Environment-friendly smelting furnace for nickel-based alloy powder coating

A powder coating, nickel-based alloy technology, applied in furnaces, crucible furnaces, furnace components and other directions, can solve the problems of the melting furnace thermal insulation performance and safety performance need to be improved, the melting furnace is inconvenient to use, not enough energy saving and environmental protection, etc. Smelting effect, guaranteeing smelting effect and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

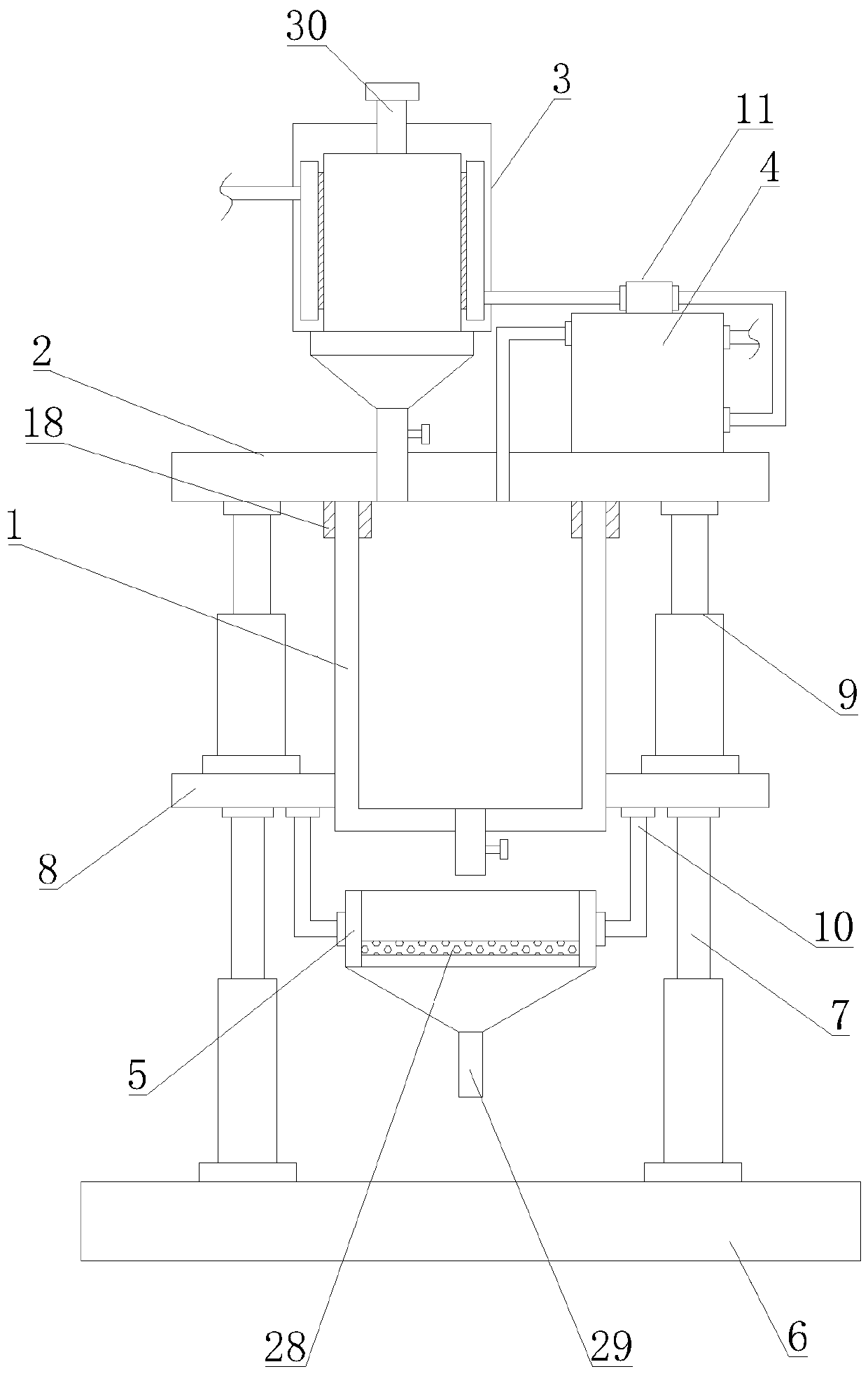

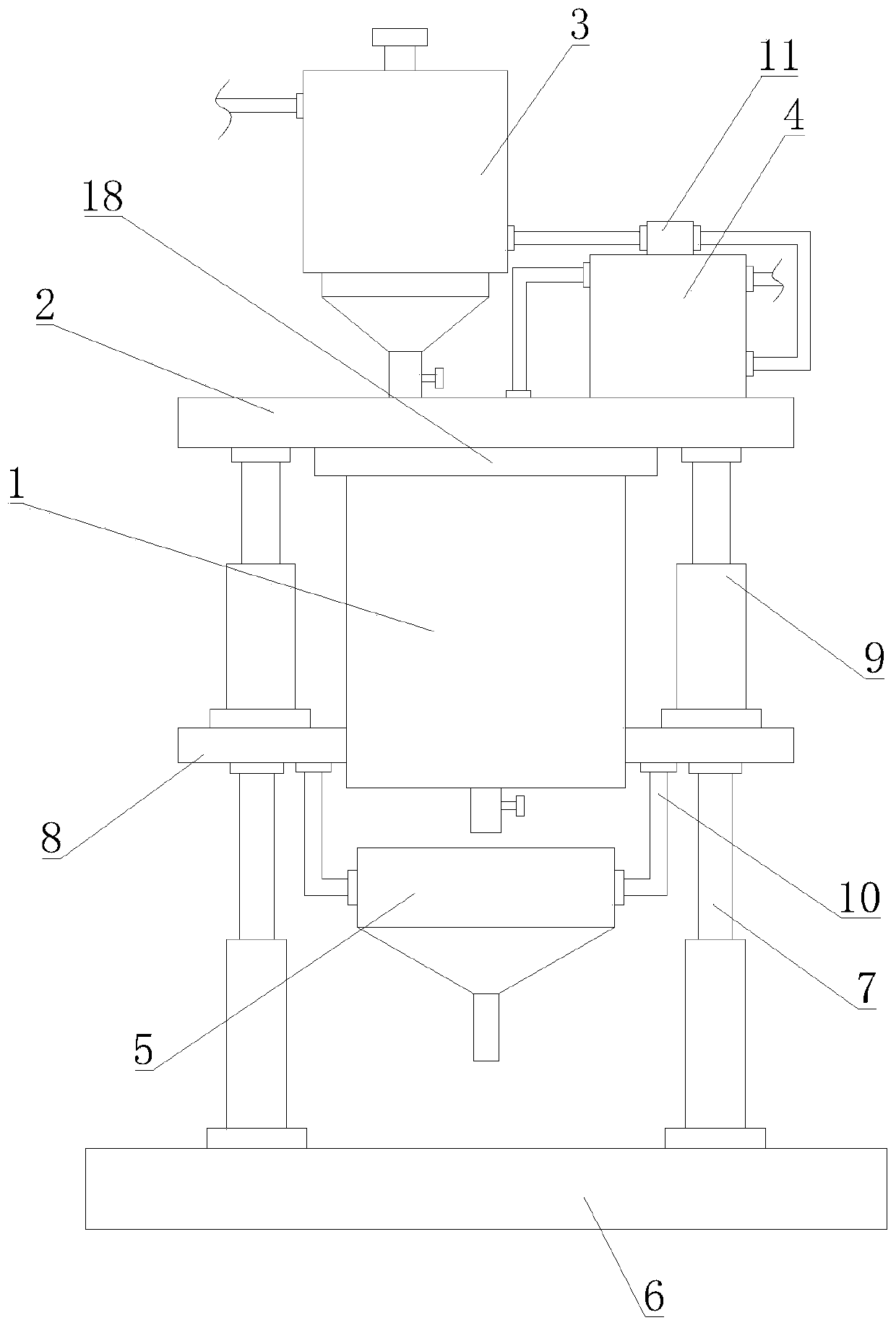

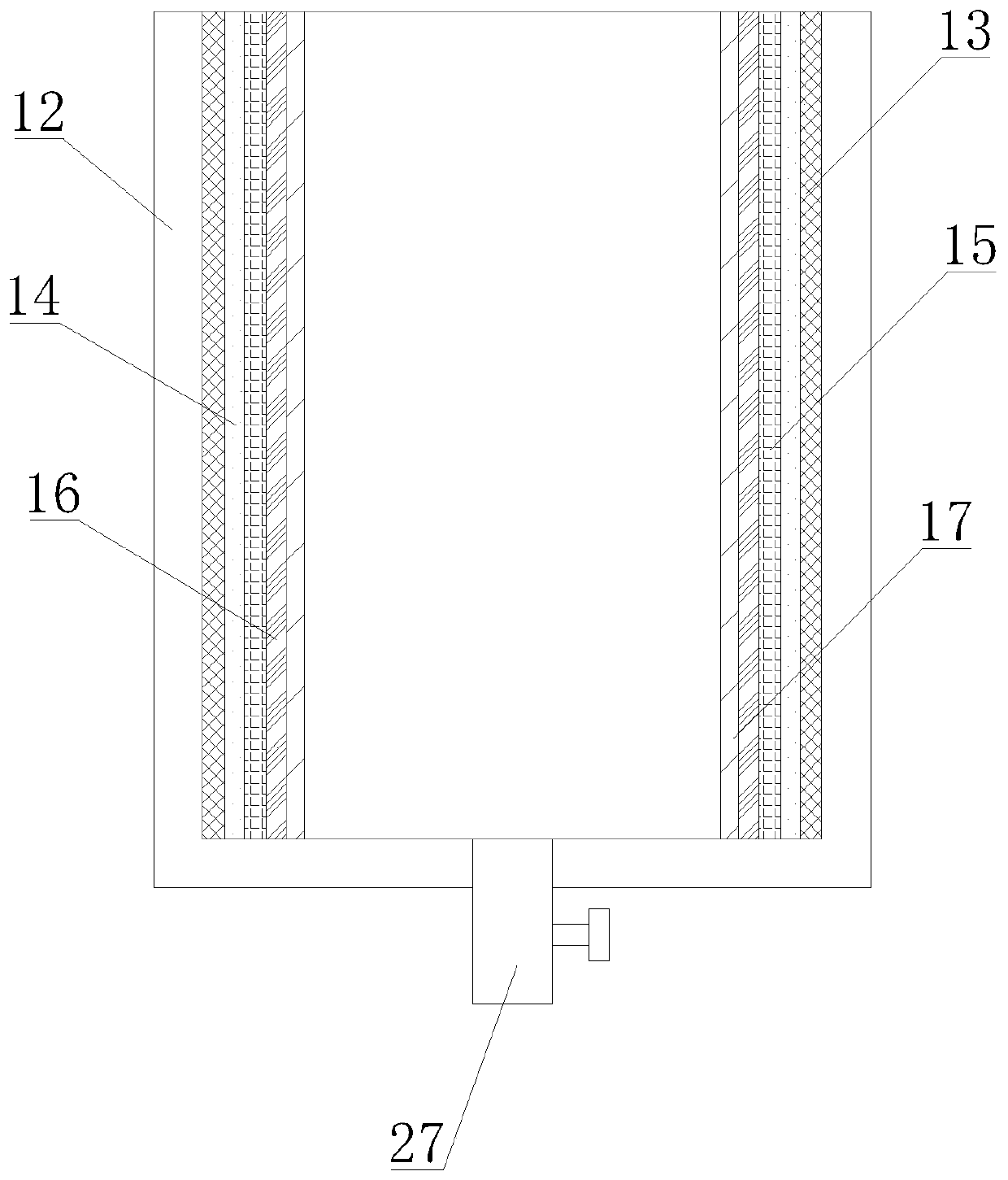

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0035] refer to Figure 1-5 , an environmentally friendly melting furnace for nickel-based alloy powder coating, comprising a melting furnace body 1, a melting furnace cover body 2, a material storage box 3, a purification heat absorption box 4, a material receiving part 5, a base 6, and a first telescopic mechanism 7 , the second telescoping mechanism 9, the second connector 10 intake pipe 19, the air-permeable plate 20, the connecting pipe 21, the exhaust pipe 22, the liquid discharge pipe 24 and the feeding pipe 26;

[0036] The opening of the melting furnace body 1 faces upward and is located above the base 6. The melting furnace cover 2 is arranged on the meltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com