Anti-blocking injection molding machine

An injection molding machine, anti-clogging technology, applied in the field of injection molding, can solve problems such as affecting injection speed and efficiency, affecting injection speed, affecting molding speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

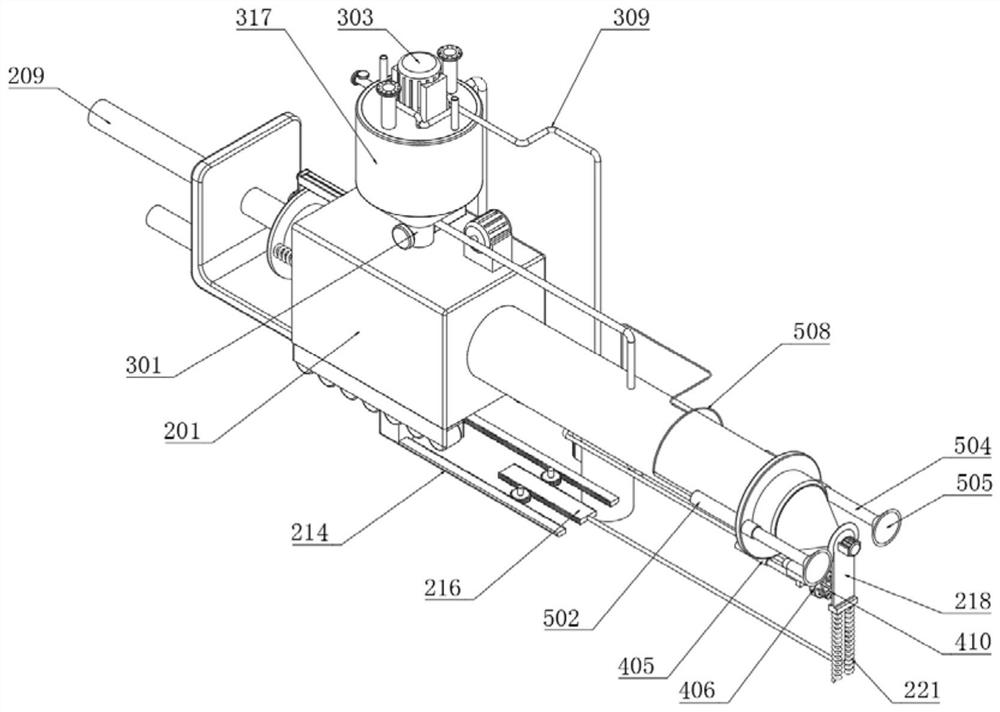

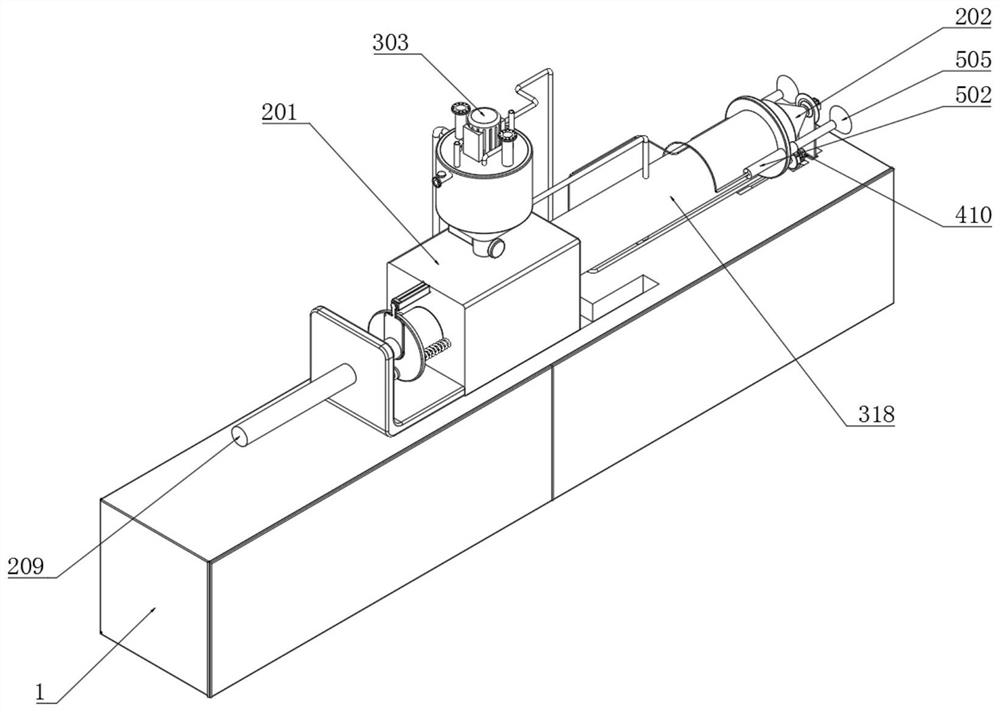

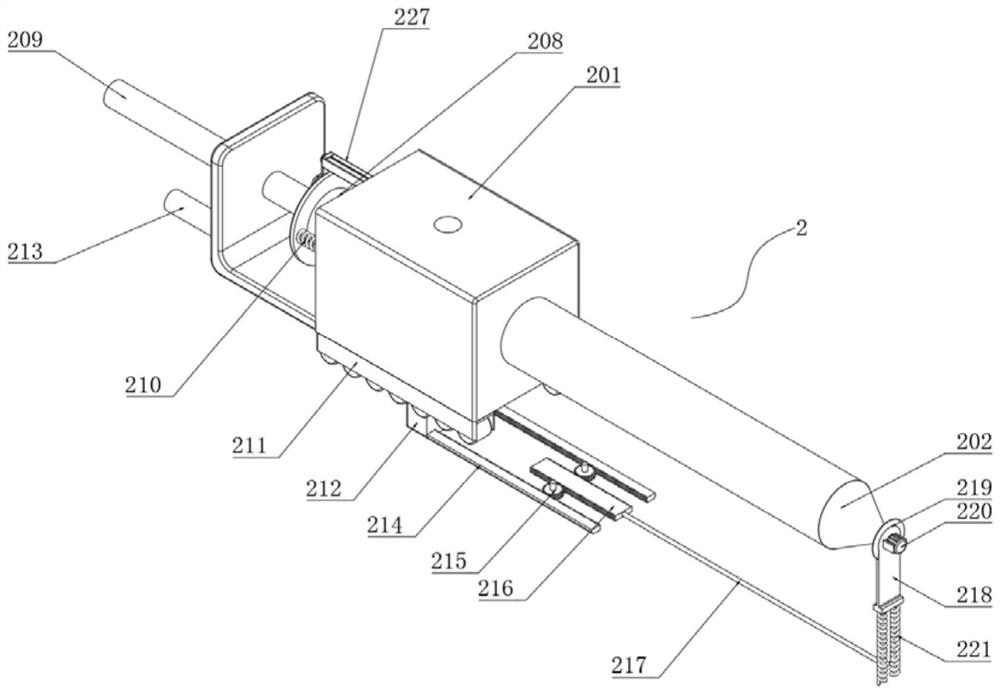

[0037] Example: such as Figure 1-12 As shown, the present invention provides a technical solution, an anti-blocking injection molding machine, including a fixed installation box 1, an anti-blocking injection assembly 2 is installed on the top of the fixed installation box 1, and a pair of delivery auger 204 and anti-backflow threaded column 205 The injection molding raw material is transported, and its transport direction is restricted at the same time to prevent the counter flow of the raw material during transport, and the extrusion hydraulic cylinder 209 is directly extruded after it is transported to a fixed position, so that the raw material is transported into the mold. And when resetting, drive the anti-blocking column 225 to move by pushing the spring 224, thereby the injection port is sealed, and the raw material condensed at the position of the injection port is pushed out, thereby avoiding the influence of subsequent injection molding discharge speed due to condensa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com