Injection mold for flame retardant housing of data interaction device

A technology of data interaction and injection molding, which is applied in the field of communication equipment manufacturing, can solve problems such as poor injection molding quality, and achieve the effect of improving injection molding quality and ensuring meltability and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

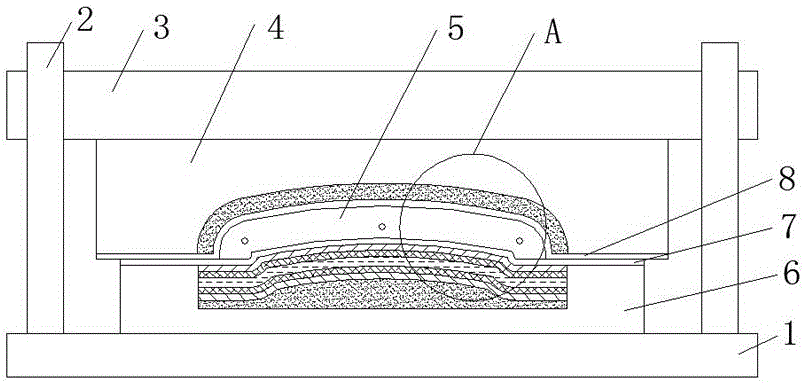

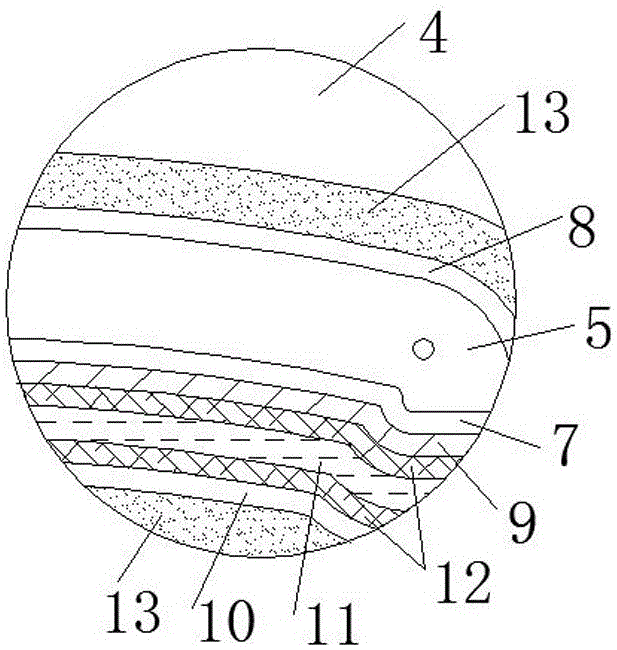

[0021] The injection mold for the flame-retardant housing of the data interaction device in this embodiment includes a fixed mold installation plate and a fixed mold, the fixed mold is installed above the fixed mold installation plate, guide columns are arranged around the fixed mold installation plate, The upper end of the guide column is covered with a movable mold mounting plate, and a movable mold is installed under the movable mold mounting plate. The movable mold includes a movable mold cavity, and the fixed mold includes a fixed mold cavity. The movable mold cavity Together with the fixed film cavity, a pouring cavity is formed, and the pouring cavity is connected with a pouring channel. The fixed mold includes a mold core and a template provided with a fixed mold cavity, and a heating device is arranged between the mold core and the template. The heating device includes an outer cylinder and an inner cylinder, the inner cylinder is fixedly connected with the template, a...

Embodiment 2

[0023] The injection mold for the flame-retardant housing of the data interaction device in this embodiment includes a fixed mold installation plate and a fixed mold, the fixed mold is installed above the fixed mold installation plate, guide columns are arranged around the fixed mold installation plate, The upper end of the guide column is covered with a movable mold mounting plate, and a movable mold is installed under the movable mold mounting plate. The movable mold includes a movable mold cavity, and the fixed mold includes a fixed mold cavity. The movable mold cavity Together with the fixed film cavity, a pouring cavity is formed, and the pouring cavity is connected with a pouring channel. The fixed mold includes a mold core and a template provided with a fixed mold cavity, and a heating device is arranged between the mold core and the template. The heating device includes an outer cylinder and an inner cylinder, the inner cylinder is fixedly connected with the template, a...

Embodiment 3

[0025] The injection mold for the flame-retardant housing of the data interaction device in this embodiment includes a fixed mold installation plate and a fixed mold, the fixed mold is installed above the fixed mold installation plate, guide columns are arranged around the fixed mold installation plate, The upper end of the guide column is covered with a movable mold mounting plate, and a movable mold is installed under the movable mold mounting plate. The movable mold includes a movable mold cavity, and the fixed mold includes a fixed mold cavity. The movable mold cavity Together with the fixed film cavity, a pouring cavity is formed, and the pouring cavity is connected with a pouring channel. The fixed mold includes a mold core and a template provided with a fixed mold cavity, and a heating device is arranged between the mold core and the template. The heating device includes an outer cylinder and an inner cylinder, the inner cylinder is fixedly connected with the template, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com