Patents

Literature

34results about How to "Guaranteed melting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

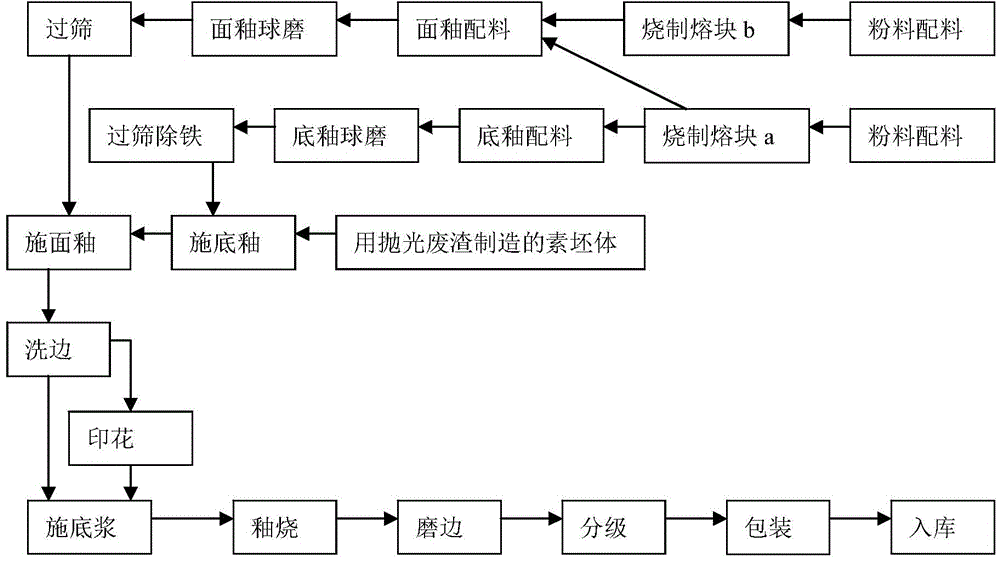

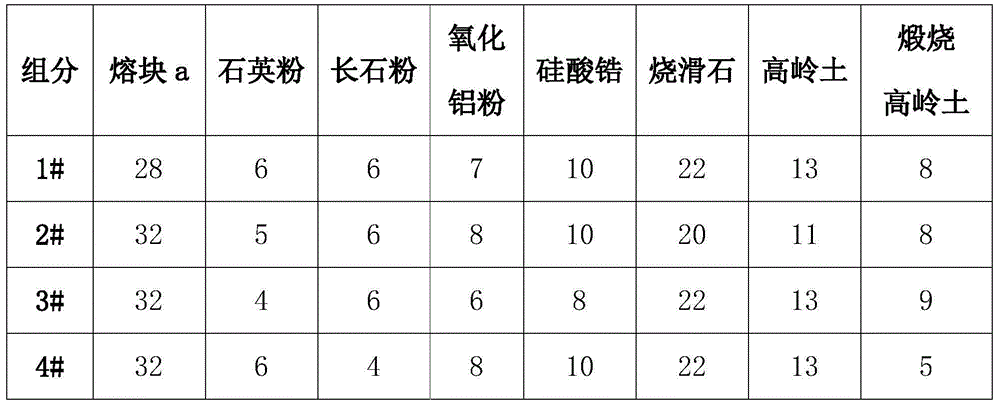

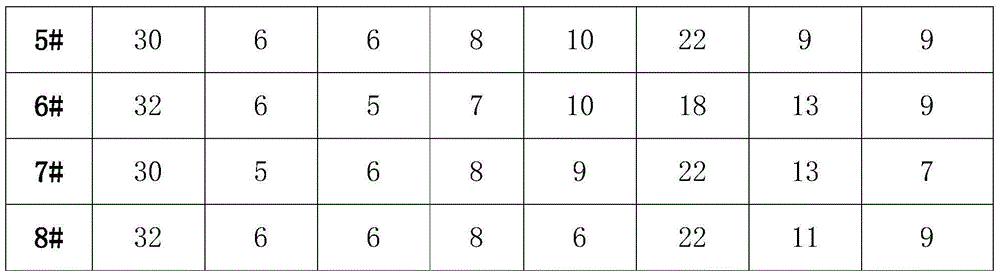

Pure black glazed tile produced by using waste glaze slip and preparation method of pure black glazed tile

The invention provides a pure black glazed tile produced by using waste glaze slip and a preparation method of the pure black glazed tile in order to overcome the defects. On the basis of greatly unchanging the existing production process of glazed tiles, by optimizing the composition of ground coat and cover coat frits, the formula composition of the ground coat, the formula composition of the cover coat, regulating and optimizing ground coat and cover coat technological processes, especially the preferable section of green body types, the fired pure black glazed tile is pure in color, and the chromaticity (L *, a *, b *) value of an unprinted product is measured by a WSD-3C type whiteness colorimeter, wherein the L * (lightness) value is 6.25 to 6.43 and is close to the L * (lightness) value of 5.0 of standard carbon black, the a * (redness) value is -0.03 to 1.60, and the b * (yellowness) value is 0.15 to 0.18. The glazed tile is carbon black like pure black, the glaze has good quality, is moisturized and bright, and has no pinholes, glaze bubbles and other defects, and the glazed tile has strong decorative effect and aesthetic feeling; meanwhile, the technology has strong universality and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

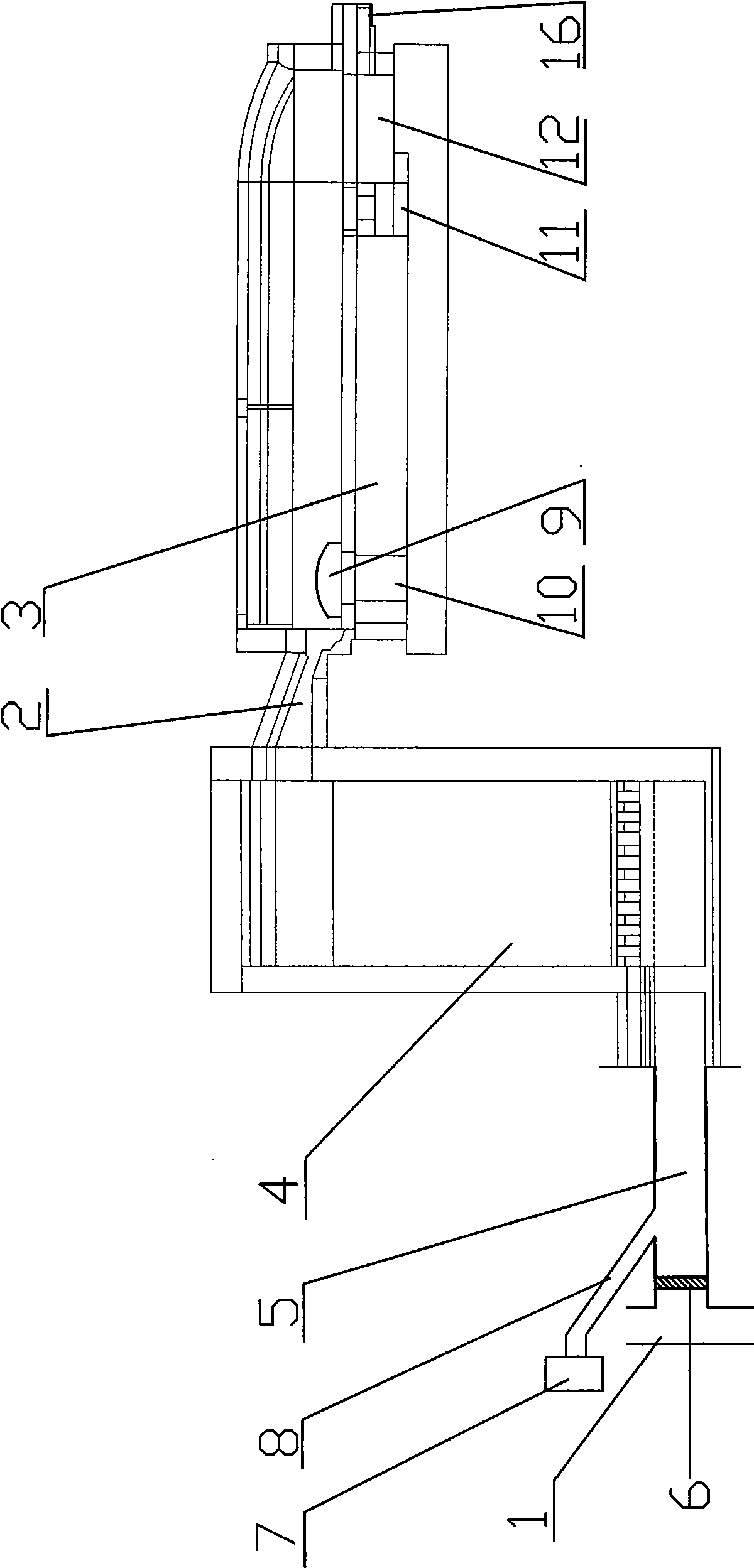

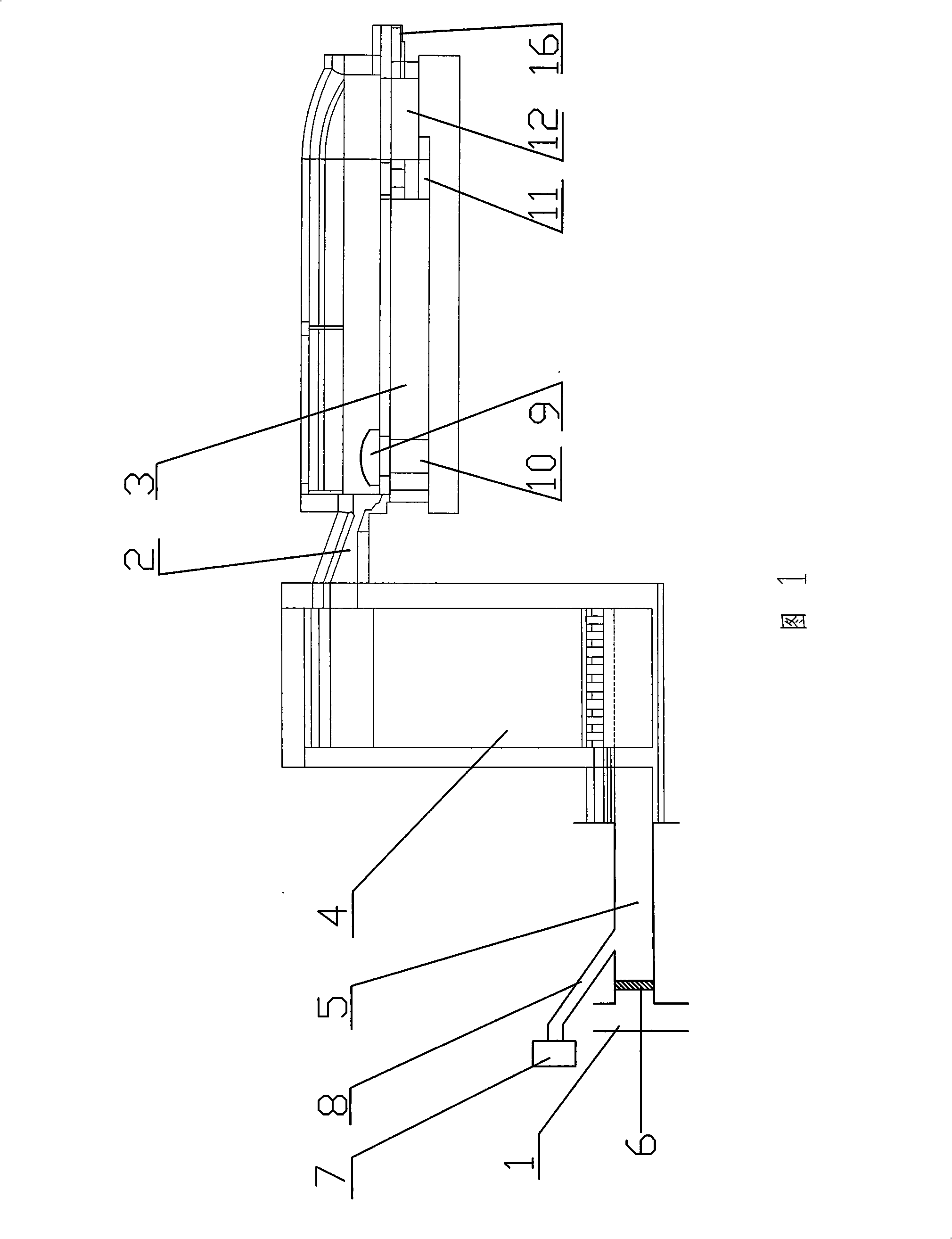

Production formula for alkali-resistant glass marble, production method and production kiln thereof

ActiveCN101531457AMix well and evenlyControl moisture contentGlass furnace apparatusGlass shaping apparatusProduction rateCLARITY

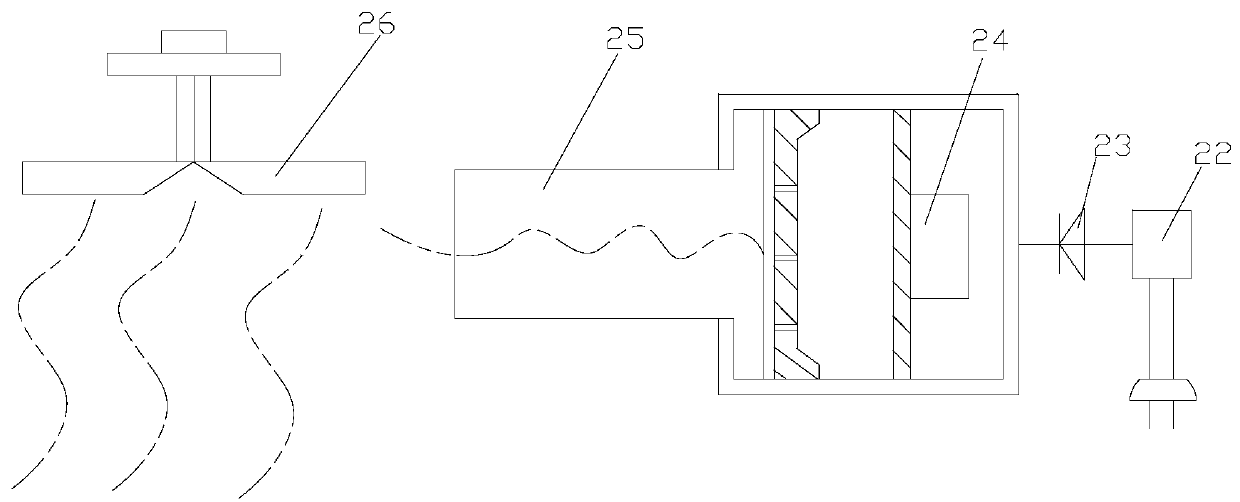

The invention relates to a production formula for alkali-resistant glass marble in building material industry, a production method and a production kiln thereof. The invention is reasonable in selecting weight proportions of ingredients, which is favorable for the control of quality system, and the produced finished product of the glass marble has high clarity and good quality; the entire technological process consists of screening, weighting and mixing raw materials, founding and discharging, the technology is simple and the operation is convenient; using a horseshoe-fired furnace for producing the alkali-resistant glass marble solves the technical prejudice in a long term that the horseshoe-fired furnace is unsuitable for the production of the alkali-resistant glass marble; a general glass marble kiln is utilized to realize the production of the alkali-resistant glass marble without improving kiln refractory, which has the advantages of large production scale, easy control and regulation for the production process, good scale effect and prominent energy-saving effect; the cost is dramatically reduced while the production rate is greatly improved in contrast to a full-electric melting kiln.

Owner:ZIGONG DENGGUAN GLASS FIBER

Anti-blocking injection molding machine

The invention discloses an anti-blocking injection molding machine is characterized in that an injection molding gun barrel is welded to one end of a supporting entering box, a conveying auger is welded to the side end of a movable transmission rod, a movable supporting barrel is welded to one end of a clamping sealing block, a reset spring is welded to one end of the movable supporting barrel, and an auxiliary moving block is welded to the bottom end of the supporting entering box; and a driving rack is welded to one end of the auxiliary moving block, a cleaning plate is rotationally connected to one end of a sliding moving plate, a pushing electromagnet is installed on the inner side of a sliding cavity, a pushing spring is welded to one end of the inner side of the sliding cavity, and an anti-blocking column is welded to one end of the pushing spring. The conveying auger and a reverse flow preventing threaded column drive a raw material to move and prevent the raw material from backflow, the hollow situation is avoided, and a contact switch controls the opening and closing of the pushing electromagnet, so that the anti-blocking column can be quickly reset when needing to be reset, and the discharge port is sealed while the requirement for discharging solidified raw materials at the discharge port position is met.

Owner:姚新耿

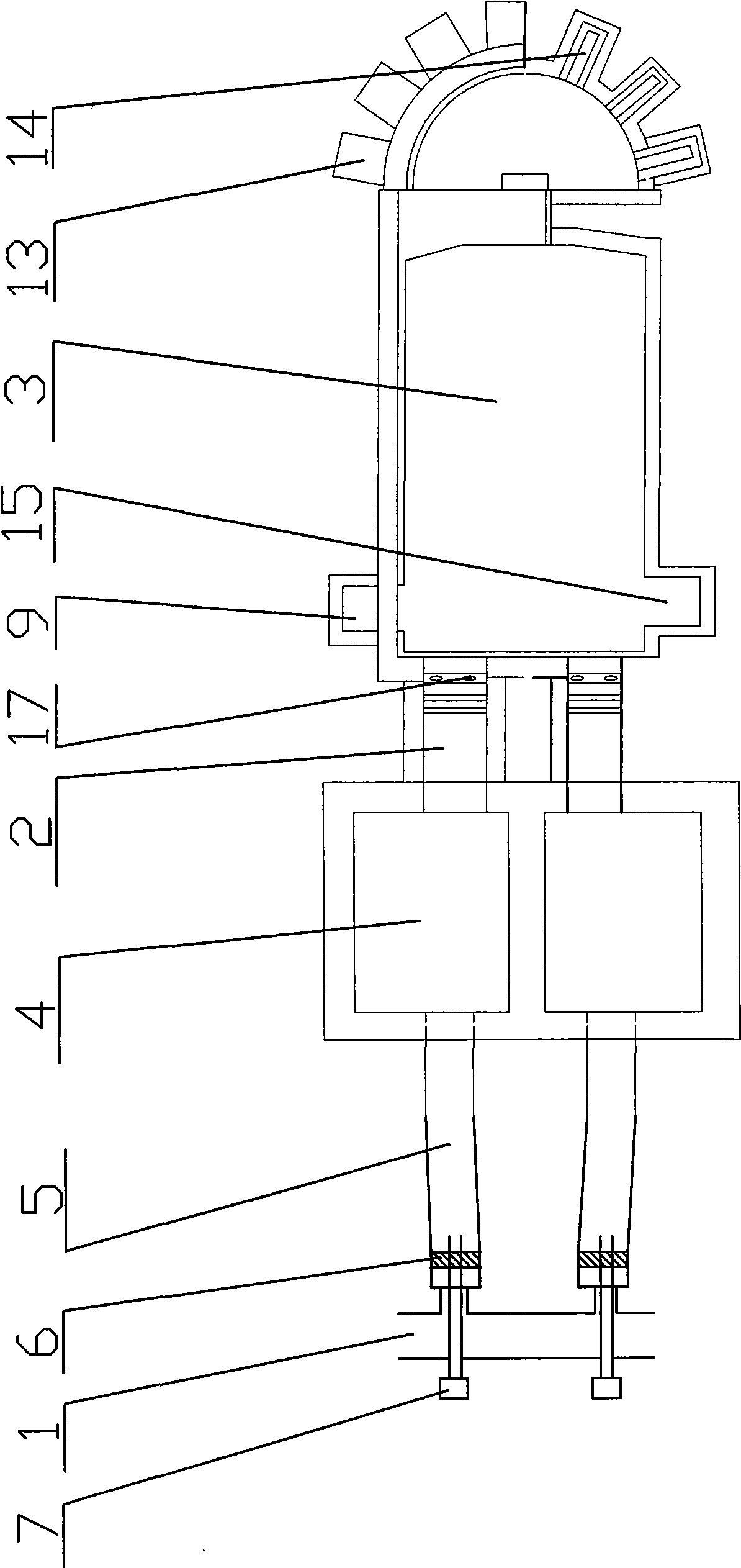

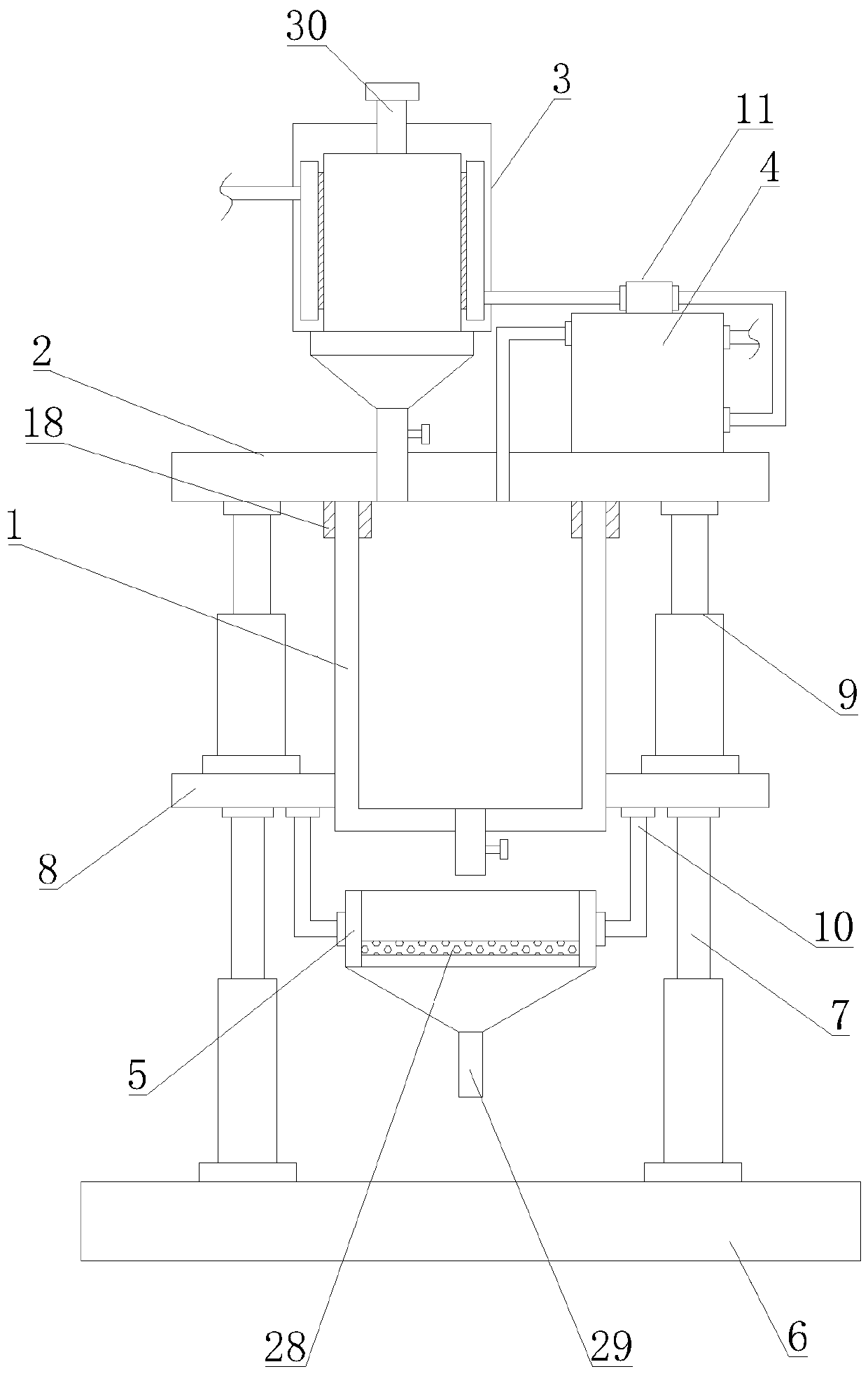

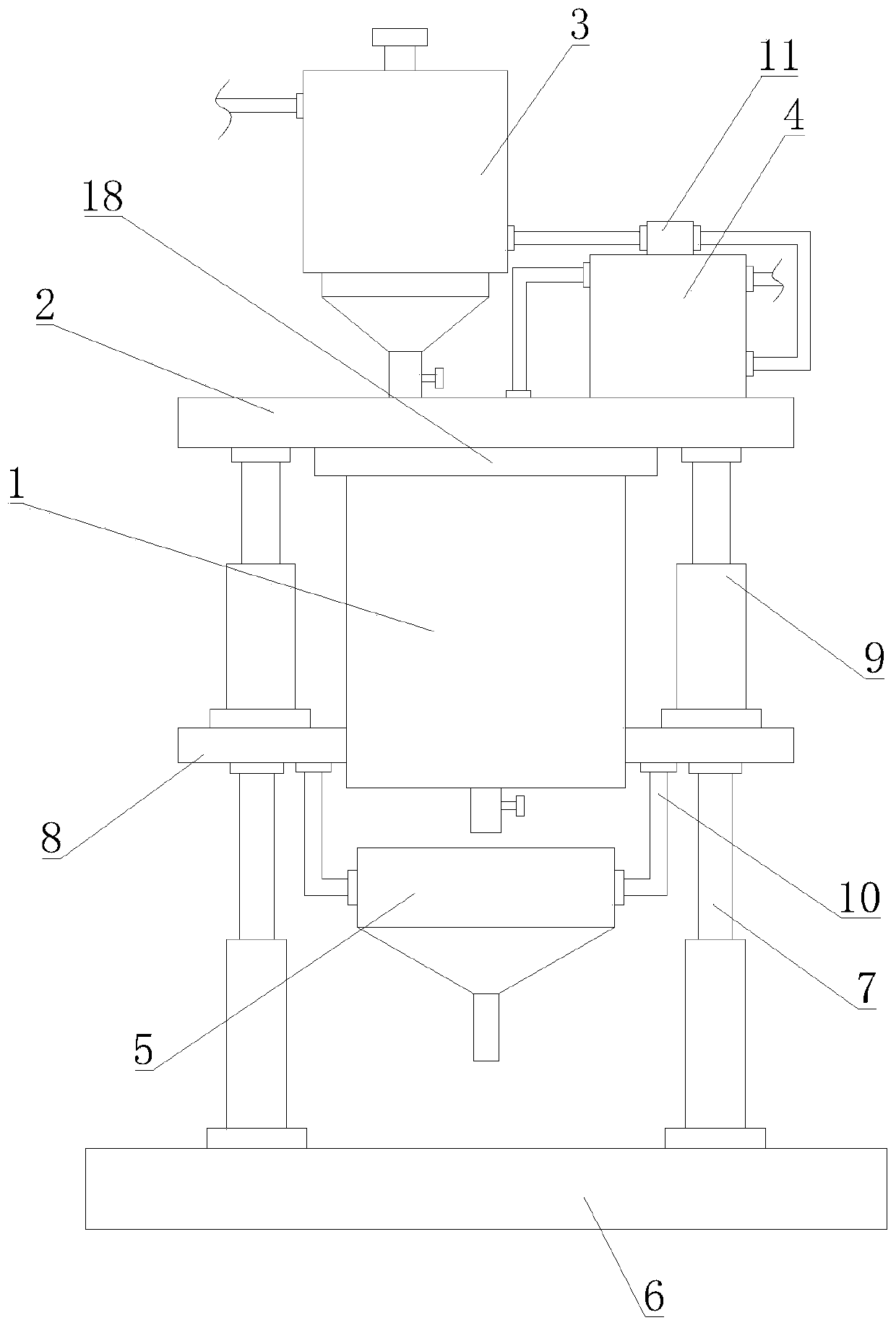

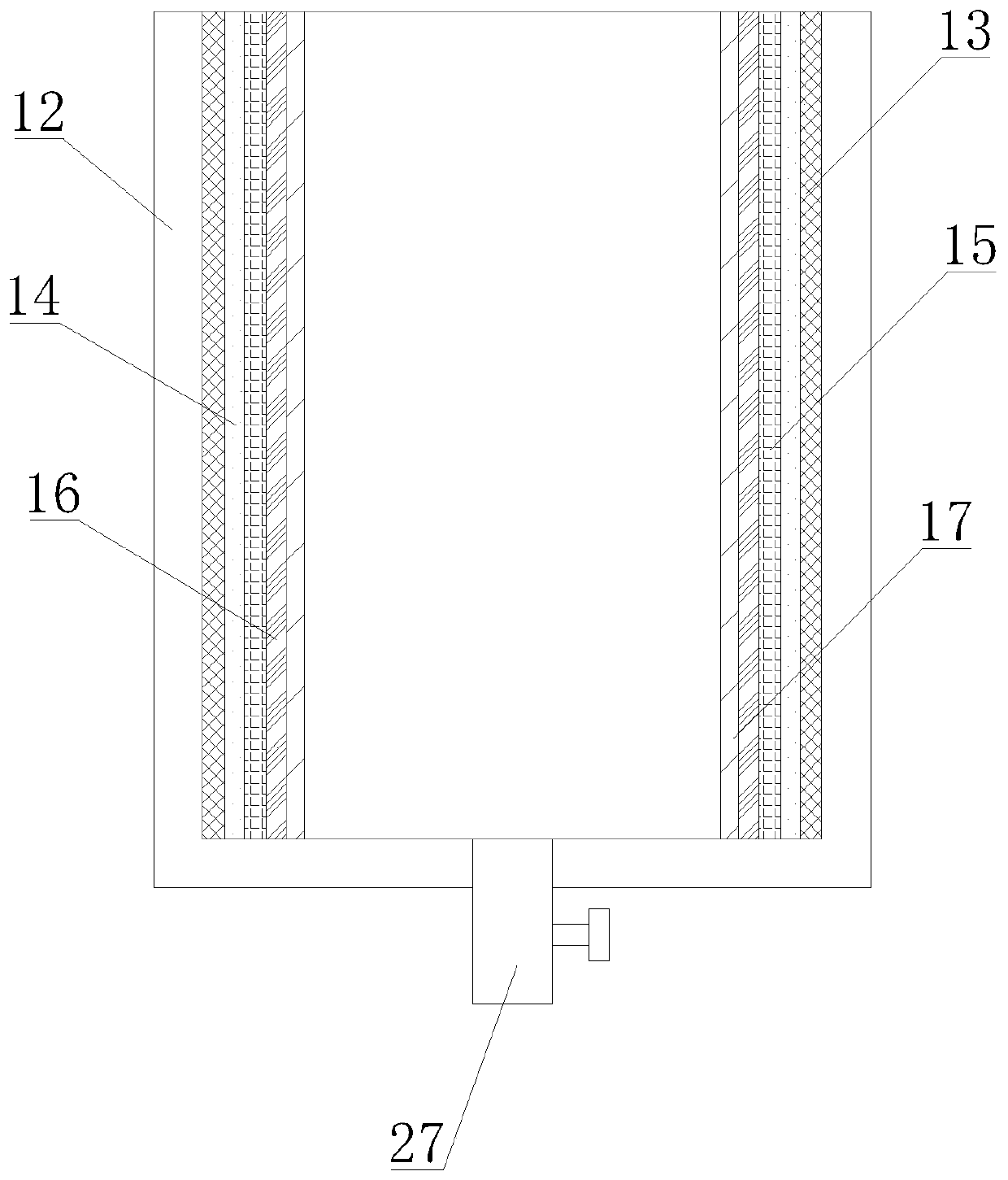

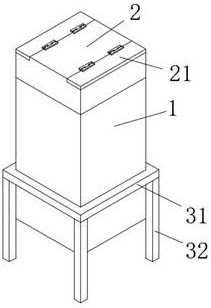

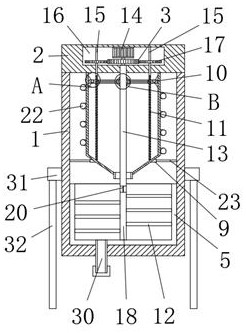

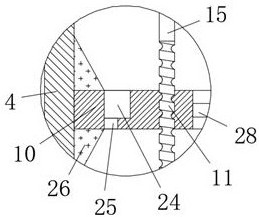

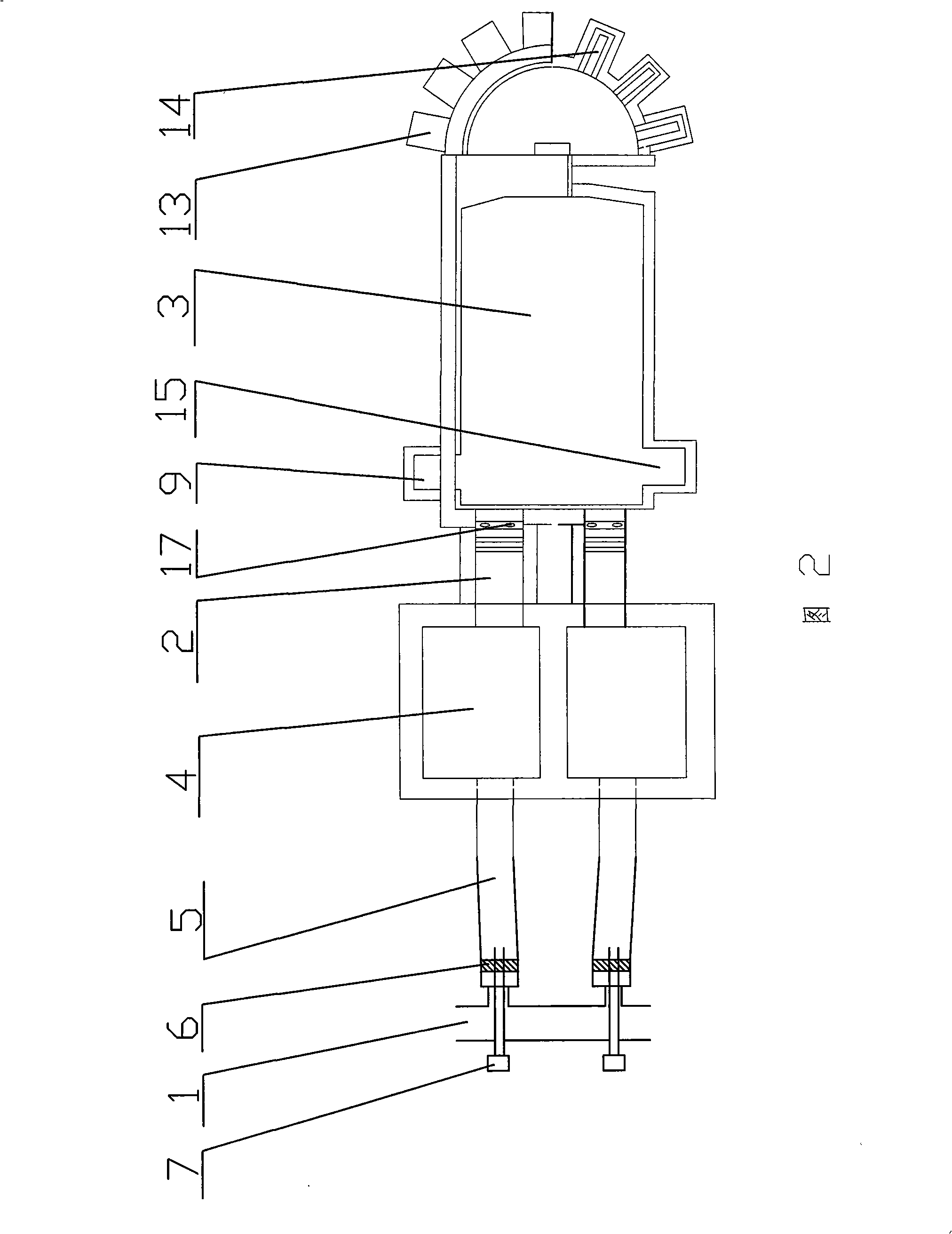

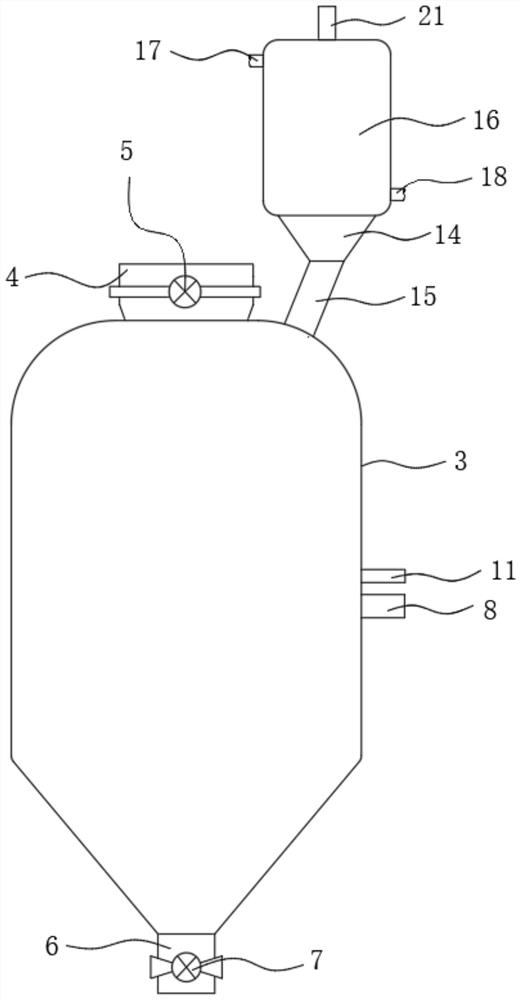

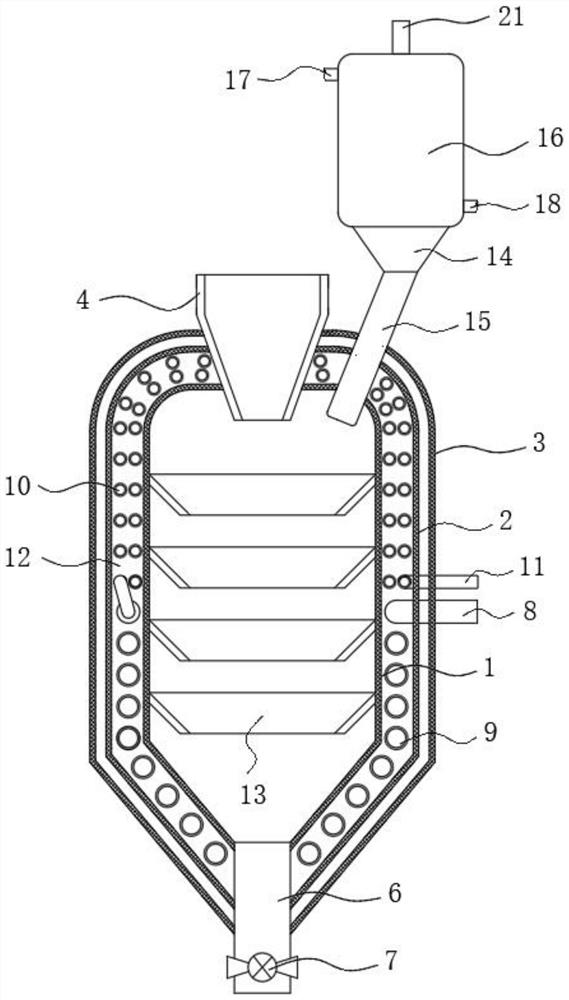

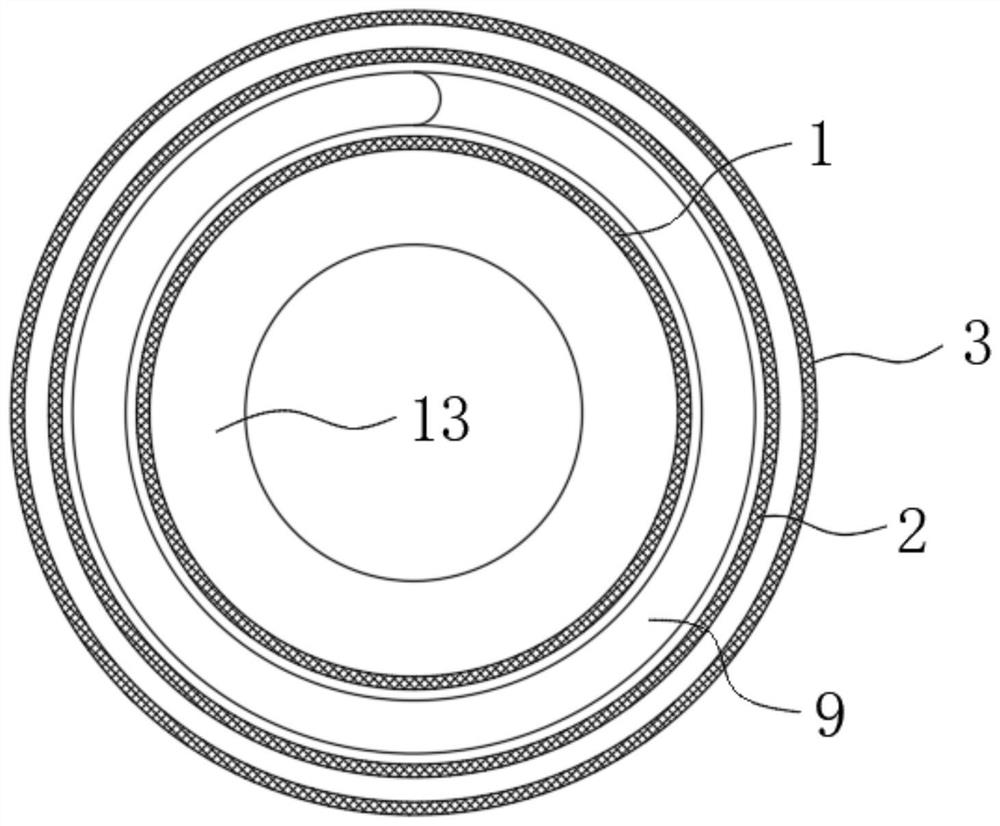

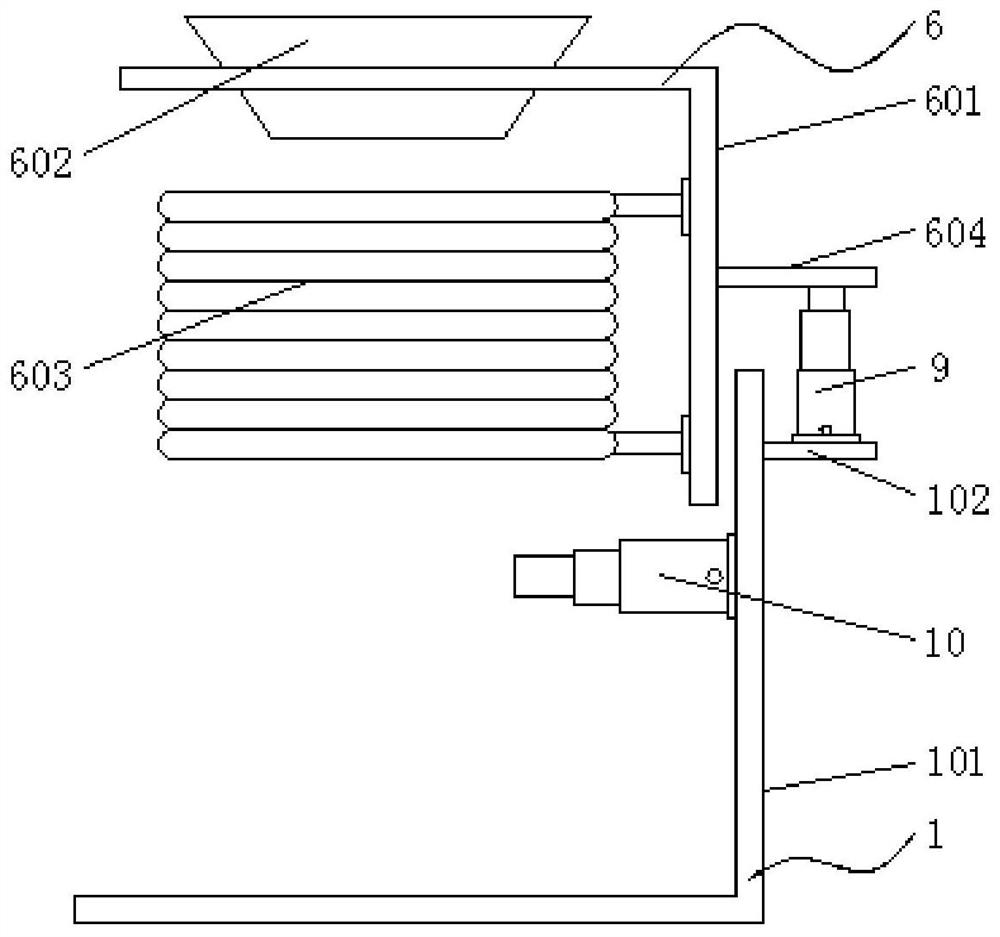

Environment-friendly smelting furnace for nickel-based alloy powder coating

InactiveCN110411208AIncrease temperatureExtended service lifeCharge manipulationIncreasing energy efficiencySmelting processAlloy

The invention belongs to the technical field of smelting furnaces, and particularly relates to an environment-friendly smelting furnace for a nickel-based alloy powder coating. The furnace aims to solve the problem that an existing smelting furnace is not energy-saving and environment-friendly. According to the technical scheme, the furnace comprises a smelting furnace body, a smelting furnace cover body, a material storage tank and a purification heat absorption tank, wherein the smelting furnace cover body is arranged on the smelting furnace body, the material storage tank is arranged on thesmelting furnace cover body, a material conveying pipe is arranged on the material storage tank, a liquid storage cavity is formed in the material storage tank, a connecting pipe communicates the liquid storage cavity and the purification heat absorption tank, a water pump is arranged on the connection pipe, a liquid discharge pipe is arranged on the material storage tank and communicates with the liquid storage cavity, the purification heat absorption tank is arranged on the smelting furnace cover body, one end of an air inlet pipe extends into the smelting furnace body, the other end of theair inlet pipe extends into the purification heat absorption tank, and a gas exhaust pipe is arranged on the purification heat absorption tank. According to the furnace, the operation is convenient,the safety performance is good, the heat preservation effect is good, the energy consumption is reduced, waste gas in the smelting process can be purified, the heat in the waste gas can be absorbed and utilized, and the energy-saving and environment-friendly effects are realized.

Owner:扬州安泰威合金硬面科技有限公司

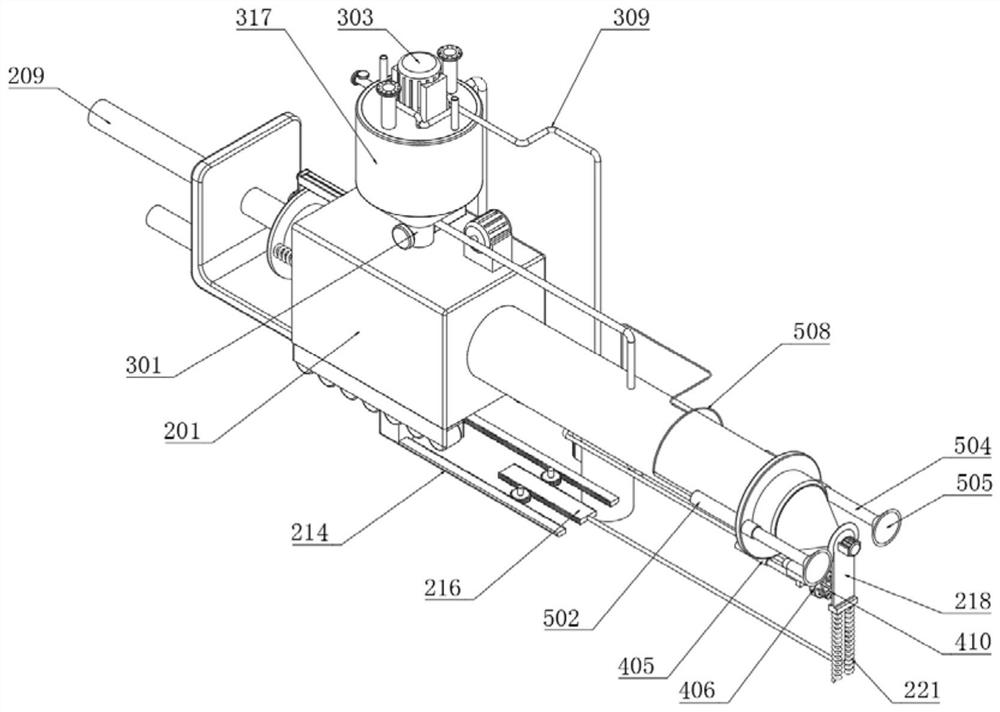

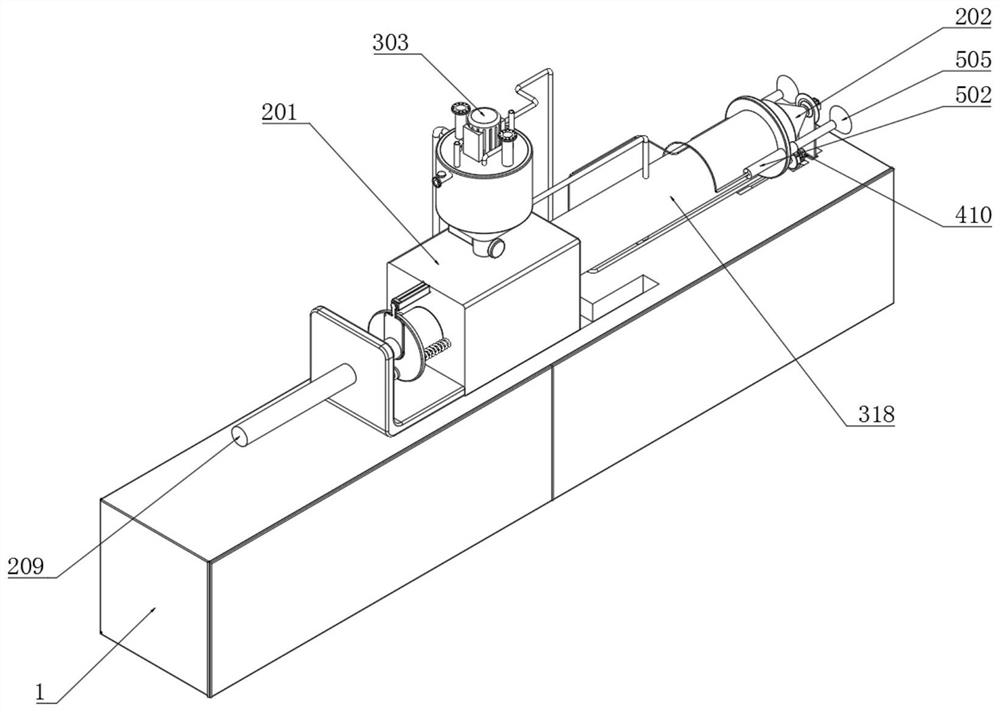

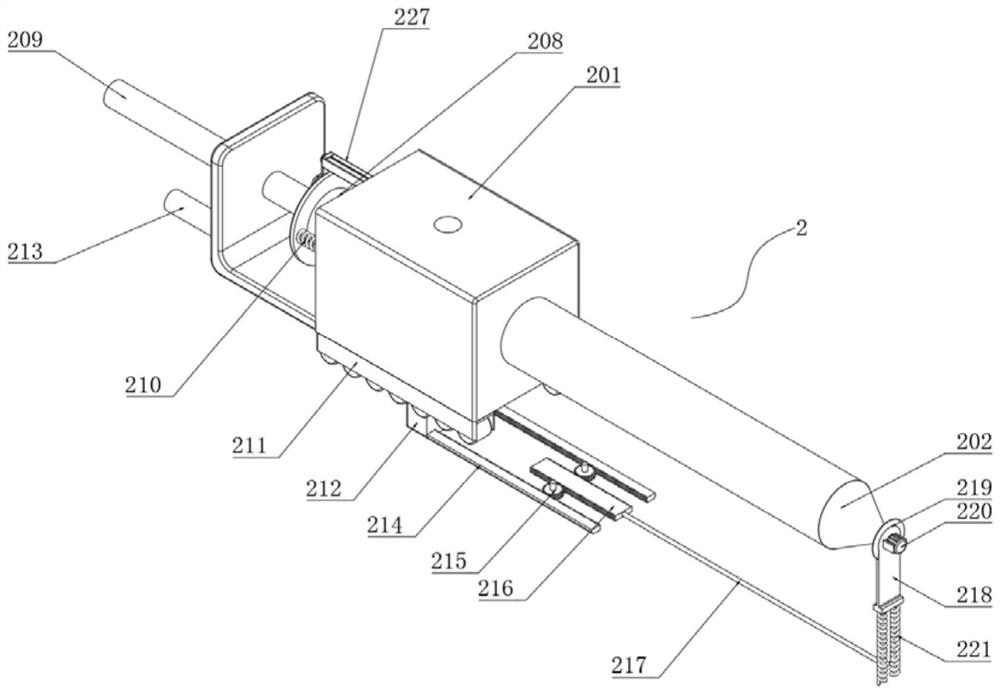

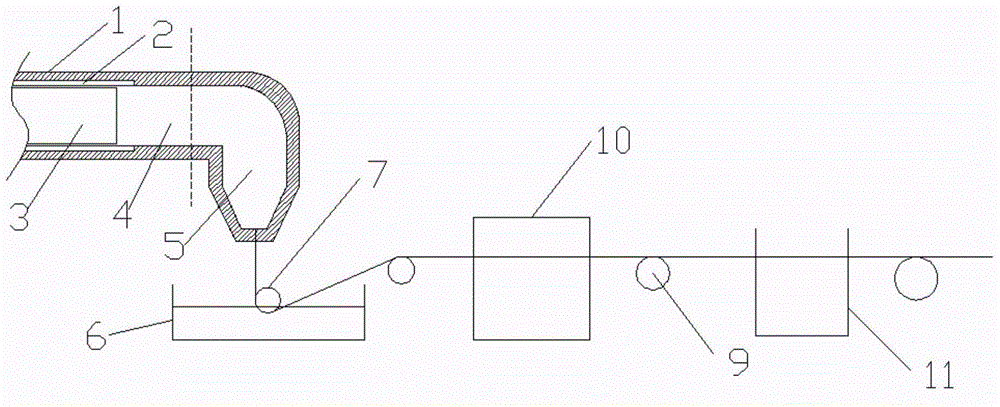

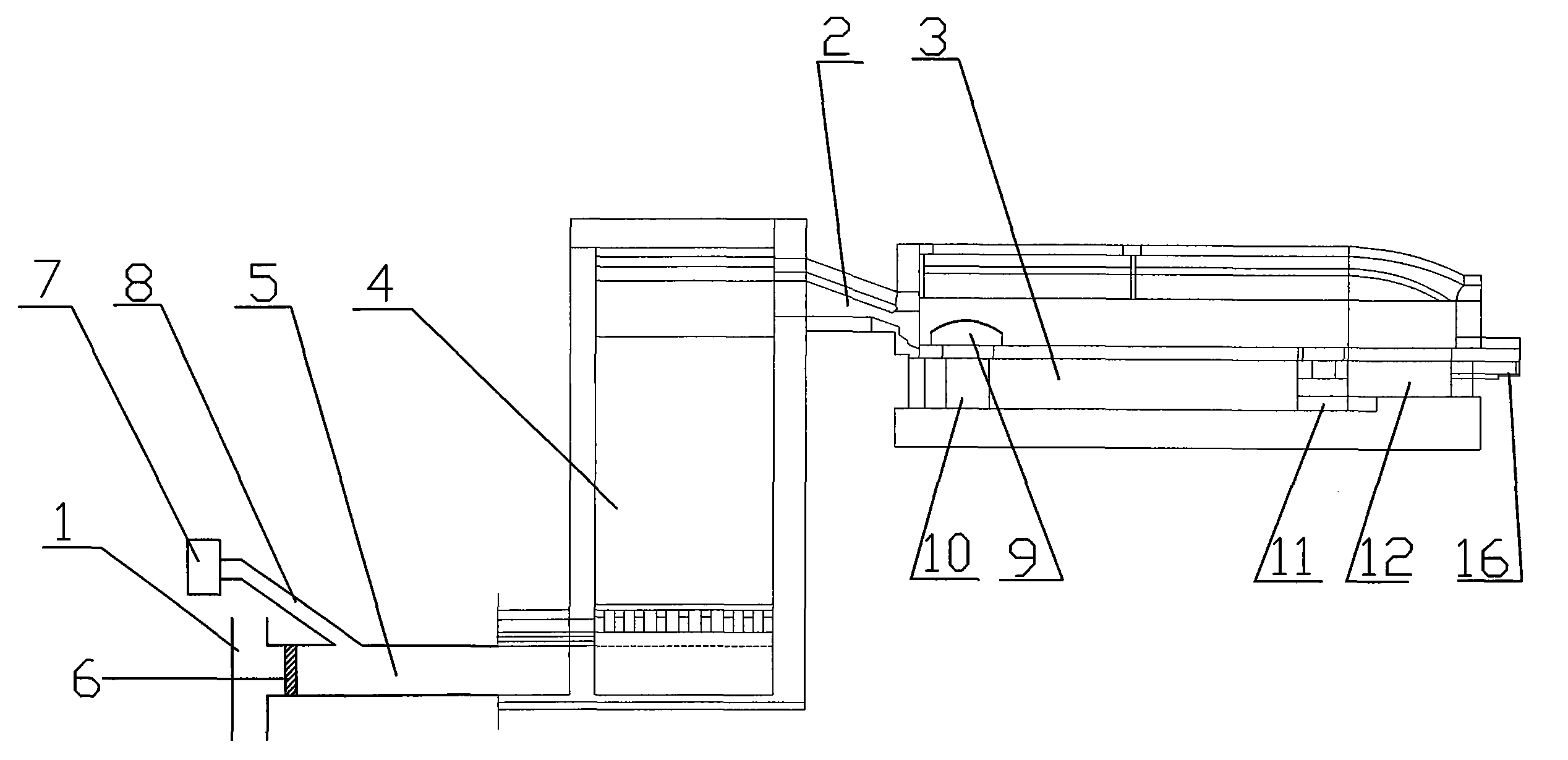

Preparation method and device of polyethylene molten spun filament of ultra-high molecular weight

ActiveCN104862800ASimple processGuaranteed melting effectArtificial thread manufacturing machinesMelt spinning methodsPolyethyleneRaw material

The invention discloses a preparation method and device of a polyethylene molten spun filament of ultra-high molecular weight. On the basis of a conventional extruder, the structure of the extruder is improved, an end part of a sleeve extends out of a melting region and a compaction region, a raw material is extruded, melted and extruded into a silk, the silk is cured, reheated and drawn into a finished filament. The integral structure and process are simple; when the extruder is in a continuous working mode, the sleeve is a vacuum section, and the temperature of a melting region is 350 DEG C, so the melting effect of the polyethylene can be effectively protected without degradation.

Owner:郑海云

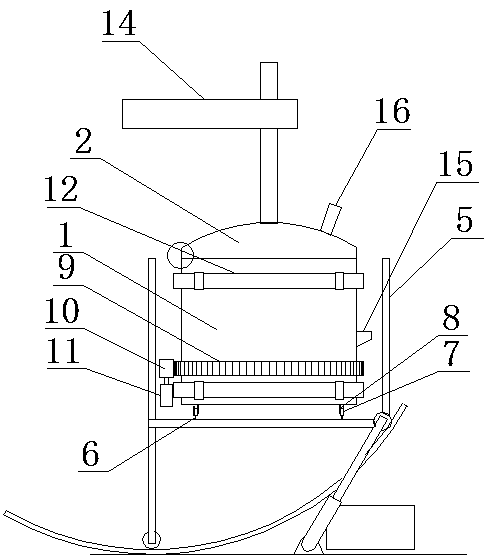

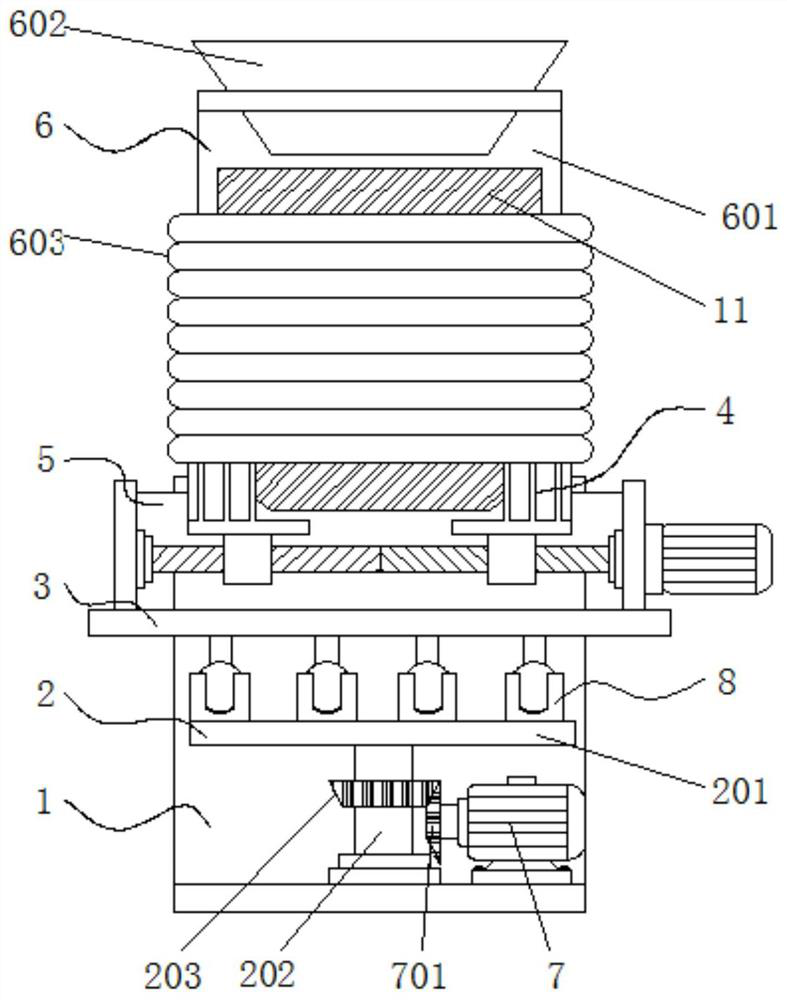

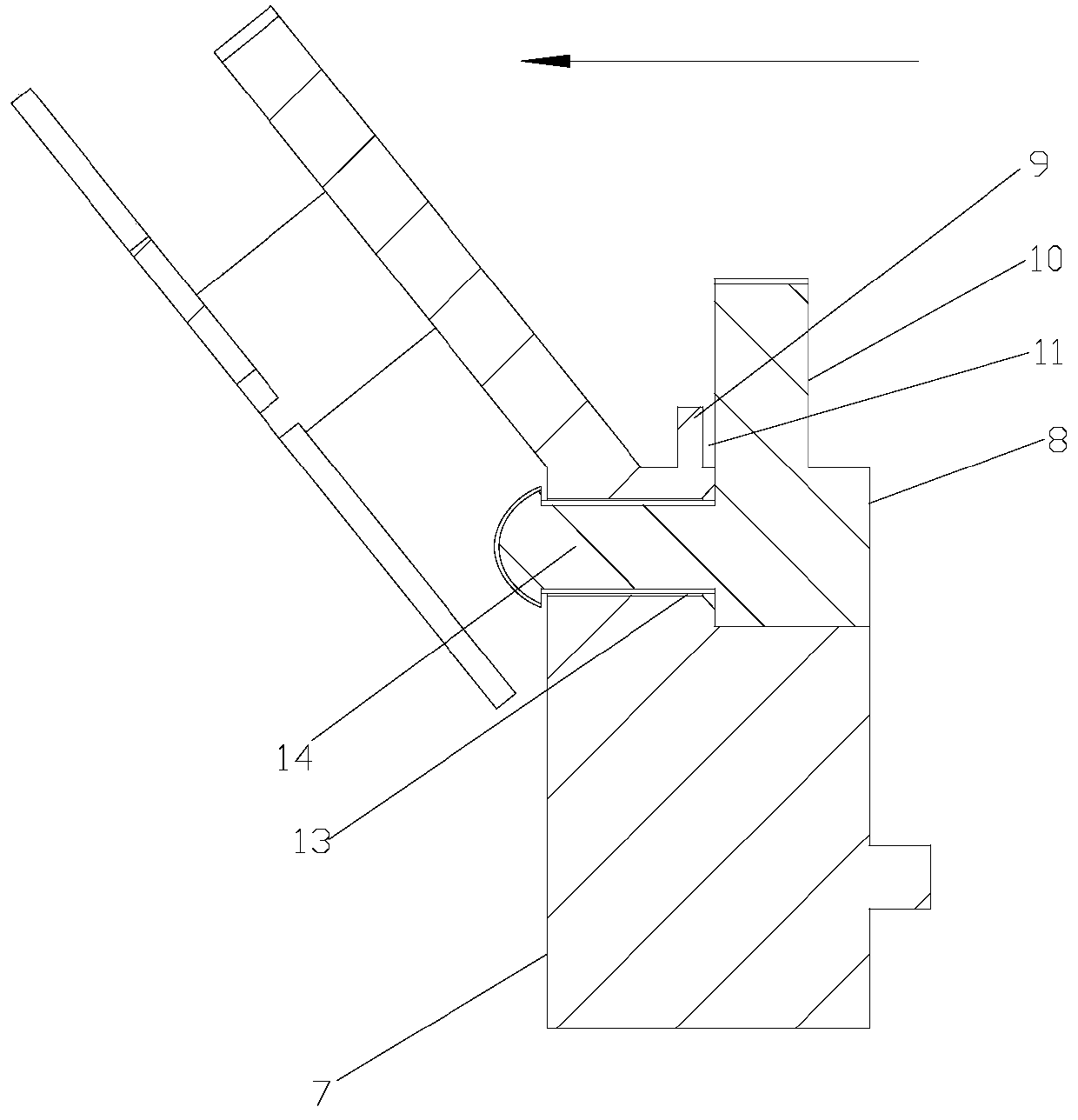

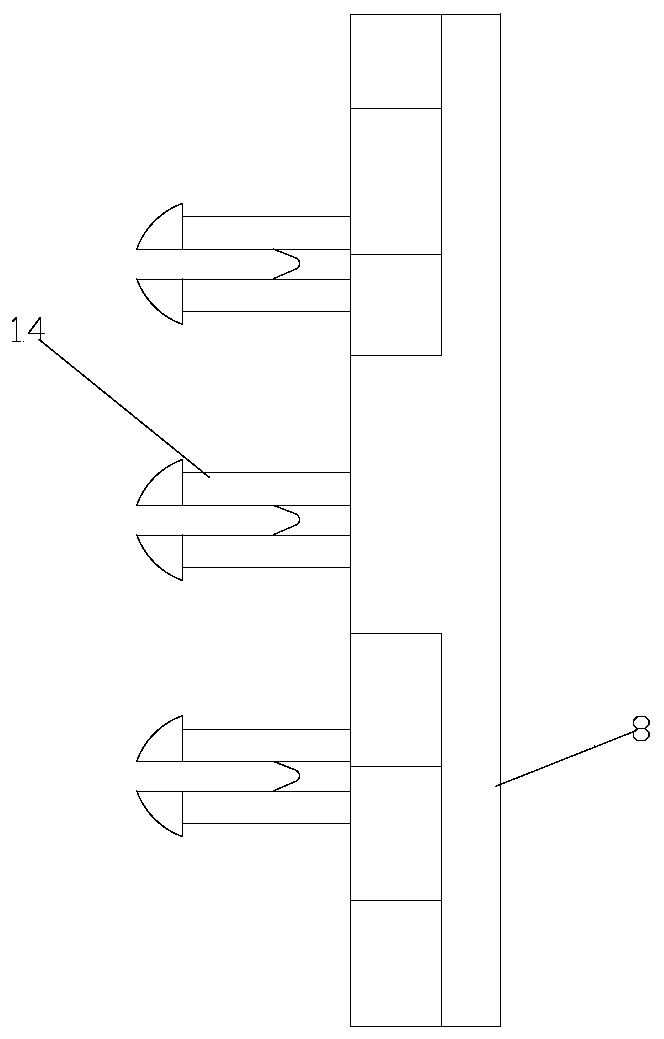

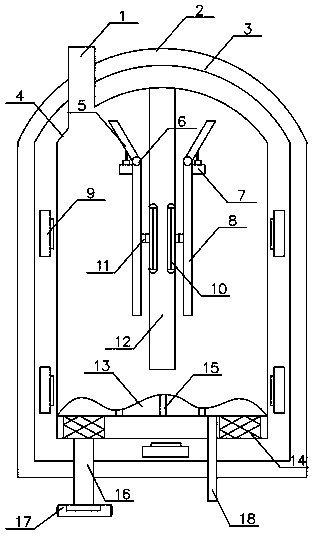

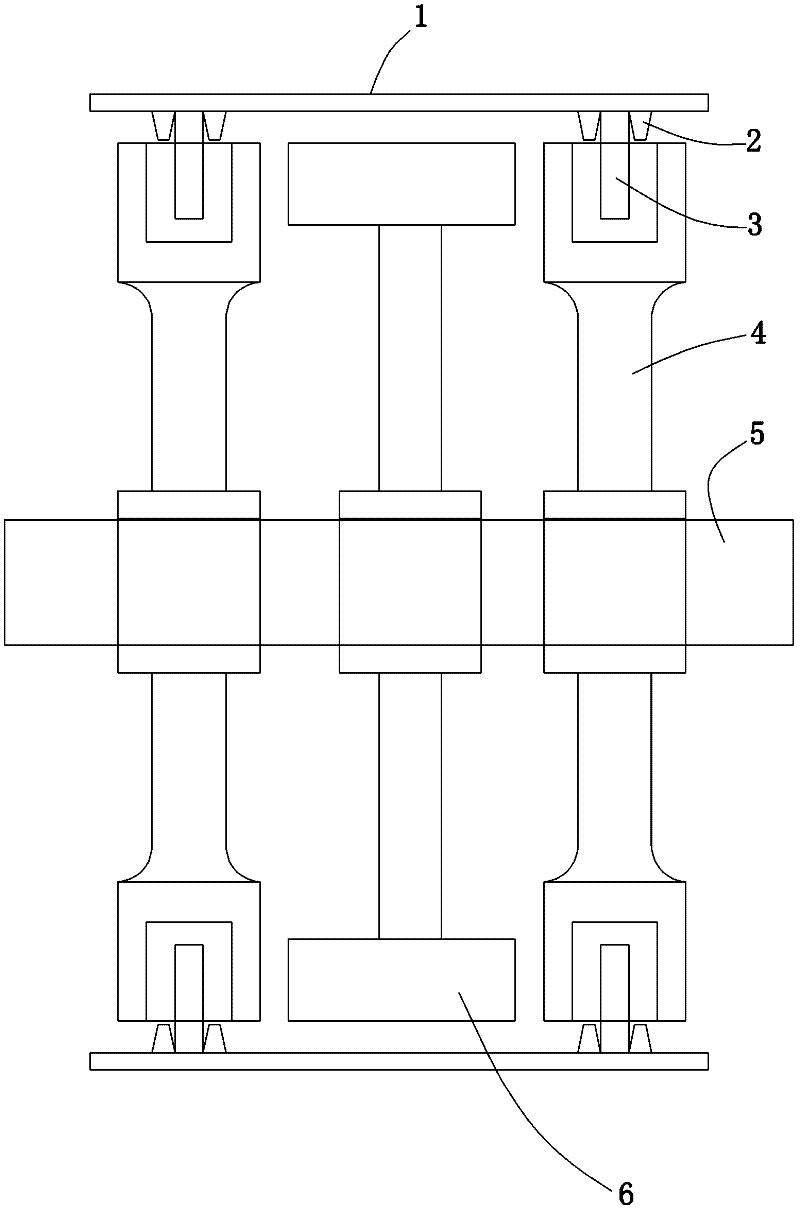

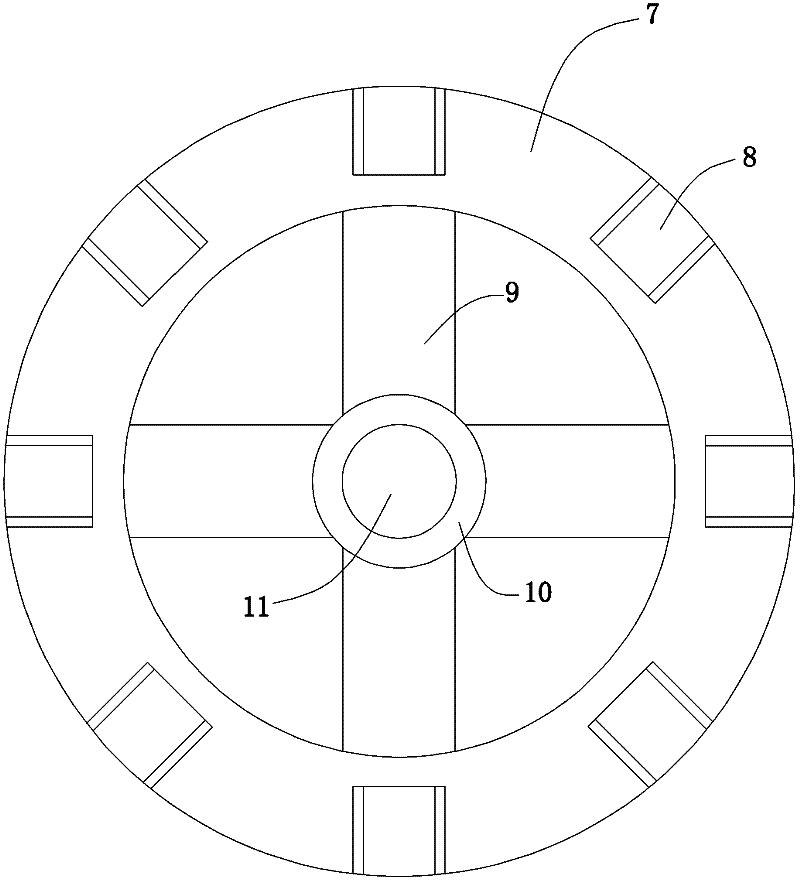

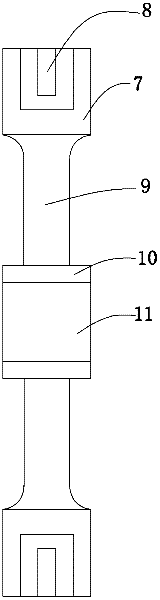

Vertical type rotary direct-current electric arc furnace

InactiveCN110260647AHeating evenlyGuaranteed melting effectElectric heating for furnacesElectric arc furnaceMolten bath

The invention discloses a vertical type rotary direct-current electric arc furnace. The furnace comprises a furnace body, a furnace lid, a negative pole electrode bar, a positive pole electrode bar, an electrode bar lifting mechanism and a furnace body rotating mechanism, wherein the furnace lid is fixedly arranged at the upper end of the furnace body, the negative pole electrode bar and the positive pole electrode bar are fixed on the furnace lid in the vertical direction, the negative pole electrode bar and the positive pole electrode bar are arranged on the electrode bar lifting mechanism and are driven by the electrode bar lifting mechanism to ascend and descend in the vertical direction, and the furnace body is arranged on the furnace body rotating mechanism and is driven by the furnace body rotating mechanism to rotate. The furnace lid of the furnace is provided with double electrodes, so that the melting space is expanded, meanwhile, a negative pole arc and a positive pole arc are used for heating a molten bath, the furnace lid does not move, the furnace body rotates, so that the molten bath is uniformly heated through the arcs, and the melting effect is ensured.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

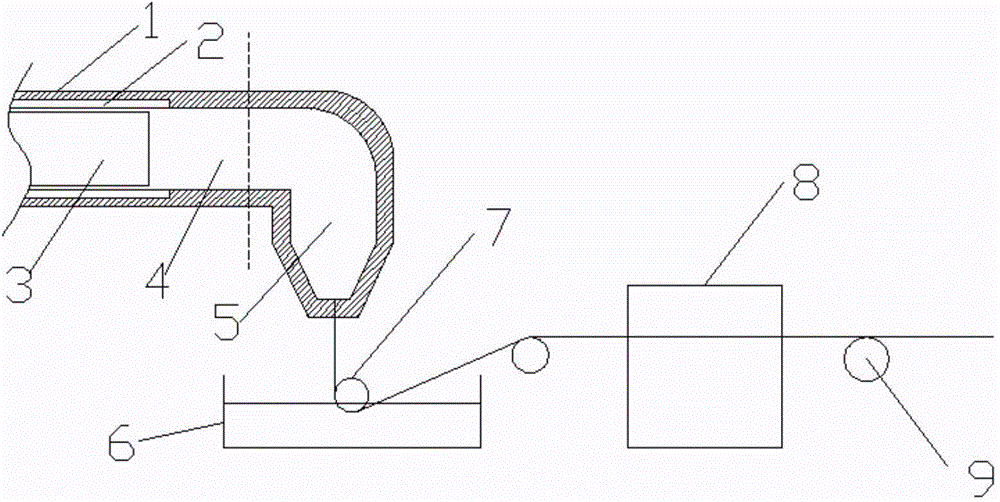

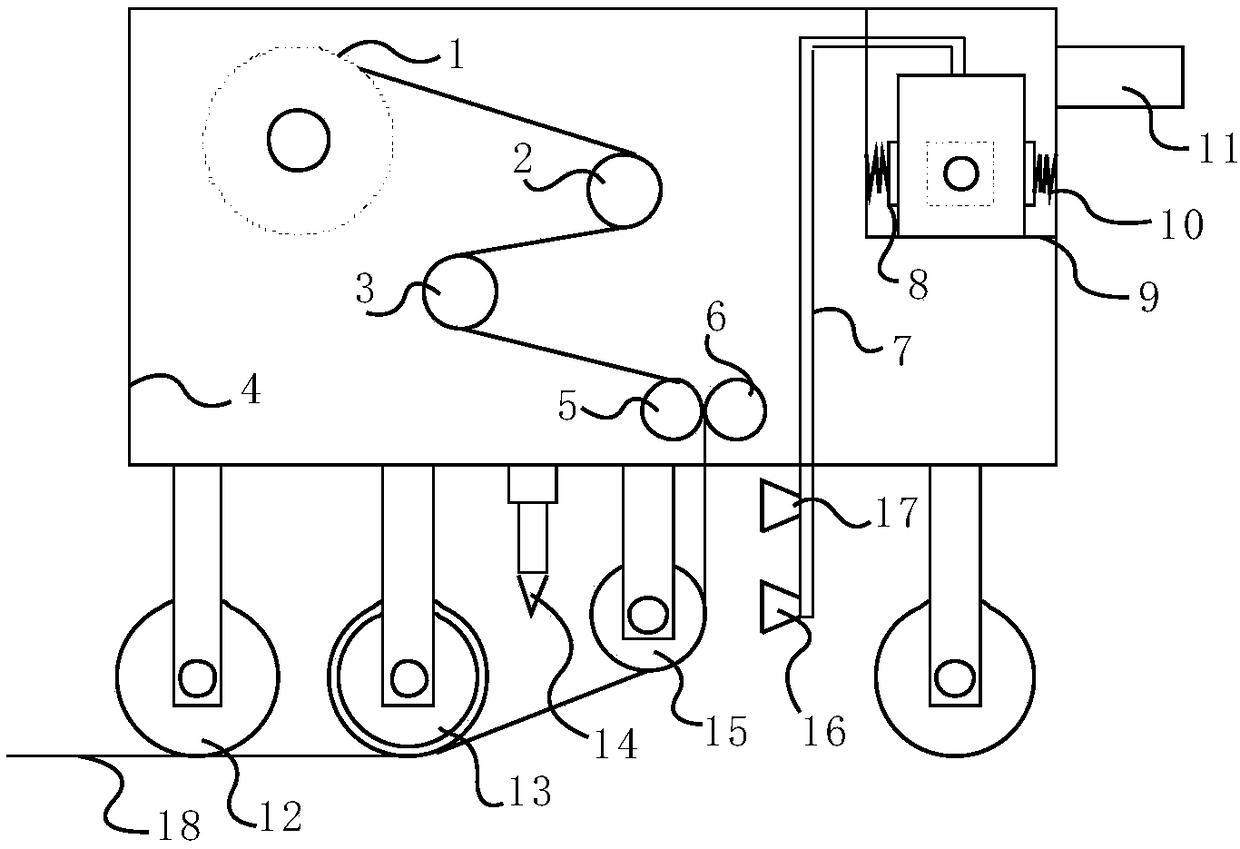

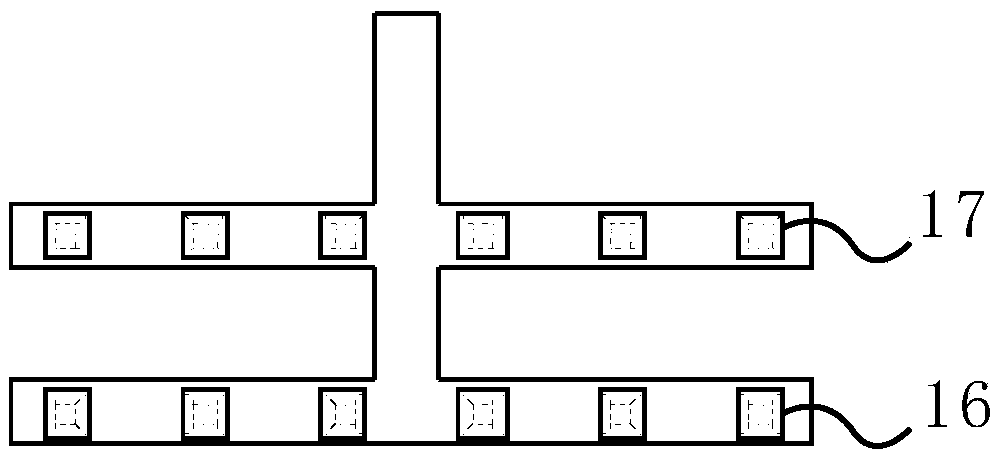

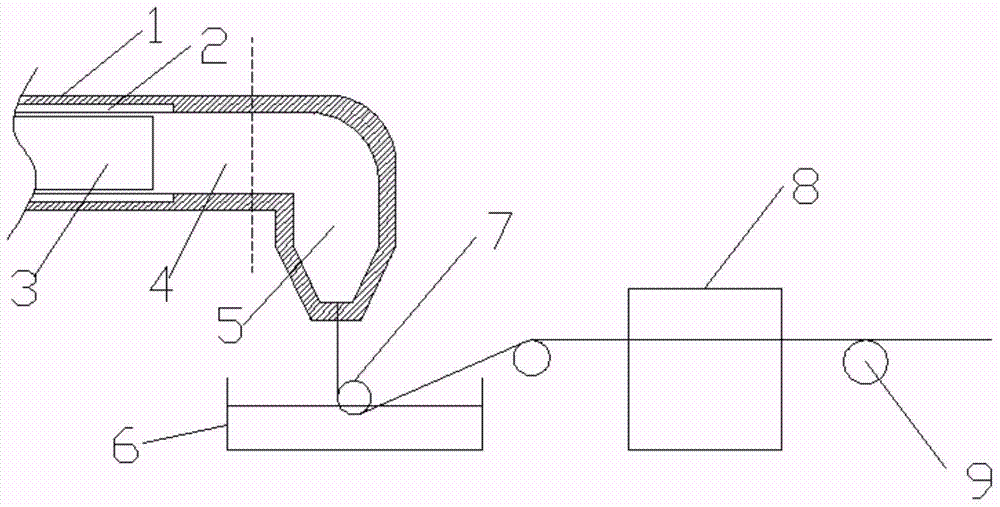

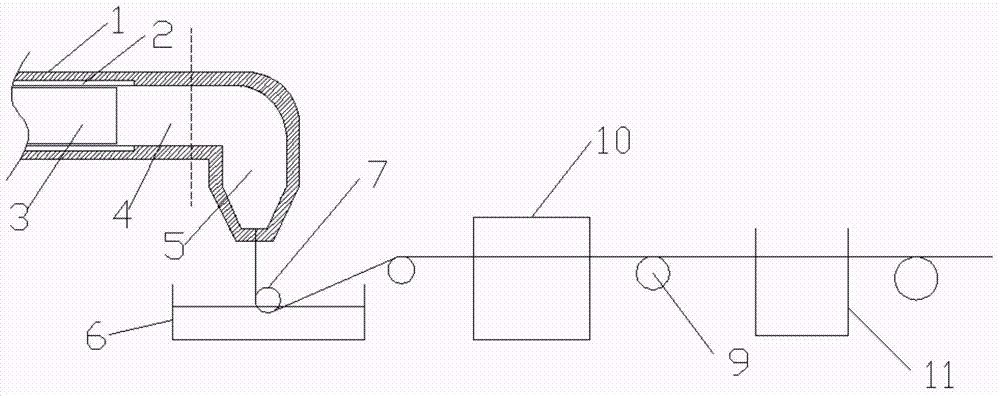

Device for laying waterproof coiled material

PendingCN108915172AGuaranteed heating effectGuaranteed heating speedUnderground chambersRoof toolsFuel tankSpray nozzle

The invention relates to a device for laying a waterproof coiled material. The device comprises a transmission box, a transmission mechanism, a hot-pressing roller arranged at the bottom of the transmission box, and a baking device. The baking device comprises a fuel tank, a set of main spraying nozzles facing a baking roller and a set of preheating spraying nozzles arranged above the main spraying nozzles. The baking device comprises the two rows of spraying nozzles which are arranged perpendicularly, thus the waterproof coiled material can be pre-heated through the preheating spraying nozzles in the using process, and accordingly the heating melting effect and the heating speed of the main spraying nozzles are ensured, and the melting speed can also be ensured while the melting effect isensured; and in addition, the waterproof coiled material penetrates through the bottom of the transmission box, is heated and molten through the baking roller and then transmitted to the hot-pressingroller with the controllable temperature, the coiled material is further hot-molten through the hot-pressing roller, the heated and molten waterproof coiled material is compressed on the ground, andthus the laying effect is further ensured.

Owner:天津欣辰湖建材有限公司

Method for manufacturing noble metal smelting vessel

InactiveCN101475392AGuaranteed melting effectHigh mechanical strengthO-Phosphoric AcidHeat stability

The invention relates to the field of noble metal melting, in particular to a method for preparing a noble metal melting vessel, which solves the problems that the prior noble metal melting vessel consists of a formed crucible and an induction coil which are difficult to match with each other and do not closely contact each other, so that the metal melting effect is influenced. The method comprises: firstly, mixing zirconia and dextrin with different mesh numbers according to certain weight ratio, and adding water into the mixture for uniform mixing; secondly, tamping forming, namely placing a refractory bottom board at the bottom of the induction coil, wrapping two pieces of asbestos cloth inside the bottom board and the induction coil respectively, placing a model into the melting vessel, filling prepared raw materials on the periphery of the model, and performing tamping and demolding; thirdly, coating, namely preparing a zirconia phosphoric acid solution, and coating the zirconia phosphoric acid solution on the inner wall of the melting vessel; and fourthly, roasting. Due to adoption of the method, the melting vessel is closely matched with the induction coil and integrated into a whole, and has the advantages of high mechanical intensity and thermal stability, high temperature resistance, convenient manufacture, low cost and the like. Moreover, the melting vessel does not contain base metals and has long service life.

Owner:CNOOC TAIYUAN PRECIOUS METALS

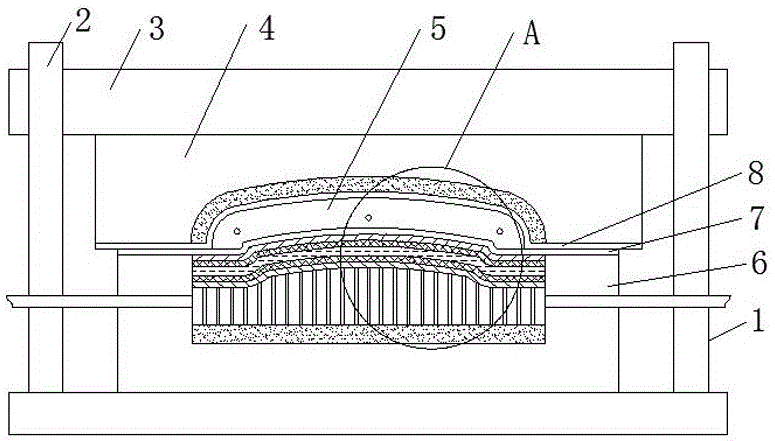

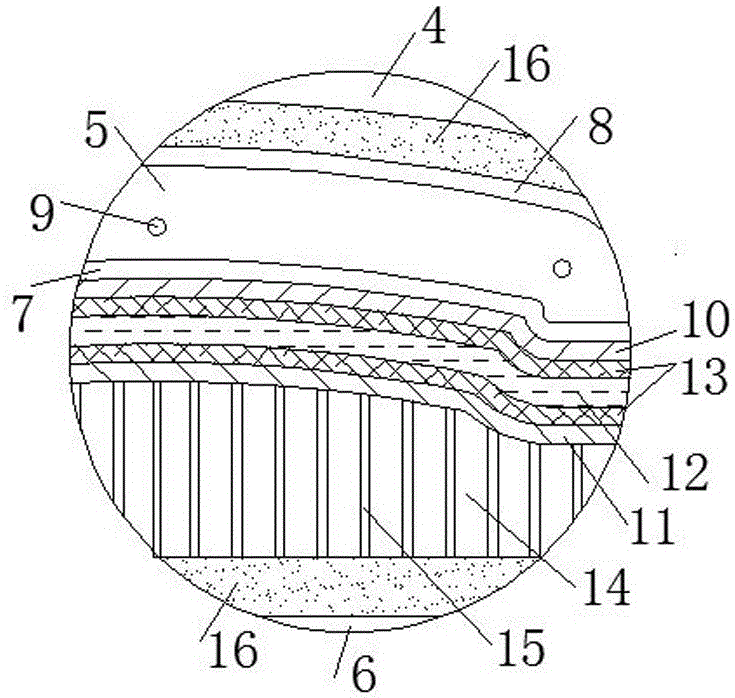

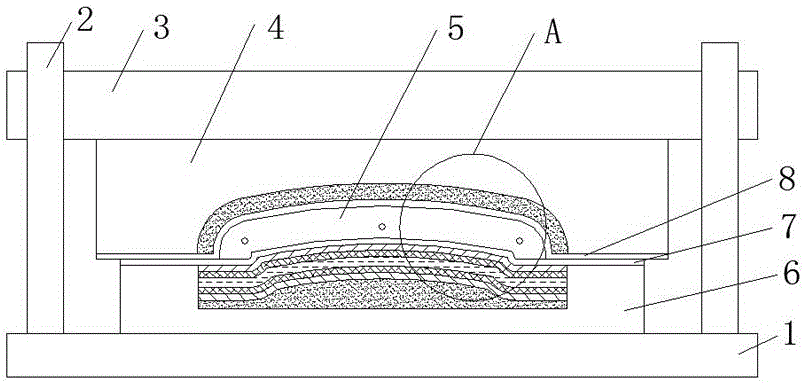

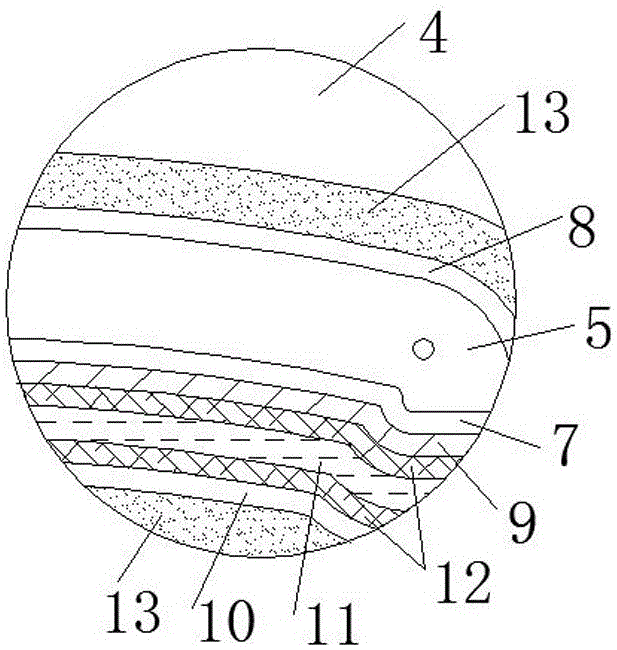

Heating and cooling injection mold for flame-retardant shell of data interaction equipment

The invention belongs to the technical field of communication equipment manufacturing, and discloses a heating and cooling injection mold for a flame-retardant shell of a data interaction device, which solves the problem of poor injection molding quality of the existing shell made of flame-retardant plastic. The invention comprises a fixed mold installation plate and a fixed mold, the fixed mold is installed above the fixed mold installation plate, guide columns are arranged around the fixed mold installation plate, and the upper end of the guide column is covered with a movable mold installation plate A movable mold is installed under the movable mold mounting plate, the movable mold includes a movable mold cavity, the fixed mold includes a fixed mold cavity, and the movable mold cavity and the fixed film cavity together form a pouring cavity, and the pouring The mold cavity is connected with a pouring channel, and it is characterized in that the fixed mold includes a mold core and a template provided with a fixed mold cavity, a heating and cooling device is arranged between the mold core and the template, and the heating and cooling device includes a heat transfer module, Cooling and heating modules.

Owner:CHENGDU KECHUANGGU TECH CO LTD

Device for increasing injection pressure through melting temperature pressurization

The invention relates to the technical field of die machining, and discloses a device for increasing the injection pressure through melting temperature pressurization. The device comprises an injection molding machine. The upper portion of the exterior of the injection molding machine is movably connected with a movable cover, the right side of the movable cover is movably connected with conveyingwheel, the upper portion of the injection molding machine is fixedly connected with a fixed sliding rail, the upper portion of the fixed sliding rail is movably connected with a conveying belt, the lower portion of the movable cover is movably connected with a hydraulic rod, the lower portion of the hydraulic rod is movably connected with an injection molding plate, and the interior of the injection molding machine is movably connected with a plastic melting box. Power sliding blocks are reset under the effects of reset springs 12, thus, power wheels are driven to continuously rotate in a reciprocating manner, the power wheels are engaged with racks on the outer sides of movable sliding blocks, through rotation of the power wheels, pressure is continuously provided for the injection molding plate, the pressure during plastic output is guaranteed, thus, the effect of continuously increasing the pressure for plastic output is achieved, and the effect of plastic output is guaranteed.

Owner:万小英

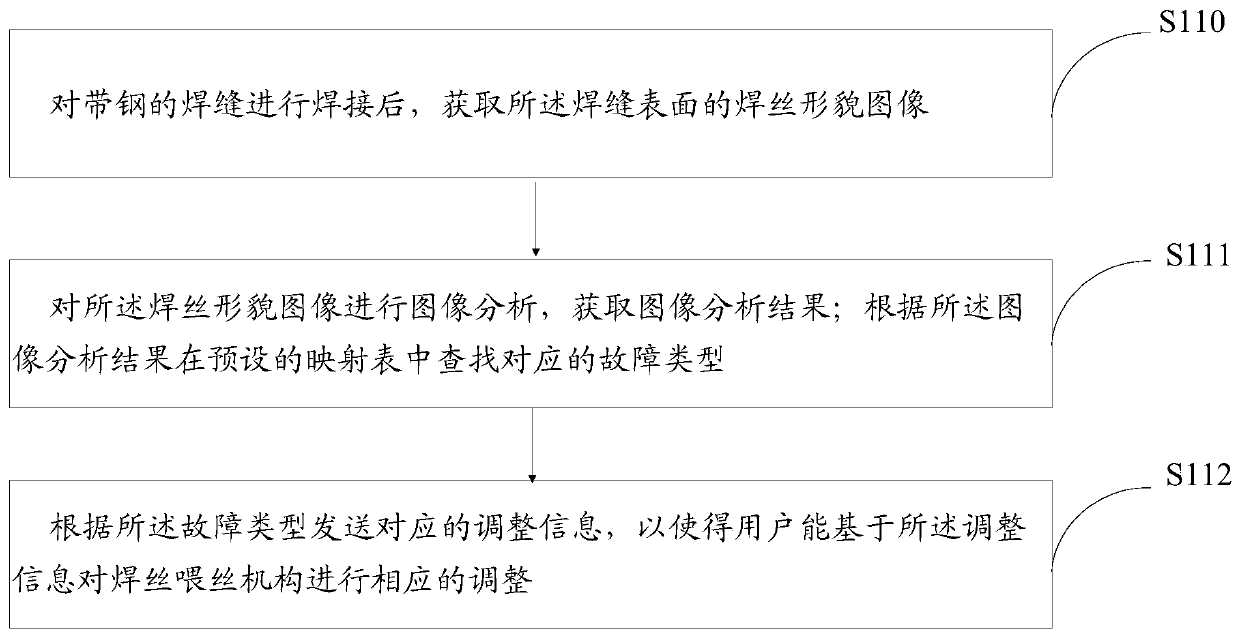

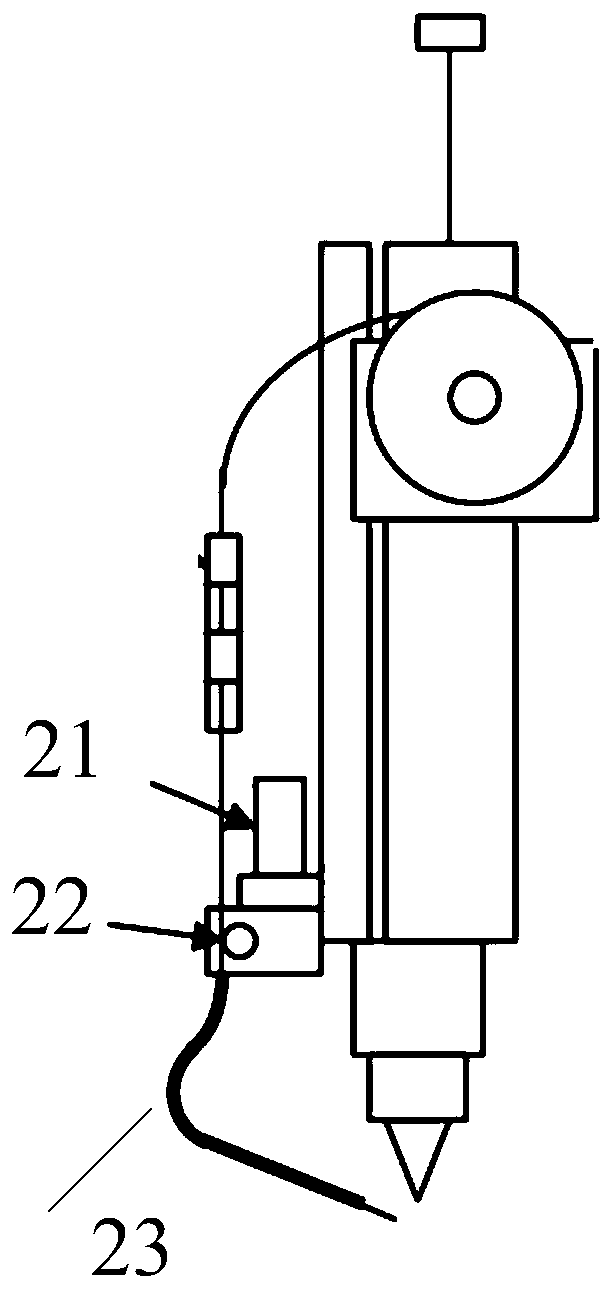

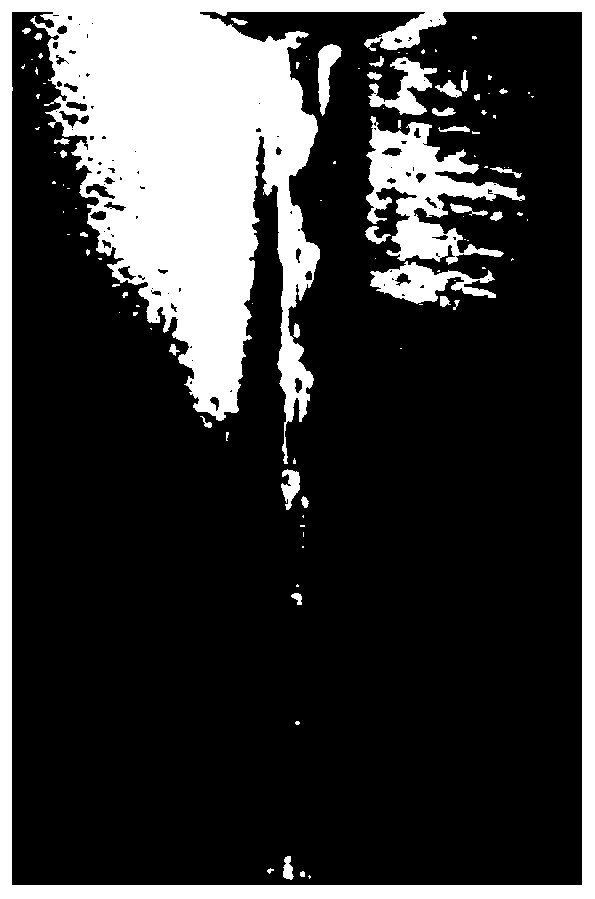

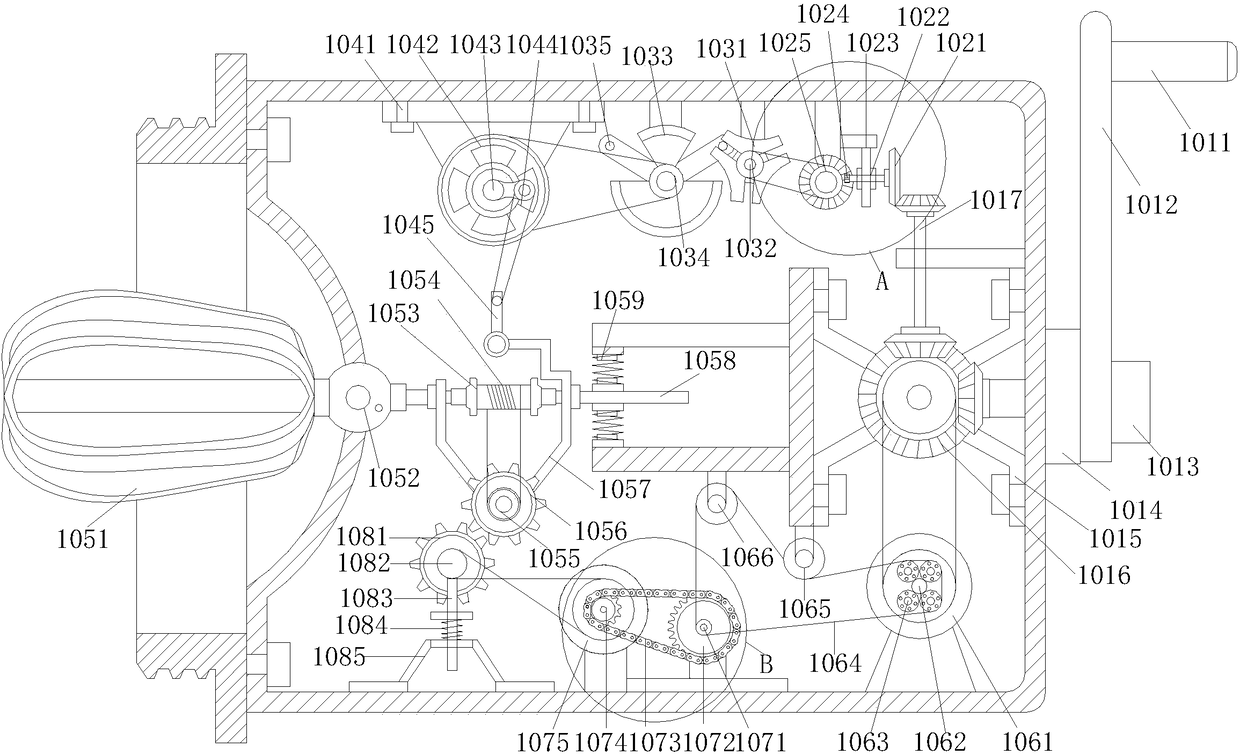

Method and device for improving quality of welding seam

InactiveCN110899973AImprove product qualityGuaranteed melting effectLaser beam welding apparatusImaging analysisStructural engineering

The invention provides a method and a device for improving the quality of a welding seam. The method comprises the following steps that a welding seam of strip steel is welded, and a welding wire morphology image of the surface of the welding seam is obtained; the welding wire morphology image is subjected to image analysis, and an image analysis result is obtained; a corresponding fault type is searched in a preset mapping table according to the image analysis result, and a corresponding relationship between the image analysis result and the fault type is stored in the mapping table in advance; the corresponding adjustment information is sent according to the fault type, so that a user can correspondingly adjust a wire feeding mechanism based on the adjustment information; and when the welding wire is poor, the welding wire morphology image is utilized to determine the fault type of the wire feeding mechanism and send the adjustment information corresponding to the fault type to the user, the user can adjust the wire feeding mechanism based on the adjustment information, the melting effect of the welding wire is ensured, the welding seam quality is improved, and then the quality of the strip steel product is improved.

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

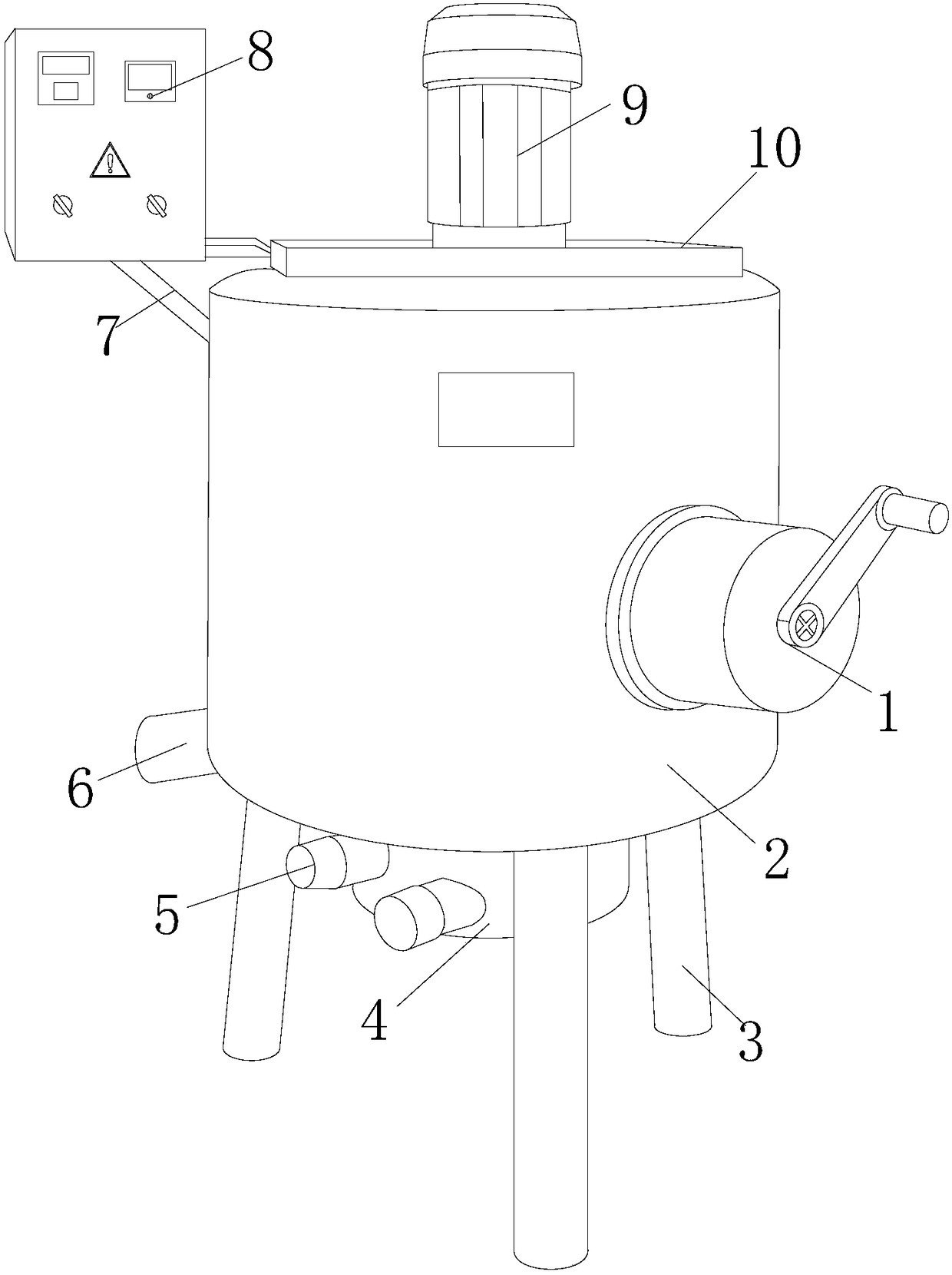

Uniform-heating fusion device for petroleum asphalt

InactiveCN108329940AStir wellGuaranteed melting effectWorking-up pitch/asphalt/bitumen by meltingHeater RodScrew thread

The invention discloses a uniform-heating fusion device for petroleum asphalt. The uniform-heating fusion device structurally comprises a stirrer, a stirring barrel, supporting columns, a heating disc, two heating rods, a discharging port, fixing angle iron, a control box, a stirring motor and a barrel cover, a thread at the front end of the stirrer and an internal thread of an open hole at the front end of the stirring barrel are in clearance fit, the heating disc is a cylinder and is horizontally welded at the bottom of the stirring barrel, the upper circle of the cylinder is big while the lower circle of the same is small, the heating rods are mounted between the supporting columns, the stirring motor is vertically fixed at the center of the top of the barrel cover through bolts, and astirring shaft at the bottom is fixed on the inner wall of the stirring barrel. The stirrer stirs beside the stirring barrel again; the stirrer is added beside the stirring barrel while middle stirring is performed and can fully stir petroleum asphalt beside the barrel, so that fusion effect is better.

Owner:罗胜楠

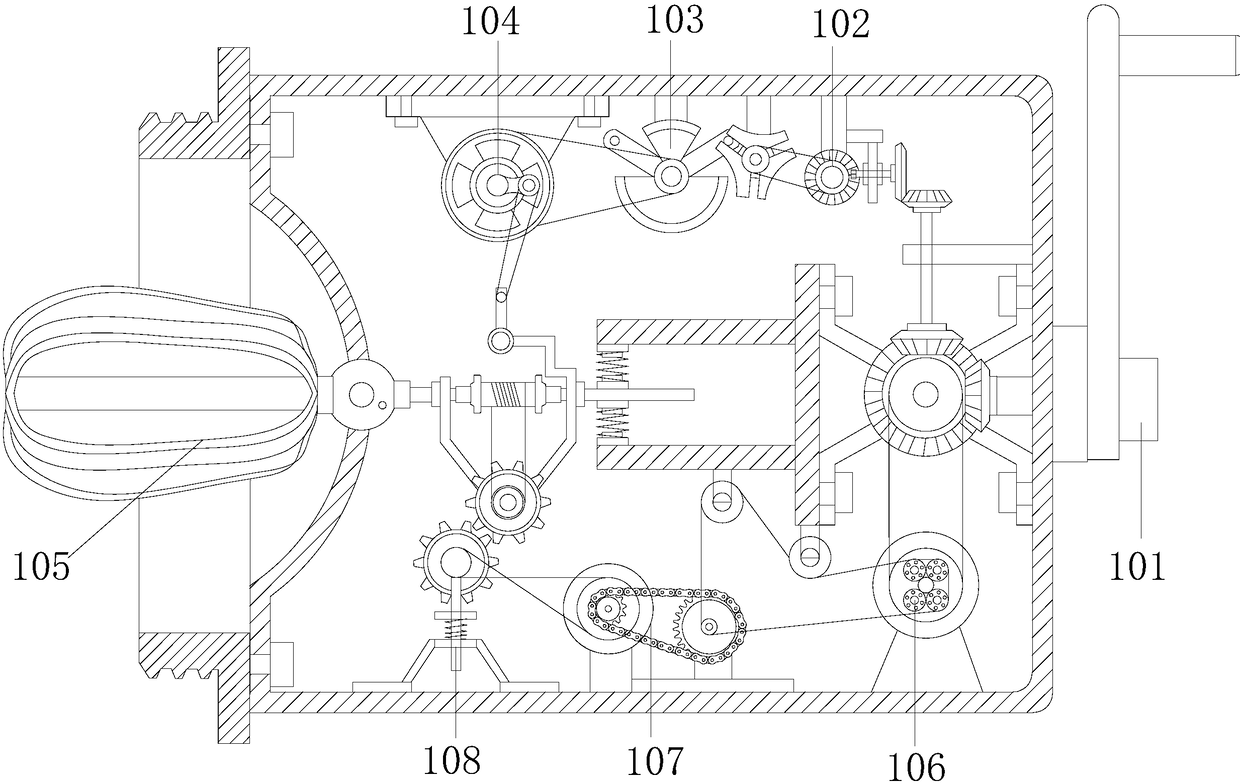

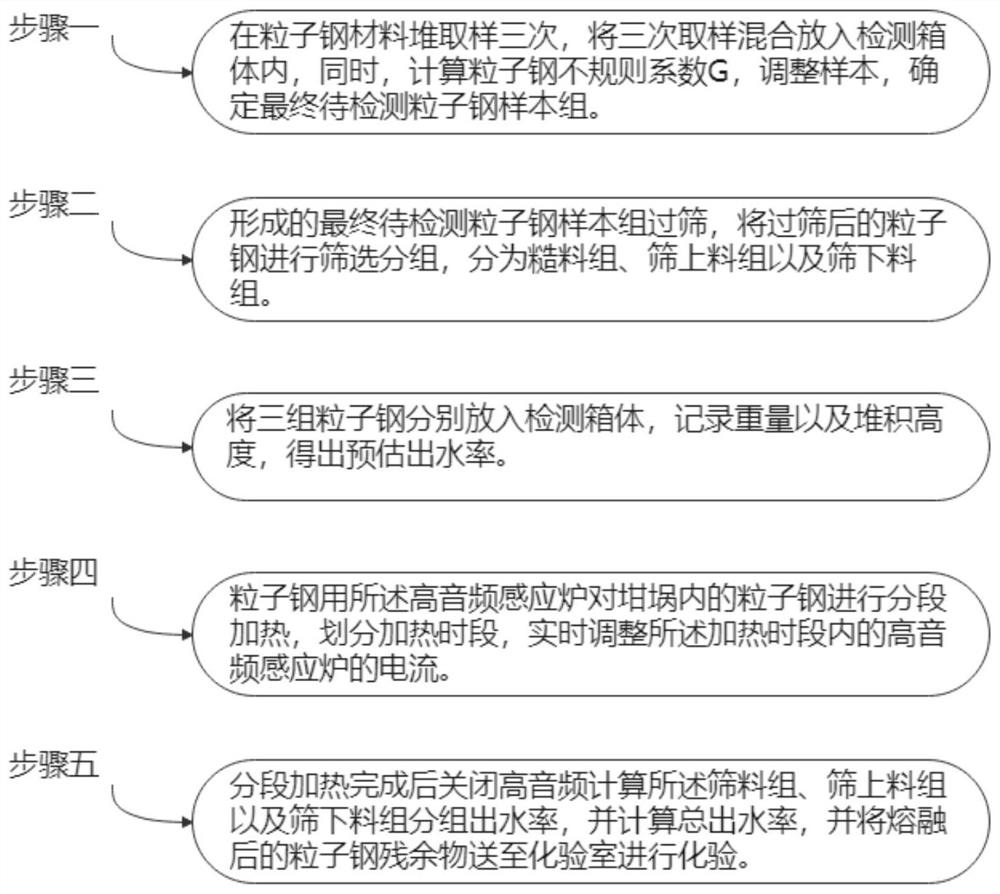

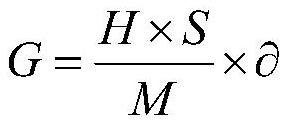

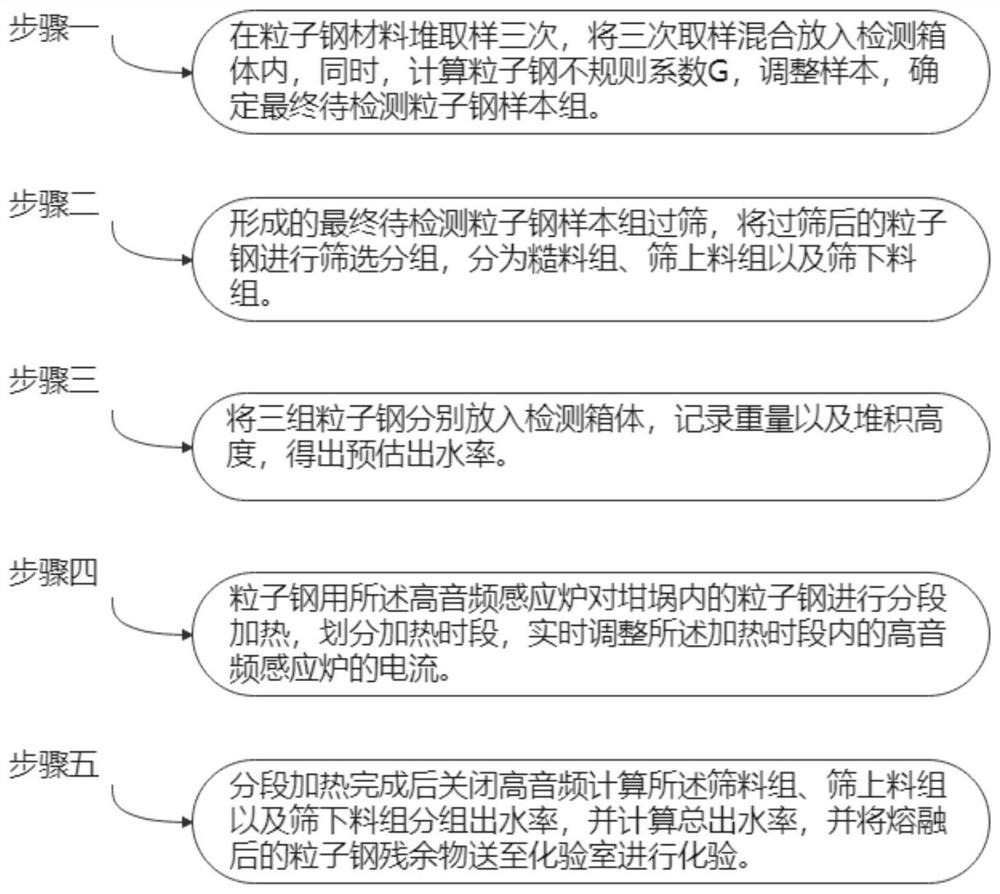

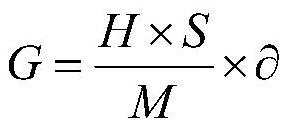

Efficient detection method for particle steel

ActiveCN112378946AChemical detection is accuratePreserve far sample propertiesMaterial weighingInvestigating phase/state changePhysicsMaterials science

The invention relates to an efficient detection method of particle steel, and the method comprises the following steps: sampling the particle steel for three times, determining a mass difference coefficient Z according to a sample ratio, processing a sample to ensure the representativeness of the sample, screening the sample, dividing the sample into a rough material group, an oversize material group and an undersize material group, and measuring the sample groups; determining an irregular coefficient G of the particle steel, estimating an estimated particle steel water outlet rate Y0 according to a preset rule, judging whether the estimated particle steel water outlet rate Y0 can be used as a final total water outlet rate or not, if not, melting the particle steel, and accurately adjusting the current and the melting time of a high-audio reaction furnace in the melting process, so that the melting effect is guaranteed, so as to determine the water yield of the particle steel.

Owner:TANGSHAN CAOFEIDIAN DISTRICT TONGXIN RENEWABLE RESOURCE RECYCLING

Polyester resin powder spraying type heat treatment device

InactiveCN112108082AEasy loadingEasy to sprayRotary stirring mixersTransportation and packagingPolymer sciencePolyester resin

The invention discloses a polyester resin powder spraying type heat treatment device which comprises a box body, a driving mechanism, a heating tank and a collecting box, and a cover plate covers theupper end surface of the box body; the driving mechanism is arranged in the cover plate, containing grooves which are symmetrically formed about the driving mechanism are formed in the upper surface of the cover plate, the bottoms of the containing grooves communicate with spray heads through pipelines, and the spray heads are located in the heating tank; the heating tank is fixedly connected to the inner side wall of the box body through an annular fixing plate, and an annular scraping plate is slidably connected into the heating tank; Polyester resin powder can be subjected to heat treatment, the melting speed of the polyester resin powder is increased, the melting effect of the polyester resin powder is guaranteed, damage of high temperature to the structure in the polyester resin powder is avoided, meanwhile, the residual amount of a polyester resin powder solution on the inner wall of the heating tank can be reduced, and resource waste is reduced.

Owner:安徽智成实业有限公司

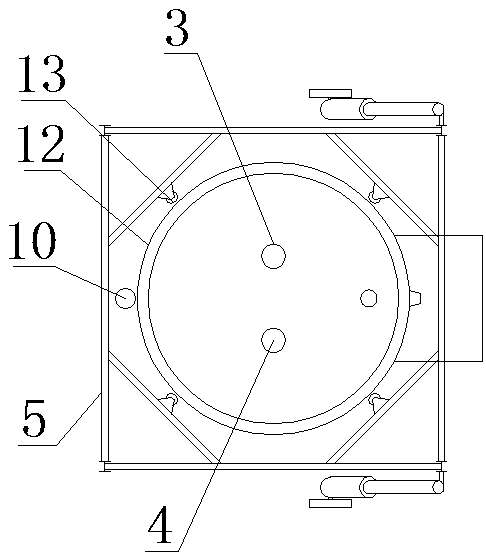

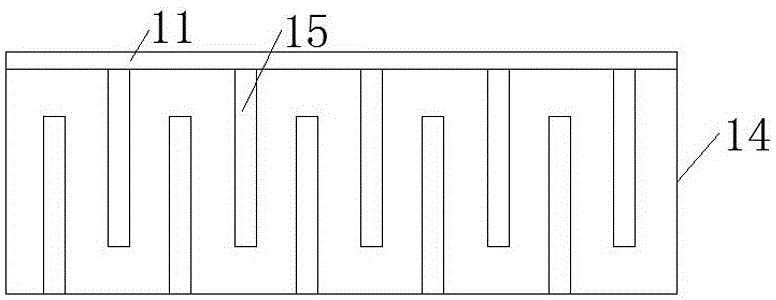

Injection mold for flame retardant housing of data interaction device

InactiveCN106042282AImprove injection molding qualityGuaranteed melting effectInteraction deviceEngineering

The invention belongs to the technical field of communication equipment manufacturing, and discloses an injection mold for a flame-retardant shell of data interaction equipment, which solves the problem of poor injection molding quality of the existing shell made of flame-retardant plastics. The invention comprises a fixed mold installation plate and a fixed mold, the fixed mold is installed above the fixed mold installation plate, guide columns are arranged around the fixed mold installation plate, and the upper end of the guide column is covered with a movable mold installation plate A movable mold is installed under the movable mold mounting plate, the movable mold includes a movable mold cavity, the fixed mold includes a fixed mold cavity, and the movable mold cavity and the fixed film cavity together form a pouring cavity, and the pouring The mold cavity is connected with a pouring channel, the fixed mold includes a mold core and a template provided with a fixed mold cavity, a heating device is arranged between the mold core and the template, and the heating device includes an outer cylinder and an inner cylinder, and the inner cylinder It is fixedly connected with the template, a vacuum steam chamber is formed between the inner cylinder and the outer cylinder, and a liquid-absorbing core is arranged on the inner wall of the steam chamber.

Owner:CHENGDU KECHUANGGU TECH CO LTD

Method for preparing glass fiber by compounding calcined bentonite and pyrophyllite

InactiveCN112759269AImprove mechanical propertiesGood chemical stabilityGlass making apparatusYarnGlass ball

The invention discloses a method for preparing a glass fiber by compounding calcined bentonite and pyrophyllite, and relates to the technical field of glass fibers. The method comprises the following steps: (1) obtaining calcined bentonite; (2) obtaining ball-milled pyrophyllite; (3) obtaining a pyrophyllite / calcined bentonite compound; (4) obtaining molten glass; (5) feeding the molten glass into a balling machine for balling to obtain glass balls; (6) feeding the glass balls into a wire drawing furnace through a feeding hopper, performing wire drawing, and then performing beam splitting and winding to obtain glass fiber yarn balls; the glass fiber prepared by mixing the pyrophyllite / calcined bentonite compound, the quartz sand, the limestone, the mica, the potassium feldspar, the szaibelyite and the sodium carbonate according to a certain weight part ratio has excellent mechanical properties.

Owner:五河县维佳复合材料有限公司

Preparation method and device for melt spinning of ultra-high molecular weight polyethylene

ActiveCN104862800BGuaranteed melting effectNo degradationArtificial thread manufacturing machinesMelt spinning methodsPolymer scienceMelt spinning

The invention discloses a preparation method and device of a polyethylene molten spun filament of ultra-high molecular weight. On the basis of a conventional extruder, the structure of the extruder is improved, an end part of a sleeve extends out of a melting region and a compaction region, a raw material is extruded, melted and extruded into a silk, the silk is cured, reheated and drawn into a finished filament. The integral structure and process are simple; when the extruder is in a continuous working mode, the sleeve is a vacuum section, and the temperature of a melting region is 350 DEG C, so the melting effect of the polyethylene can be effectively protected without degradation.

Owner:郑海云

Method for manufacturing noble metal smelting vessel

The present invention relates to the field of noble metal melting, in particular to a method for preparing a noble metal melting vessel, which solves the problems that the prior noble metal melting vessel consists of a formed crucible and an induction coil which are difficult to match with each other and do not closely contact each other, so that the metal melting effect is influenced. The method comprises: firstly, mixing zirconia and dextrin with different mesh numbers according to certain weight ratio, and adding water into the mixture for uniform mixing; secondly, tamping forming, namely placing a refractory bottom board at the bottom of the induction coil, wrapping two pieces of asbestos cloth inside the bottom board and the induction coil respectively, placing a model into the melting vessel, filling prepared raw materials on the periphery of the model, and performing tamping and demolding; thirdly, coating, namely preparing a zirconia phosphoric acid solution, and coating the zirconia phosphoric acid solution on the inner wall of the melting vessel; and fourthly, roasting. Due to adoption of the method, the melting vessel is closely matched with the induction coil and integrated into a whole, and has the advantages of high mechanical intensity and thermal stability, high temperature resistance, convenient manufacture, low cost and the like. Moreover, the melting vessel does not contain base metals and has long service life.

Owner:CNOOC TAIYUAN PRECIOUS METALS

Production formula for alkali-resistant glass marble, production method and production kiln thereof

ActiveCN101531457BMix well and evenlyControl moisture contentGlass furnace apparatusGlass shaping apparatusElectricityProduction rate

The invention relates to a production formula for alkali-resistant glass marble in building material industry, a production method and a production kiln thereof. The invention is reasonable in selecting weight proportions of ingredients, which is favorable for the control of quality system, and the produced finished product of the glass marble has high clarity and good quality; the entire technological process consists of screening, weighting and mixing raw materials, founding and discharging, the technology is simple and the operation is convenient; using a horseshoe-fired furnace for producing the alkali-resistant glass marble solves the technical prejudice in a long term that the horseshoe-fired furnace is unsuitable for the production of the alkali-resistant glass marble; a general glass marble kiln is utilized to realize the production of the alkali-resistant glass marble without improving kiln refractory, which has the advantages of large production scale, easy control and regulation for the production process, good scale effect and prominent energy-saving effect; the cost is dramatically reduced while the production rate is greatly improved in contrast to a full-electric melting kiln.

Owner:ZIGONG DENGGUAN GLASS FIBER

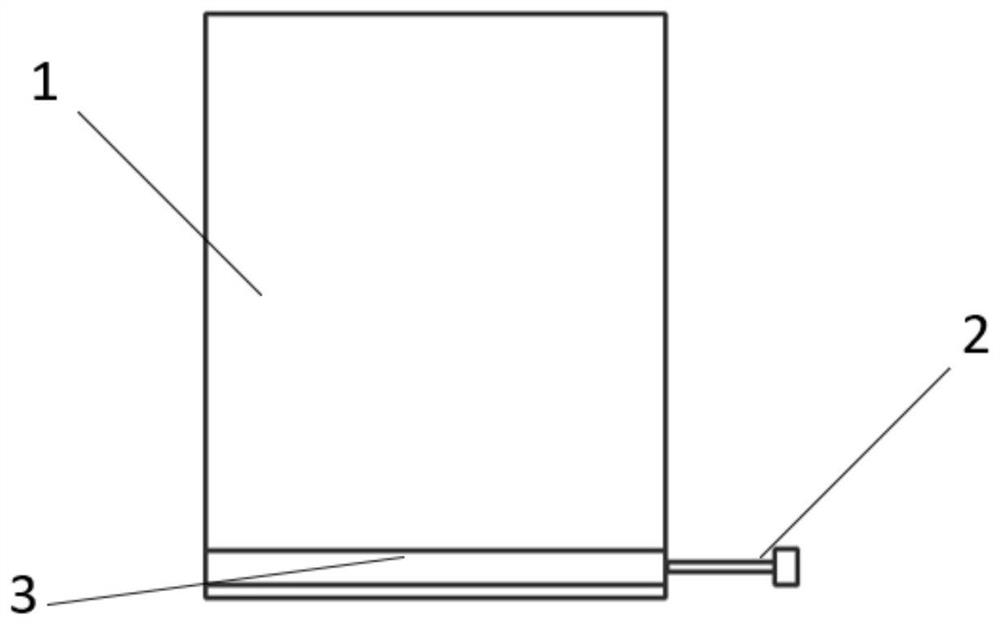

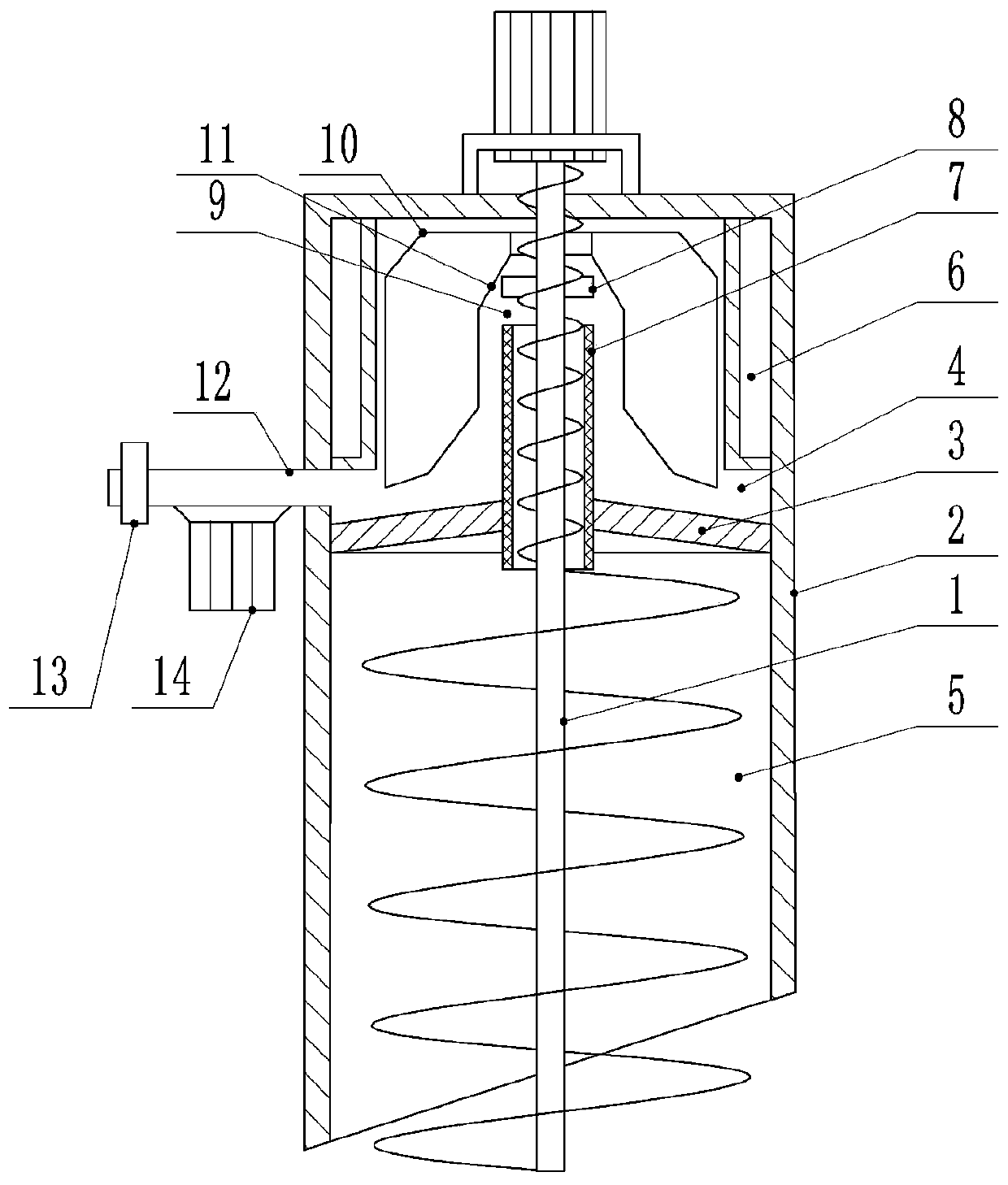

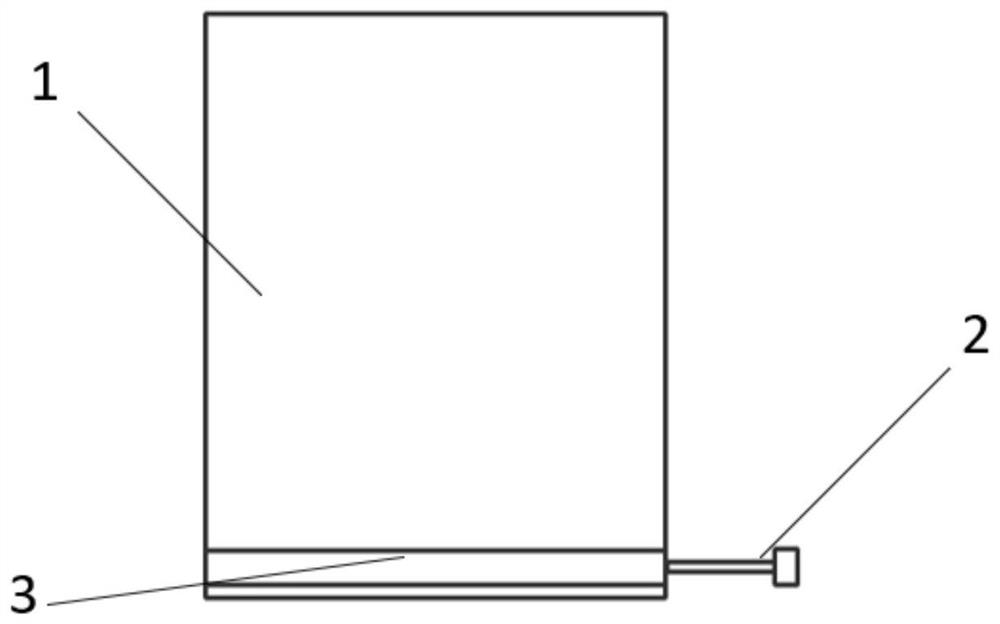

Quantitative indoor solid bitumen rapid heating extraction system

ActiveCN108844769BEasy to removeEasy to useWithdrawing sample devicesPreparing sample for investigationThermodynamicsEngineering

The invention relates to the technical field of asphalt sampling, and discloses a quantitative type indoor solid-state asphalt quick heating and extracting system. The quantitative type indoor solid-state asphalt quick heating and extracting system comprises a spiral sampling transmission rod and a barrel body, wherein the barrel body is arranged at the outside of the spiral sampling transmissionrod in a sleeving manner, an opening is formed in one end of the barrel body, a heating chamber is arranged in the barrel body, one end of the spiral sampling transmission rod penetrates into the heating chamber, and the other end of the spiral sampling transmission rod extends towards one side with the opening of the barrel body. Through adoption of the quantitative type indoor solid-state asphalt quick heating and extracting system disclosed by the invention, the problems that the asphalt sampling operation is tedious and the asphalt samples are easy to age can be solved.

Owner:云南通衢工程检测有限公司

An energy-saving and environment-friendly sulfur melter

ActiveCN109336060BReduce lossIncrease contact areaSulfur preparation/purificationExhaust fumesProcess engineering

Owner:浙江程阳机电有限公司

Luminous glaze for enamel color porcelain and preparation method and application of glaze paste

The invention discloses luminescent glaze for enamel painted porcelain and a preparation method and application thereof. The luminescent glaze for enamel painted porcelain comprises basic glaze for the enamel painted porcelain and a protective-glaze luminescent material, wherein the protective-glaze luminescent material is prepared by firstly mixing and then repeatedly braking the flux for the protective-glaze luminescent material and a luminescent material, and the flux for the protective-glaze luminescent material comprises the following components in percentage by weight: 42-48 percent of SiO2, 3-7 percent of SrO, 15-21 percent of B2O3, 0.2-1.2 percent of Al2O3, 3-7 percent of Li2O, 2-7 percent of Na2O, 1-3 percent of K2O, 0.6-3.8 percent of metal fluoride, 2-3.5 percent of P2O5, 0-0.5 percent of Ta2O3, 0-1 percent of Nb2O5, 0-0.5 percent of ZrO2, 0-3 percent of CeO2, 0-0.5 percent of La2O3, 0-2 percent of Y2O3, 5-10 percent of ZnO, and 0-5 percent of MgO. According to the luminescent glaze for the enamel painted porcelain provided by the invention, the thermal stability and luminescence properties of the luminescent material can be guaranteed so as to improve the luminance and luminous time of the prepared painted porcelain after irradiation, while the various characteristics of the traditional enamel painted porcelain can be maintained.

Owner:HUNAN LILING HONGYU HONGCI CERAMICS

A method for melting eps waste

ActiveCN109747072BIncrease profitImprove melting effectPlastic recyclingExhaust fumesEnvironmental engineering

Owner:湖南丰源环保设备科技有限公司

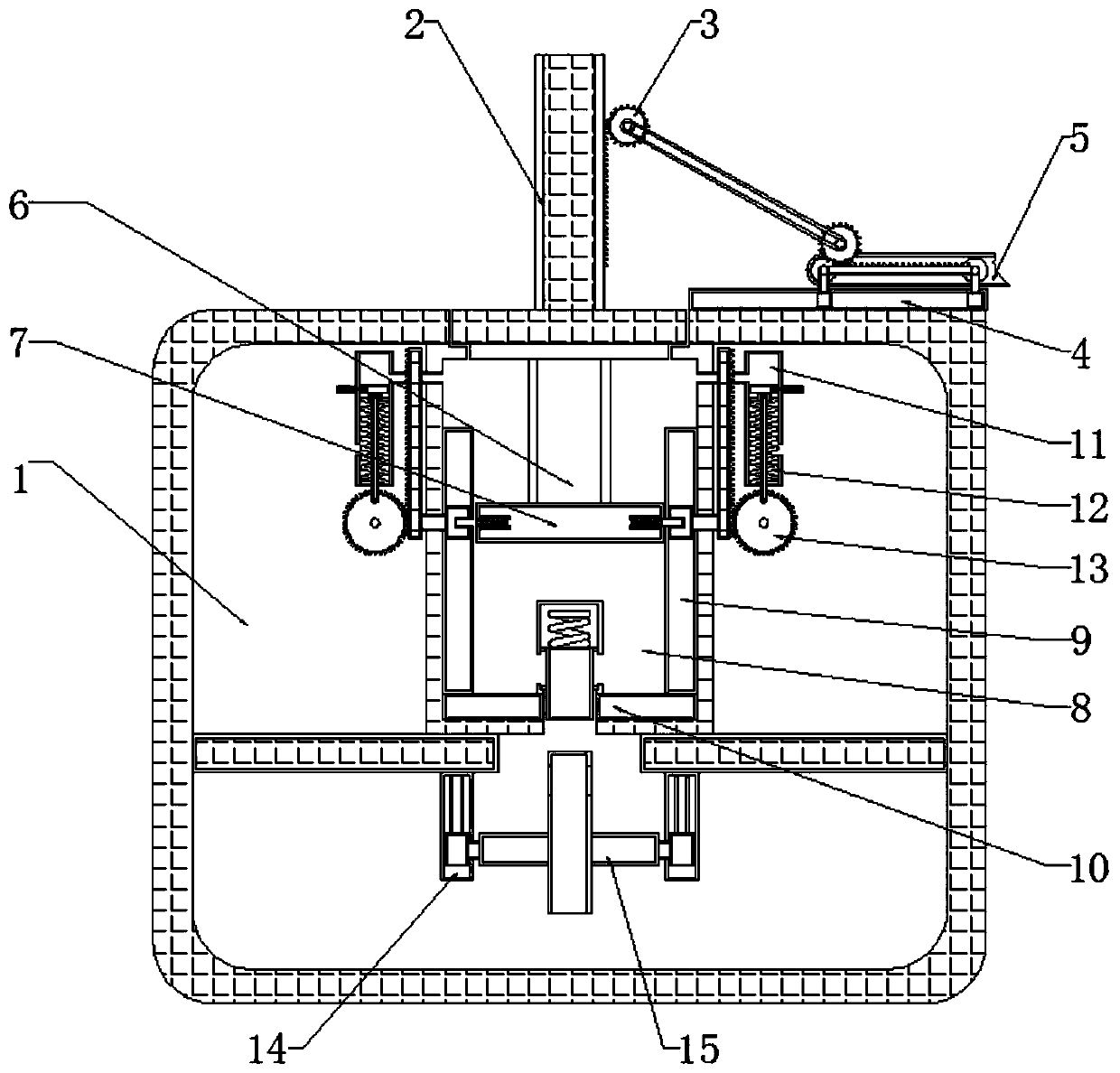

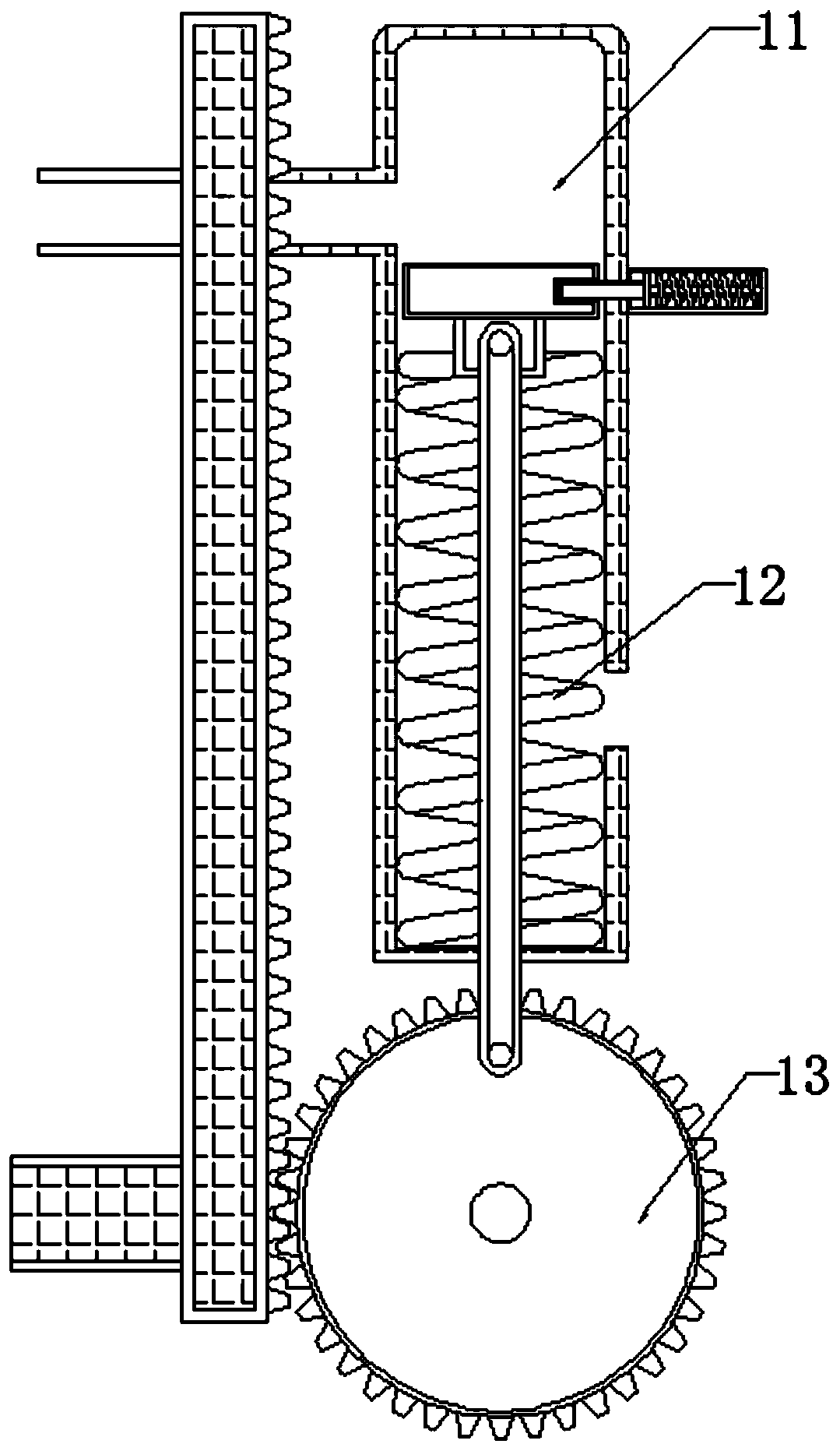

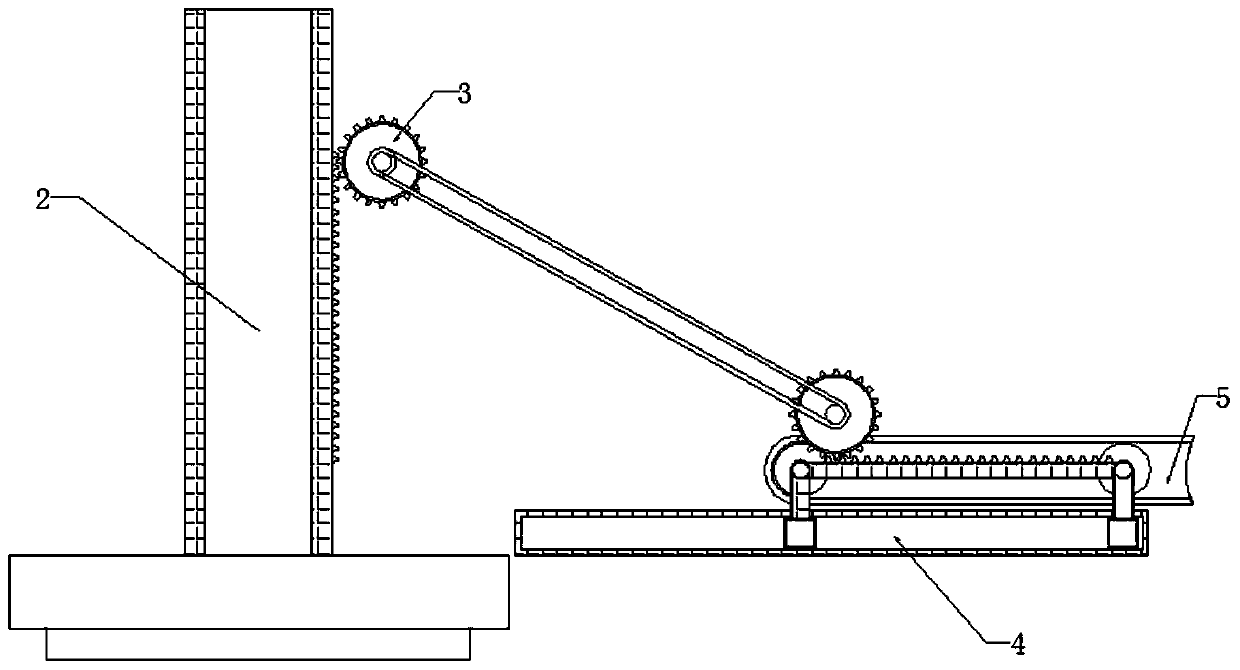

Smelting equipment for aluminum hot working

InactiveCN111912225AGuaranteed melting effectRealize flipping and unloading operationsCrucible furnacesGear wheelElectric machine

The invention discloses smelting equipment for aluminum hot working. The smelting equipment comprises a supporting bottom plate assembly, wherein a rotating assembly is rotatably arranged on the top end face of the supporting bottom plate assembly, a plurality of sets of overturning assemblies are fixedly arranged on the top end face of the rotating assembly, and clamping assemblies are fixedly arranged at the tops of the plurality of sets of overturning assemblies; and two sets of clamping plate assemblies are symmetrically distributed on the clamping assemblies in a threaded mode, material pouring assemblies are fixedly arranged on the rear sides of the clamping assemblies, and supporting top plate assemblies are arranged over the two sets of clamping plate assemblies. When the smeltingequipment is used, an aluminum material is smelted through an induction coil outside a copper crucible, a rotating motor drives the rotating assembly to rotate through cooperation of a second bevel gear and a first bevel gear, and through linkage cooperation of material pouring air cylinders, the material pouring assemblies and the overturning assemblies, overturning pouring operation of the copper crucible is achieved, so that discharging after aluminum material smelting is facilitated.

Owner:张满凤

Outdoor unit, control method thereof, and air conditioner

ActiveCN110274309BReduce frictionAvoid frictional collisionsMechanical apparatusCondensate preventionEngineeringFan blade

The invention provides an outdoor unit and a control method thereof, and an air conditioner. The outdoor unit comprises a controller, a base tray (1) and an outdoor heat exchanger (2), a microwave heating device (3) and / or an infrared heating device are / is arranged in a manner of corresponding to the base tray (1), a heating part of the microwave heating cavity (3) and / or a heating part of the infrared heating device face / faces the base tray (1), and can heat the base tray (1), a temperature sensor is arranged on the base tray (1), and is electrically connected to the controller, and the controller controls the microwave heating device (3) and / or the infrared heating device according to the temperature, detected by the temperature sensor, of the base tray (1). According to the outdoor unit, the deicing effect of the outdoor unit can be improved, and the friction between fan blades and an ice block can be effectively avoided.

Owner:GREE ELECTRIC APPLIANCES INC

Tin melting furnace for producing tin ingots

PendingCN108562167AImprove melting effectSave energyStirring devicesCrucible furnacesElectricityThermal insulation

The invention discloses a tin melting furnace for producing tin ingots and belongs to the technical field of tin ingot production equipment. A lining is arranged in a furnace body, electric heaters are arranged between the lining and the furnace body, the electric heaters are connected with an external power supply through wires, a feeding opening and a discharging opening are arranged in the furnace body, a supporting rod is arranged on the lining, hydraulic pumps are arranged in the supporting rod, push plates are arranged outside the supporting rod, the hydraulic pumps are connected with the push plates through hydraulic rods, the amount of the push plates is two or more than two, movable plates are arranged at the upper ends of the push plates, the movable plates are connected with thepush plates through rotating shafts, pushers are arranged on the push plates, the pushers are connected with the movable plates, movable angles of the movable plates are 30 to 45 degrees, and a thermal-insulation layer is arranged outside the furnace body. The movable plates are driven by the pushers to move fro and back, so that the melting effect is improved; the thermal-insulation layer is used for thermal insulation, and energy is saved.

Owner:NANJING DAMAI SCI&TECH IND CO LTD

A high-efficiency detection method for particle steel

ActiveCN112378946BChemical detection is accuratePreserve far sample propertiesMaterial weighingInvestigating phase/state changeMaterials sciencePhysics

The invention relates to a high-efficiency detection method for particle steel, which includes: sampling the particle steel three times, determining the quality difference coefficient Z according to the sample ratio, and then processing the sample to ensure the representativeness of the sample, sieving the sample, and classifying the sample. It is the rough material group, the sieve material group, and the sieve material group. At the same time, the above sample groups are measured to determine the particle steel irregularity coefficient G and estimate the estimated particle steel water yield Y0 according to the preset rules, and determine Estimate whether the water yield Y0 can be used as the final total water yield. If not, melt the particle steel, and accurately adjust the current and melting time of the high-frequency reaction furnace during the melting process to ensure the melting effect, so as to determine the particle steel Water yield.

Owner:TANGSHAN CAOFEIDIAN DISTRICT TONGXIN RENEWABLE RESOURCE RECYCLING

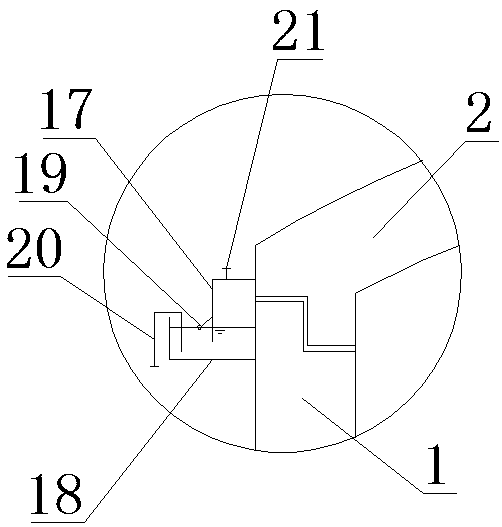

Composite molding die for polyethylene winding structure wall tube

The invention relates to a composite molding die for a polyethylene winding structure wall tube, which solves the defects that die core tubes of various specifications need to be prepared for producing tubing of different lengths because the length of the die core tube and the length of the tubing correspond one by one in the prior art, the cost is high and the die core tube is inconvenient to replace. The composite molding die for the polyethylene winding structure wall tube comprises a cylinder with a smooth outer wall, wherein the cylinder can be freely sheathed on a support frame in a rotating mode; the middle of the support frame is provided with an axle hole connected with a main axle; the inner wall of the cylinder is provided with an axial spacing component matched with the support frame; a heating device for heating the inner wall of the cylinder is arranged in the cylinder; the length of the cylinder is at last two times of the width of the winding unit of the polyethylene winding structure wall tube to be produced; and the length of the cylinder is at least two times of the width of the winding unit to ensure that the an overlapped part is positioned on the outer wall of the cylinder when the winding unit is winded. Temperature required by the winding unit to fuse is provided by the cylinder to guarantee the fusion effect. Meanwhile, a lap joint seam is eliminated, and the tubing quality is improved.

Owner:何军

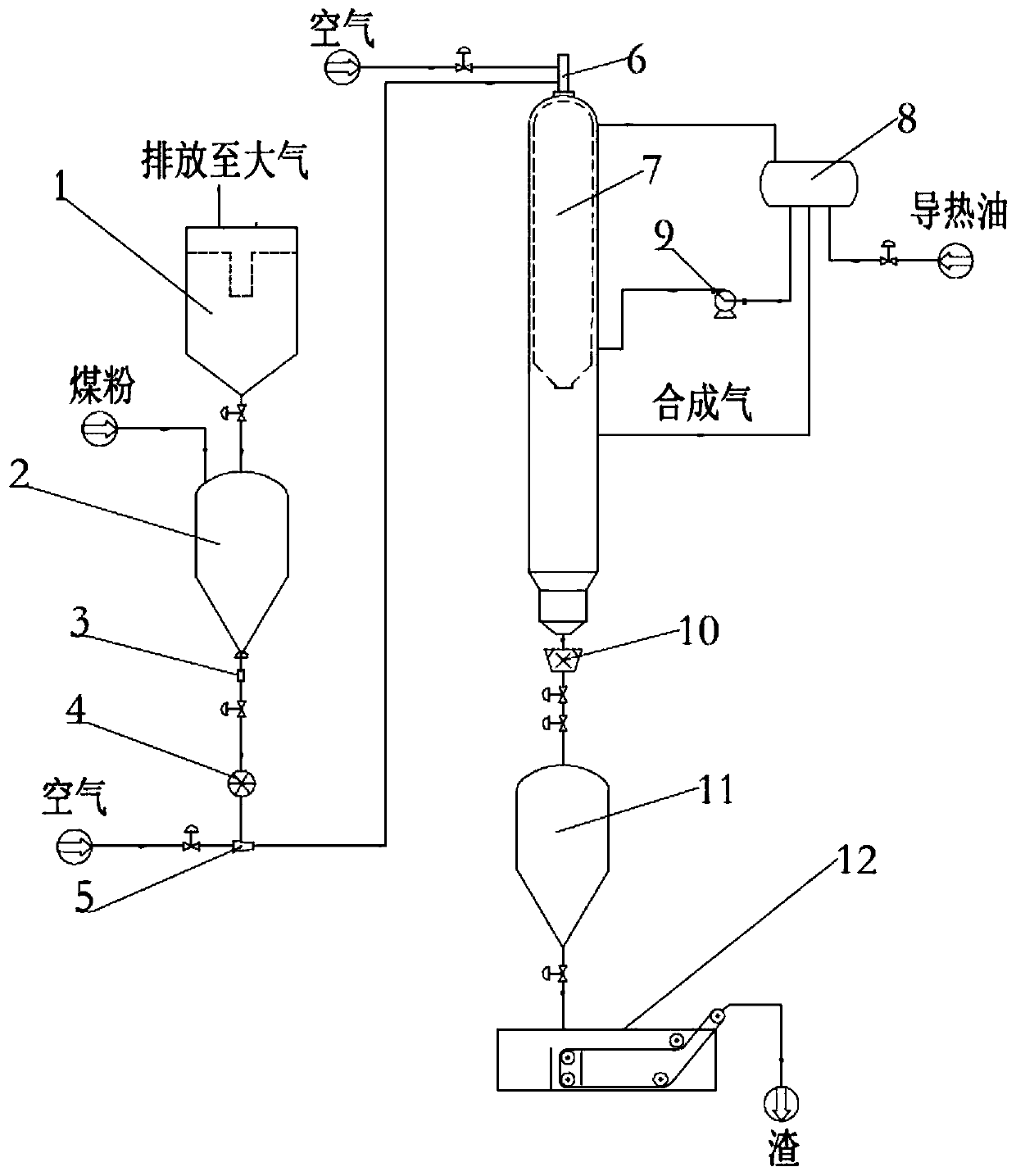

Gasification equipment for heating asphalt and method of equipment

PendingCN110591760AGuaranteed melting effectSpeed up the gasification reactionGasification processes detailsRoads maintainenceMolten stateHigh carbon

The invention provides gasification equipment for heating asphalt and a method of the equipment. The equipment mainly includes a pulverized coal storage tank, an aerator, a volumetric screw conveyor,an ejector, a gasification furnace burner, a gasification furnace, an asphalt mixing station device, a residue breaker, a residue tank and a residue catching machine; and the method comprises the following steps: dry pulverized coal is sent into the normal-pressure gasification furnace, the dry pulverized coal and air are subjected to a high-temperature gasification reaction to generate crude coalgas mainly composed of CO and H2, the crude coal gas is sent to the asphalt mixing station device, and at the same time, ash residues are in a molten state in the gasification process and flows out through the lower part of the gasification furnace and is discharged through a residue discharge unit. The gasification furnace is core equipment of the entire equipment, and has the characteristics ofultra-high temperature gasification and a high residue catching rate through the unique design; and the equipment provided by the invention is used for heating the asphalt, has the characteristics ofa high carbon conversion rate and a high residue catching rate, and the economical and environmental protection performance of the equipment can be improved.

Owner:NINGXIA UNIVERSITY

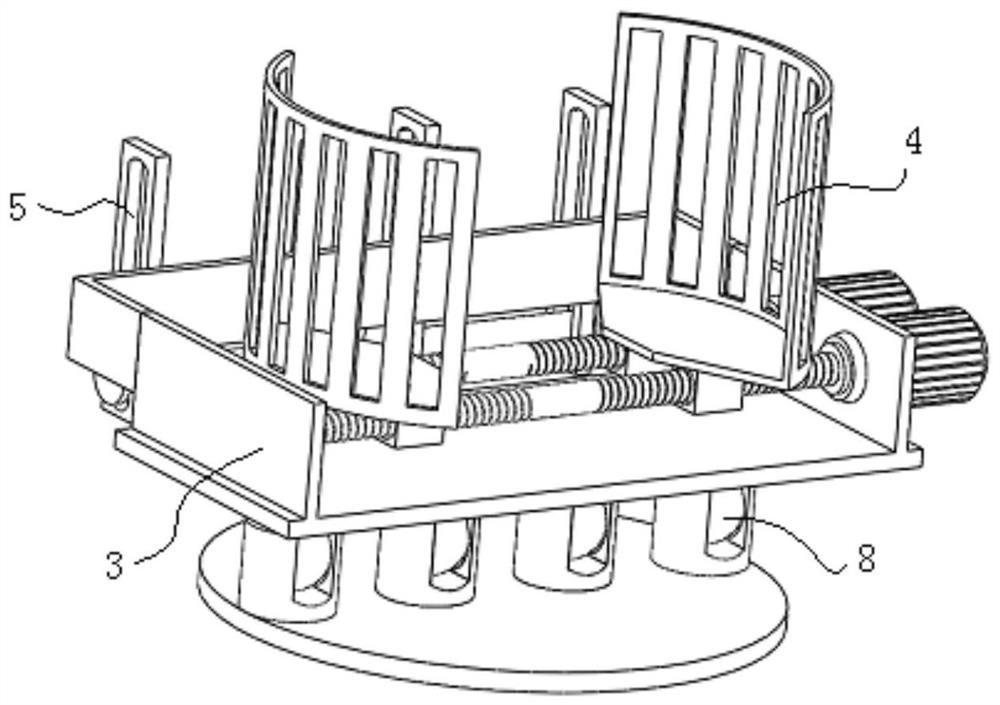

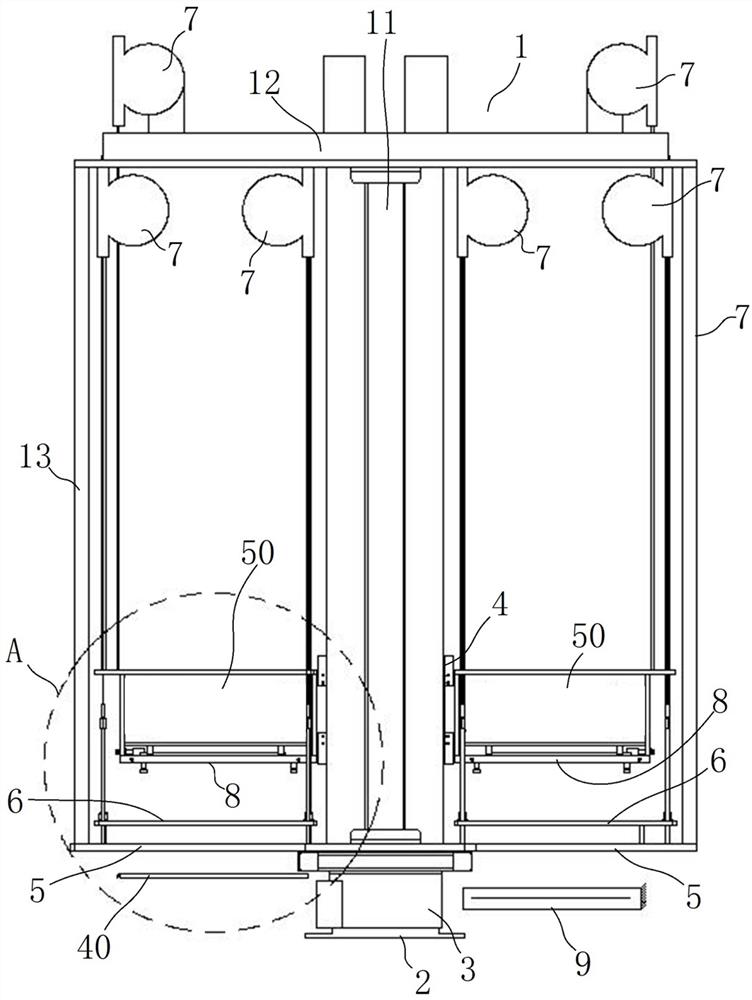

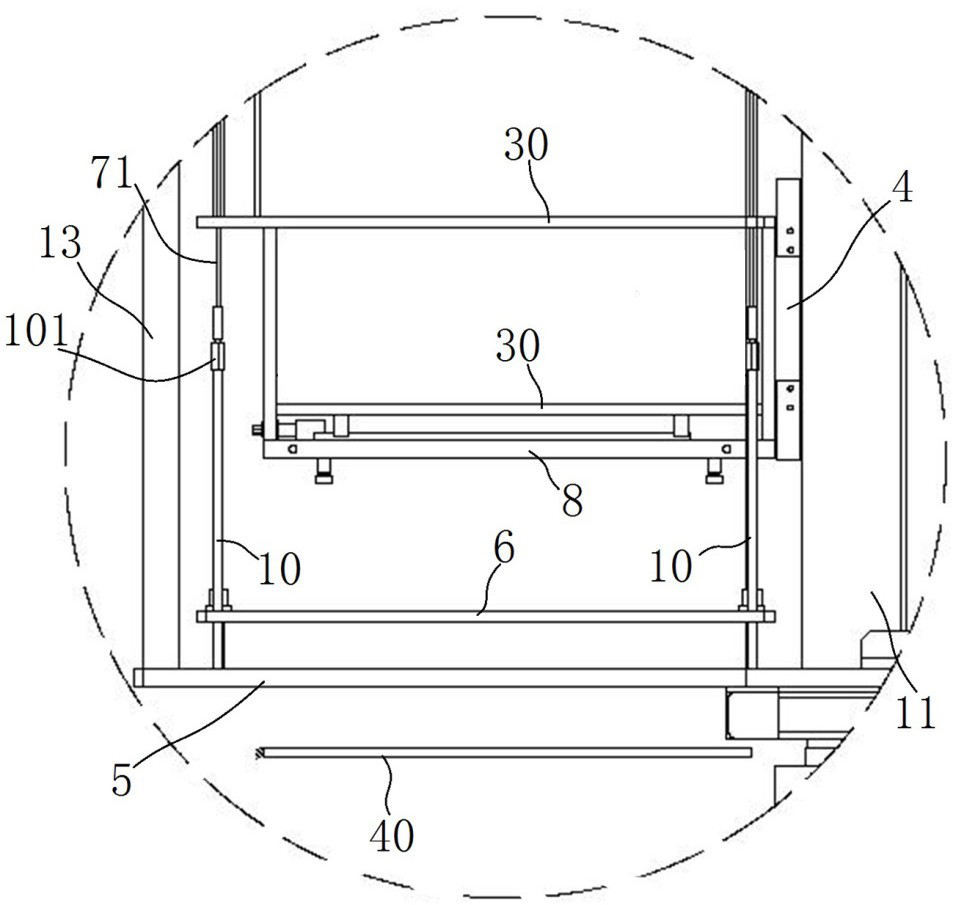

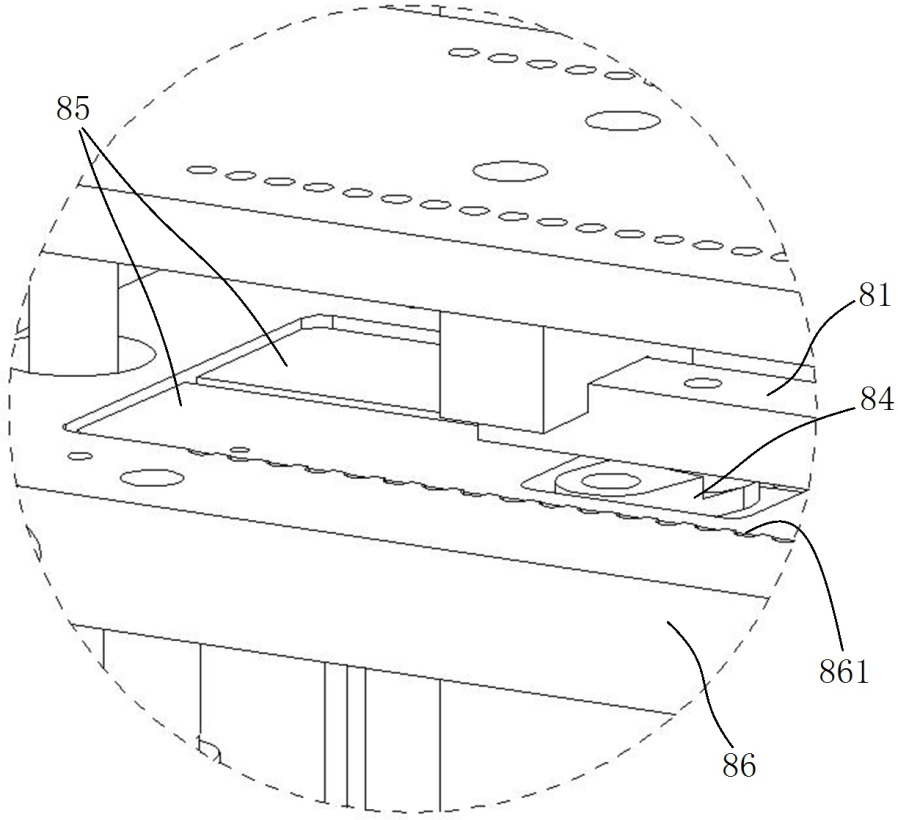

Rod clamping mechanism for efficient rod changing and wire drawing feeding device

PendingCN114605064AHigh positioning accuracyGuaranteed uptimeGlass making apparatusClassical mechanicsStructural engineering

The invention relates to a rod clamping mechanism for an efficient rod changing and wire drawing feeding device. The rod clamping mechanism is used for solving the technical problems that an existing rod clamping mechanism is tedious and troublesome in operation, low in efficiency and poor in quartz rod positioning precision. The rod clamping mechanism for the efficient rod changing and wire drawing feeding device comprises a fixed clamping plate, a transverse guide rod, a movable clamping plate, a sliding rod and a driving mechanism. The sliding rod is driven by the driving mechanism to move so as to drive the at least two connecting rod groups to act, and each connecting rod group drives the two movable clamping plates to synchronously move towards the corresponding fixed clamping plates, so that the two rows of quartz rods are synchronously clamped. The quartz rod clamping device has the advantages of being convenient, fast and efficient to operate, high in quartz rod positioning precision and uniform and consistent in clamping force on all quartz rods.

Owner:河南神玖天航新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com