Injection mold for forming double-color product

An injection mold and molding mold technology, applied in the field of injection molds for forming two-color products, can solve the problems of cooling molding shrinkage, difficult bonding, injection failure, etc., to prevent shrinkage and cracking, safe and convenient to use, and ensure integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

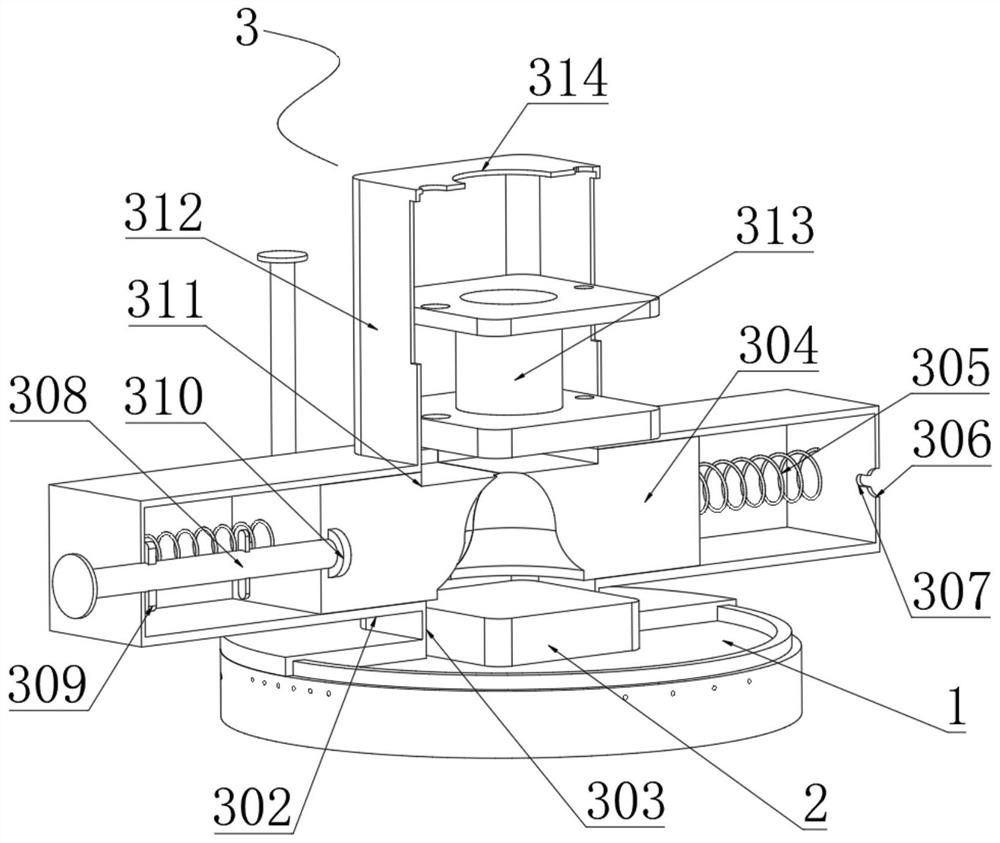

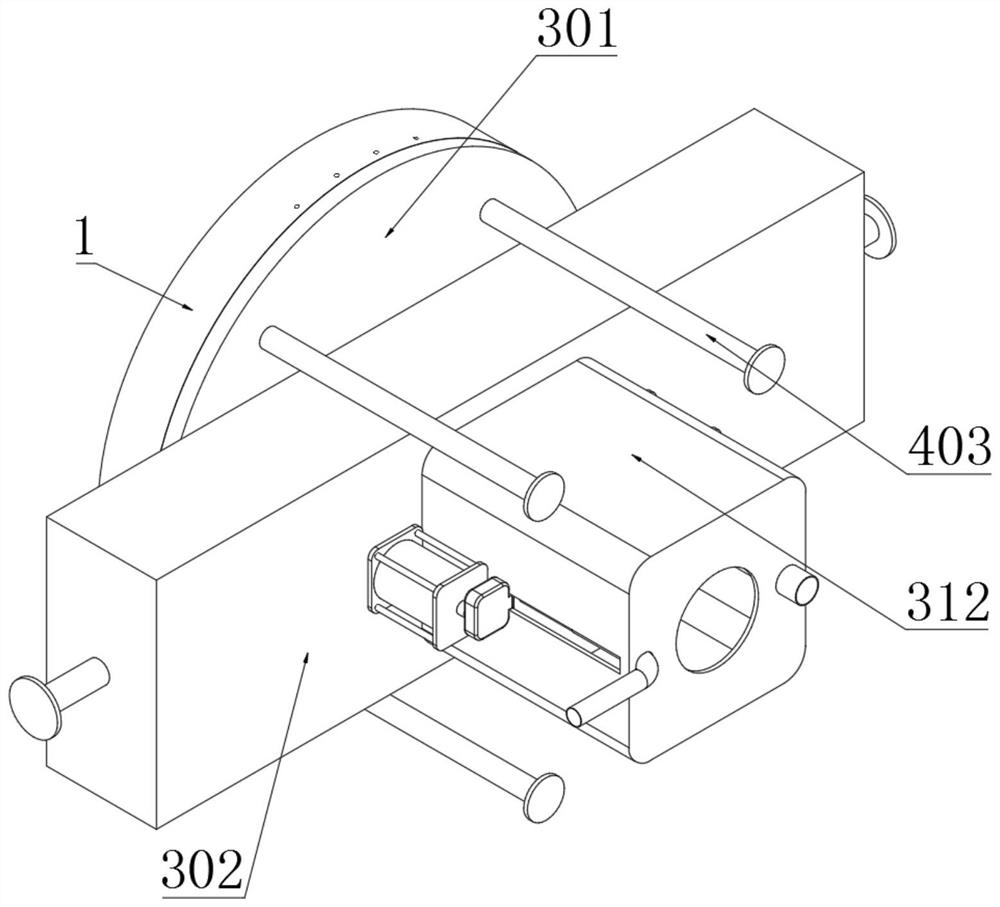

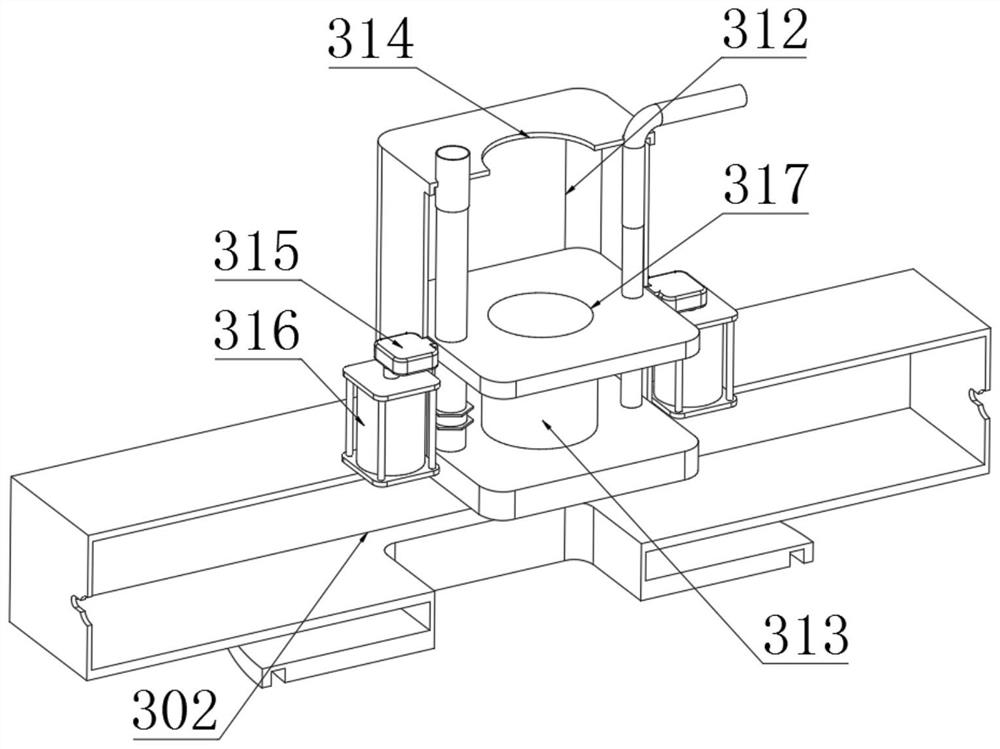

[0029] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, an injection mold for forming two-color products, including a receiving chassis 1, a first forming mold 2 is installed at the middle of the end face of one side of the receiving chassis 1, and a Die changing component 3;

[0030] The mold change assembly 3 includes a protective shell 301, a sliding shell 302, a molding chamber 303, a second sliding molding mold 304, a return spring 305, a sliding groove 306, a limiting chute 307, a pulling rod 308, a limiting block 309, Rotating block 310, clamping groove 311, top sliding cylinder 312, sliding fixed film 313, injection hole 314, moving block 315, cylinder 316 and internal injection hole 317;

[0031] The outer side of the first molding die 2 is sleeved with a protective shell 301, and a sliding shell 302 is installed on one end surface of the protective shell 301. A molding chamber 303 is formed between the protective shell 301 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com