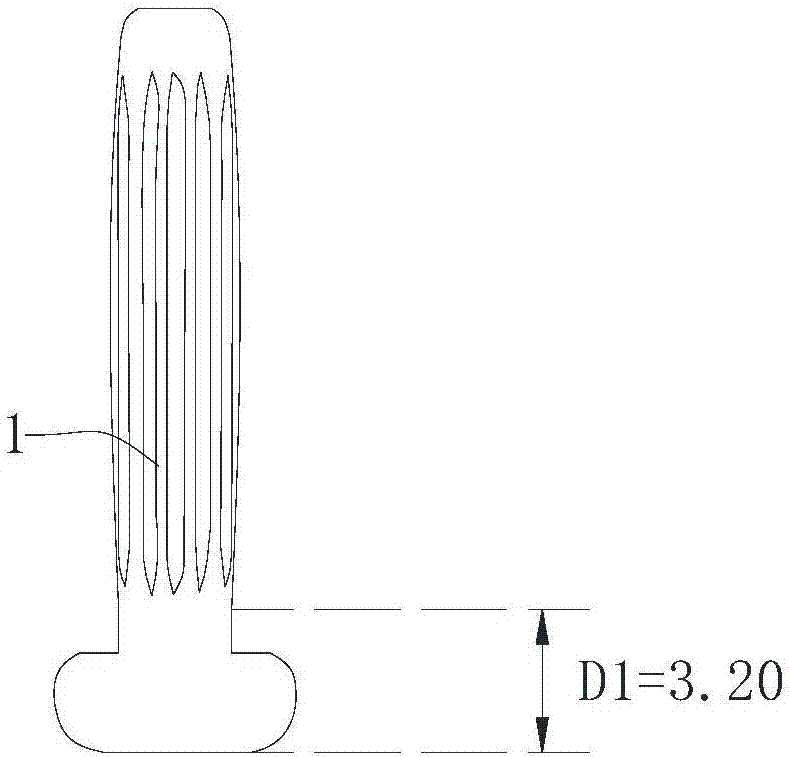

Charger pin and production technology thereof

PendingCN110098516AReduce difficultyImprove matchContact member manufacturingBatteries circuit arrangementsEngineeringElectrical equipment

The invention discloses a charger pin and a production technology thereof, and relates to the field of electric appliance assembly manufacture. The charger pin comprises a pin body which is composed of a substrate and pin assemblies, the two pin assemblies are symmetrically distributed at the two ends of the substrate, each pin assembly is composed of a conductive hardware cylinder and a glue sealing surface arranged in the outer side of the middle portion of the conductive hardware cylinder, the two sides of the substrate are provided with positioning slots respectively, and one side of the substrate is provided with a groove. The conductive hardware cylinders are processed to serve as conductive insertion rods, the two conductive insertion rods are symmetrically and inclinedly placed ina casting cavity, the casting cavity is buckled, a rubber solution is injected to implement casting, the rubber solution enters the casting cavity via first and second branch channels, the pin body isprepared after molding, the integrated degree is high, parts are convenient to produce, the casting cavity highly matches the conductive hardware cylinders, the difficulty in placing the conductive cylinders is reduced, the yield rate of injection molding is improved, and the injection molding quality is improved.

Owner:广州正业科技有限公司

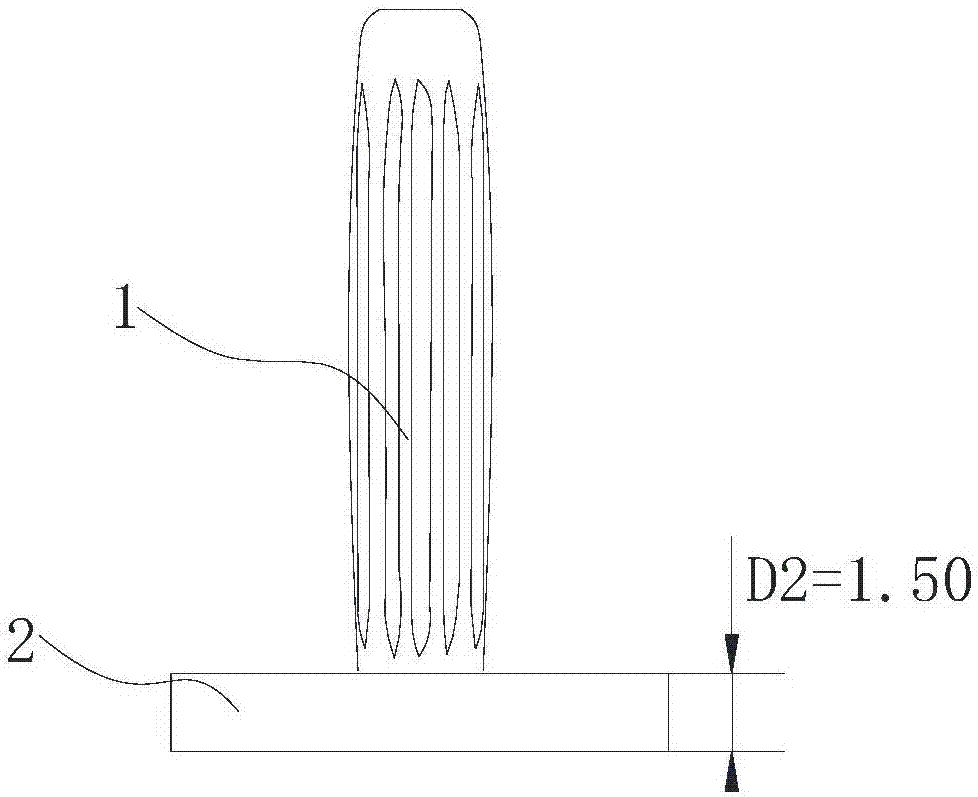

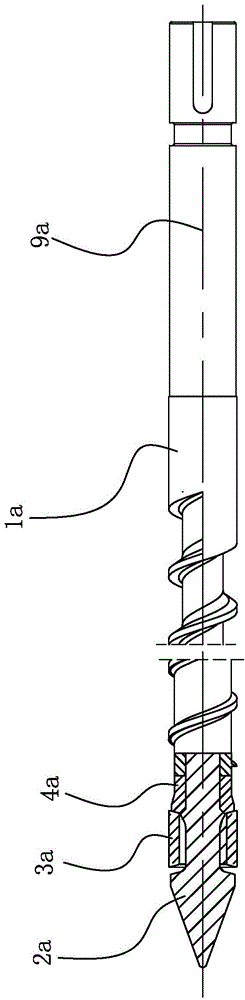

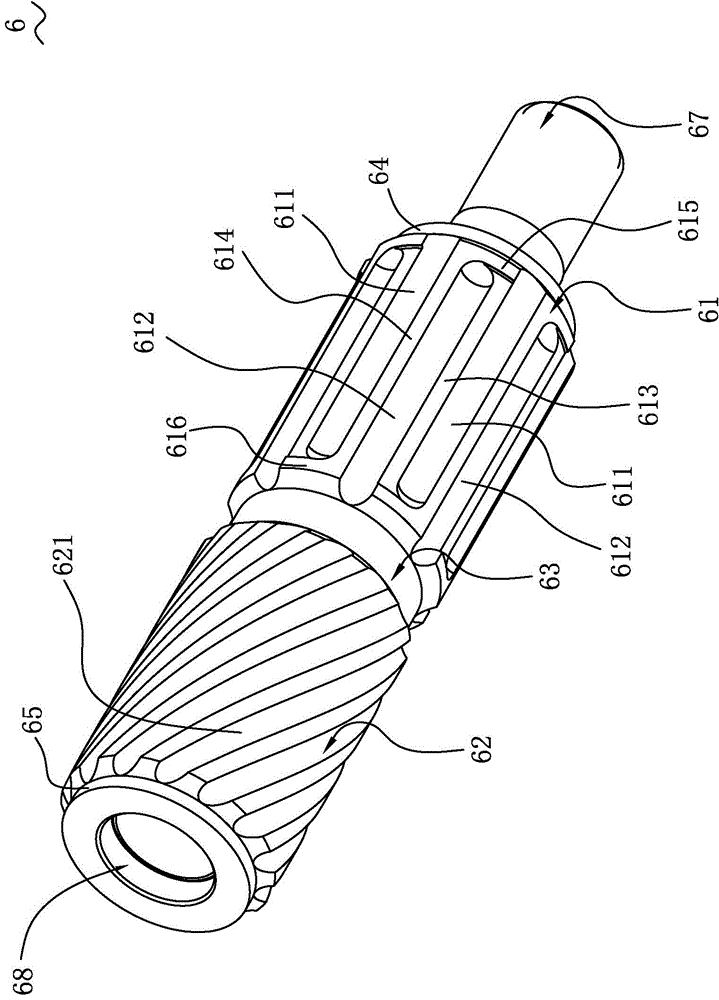

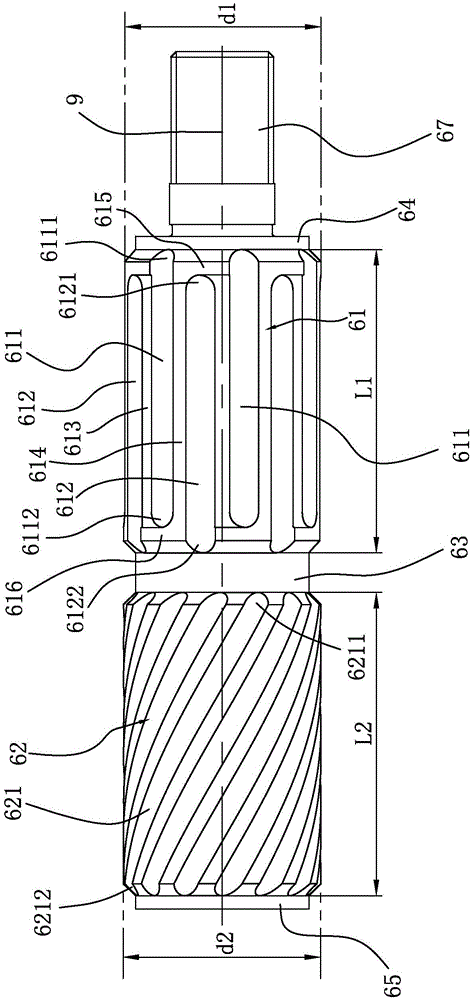

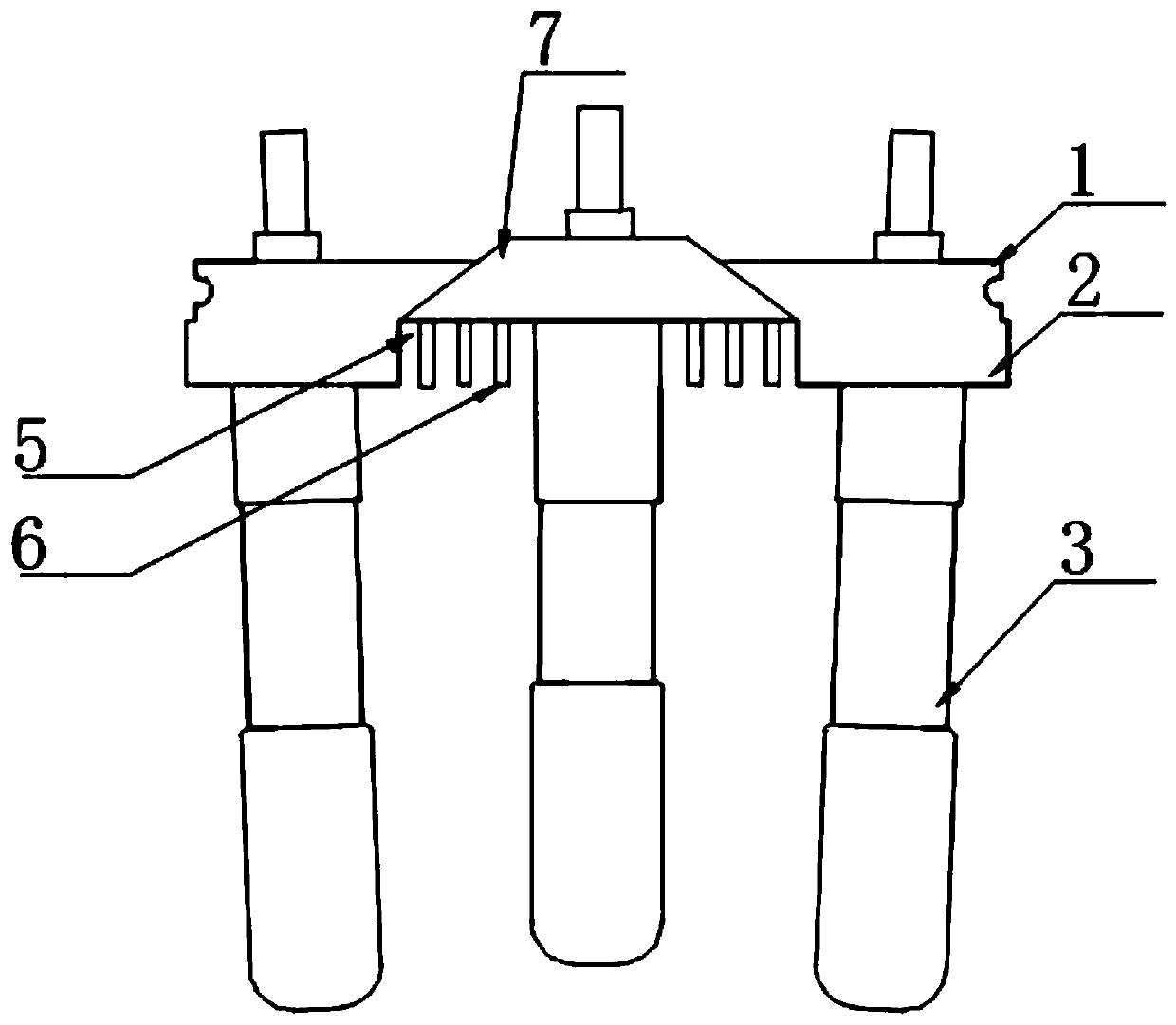

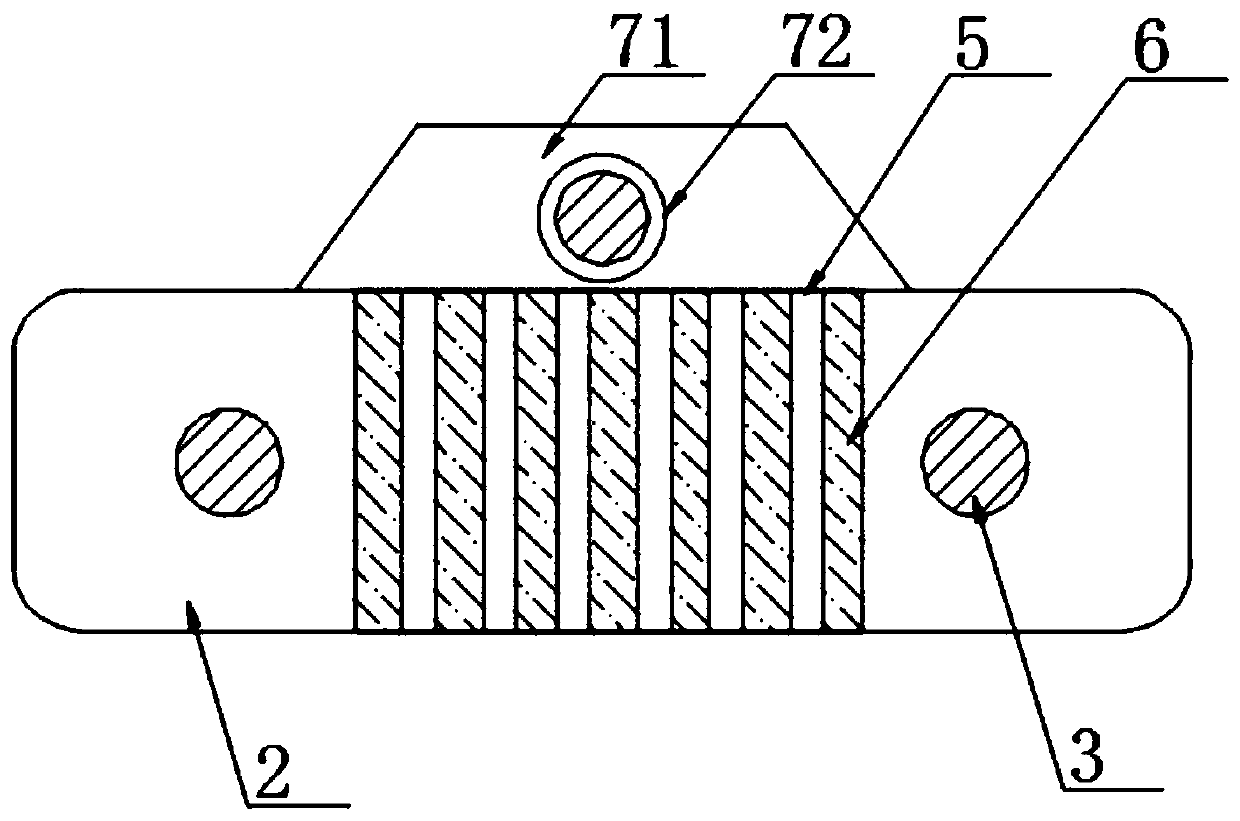

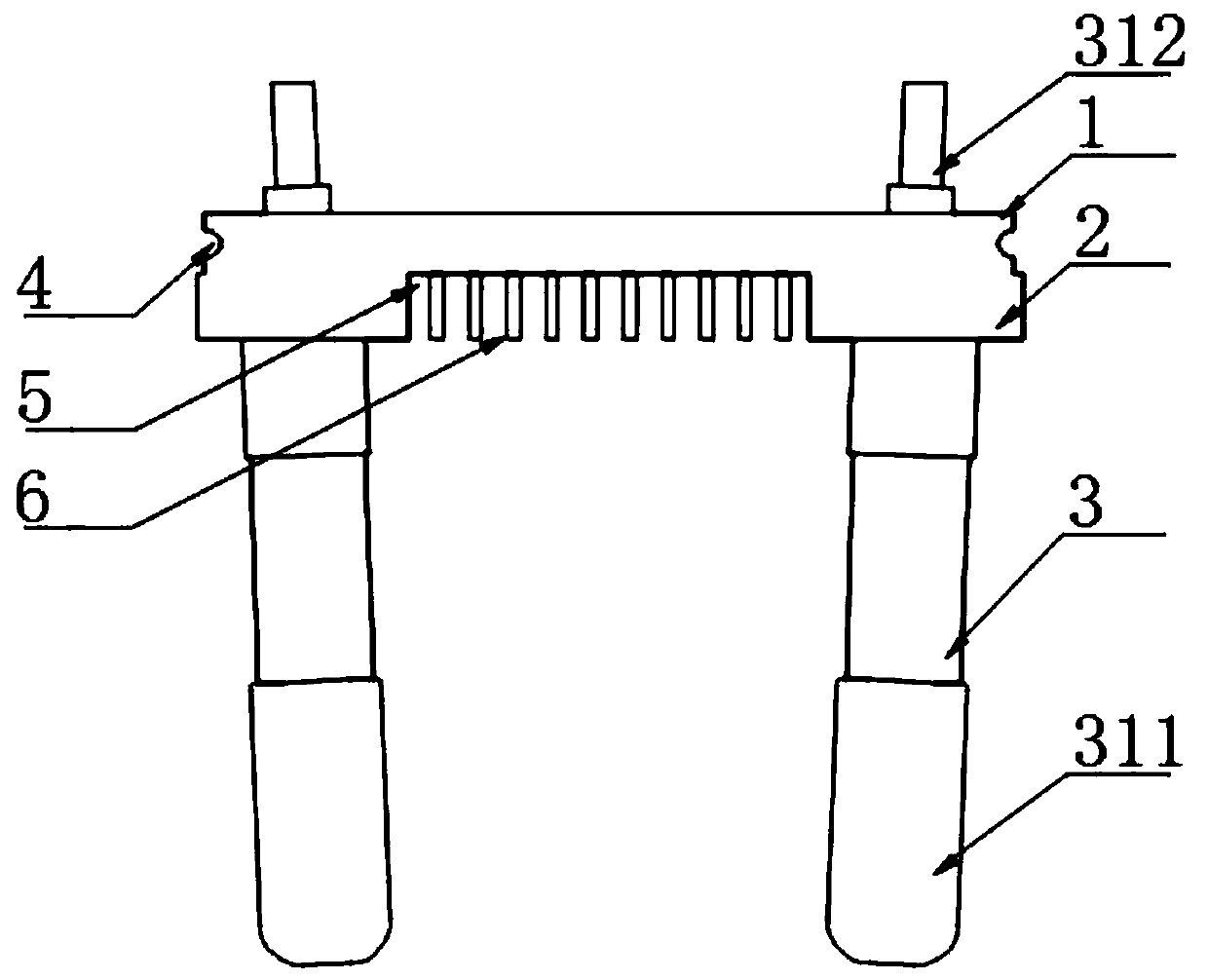

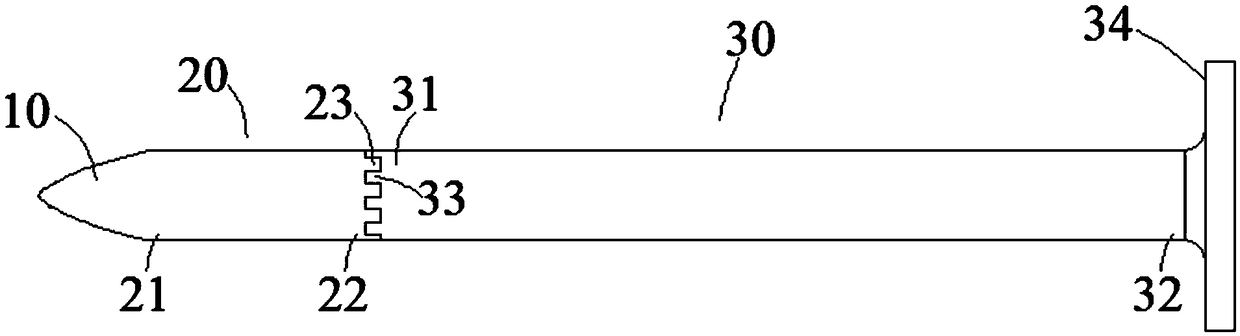

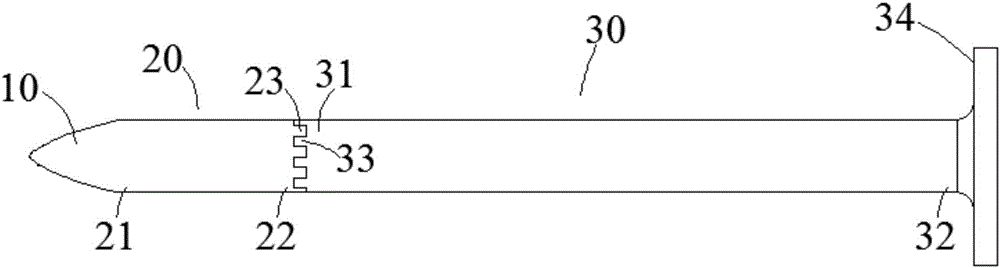

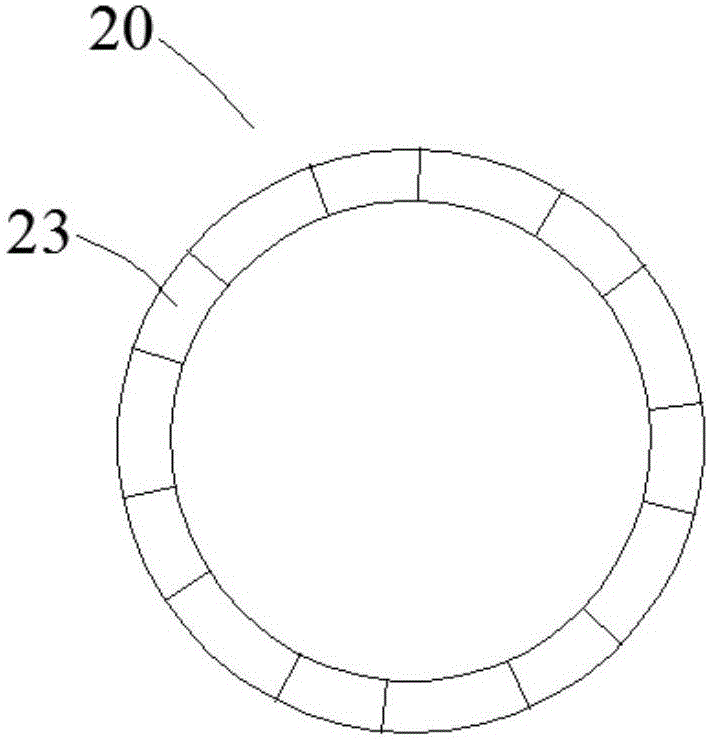

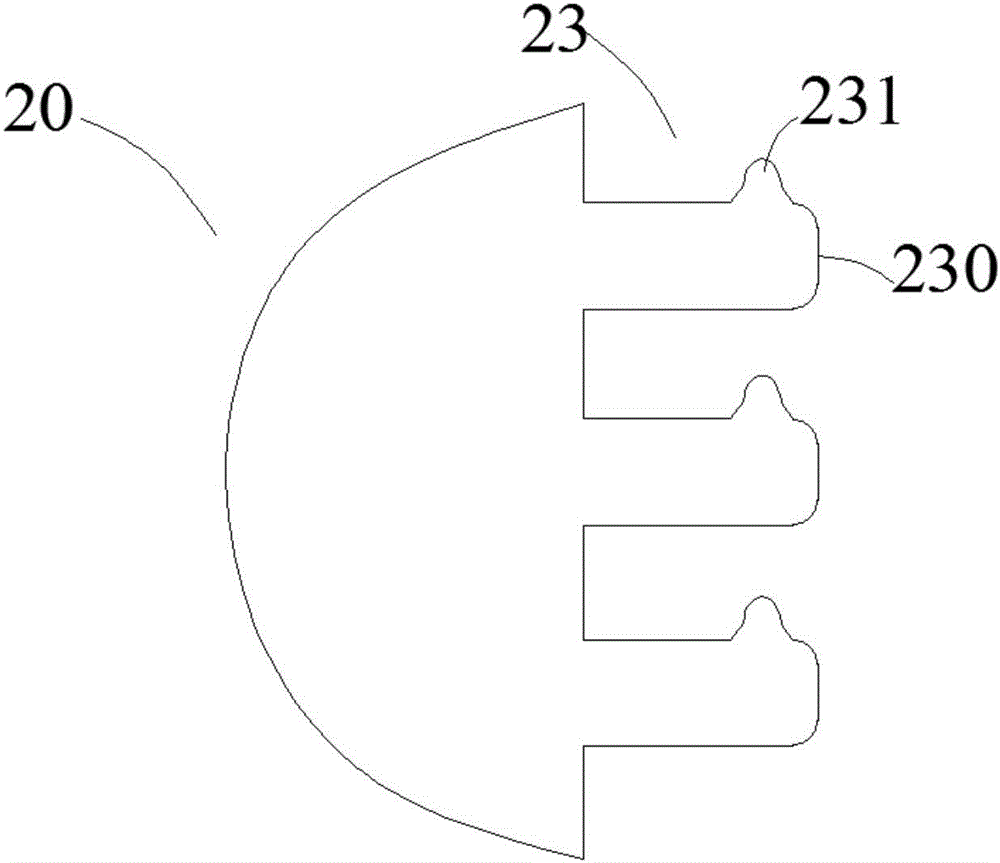

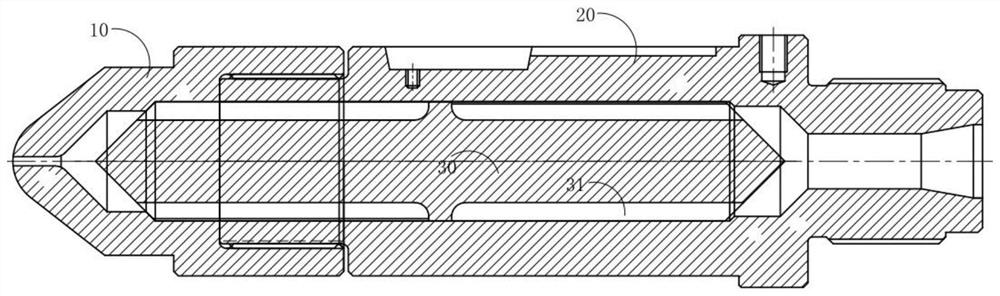

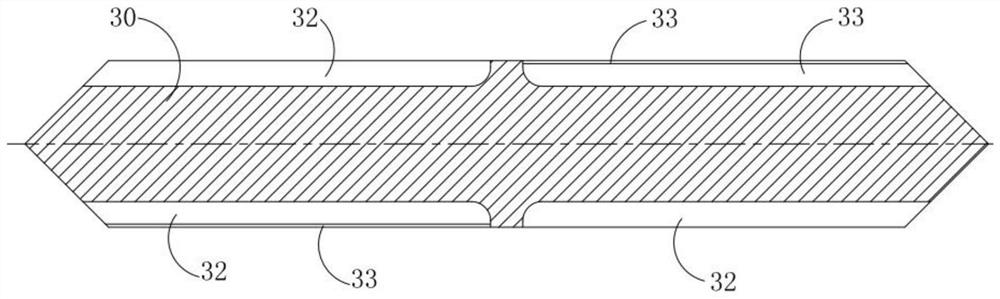

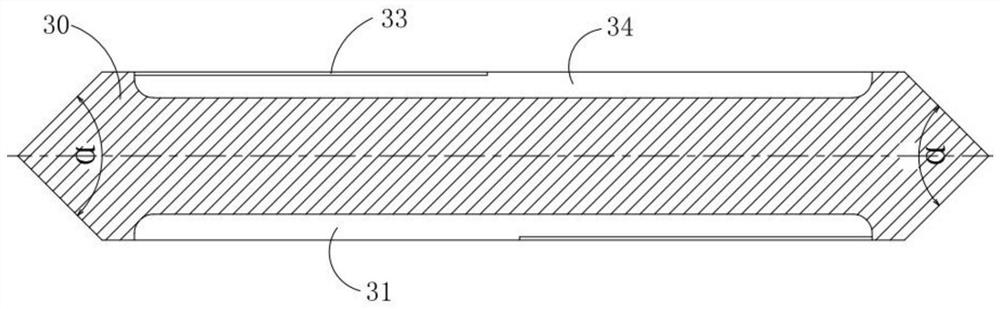

Puncture mandrel and trocar with same

ActiveCN106361415BImprove injection molding qualityMeet the needs of useCannulasSurgical needlesMedicineInjection moulding

Owner:FENGH MEDICAL CO LTD

Hydraulic equipment

ActiveCN107150403ASimple structureLow costFeeding arrangmentsAuxillary shaping apparatusEngineeringHydraulic equipment

The invention discloses hydraulic equipment. The hydraulic equipment comprises a frame body; a port connected with stirring equipment is fixedly mounted at the upper end of the frame body; a transfer groove is formed in the frame body; a first transfer machine is mounted in the transfer groove; a drainage groove for extending up and down is formed in the frame body; a rotating cavity is formed in the frame body; a discharge port is formed in the bottom wall of the rotating cavity; a rotating frame is rotationally mounted in the rotating cavity; the rotating frame comprises rotating shafts rotationally mounted in the front and back end walls of the rotating cavity, and rotating plates uniformly and fixedly mounted on the rotating shafts; an extension groove is formed in the left end wall of the frame body; a guide groove for extending up and down is formed in the top wall of the rotating cavity; a through groove is formed in the bottom wall of the guide groove; a guide block is mounted in the guide groove in a up-down sliding manner; a touch rod is fixedly mounted at the lower end of the guide block; and the touch rod penetrates through the through cavity to enter the rotating cavity. The hydraulic equipment is simple in structure and low in equipment cost.

Owner:温岭市仁全机械设备有限公司

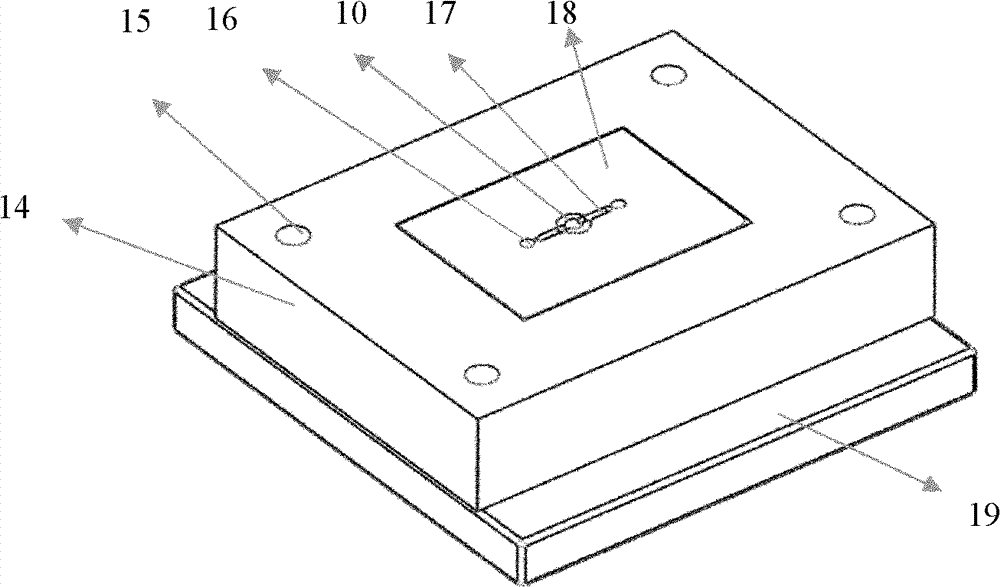

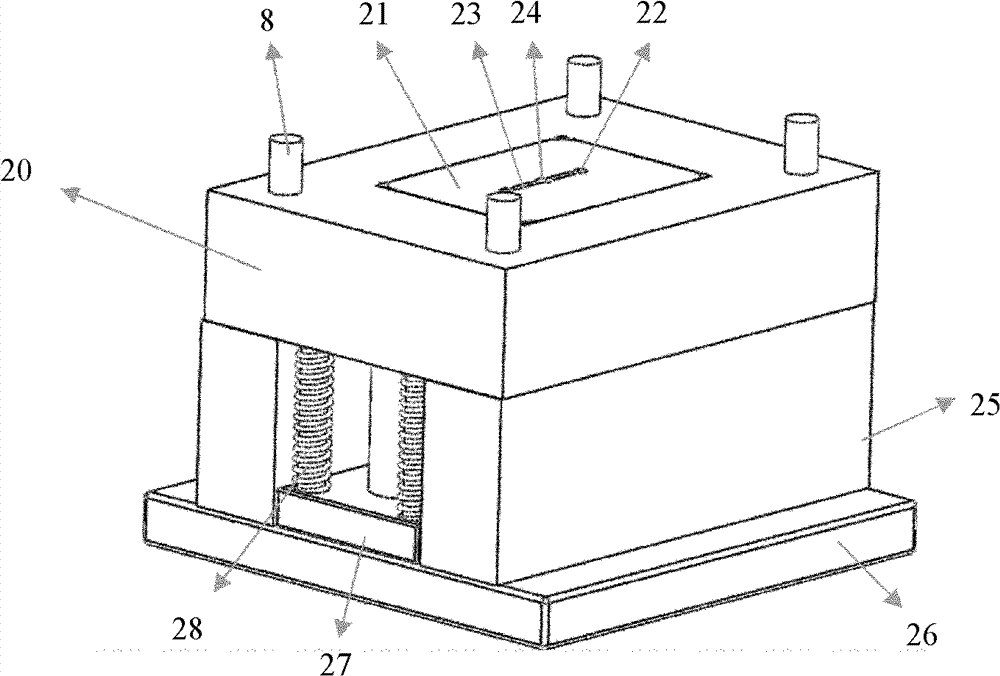

Ultrasonic auxiliary micro injection forming die

Owner:TIANJIN UNIV

a water conservancy equipment

ActiveCN107142944BStable flowImprove injection molding qualityFoundation engineeringEngineeringHydraulic equipment

The invention discloses novel hydraulic equipment. The novel hydraulic equipment comprises a frame body; a port connected with stirring equipment is fixedly mounted at the upper end of the frame body; a transfer groove is formed in the frame body; a first transfer machine is mounted in the transfer groove; a discharge groove lengthened up and down is formed in the frame body; a rotating cavity is formed in the frame body; a discharge port is formed in the bottom wall of the rotating cavity; a rotating frame is rotationally mounted in the rotating cavity; the rotating frame comprises rotating shafts rotationally mounted in the front and back end walls of the rotating cavity, and rotating plates uniformly and fixedly mounted on the rotating shafts; an extension groove is formed in the left end wall of the frame body; a guide groove lengthened up and down is formed in the top wall of the rotating cavity; a through groove is formed in the bottom wall of the guide groove; a guide block is mounted in the guide groove in a up-down sliding manner; a touch rod is fixedly mounted at the lower end of the guide block; and the touch rod penetrates through the through groove to insert in the rotating cavity. The novel hydraulic equipment is simple in structure and low in equipment cost.

Owner:湖南长信建设集团有限公司

Intelligent injection mold facilitating sprue stripping

The invention discloses an intelligent injection mold facilitating sprue stripping. The intelligent injection mold comprises an upper injection mold body and a lower mold plate, wherein an intelligent temperature displayer is fixedly connected to the middle position of the front face of the exterior of the upper injection mold body, and a pouring part is arranged in the middle position of the top end of the exterior of the upper injection mold body; the pouring part comprises a butt joint groove, the bottom end of the butt joint groove is fixedly communicates with an extrusion conical groove, a feeding groove is formed below the butt joint groove, a pouring stirring mechanism is arranged in the middle of the interior of the butt joint groove, and an air separation mechanism is arranged in the middle of the interior of the feeding groove; and the inner side of the pouring stirring mechanism is fixedly connected with a pouring gate deformation mechanism. According to the intelligent injection mold facilitating sprue stripping, materials are separated from the surface of a sprue as far as possible, the size of the materials at the sprue is reduced, and workers can conveniently separate the materials at the sprue.

Owner:赵红艳

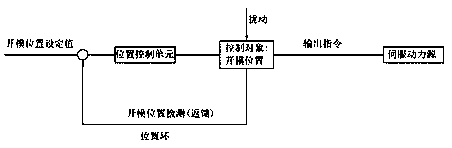

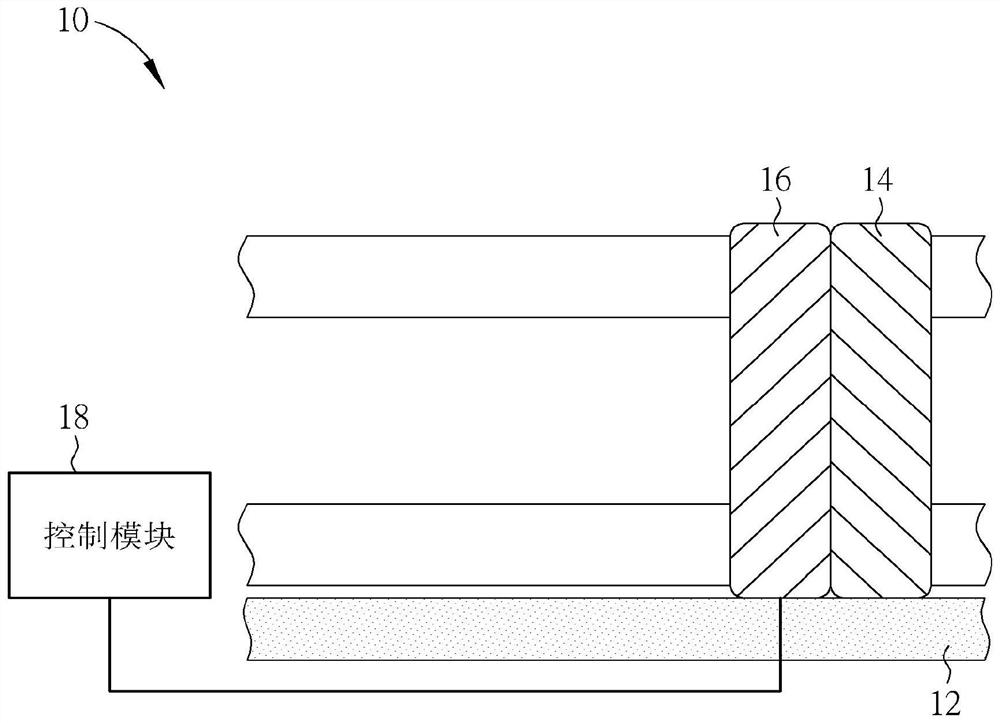

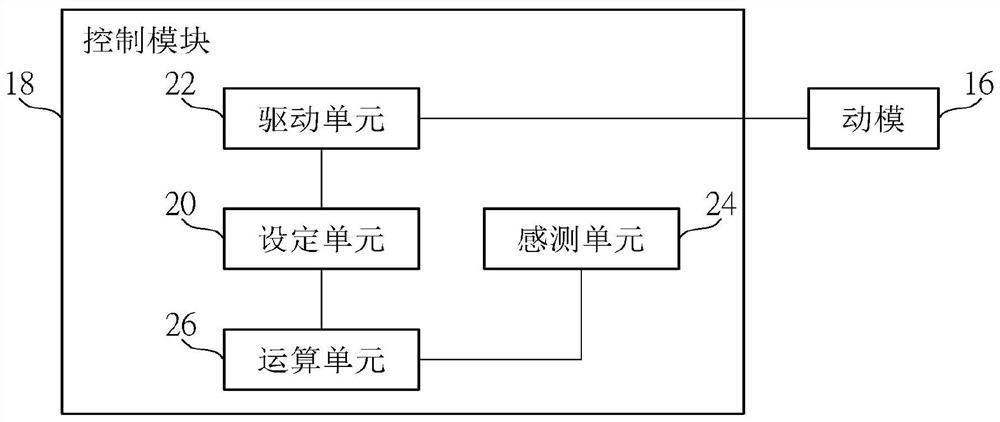

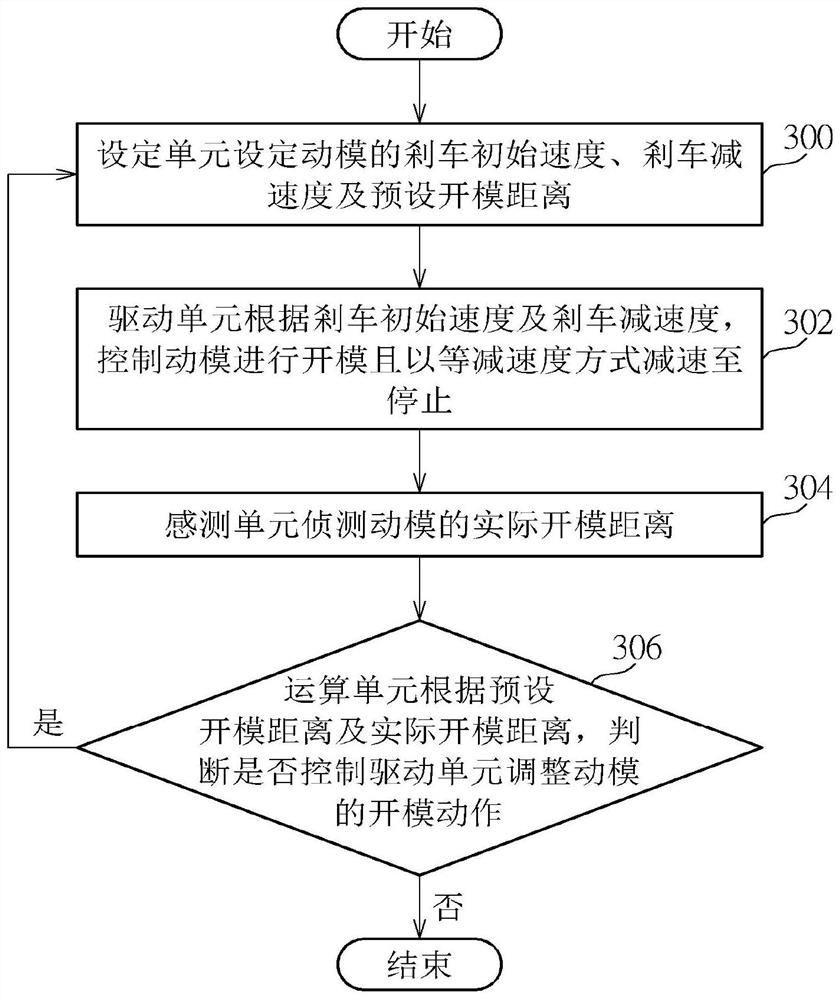

Mold opening control method and injection molding machine thereof

The invention discloses a mold opening control method which is suitable for an injection molding machine table, the injection molding machine table is provided with a movable mold and a static mold, and the movable mold is operably far away from or close to the static mold so as to execute an injection molding process. The mold opening control method comprises the steps that a setting unit sets the brake initial speed, the brake deceleration and the preset mold opening distance of the movable mold, a driving unit controls the movable mold to be opened according to the brake initial speed and the brake deceleration and decelerates to stop in an equal deceleration mode, and a sensing unit detects the actual mold opening distance of the movable mold; and an arithmetic unit judges whether theinitial brake speed and the brake deceleration of the movable mold are changed through the setting unit or not according to the preset mold opening distance and the actual mold opening distance, and controls the driving unit to adjust the mold opening action of the movable mold according to the preset mold opening distance. Therefore, the problem that the machine table shakes and vibrates when themovable mold is controlled by the friction force of the machine table to perform nonlinear deceleration emergency stop in the prior art can be solved, so that the service life of the machine table isprolonged, and the injection molding quality is improved.

Owner:MIRLE AUTOMATION CORPORATION

Novel hydraulic equipment

ActiveCN107142944AStable flowImprove injection molding qualityFoundation engineeringHydraulic equipmentEngineering

The invention discloses novel hydraulic equipment. The novel hydraulic equipment comprises a frame body; a port connected with stirring equipment is fixedly mounted at the upper end of the frame body; a transfer groove is formed in the frame body; a first transfer machine is mounted in the transfer groove; a discharge groove lengthened up and down is formed in the frame body; a rotating cavity is formed in the frame body; a discharge port is formed in the bottom wall of the rotating cavity; a rotating frame is rotationally mounted in the rotating cavity; the rotating frame comprises rotating shafts rotationally mounted in the front and back end walls of the rotating cavity, and rotating plates uniformly and fixedly mounted on the rotating shafts; an extension groove is formed in the left end wall of the frame body; a guide groove lengthened up and down is formed in the top wall of the rotating cavity; a through groove is formed in the bottom wall of the guide groove; a guide block is mounted in the guide groove in a up-down sliding manner; a touch rod is fixedly mounted at the lower end of the guide block; and the touch rod penetrates through the through groove to insert in the rotating cavity. The novel hydraulic equipment is simple in structure and low in equipment cost.

Owner:湖南长信建设集团有限公司

Injection mold for forming double-color product

ActiveCN113771292AScientific and reasonable structureEasy to useMechanical engineeringMaterials science

The invention discloses an injection mold for a forming double-color product. The injection mold comprises a bearing base plate, a first forming mold is installed in the middle of the end face of one side of the bearing base plate, a mold changing assembly is installed on the outer side of the bearing base plate, the outer side of the first forming mold is sleeved with a protection shell, and a sliding shell is installed on the end face of one side of the protection shell; a forming cavity is formed between the protection shell and the first forming mold, a second sliding forming mold is slidably connected to the inner side of the sliding shell, a top sliding barrel is installed at the top of a sliding groove, a sliding fixed mold is slidably connected to the inner side of the top sliding barrel. According to the injection mold for the forming double-color product, the second sliding forming mold stays at different positions, so that mold opening is not needed; therefore, the temperature in the mold cannot be reduced, two materials can be guaranteed to be rapidly fused and bonded when a second material is injected, the success rate of injection molding is guaranteed, the extra time generated by replacing the mold can be shortened, the injection molding quality is improved, meanwhile, the working efficiency is improved, and two purposes are achieved.

Owner:湘巨电子科技(昆山)有限公司

a water conservancy equipment

ActiveCN107150403BStable flowImprove injection molding qualityFeeding arrangmentsAuxillary shaping apparatusEngineeringHydraulic equipment

The invention discloses hydraulic equipment. The hydraulic equipment comprises a frame body; a port connected with stirring equipment is fixedly mounted at the upper end of the frame body; a transfer groove is formed in the frame body; a first transfer machine is mounted in the transfer groove; a drainage groove for extending up and down is formed in the frame body; a rotating cavity is formed in the frame body; a discharge port is formed in the bottom wall of the rotating cavity; a rotating frame is rotationally mounted in the rotating cavity; the rotating frame comprises rotating shafts rotationally mounted in the front and back end walls of the rotating cavity, and rotating plates uniformly and fixedly mounted on the rotating shafts; an extension groove is formed in the left end wall of the frame body; a guide groove for extending up and down is formed in the top wall of the rotating cavity; a through groove is formed in the bottom wall of the guide groove; a guide block is mounted in the guide groove in a up-down sliding manner; a touch rod is fixedly mounted at the lower end of the guide block; and the touch rod penetrates through the through cavity to enter the rotating cavity. The hydraulic equipment is simple in structure and low in equipment cost.

Owner:温岭市仁全机械设备有限公司

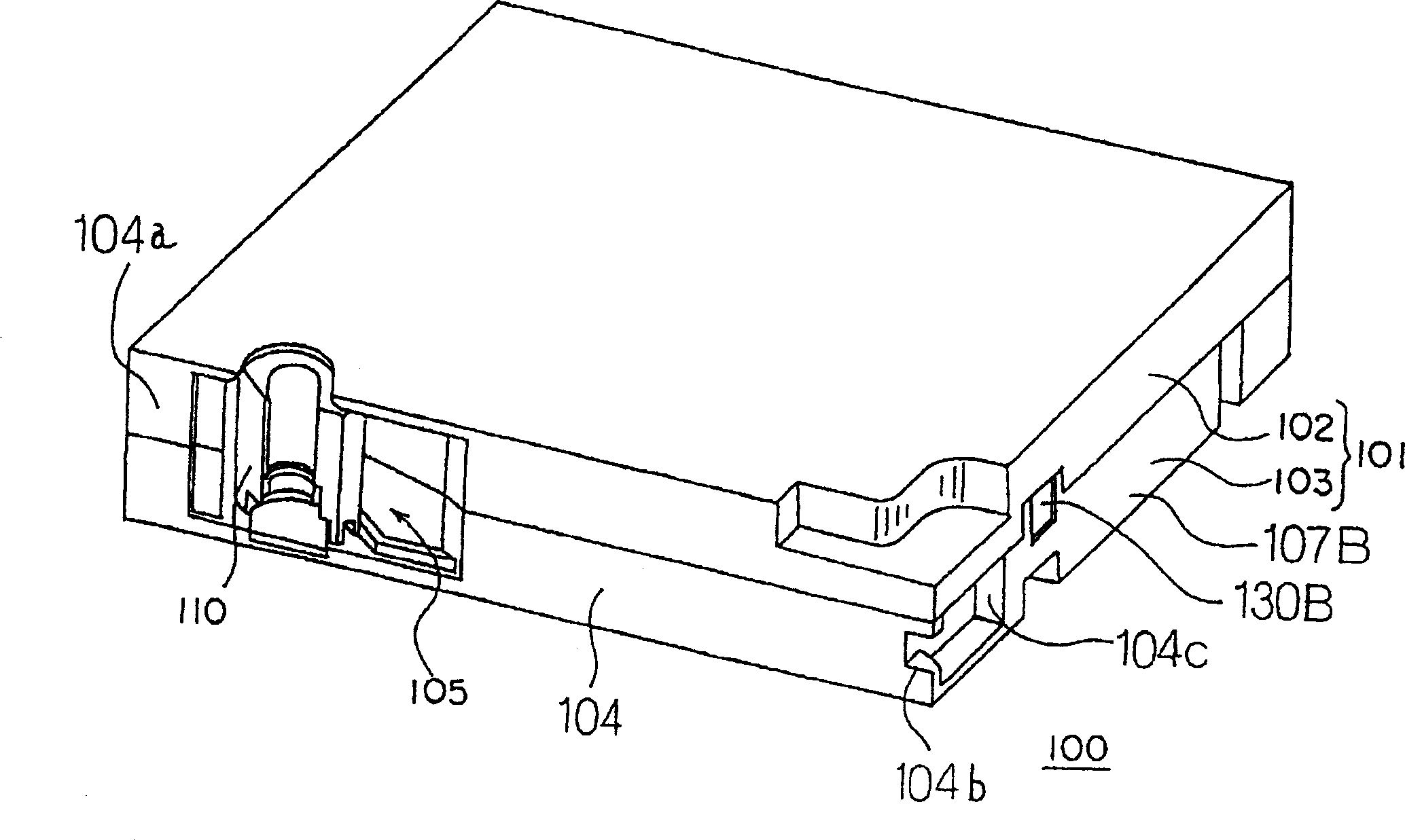

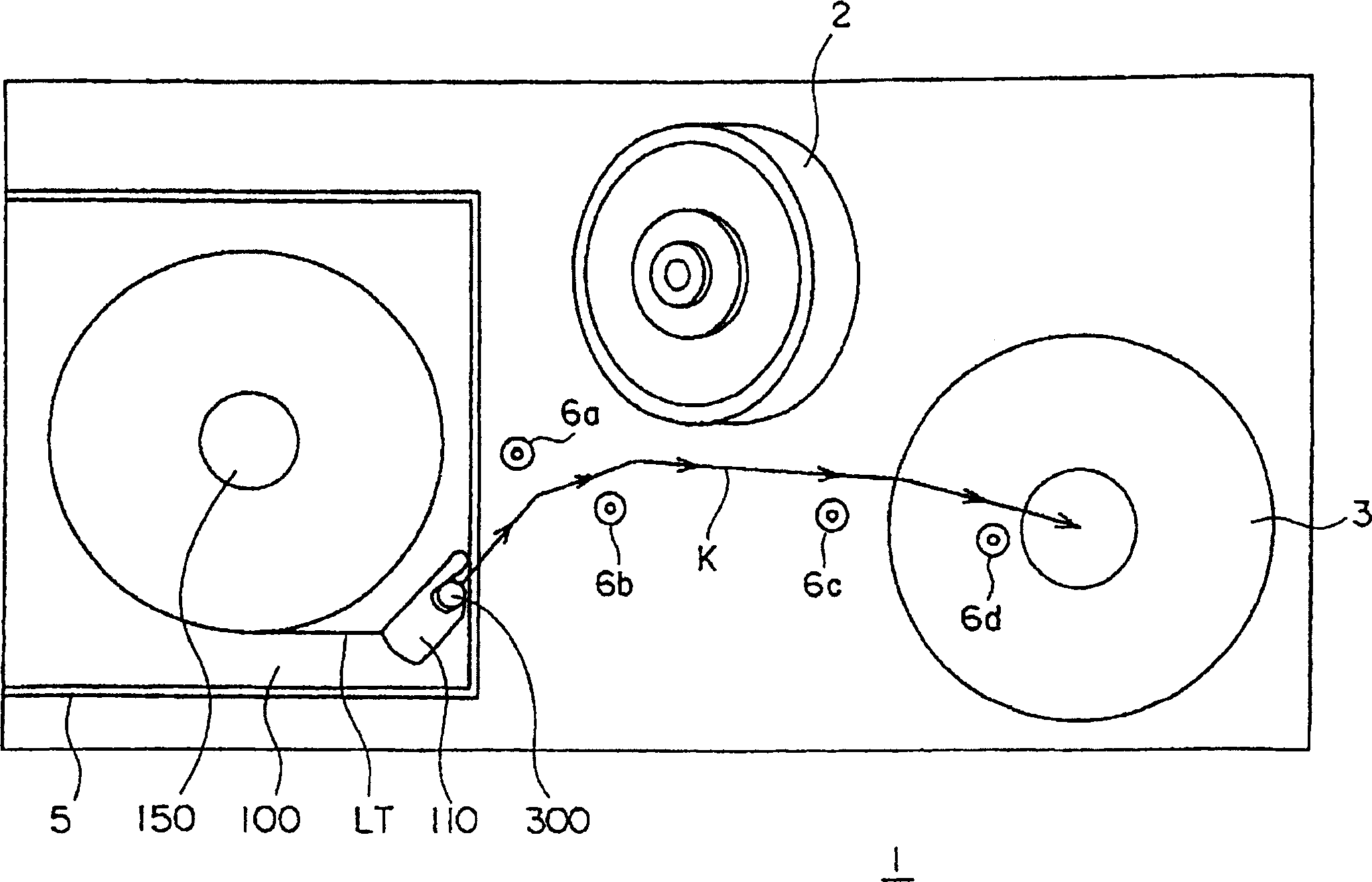

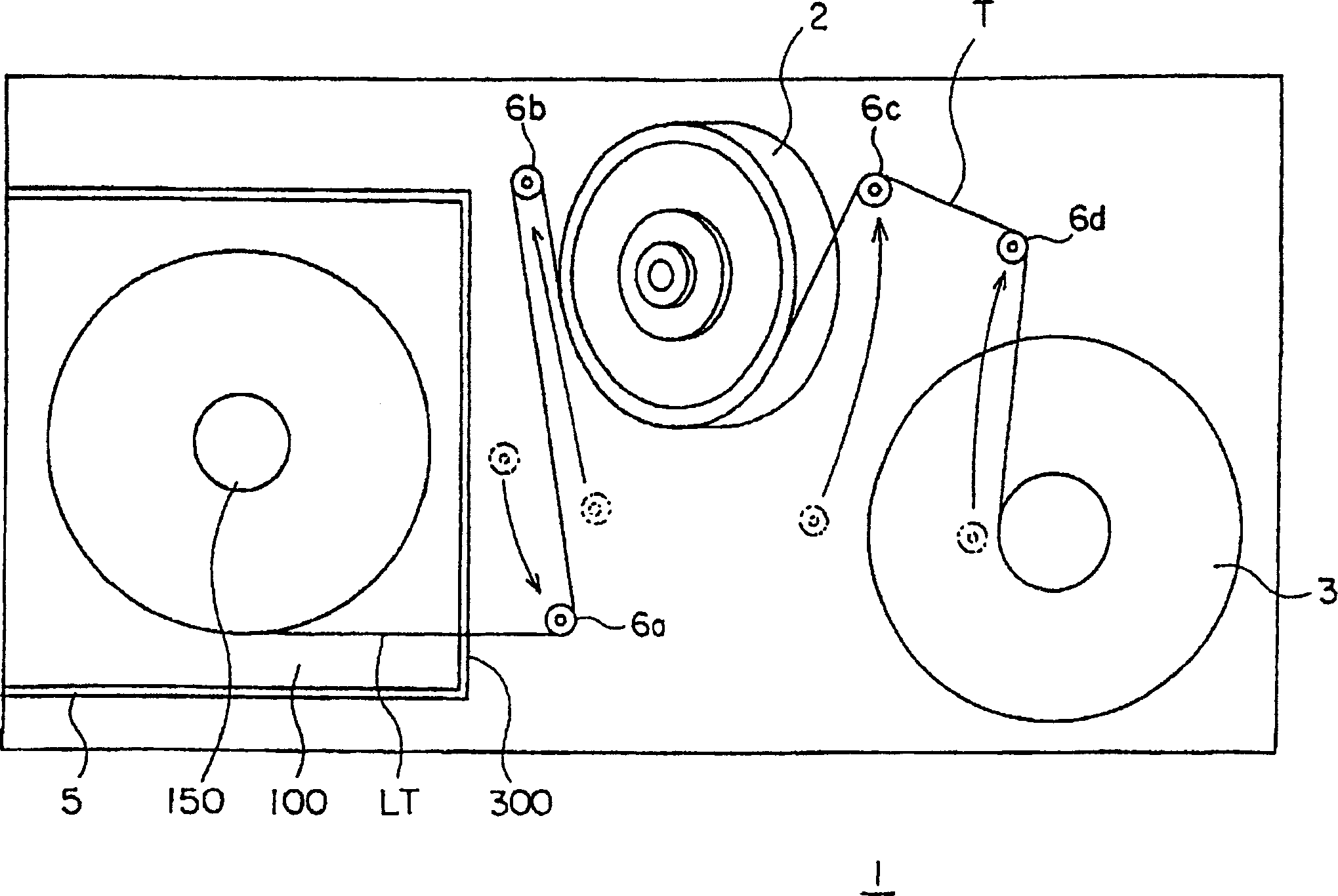

Tape reel and tape cartridge having the same

InactiveCN1502105AReduce saggingImprove injection molding qualityRecord information storageMagazines/cassettes storageMagnetic tapeFlange

A tape reel having an improved reliability during high-speed transport of the magnetic tape by improving the molding quality of the flange portion of the tape reel and a tape cartridge having this are disclosed. Reference faces (152v) are provided between a chucking gear (152b) and an outer circumferential rib (152r2) outside the chucking gear (152b), independently of the outer circumferential rib (152r2). Each of the reference faces (152v) is composed two faces: a first rib (152v1) extending circumferentially and a second rib (152v2) extending perpendicularly to the first rib (152v1). The volume of the portions forming the reference faces (152v) is small, and consequently the sink marks after the resin is cured are suppressed, the molding quality of the flange portion (152) is improved. Consequently, the straight-ahead transportability of the magnetic tape during high-speed transport and the reliability of recording / reproduction are both improved..

Owner:SONY CORP

An integrated anti-collision injection molding equipment for automobile sunroof wrapping

ActiveCN108839300BAvoid false collisionsImprove protectionDomestic articlesEngineeringInjection molding machine

The invention discloses an integrated type anti-collision injection molding machine for vehicle skylight covered edges. The integrated type anti-collision injection molding machine for the vehicle skylight covered edges comprises a work platform; the work platform is provided with an injection molding lower mold; supporting frames are installed at two ends of the surface of the work platform; thetwo supporting frames are fixedly connected through a gantry cross beam; the bottom end of the gantry cross beam is connected with a movable upper mold through a pressure applying mechanism; a movablegroove used for rotation of the injection molding lower mold is installed inside the work platform; a cooling mechanism is installed on the outer wall of the movable upper mold; the injection moldinglower mold is connected with the work platform through a rotary assembly; a reset blocking mechanism is installed at the bottom of the injection molding lower mold; and an injection molding mold cavity is installed on the surface of the injection molding lower mold. The whole injection molding mold is protected by the reset blocking mechanism, the mold angle can be adjusted freely, operation is convenient, the situation of mold collision is avoided during adjusting, the cooling speed is increased in a circular flowing cooling mode, and the molding quality of the vehicle skylight covered edgesis improved.

Owner:芜湖众梦电子科技有限公司

Puncture core rod and puncture device comprising same

Melting-increasing mixing nozzle

PendingCN113459409AFlip over to melt and mix wellImprove injection molding qualityPlasticultureEngineering

The invention discloses a melting-increasing mixing nozzle. The melting-increasing mixing nozzle comprises a sub-nozzle, a flange connector and at least one melting-increasing valve core, the melting-increasing valve core is of a cylinder structure, at least one group of mixing flow channels are formed in the periphery of the melting-increasing valve core in the axial direction, and each mixing flow channel is formed by connecting a plurality of grooves with different depths. The melting-increasing valve core in the melting-increasing mixing nozzle adopts the cylindrical structure, and the plurality of grooves with different depths are formed in the periphery of the melting-increasing valve core, so that plastic is better to climb over, melt and mix, and the injection molding quality is greatly improved; and the nozzle is simple and novel in structural design, the defects that an existing screw is poor in plasticization and color mixing, unstable in glue melting time, not easy to clean after color changing, black spots and black lines exist and the like are effectively overcome, the production efficiency is improved, and the production cost of enterprises is reduced.

Owner:GILLKON SCREW MFG SHANGHAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com