Method and device for improving quality of welding seam

A quality and weld surface technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems affecting the quality of strip steel products, poor weld quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

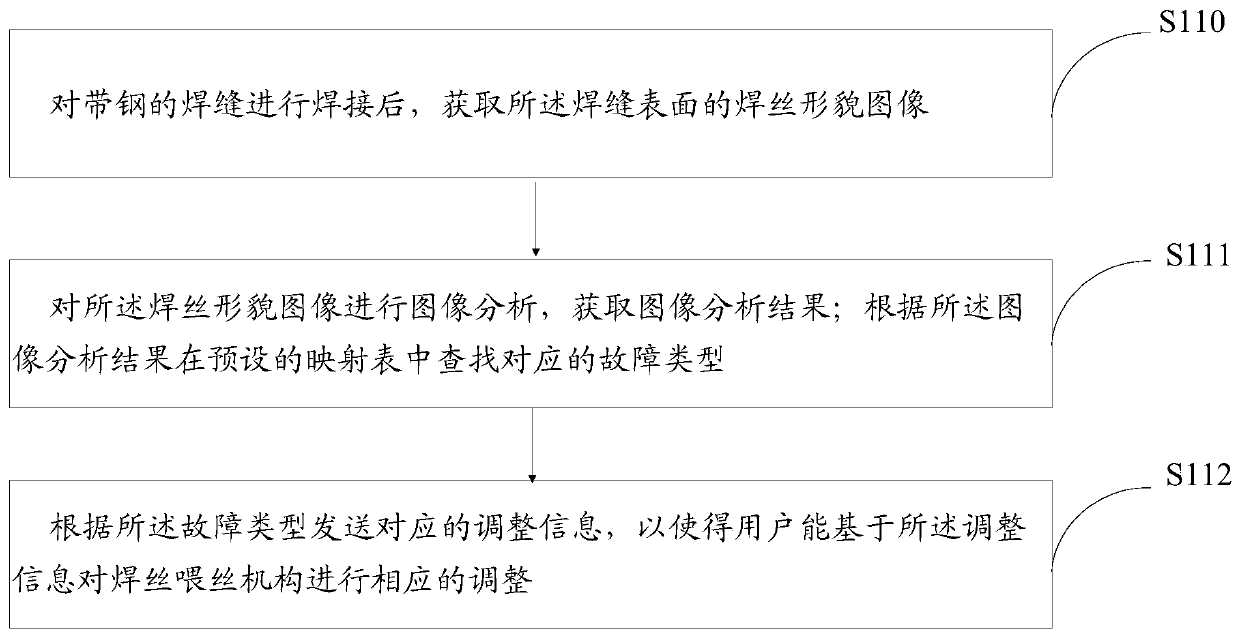

[0044] This embodiment provides a method for improving the quality of welds, such as figure 1 As shown, the methods include:

[0045] S110, after welding the weld seam of the steel strip, acquiring a welding wire morphology image on the surface of the weld seam;

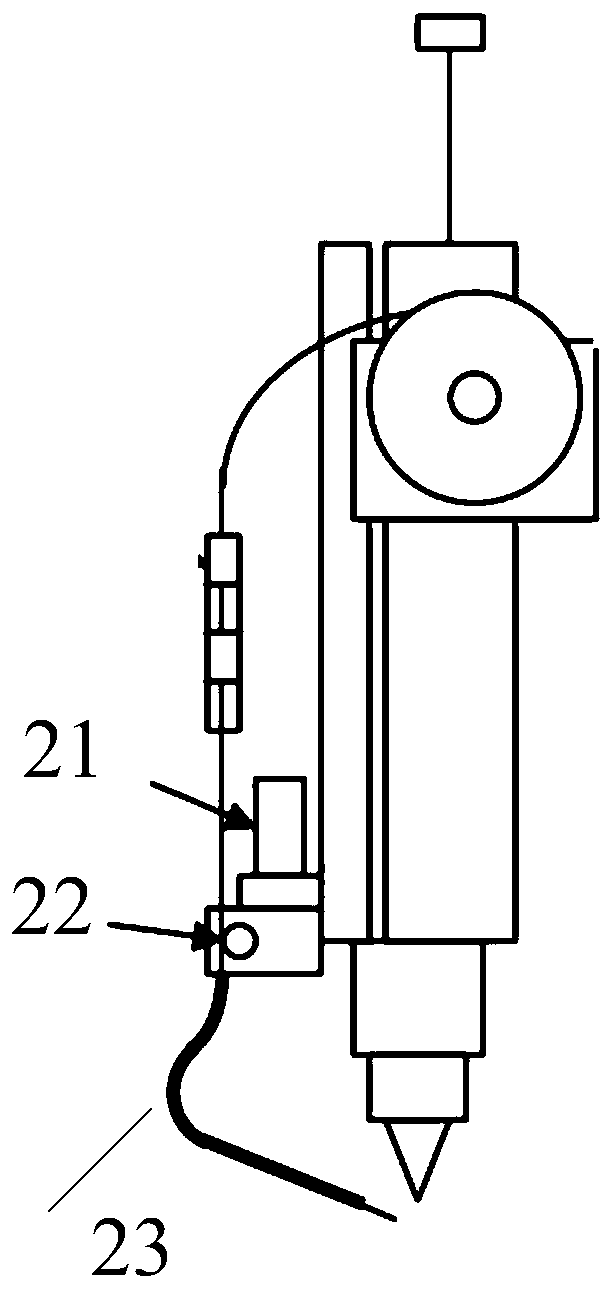

[0046] Due to the relative offset between the position of the welding wire and the position of the laser beam during the welding process, the welding wire will not melt and have melting defects. In order to better understand the technical solution, first introduce the structure of the welding wire feeding mechanism of the laser welding machine, such as figure 2 As shown, the welding wire feeding mechanism includes: a tensioning wheel 21, a welding wire driving unit 22, and a wire feeding guide nozzle composition 23, and the working status of each component of the welding wire feeding mechanism is a key factor to ensure the quality of welding wire melting.

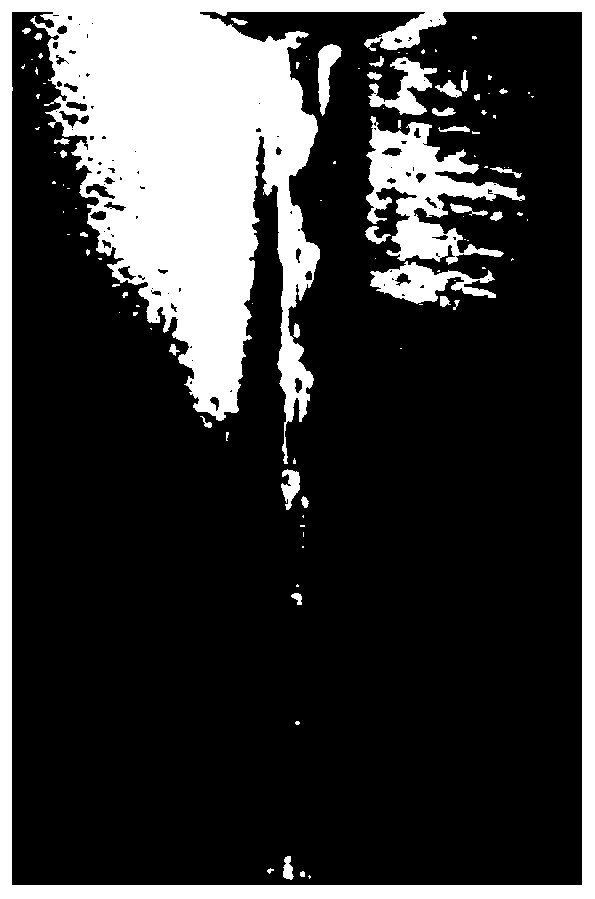

[0047] After welding, when different components fail, the...

Embodiment 2

[0081] This embodiment provides a device for improving the quality of the weld, refer to Figure 5 , the device includes: an acquisition unit 51, an analysis unit 52, a search unit 53 and a sending unit 54; wherein,

[0082] During the welding process, when the position of the welding wire and the position of the laser beam are offset relative to each other, the welding wire will not melt and have melting defects. In order to better understand the technical solution, first introduce the structure of the welding wire feeding mechanism of the laser welding machine, such as figure 2 As shown, the welding wire feeding mechanism includes: a tensioning wheel 21, a welding wire driving unit 22, and a wire feeding guide nozzle composition 23, and the working status of each component of the welding wire feeding mechanism is a key factor to ensure the quality of welding wire melting.

[0083] After welding, when different components fail, the topographic images of the welding wire on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com