Quantitative indoor solid bitumen rapid heating extraction system

A technology of rapid heating and extraction system, applied in sampling devices, preparation of test samples, etc., can solve the problems of cumbersome sampling operation and easy aging of asphalt, and achieve the effect of ensuring melting effect, avoiding waste and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail through specific implementation methods:

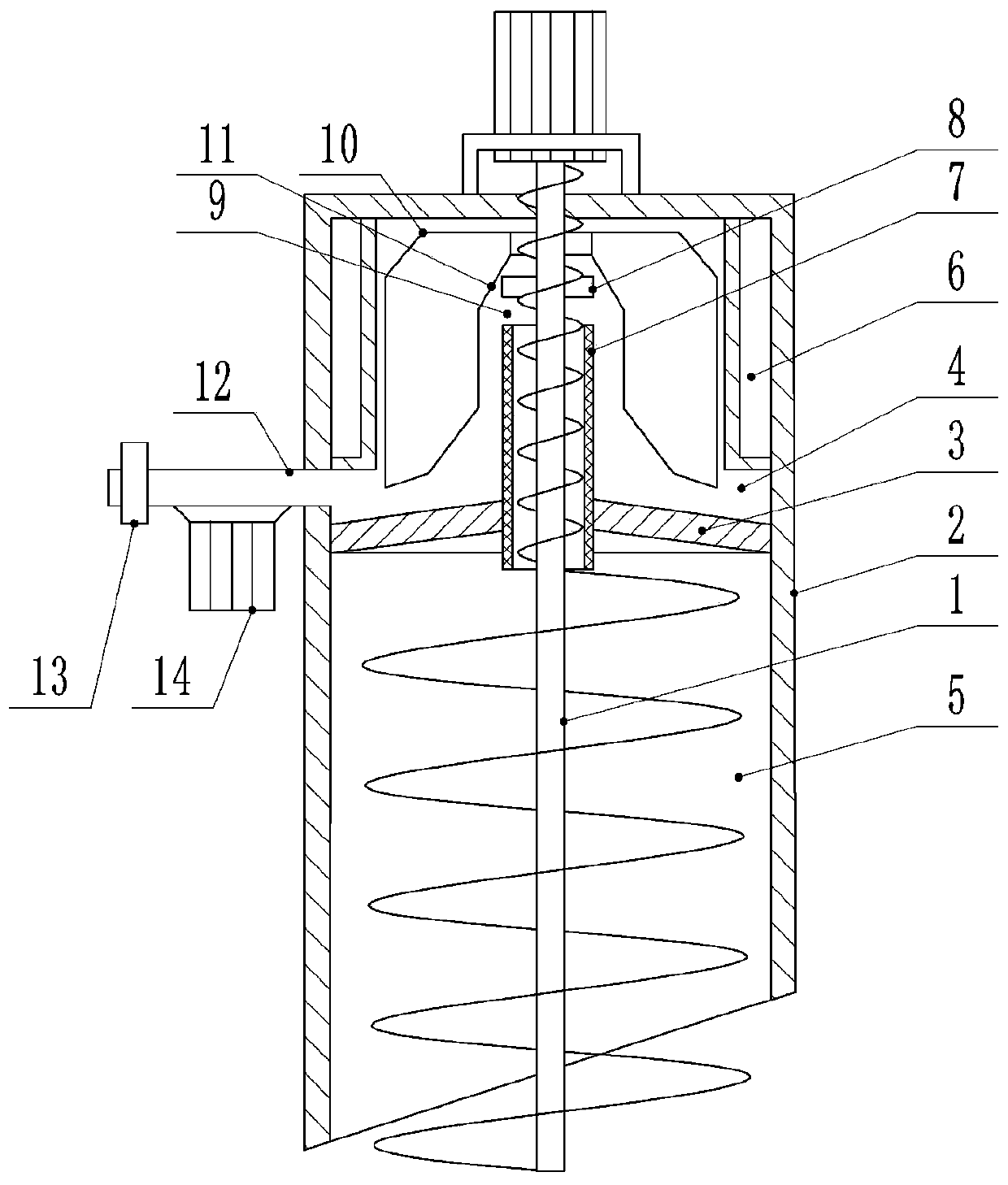

[0020] The reference signs in the drawings of the description include: spiral sampling transmission rod 1, cylinder body 2, partition plate 3, heating chamber 4, sampling transmission chamber 5, interlayer 6, sleeve 7, blocking cap 8, feed port 9. Stirring plate 10, slope 11, discharge pipe 12, flow meter 13, power pump 14.

[0021] Examples are attached figure 1 Shown: Quantitative indoor solid asphalt rapid heating extraction system, including a spiral sampling transmission rod 1 and a cylinder 2 with an opening at one end. The end of the cylinder 2 with an opening is inclined and has a tip. A partition plate 3 with a conical structure is connected, the upper end surface of the partition plate 3 is a conical surface, and the lower end surface is concave upward. The partition 3 divides the inside of the cylinder body 2 into an upper heating chamber 4 and a lower sampling transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com