Device for laying waterproof coiled material

A technology of waterproofing membrane and baking device, which is applied to tools for roofing, mining equipment, shaft equipment, etc., can solve problems such as affecting the laying effect of waterproofing membranes and not being able to melt the waterproofing membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

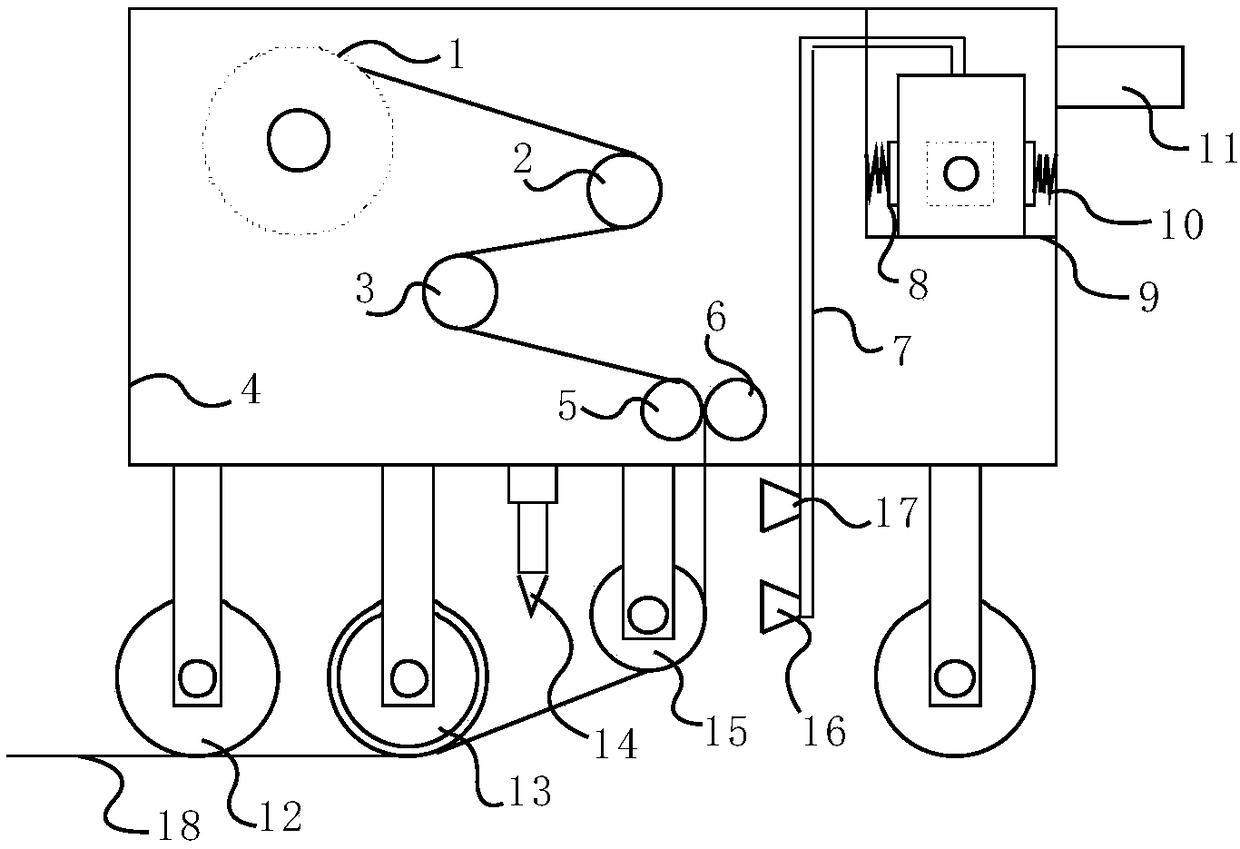

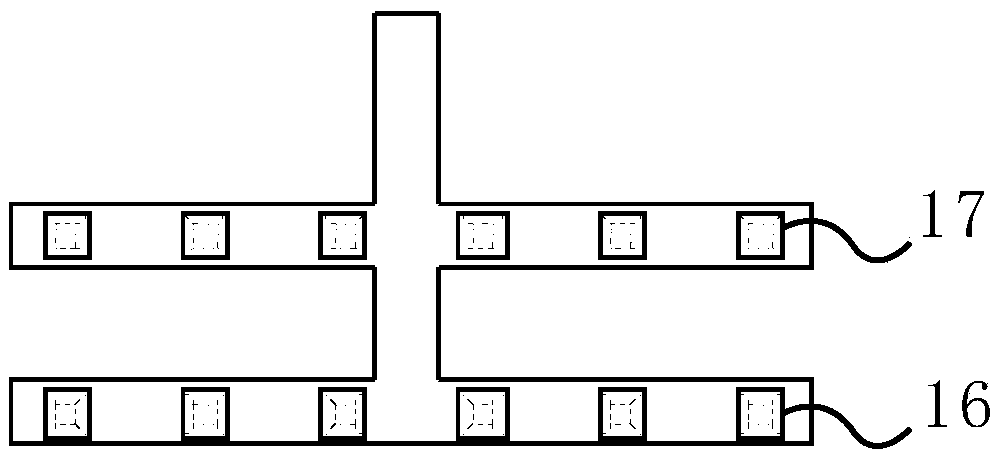

[0019] As shown in the figure, the present invention includes a transmission case 4 with an opening on the upper surface, a transmission mechanism, a hot pressing roller 13 and a baking device located at the bottom of the transmission case 4, and the hot pressing roller 13 communicates with the motor in the transmission case 4 in this example. The hot pressing roller 13 provides electric power, and the transmission mechanism includes a coil unwinding roller 1 arranged inside the transmission case 4, a straightening roller assembly and a baking roller 15 arranged under the transmission case 4, and the baking device includes a fuel tank, a group of main nozzles 16 facing the baking roller 15, and a group of preheating nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com