Tape reel and tape cartridge having the same

A technology of tape reels and gears, applied in the field of tape cassettes having the tape reels, can solve the problems of data damage to the reliability of recording/playback operations and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

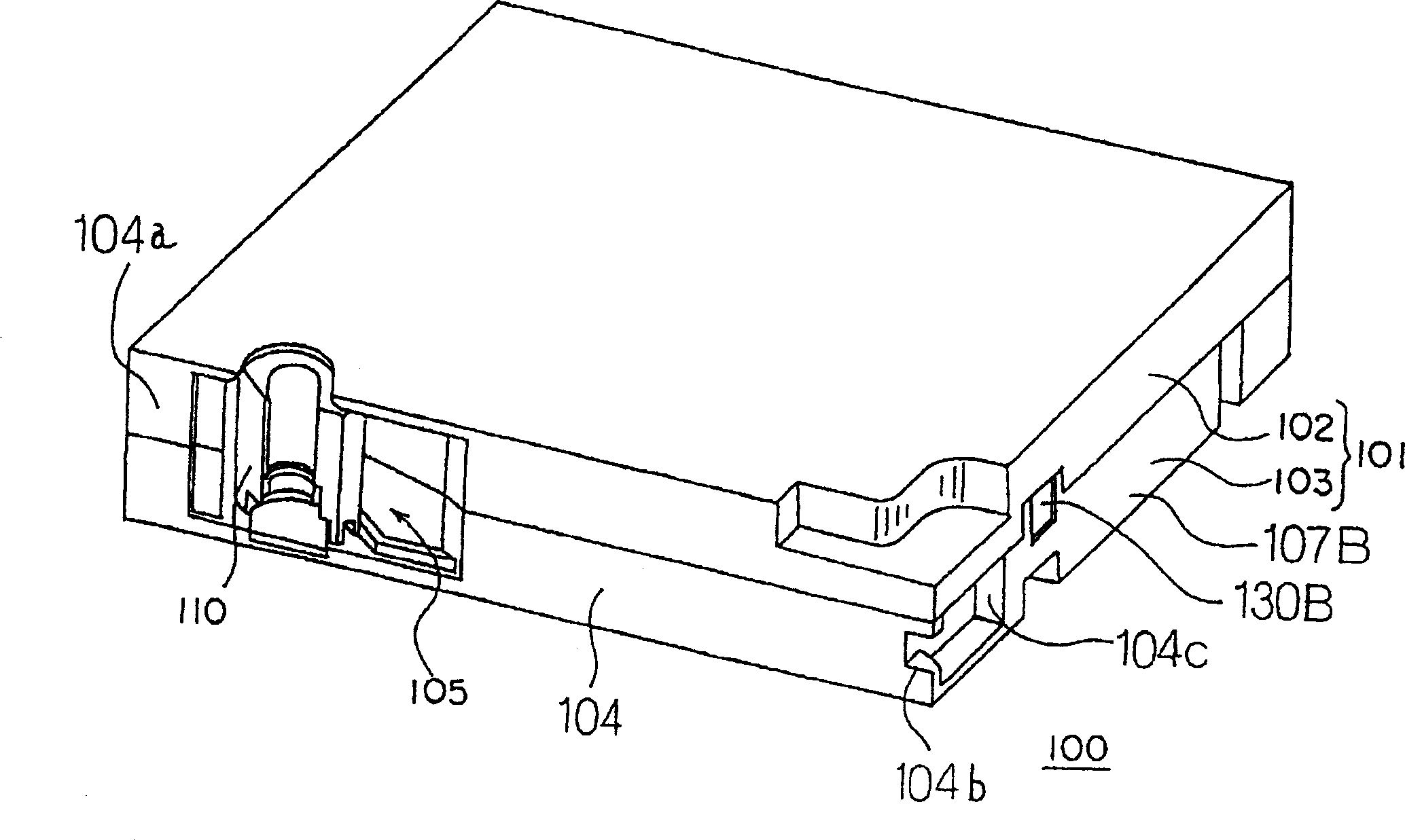

[0049] figure 1 A perspective view showing an external form of a tape cassette according to an embodiment of the present invention.

[0050] Such as figure 1 As shown, the belt box 100 of the present embodiment has a substantially rectangular chamber 101, comprising: an upper cover 102 and a lower cover 103, and an opening 105 arranged in the chamber 101 and the front panel 104 of the chamber 101 The boot block 110.

[0051] The upper cover 102 and the lower cover 103 are formed by injection molding using synthetic resin, such as polycarbonate.

[0052]Moreover, the guide block 110 is connected to one end of the magnetic tape, and the magnetic tape is wound on a tape roll through a guide tape, and the tape roll is accommodated by the chamber 101 (not shown in the figure).

[0053] The front panel 104 of the chamber 101 is the end where the tape cassette is inserted toward the tape drive, and the opening 105 is formed on the chamber 101; figure 1 in the left end), and th...

no. 2 example

[0115] Below, refer to the attached Figure 13 with Figure 14A to Figure 14C A second embodiment of the present invention is described.

[0116] here, Figure 13 A bottom view of the lower flange unit 252 constituting the coil in this embodiment is shown. and Figure 14B with Figure 14C A schematic diagram showing the flow of resin in the main part during injection molding at positions cut by section lines SS31 and SS32, respectively.

[0117] An annular protruding portion 252f engages with an annular opening formed in the lower cover, the opening being disposed at the center of the lower surface of the lower flange unit 252 of this embodiment.

[0118] The protruding portion 252 has a ring clamping gear 252b inside. When the tape cassette is received by the tape receiving unit of the tape drive, the gear 252b meshes with the gear 271a of the rotation shaft provided by the tape drive, and transmits the rotation of the rotation shaft to the tape roll.

[0119] Furtherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com