Preparation method and device for melt spinning of ultra-high molecular weight polyethylene

An ultra-high molecular weight, melt spinning technology, used in the field of melt spinning, can solve the problems of uneven thickness of the thread, the molecules cannot be rearranged, and the uniform distribution of the molecules cannot be guaranteed, and the process is simple and the melting effect is guaranteed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

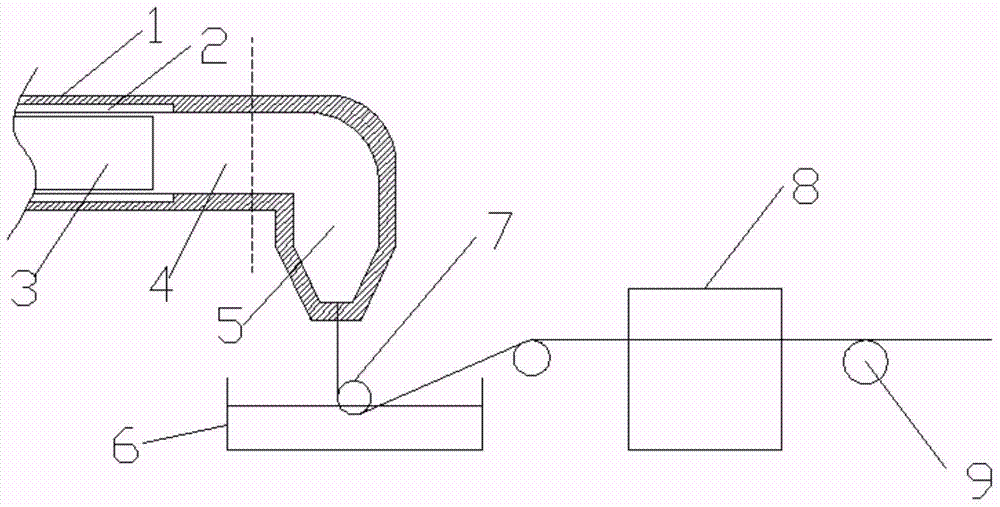

[0024] Such as figure 1 Shown, the preparation method and device of ultra-high molecular weight polyethylene melt spinning,

[0025] (1) Raw material extrusion treatment: the raw material is extruded to the melting zone through the sleeve-type die, and the inside of the sleeve-type die is vacuum. The sleeve-type die includes a sleeve and a screw inside the sleeve. There are several rifling lines, and the end of the sleeve is extended with a melting zone and a dense zone. The inside of the sleeve is a vacuum, and the temperature of the melting zone is 350 degrees. Under the continuous extrusion of subsequent raw materials, the melted raw materials pass through the dense zone. The wire hole at the lower end of the tube is extruded into a wire, and the dense area is a bent tube whose radius decreases linearly to the lower end;

[0026] (2) Silk thread curing treatment: the silk thread is cured by a warm water tank, and the water temperature in the warm water tank is 50 degrees. ...

Embodiment 2

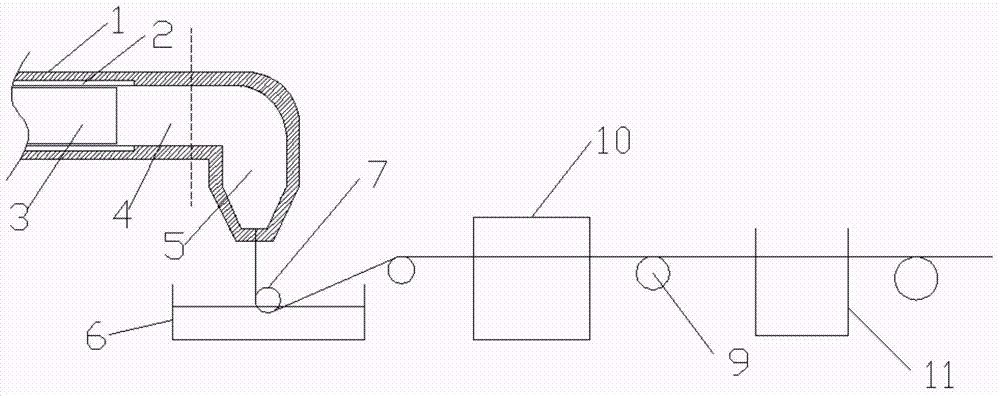

[0030] Such as figure 2 Shown, the preparation method and device of ultra-high molecular weight polyethylene melt spinning,

[0031] (1) Raw material extrusion treatment: the raw material is extruded to the melting zone through the sleeve-type head. The sleeve-type head includes a sleeve and a screw inside the sleeve. There is a melting zone and a dense zone extending from the inside of the sleeve. The inside of the sleeve is vacuum, and the temperature of the melting zone is 360 degrees. Under the continuous extrusion of subsequent raw materials, the melted raw materials are extruded into silk threads through the outlet hole at the lower end of the dense zone. , the dense area is a bent tube and its radius decreases linearly to the lower end.

[0032] (2) Silk thread curing treatment: the silk thread is cured by a warm water tank, and the water temperature in the warm water tank is 50 degrees.

[0033] (3) Silk thread stretching treatment: the thread treated in step (2) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com