Patents

Literature

52results about How to "Fast injection molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

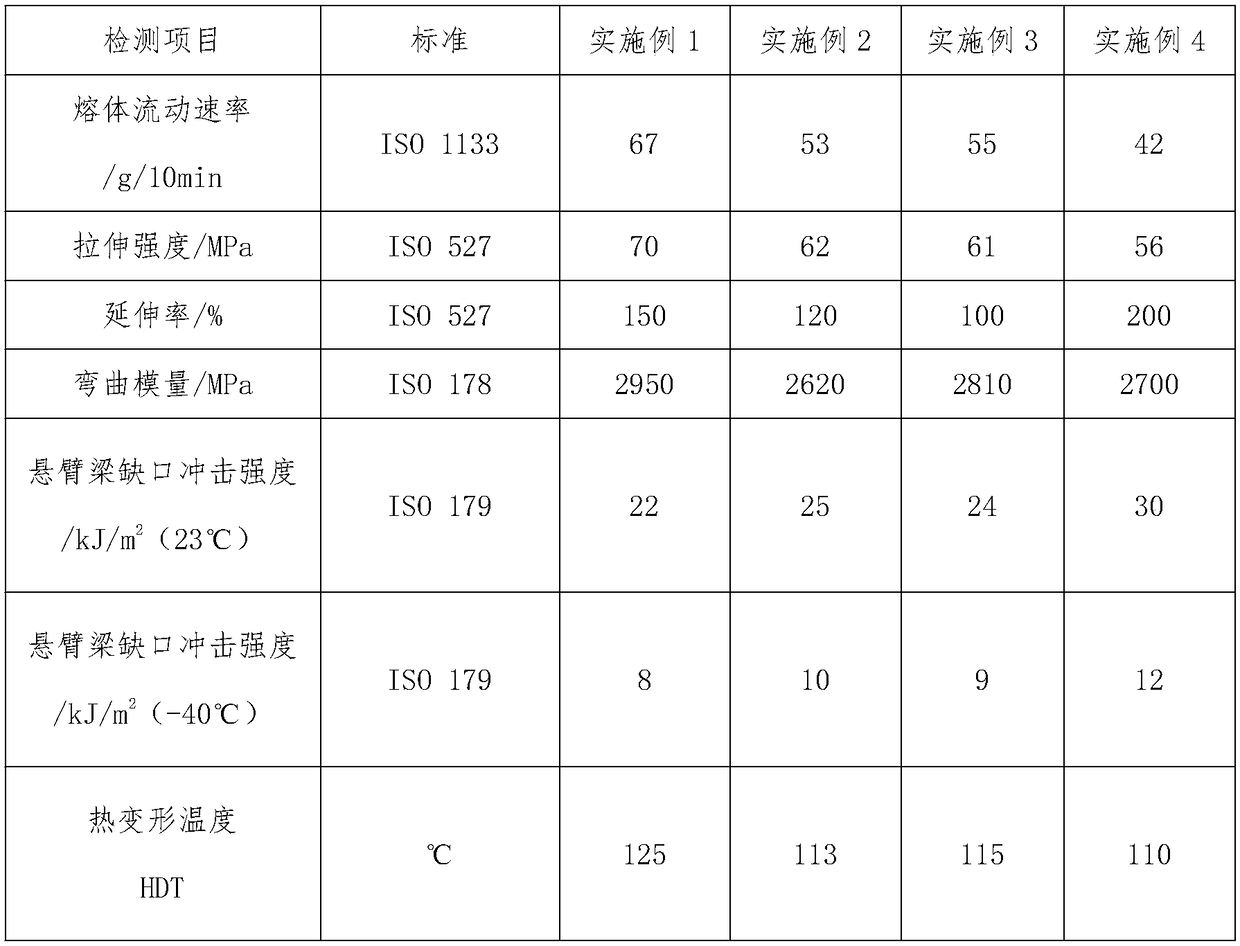

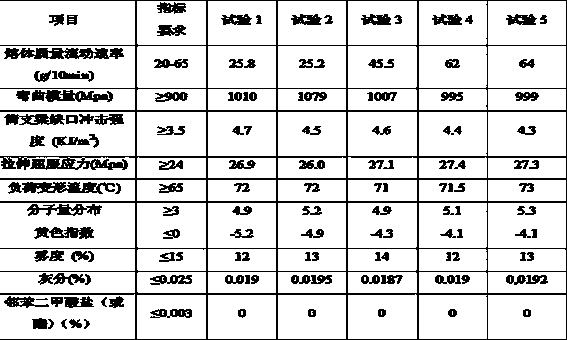

Quickly crystallized polyester engineering plastic and preparation method thereof

The invention relates to a quickly crystallized polyester engineering plastic and a preparation method thereof. The quickly crystallized polyester engineering plastic is prepared with the following components by way of extrusion in a double-screw extruder: 100 parts by weight of modified quickly crystallized polyester A, 0.05 to 5 parts by weight of nucleating agent B, 10 to 40 parts by weight of glass fibers C, 10 to 30 parts by weight of flame retardant D, 1 to 15 parts by weight of flexibilizer E and 0.01 to 3 parts by weight of antioxidant F. The engineering plastic has the advantages of high crystallization speed, high mechanical strength, quick injection moulding and low-temperature demoulding, the finished product cannot be deformed, and the engineering plastic prepared with the quickly crystallized polyester engineering plastic composition has the advantages of high crystallization speed, high mechanical strength, quick injection moulding and low-temperature demoulding.

Owner:CHINA PETROLEUM & CHEM CORP +1

Die casting machine and die casting method

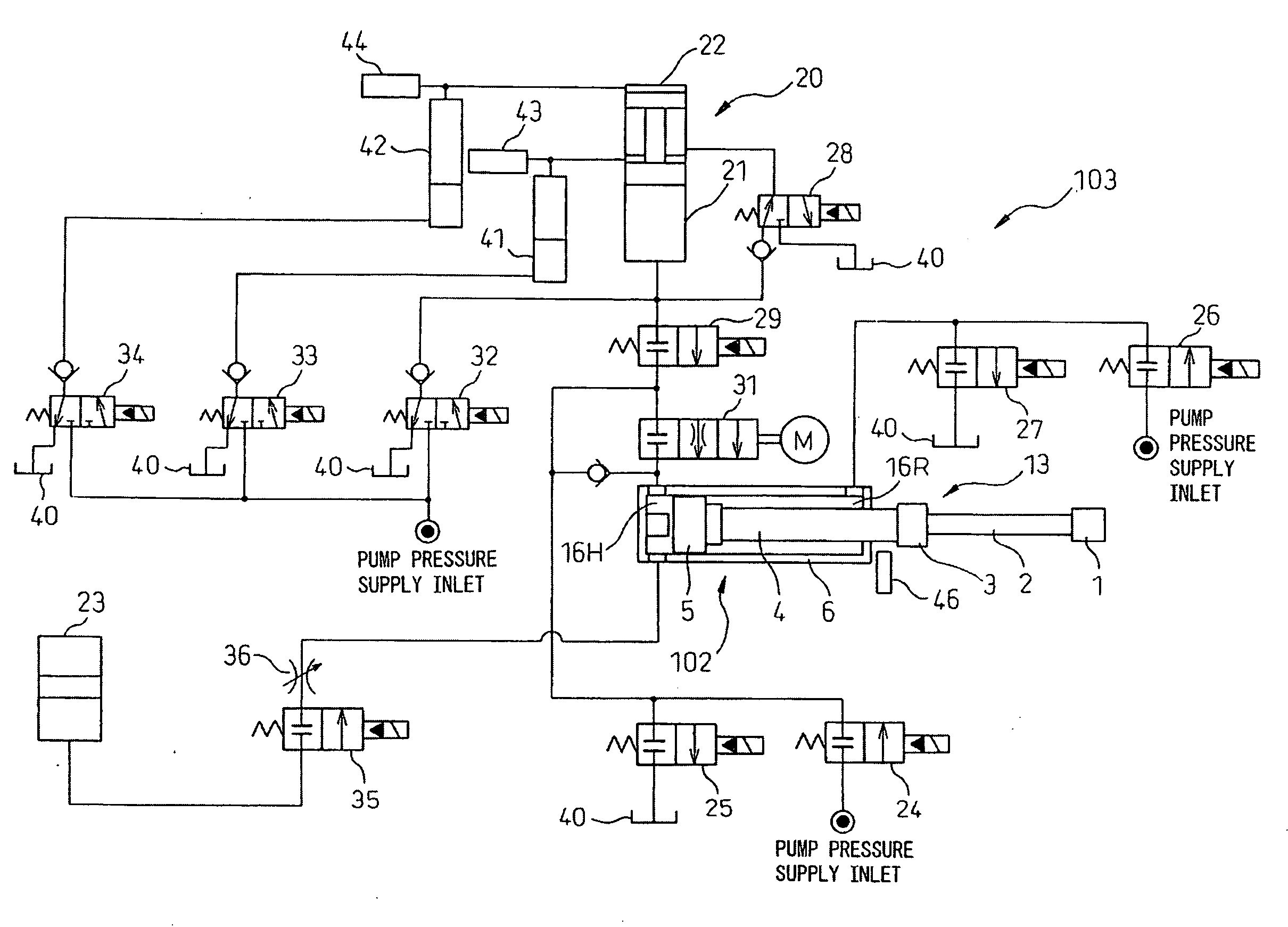

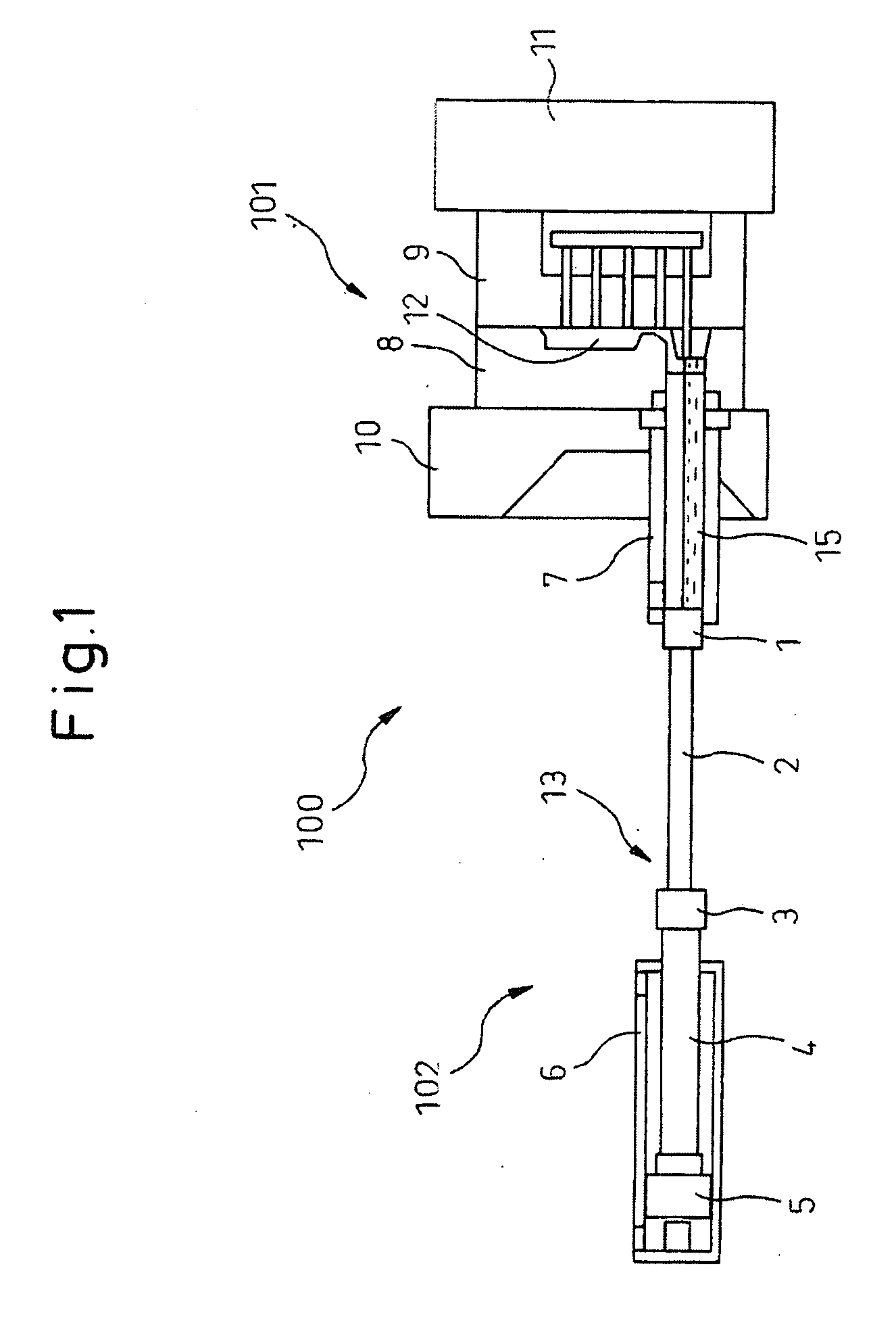

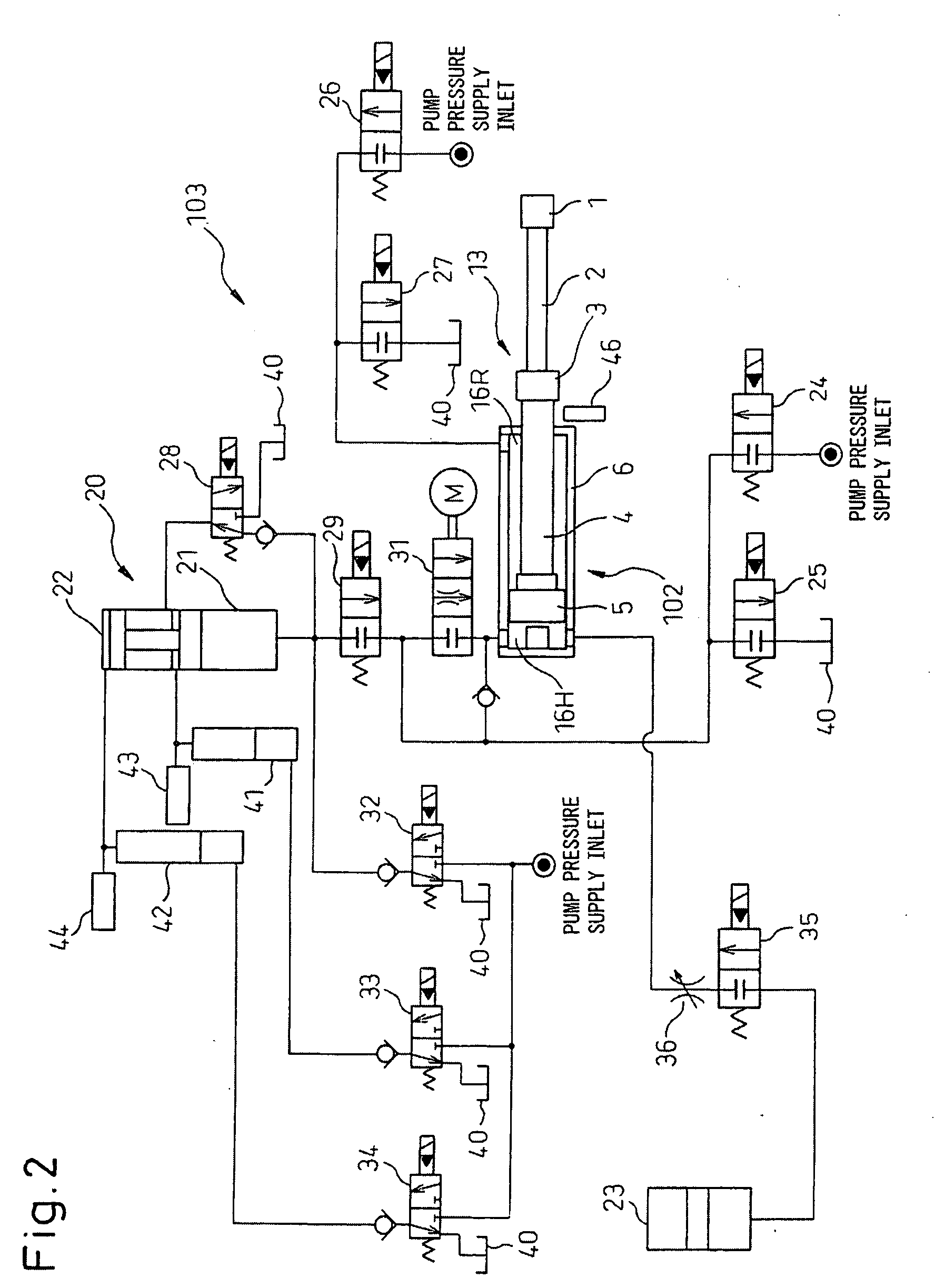

InactiveUS20100000699A1Fast injection moldingHigh speedCasting safety devicesMould controlling devicesThermodynamicsDie casting

A die casting machine that suppresses the occurrence of surge pressure, prevents the occurrence of burrs and spouting of molten metal, and further minimizes variations in the quality of a molded product on site.The die casting machine comprises a mold (101) that cast-molds a product, an injection cylinder (102) for injecting molten metal (15) to the mold, and a hydraulic device (103) for pressing under high pressure the injection cylinder. The hydraulic device comprises a piston ACC (20) that supplies hydraulic oil to press under pressure a piston (13) of the injection cylinder (102) and an injection cylinder inlet valve (31). The piston ACC comprises a high pressure fast pressure-raising piston accumulator (22, 322) and a low-pressure injection piston accumulator (21, 321).

Owner:UBE MASCH CORP LTD

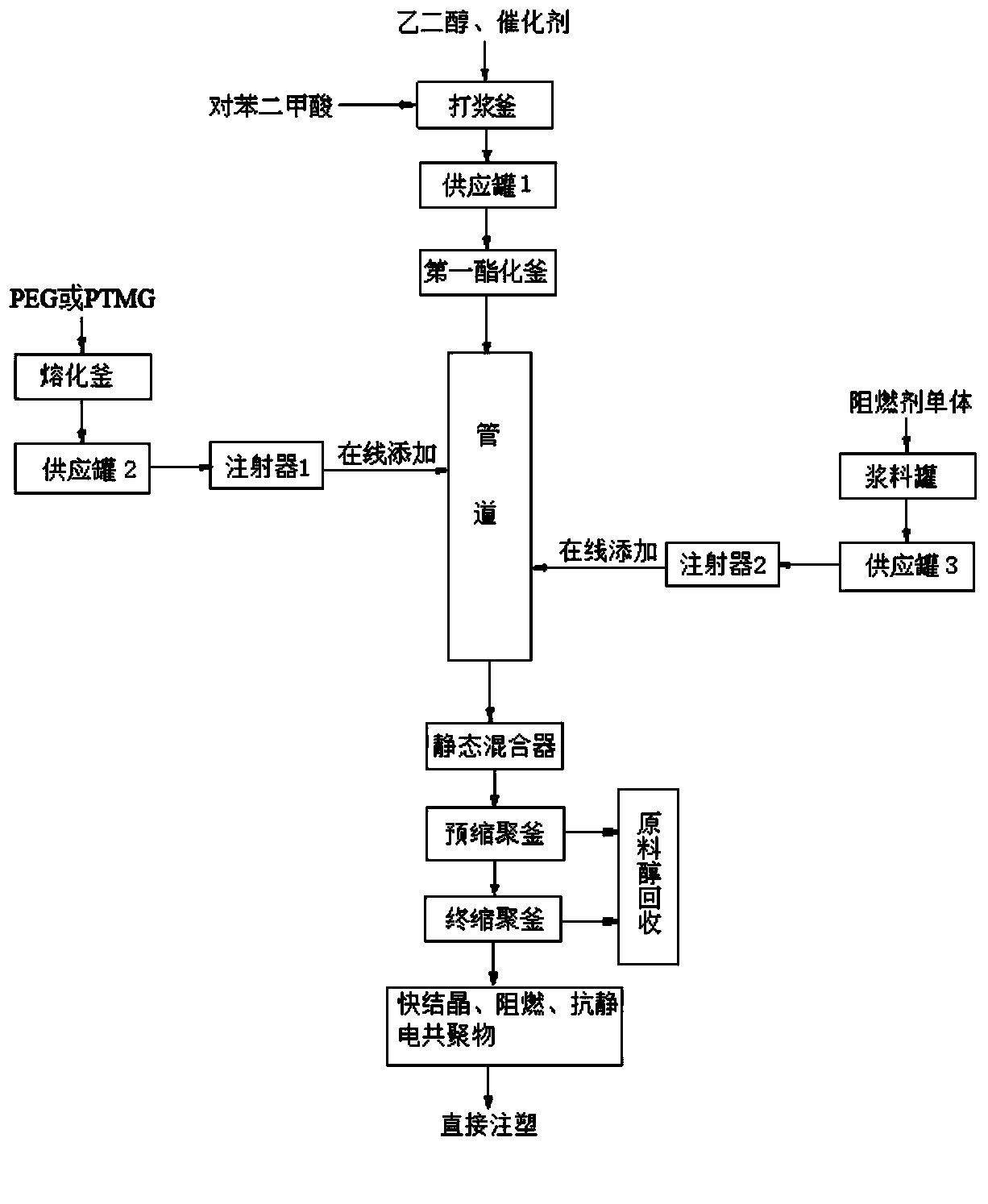

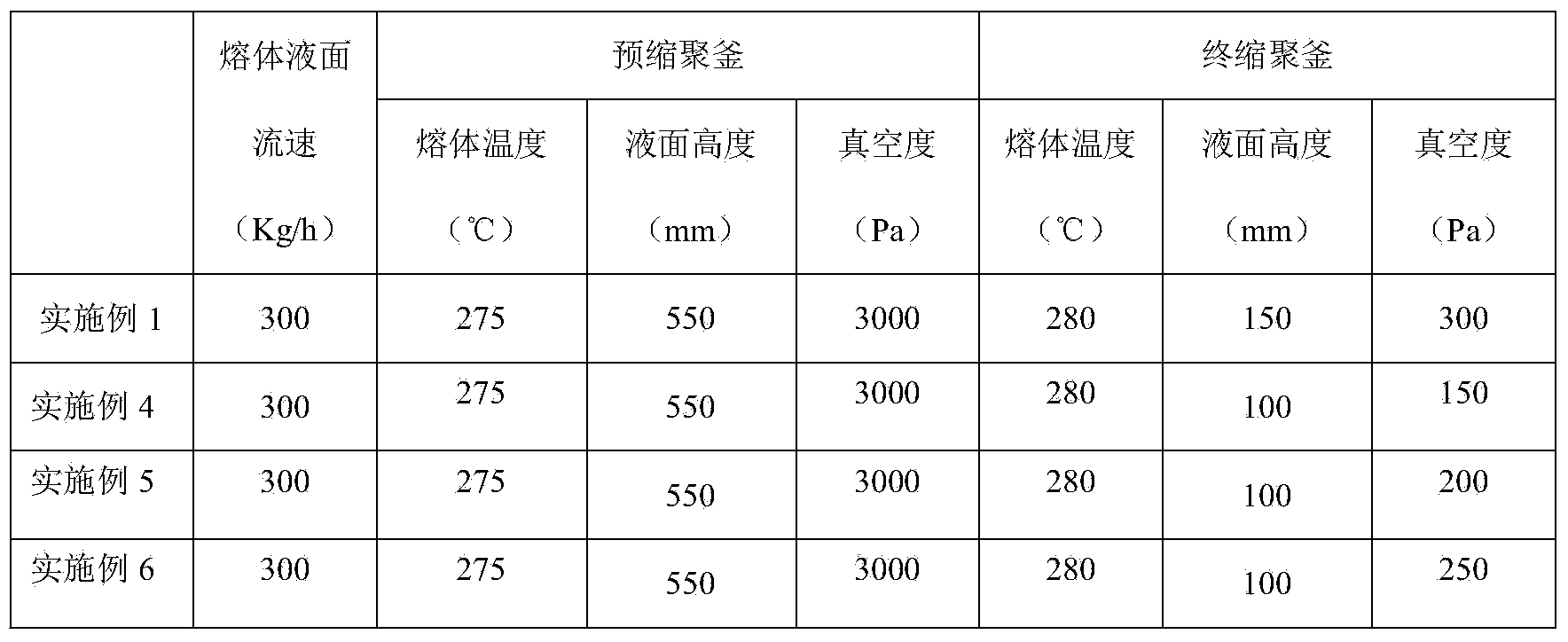

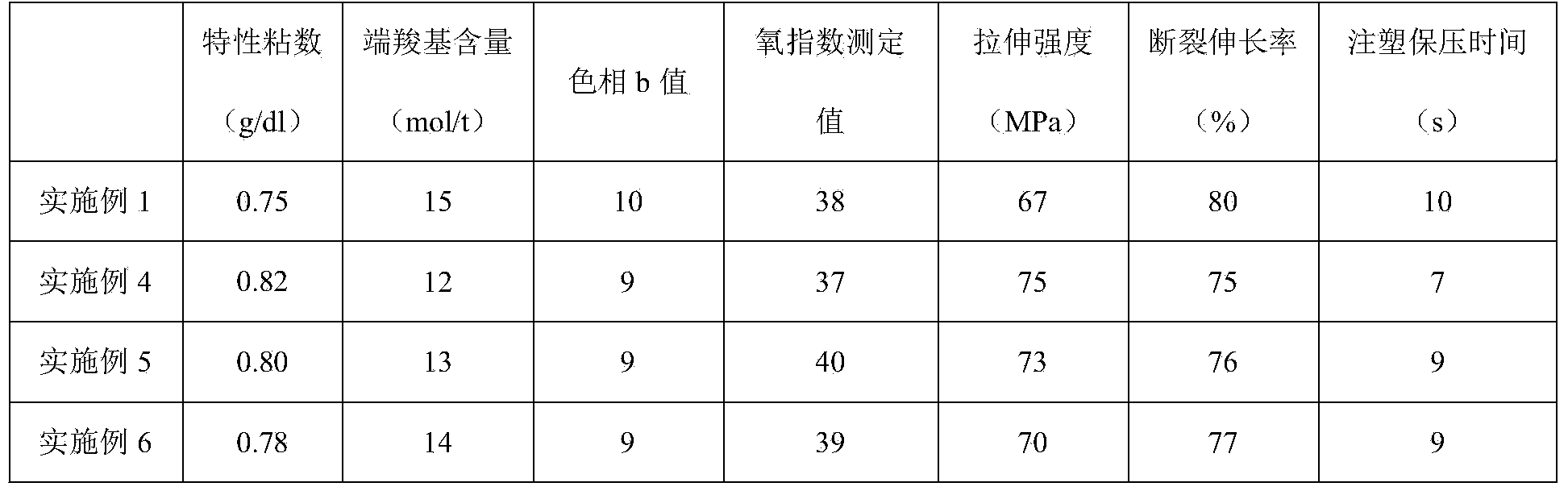

Continuous polymerization preparation method of fast crystallized and flame-retardant PET (Polyethylene Terephthalate) copolymer

The invention relates to the field of PET (Polyethylene Terephthalate) copolymer and particularly relates to a continuous polymerization preparation method of a fast crystallized and flame-retardant PET copolymer. On a continuous polymerization production line of flexible modified polyester, the fast crystallized and flame-retardant PET copolymer is continuously prepared by a novel short-flow continuous polymerization device comprising an esterification kettle, a pre-shrinking kettle and a final polycondensation kettle. The method has the advantages of low energy consumption in the preparation process, high yield and good stability of the quality, the large-scale industrial production is achieved and the products have strong market competitiveness.

Owner:CHINESE TEXTILE ACAD

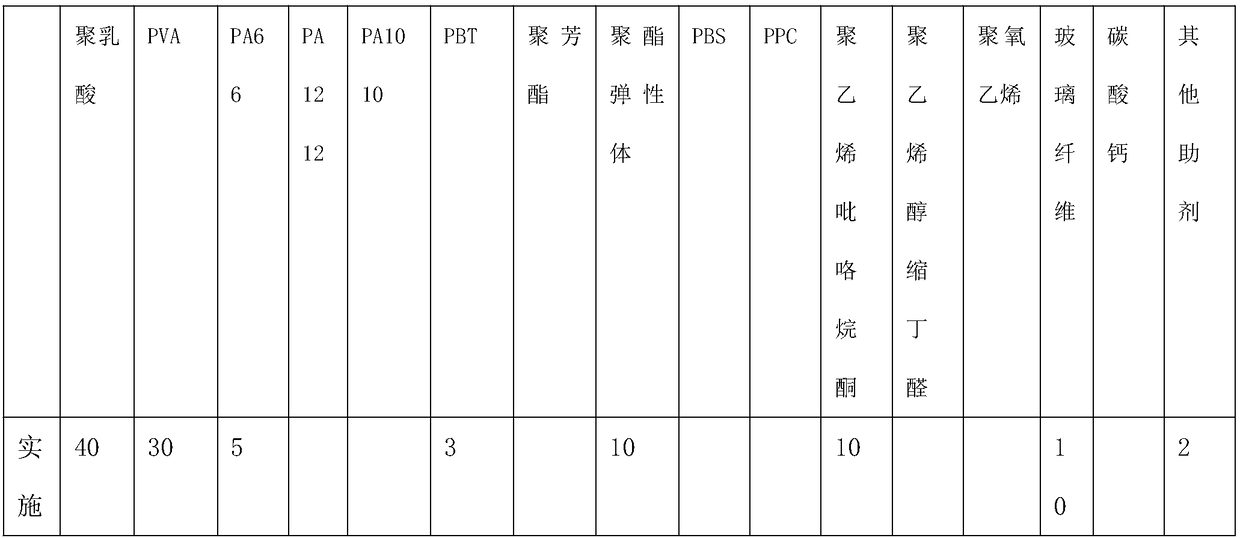

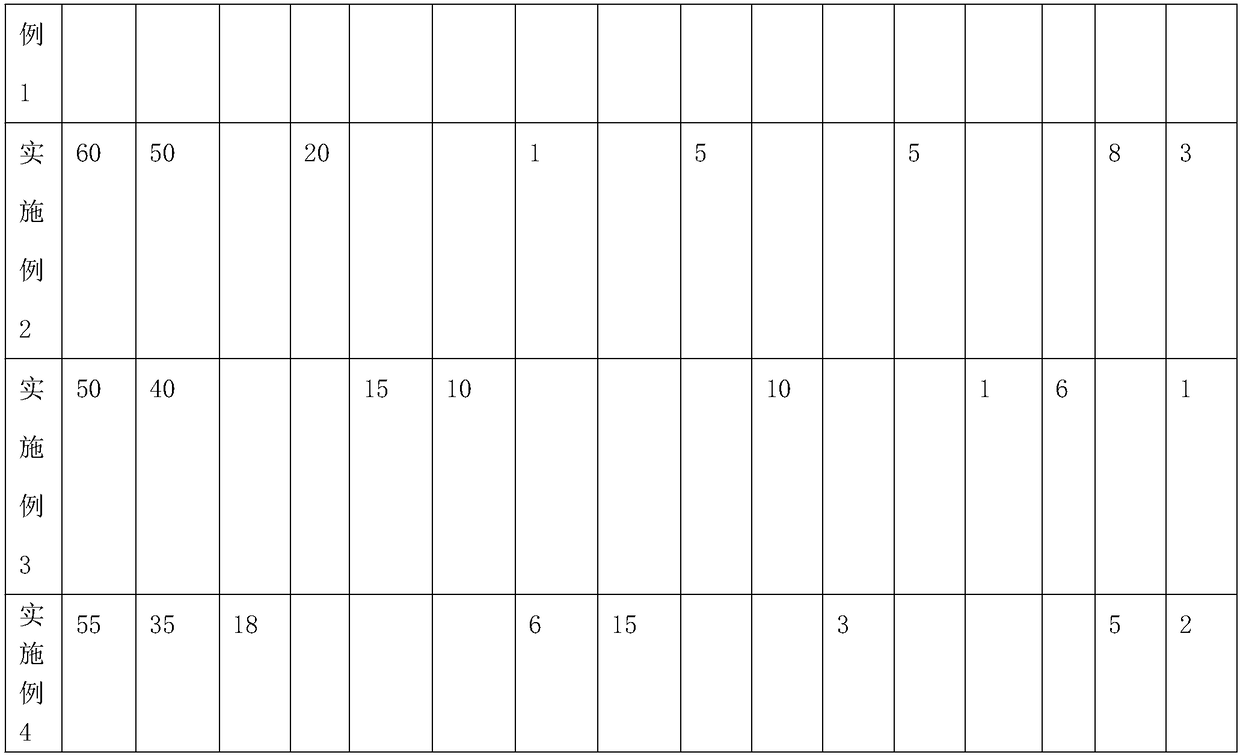

Degradable cable tie material and preparation method thereof

The invention relates to a cable tie material and a preparation method thereof, and in particular discloses a degradable cable tie material and a preparation method thereof. The material comprises thefollowing components in parts by weight: 40-60 parts of polylactic acid, 30-50 parts of polyvinyl alcohol, 5-20 parts of aliphatic polyamide, 1-10 parts of polyester, 5-15 parts of toughener, 5-10 parts of filler, 1-10 parts of degradation synergist and 1-3 parts of other additives. The material has the characteristics of high strength, high elongation, excellent high and low temperature performance, etc., and satisfies requirements of normal use of cable ties at high temperature heat resistance to 85 DEG C, and no fracture at low temperature of extreme weathers of Xinjiang, Heilongjiang, etc.; meanwhile, the material has the advantages of natural easy degradation, good biocompatibility and direct degradation or composting treatment after use, is natural and environmentally friendly, is pollution-free, and meets environmental friendliness requirements; and moreover, the material also has good hydrophilicity and anti-static property, and can meet anti-static requirements of wire harness cable ties of electronic industry.

Owner:NANJING JULONG SCI&TECH CO LTD

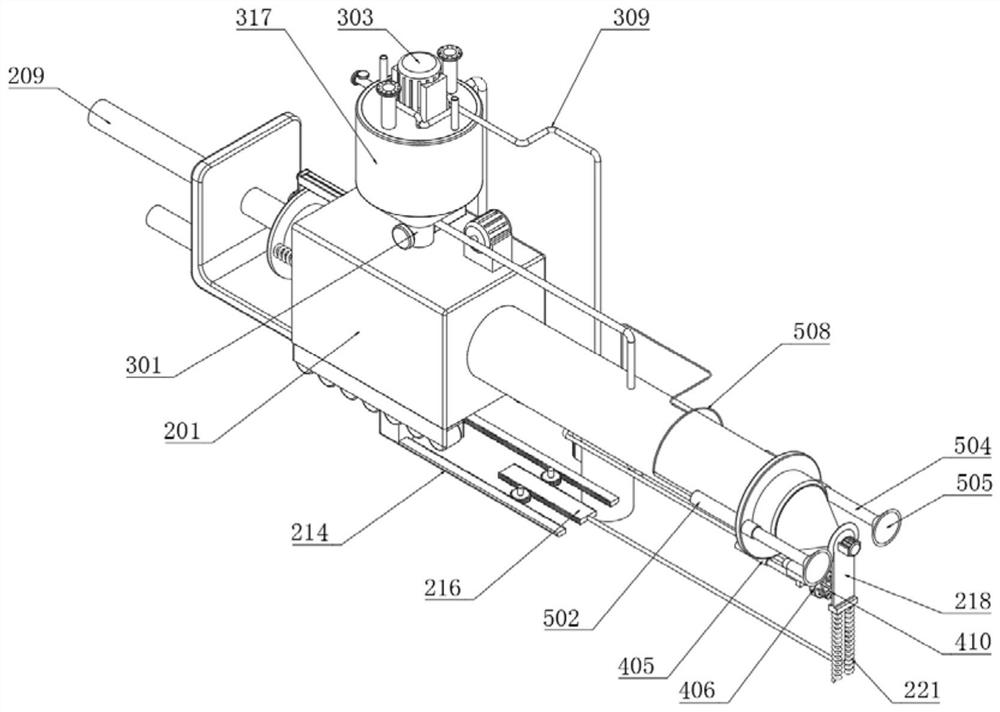

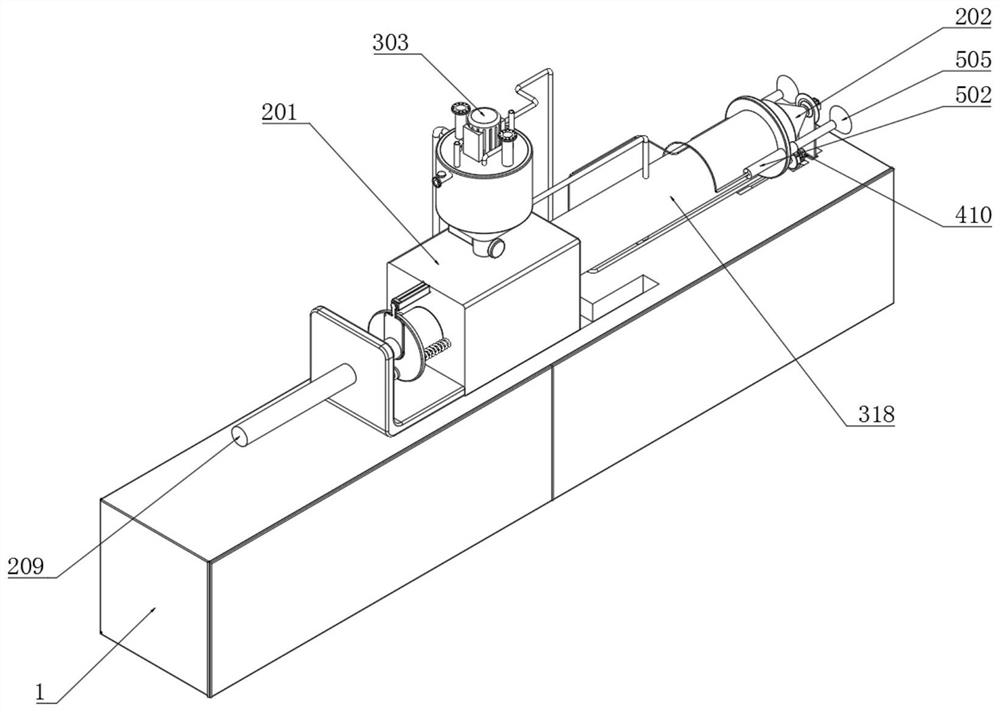

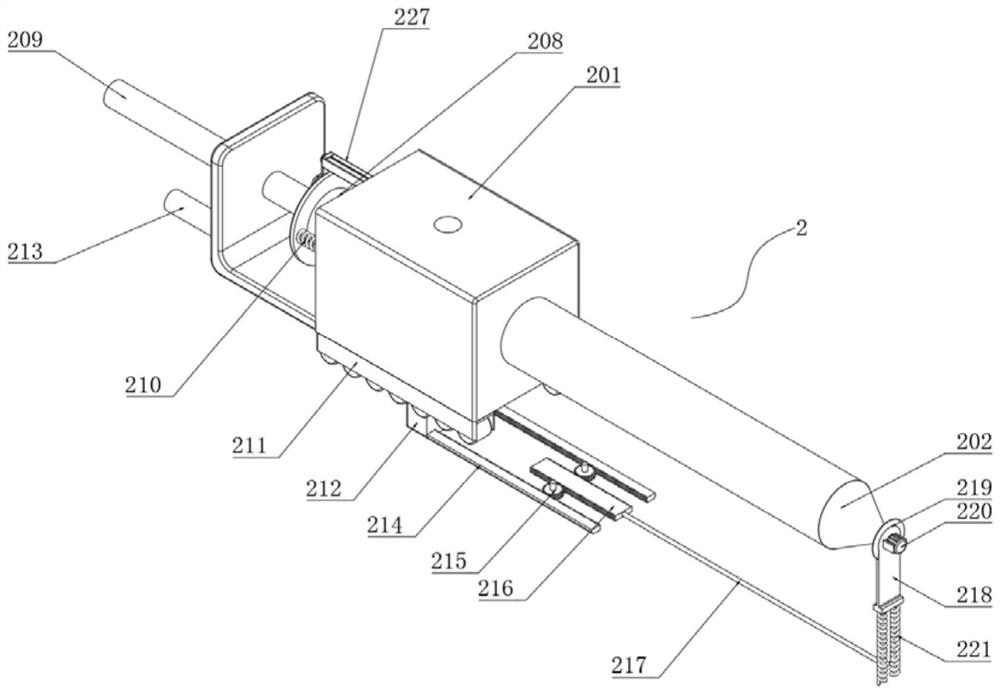

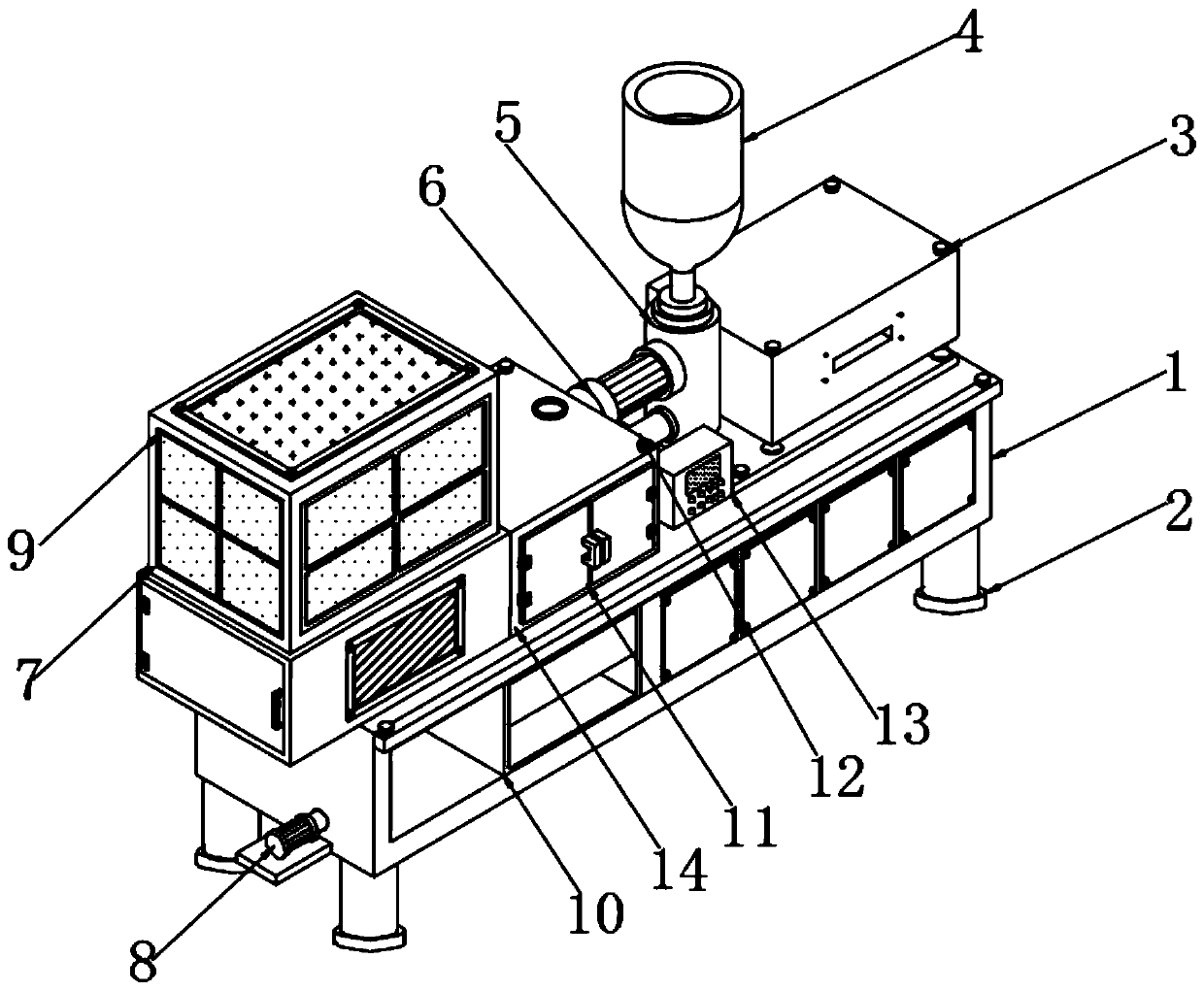

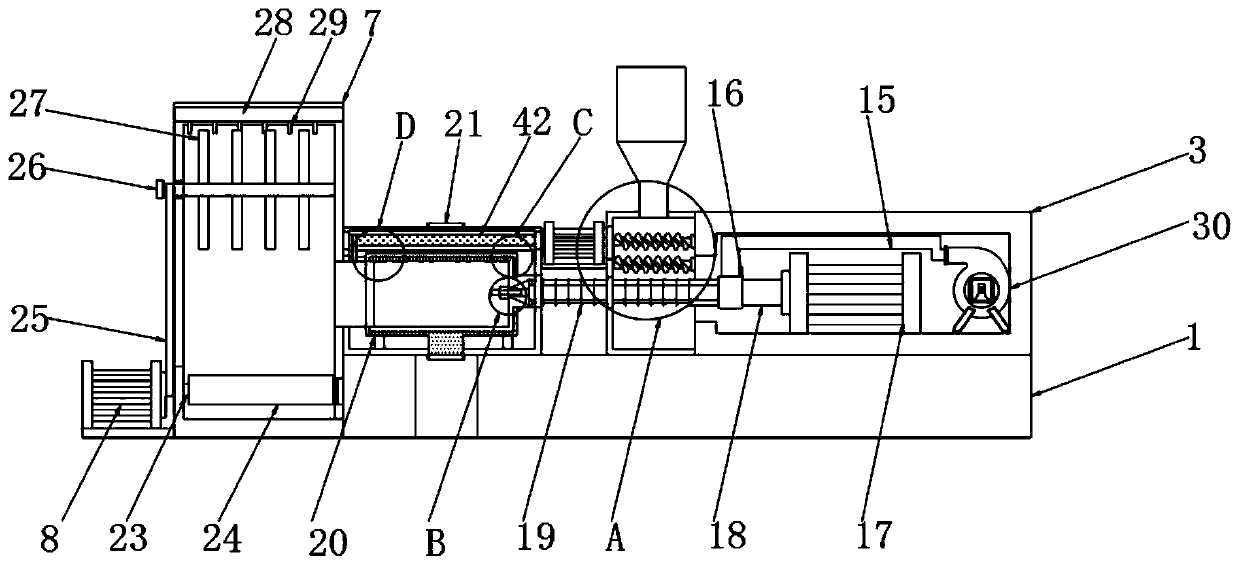

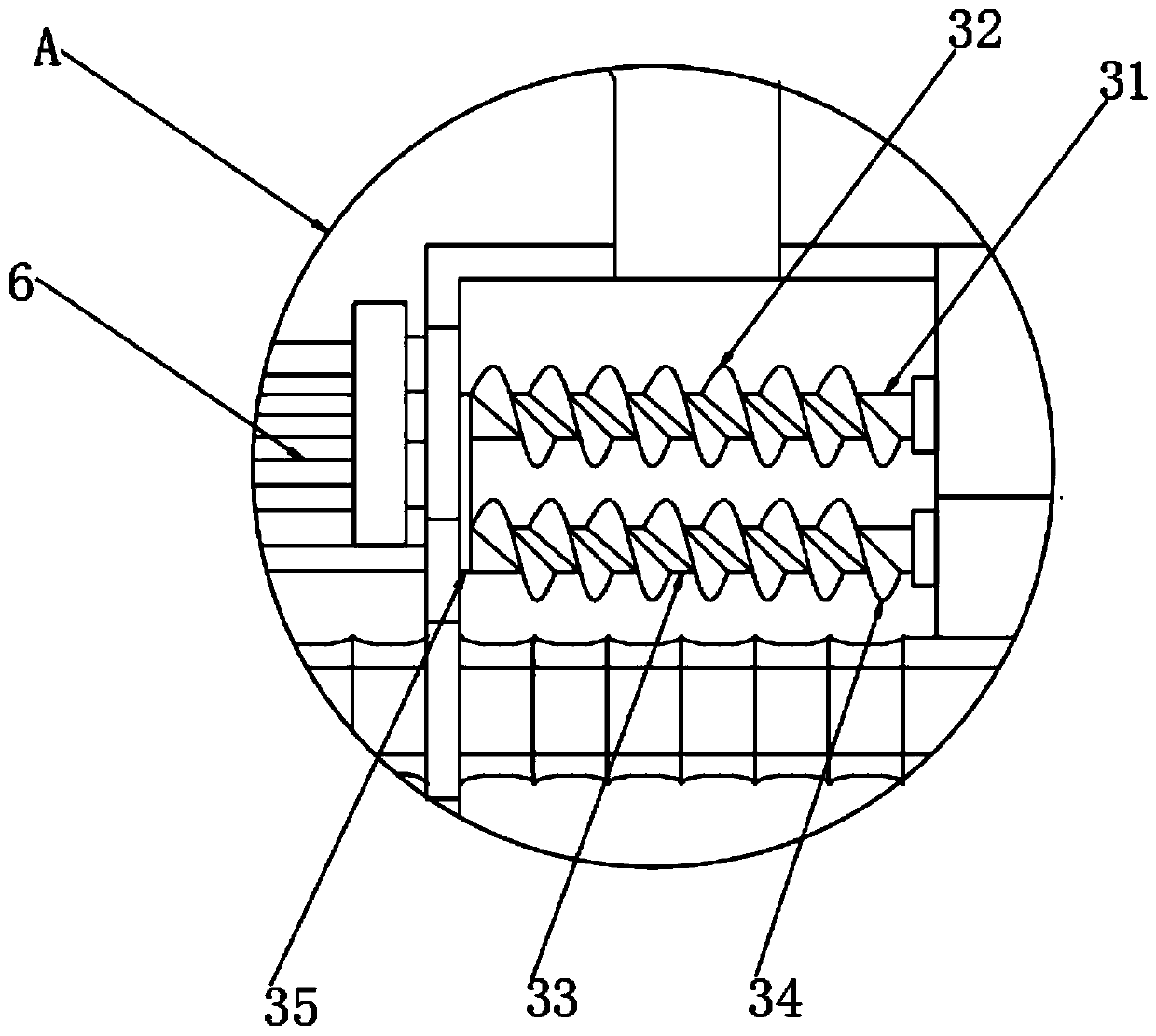

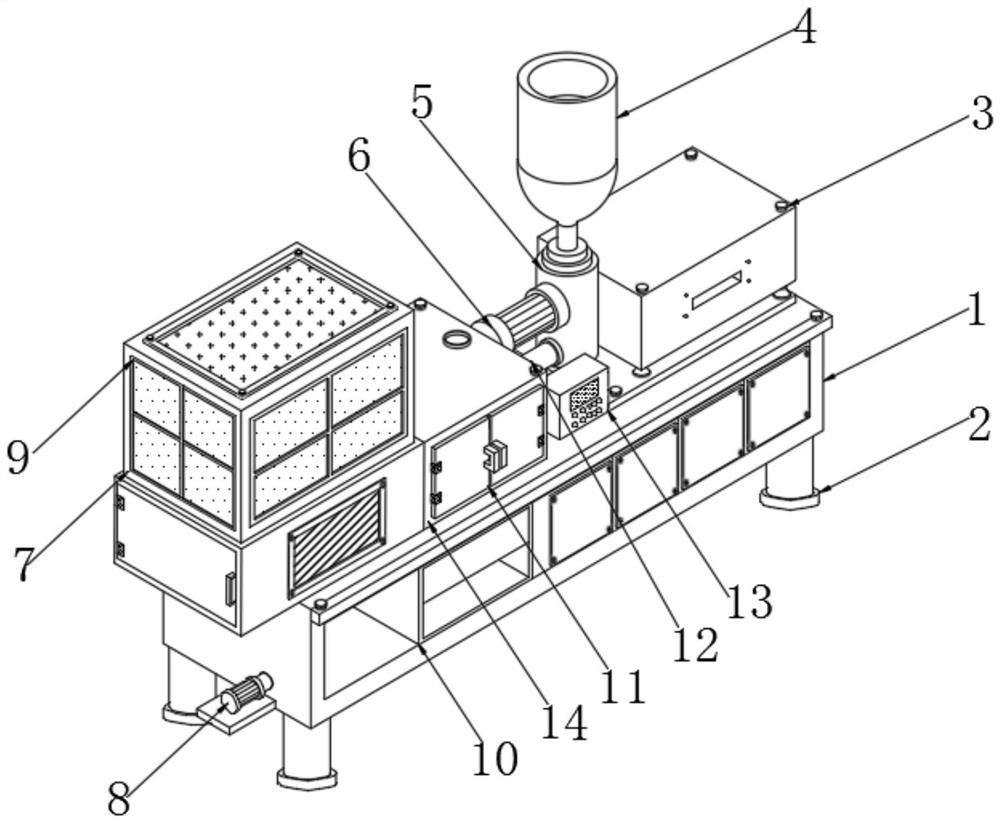

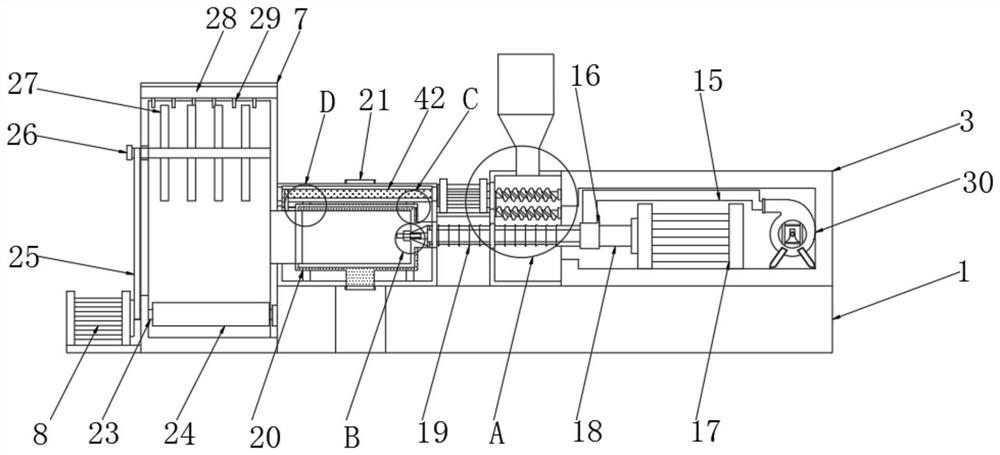

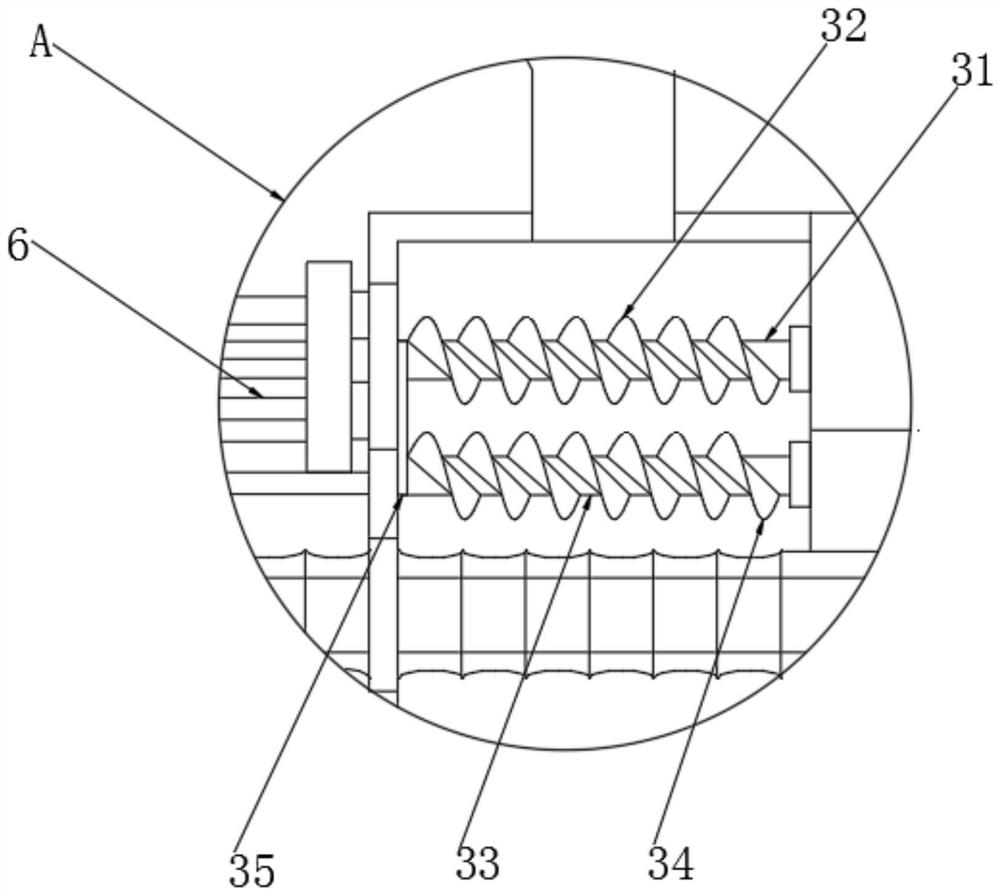

Anti-blocking injection molding machine

The invention discloses an anti-blocking injection molding machine is characterized in that an injection molding gun barrel is welded to one end of a supporting entering box, a conveying auger is welded to the side end of a movable transmission rod, a movable supporting barrel is welded to one end of a clamping sealing block, a reset spring is welded to one end of the movable supporting barrel, and an auxiliary moving block is welded to the bottom end of the supporting entering box; and a driving rack is welded to one end of the auxiliary moving block, a cleaning plate is rotationally connected to one end of a sliding moving plate, a pushing electromagnet is installed on the inner side of a sliding cavity, a pushing spring is welded to one end of the inner side of the sliding cavity, and an anti-blocking column is welded to one end of the pushing spring. The conveying auger and a reverse flow preventing threaded column drive a raw material to move and prevent the raw material from backflow, the hollow situation is avoided, and a contact switch controls the opening and closing of the pushing electromagnet, so that the anti-blocking column can be quickly reset when needing to be reset, and the discharge port is sealed while the requirement for discharging solidified raw materials at the discharge port position is met.

Owner:姚新耿

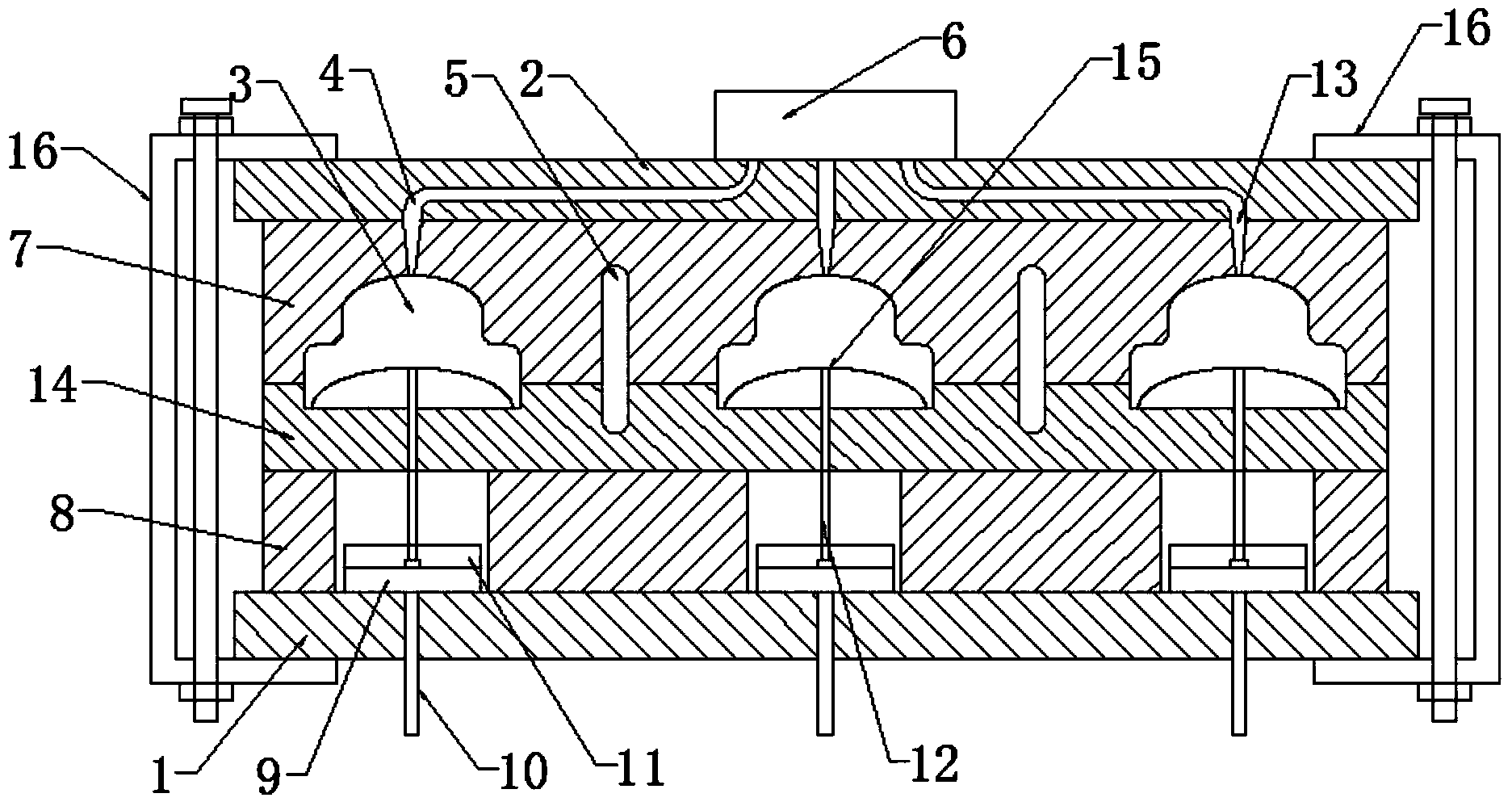

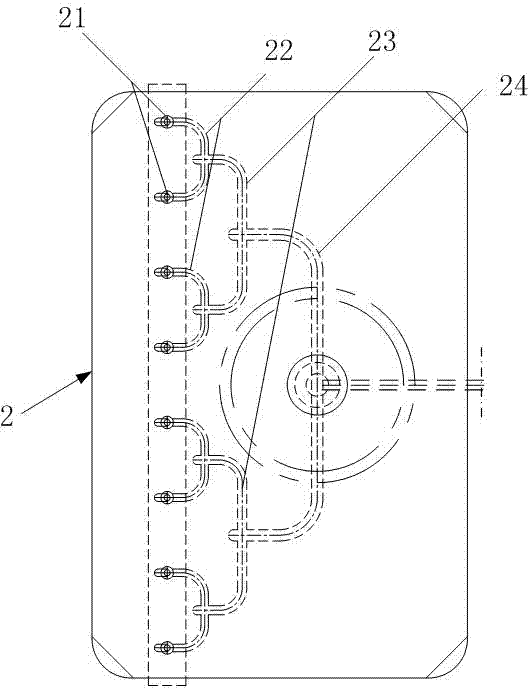

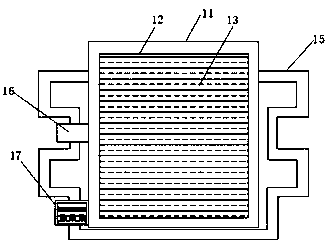

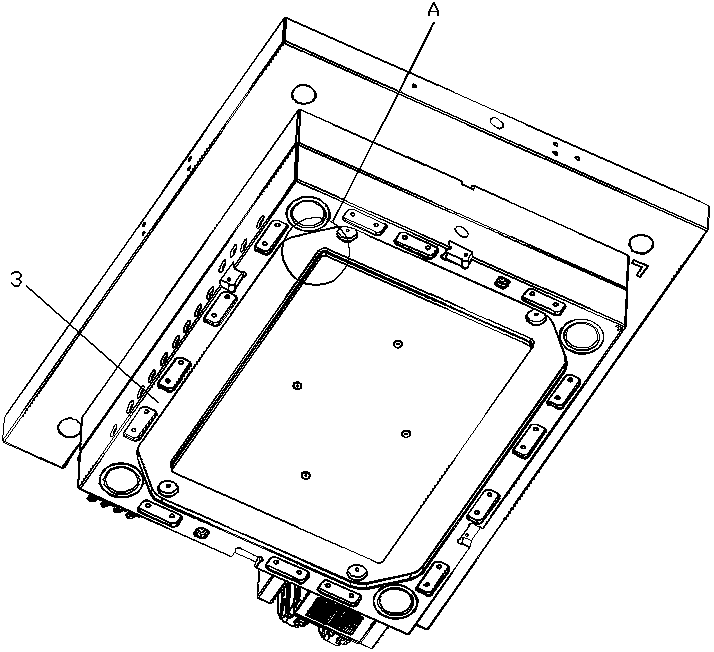

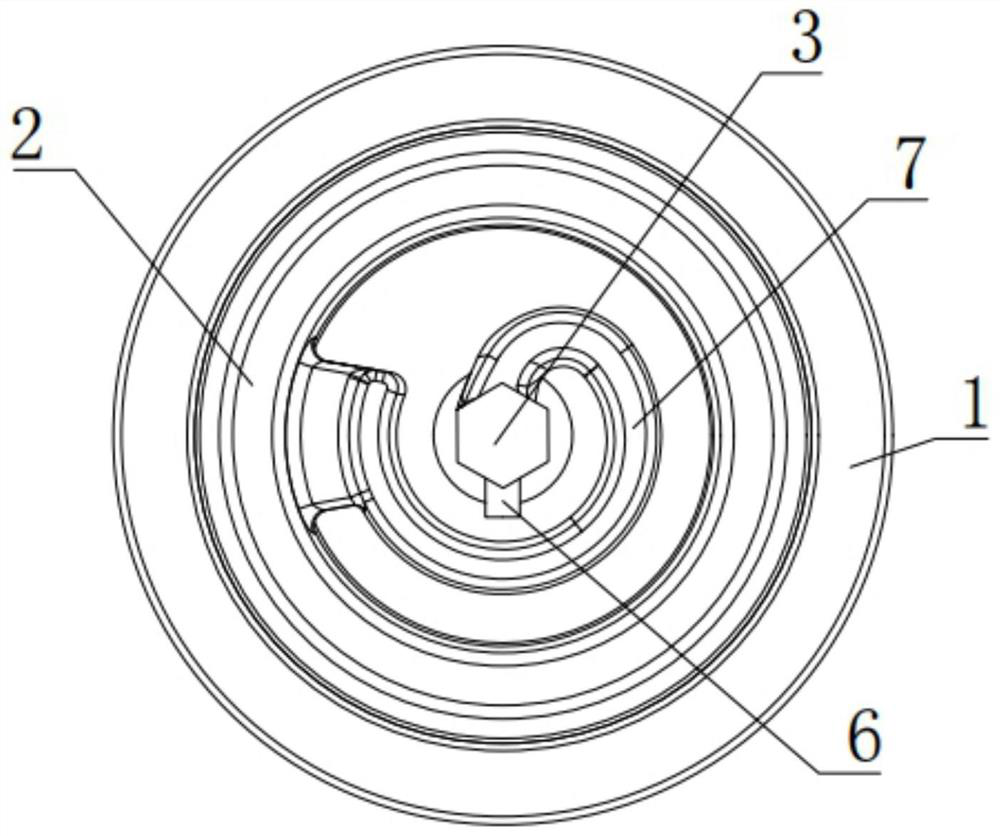

Multi-channel injection mold

The invention discloses a multi-channel injection mold. The multi-channel injection mold comprises a fixed mold plate, a mobile mold plate, a fixed mold template, a mobile mold template and a fixing clamper. A pouring device is fixed on the upper surface of the mobile mold plate; both the internal part of pouring device and the upper surface of the mobile template are provided with eight pouring openings; the mobile mold plate is provided with pouring channels adaptive to the pouring openings; the mobile mold template is fixedly installed between the lower surface of the mobile mold plate and the upper surface of the fixed mold template; a fixed mold backing plate is fixedly installed between the fixed mold template and the fixed mold plate; the fixed mold backing plate is provided with a push plate; an inner push rod fixing plate is arranged above the push plate; and the push rod fixing plate is connected to an inner push rod with a mold core. The multi-channel injection mold can finish injection simultaneously, is fast in injection molding, increases output, and effectively increases work efficiency. The distance of the pouring channel between the pouring openings is the shortest, so that injection liquid can enter the mold cavity rapidly; the phenomenon of injection liquid condensation can be prevented; injection quality is increased; and at the same time, the injection profile is pulled out of the mold for cooling.

Owner:NINGBO POLYTECHNIC

Pen core plastic mould for electronic pens

Owner:TAKAHATA PRECISION SUZHOU

Method for preparing polypropylene filter plate

ActiveCN104526953AShorten the production cycleExtended service lifeCoatingsInjection mouldingInjection molding machine

The invention relates to a method for preparing a polypropylene filter plate. The method is rapid injection molding. The filter plate comprises a diaphragm core plate. A material is put into a material barrel of a stirring dryer and dried at 70 DEG C, the temperature of the two ends of an injection molding machine is set to be 210 DEG C, and the temperature of the middle of the injection molding machine is set to be 240 DEG C. Mold closing locking is performed for two times; in the first mold closing locking process, the mold locking pressure is set to be 20000KN, the injection feeding propelling is set to be multi-stage type, the first-stage time is set to be 35 seconds, the first-stage injection propelling pressure is set to be 11.0 MPa, the second-stage time is set to be 25 seconds, the second-stage injection propelling pressure is set to be 9.0 MPa, the third-stage time is set to be 20 seconds, the third-stage injection propelling pressure is set to be 7.0 MPa, the fourth-stage time is set to be 10 seconds, the fourth-stage injection propelling pressure is set to be 6.0 MPa, the fifth-stage pressure-maintaining time is set to be 3 minutes, the pressure-maintaining propelling pressure is 4.0 MPa; in the second mold closing locking process, the mold locking pressure is set to be 28000KN, a slider on a rabbet of a sealing surface automatically draws out before a mold is locked, the mold locking cooling pressure-maintaining time is 14-16 minutes, and the slider automatically resets when the mold of a second filter plate is closed, and the above procedures are cycled in turn, and the polypropylene filter plates are prepared through rapid injection molding.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

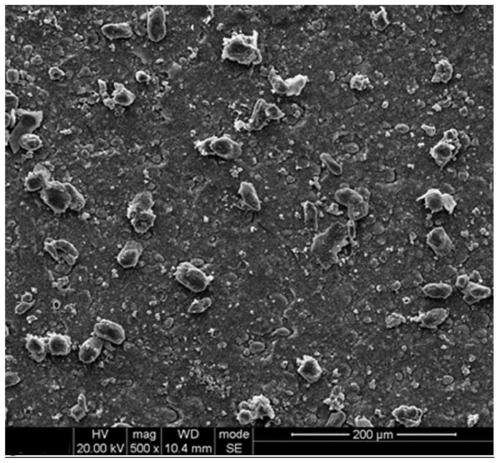

Precipitation-resistant halogen-free flame-retardant reinforced nylon material and preparation method thereof

The invention relates to a precipitation-resistant halogen-free flame-retardant reinforced nylon material and a preparation method thereof. The material provided by the invention comprises the following components in parts by weight: 30-55 parts of nylon, 25-40 parts of glass fiber, 5-10 parts of modified melamine cyanurate, 0.5-3 parts of a compatilizer, 10-25 parts of a flame-retardant toughening agent and 1-3 parts of other auxiliaries. According to the invention, the surface modified melamine cyanurate is adopted to enhance nylon, the nylon has excellent compatibility and is compounded with the flame-retardant toughening agent with flame-retardant elements, so that low precipitation and low corrosion of the halogen-free flame retardant and high electrical performance of the flame-retardant enhanced nylon material are realized on the premise of keeping good mechanical properties, heat resistance and the like. Due to the adoption of the flame-retardant toughening agent, the use of a traditional flame retardant is greatly reduced, and the mechanical property of the material is powerfully improved. Meanwhile, the product has the characteristics of environmental protection, high dimensional stability and the like, and meets the key material requirements of products such as household appliances and new energy automobiles.

Owner:NANJING JULONG SCI&TECH CO LTD

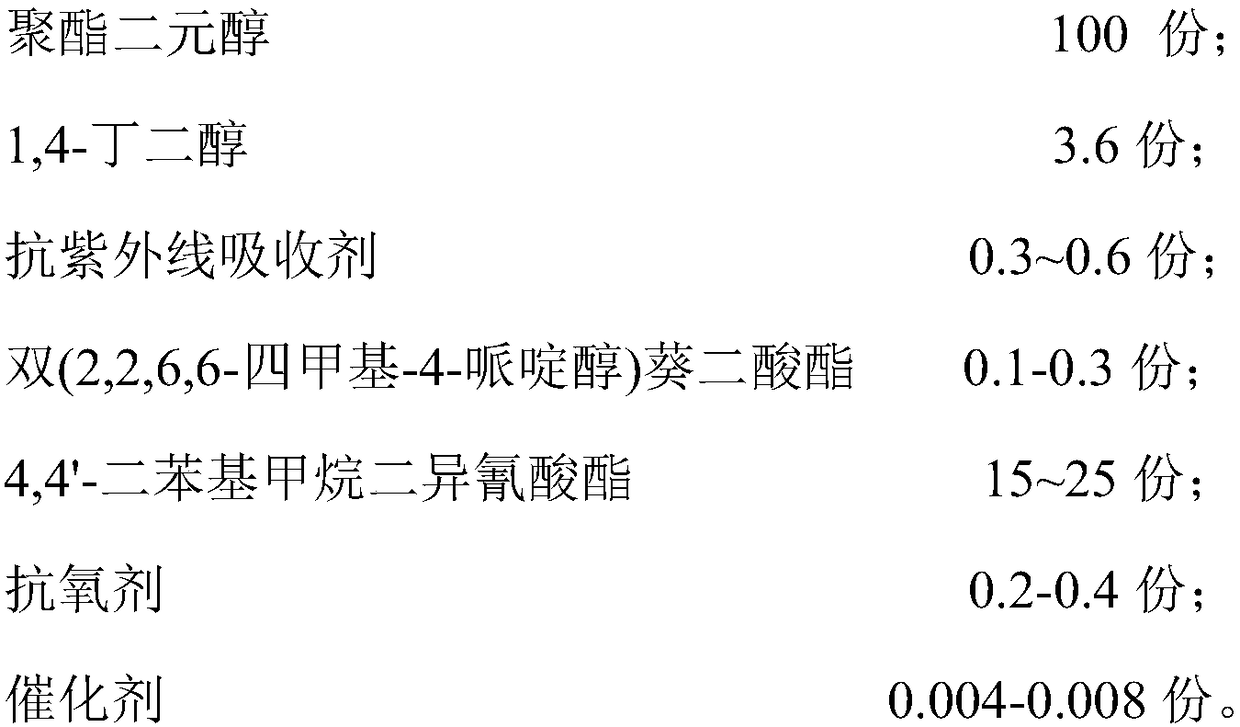

Anti-yellowing thermoplastic polyurethane elastomer and preparation method thereof

InactiveCN108164676AGood yellowing resistanceThe preparation method is economical and environmentally friendlyPolyesterAntioxidant

The invention discloses an anti-yellowing thermoplastic polyurethane elastomer and a preparation method thereof. The polyurethane elastomer has shore hardness of 60 to 75 A. The polyurethane elastomeris prepared from the following raw materials: polyester glycol, 1,4-butanediol, an anti-ultraviolet absorbent, di(2,2,6,6-tetramethyl-4-pipradrol)sebacic acid ester, 4,4'-diphenylmethane diisocyanate, an antioxidant and a catalyst. According to the anti-yellowing thermoplastic polyurethane elastomer and the preparation method thereof, the shore hardness of the thermoplastic polyurethane elastomeris up to 60 to 75 A, and the injection molding period is effectively shortened, so that a phenomenon of sticking of a mold during processing is avoided. Furthermore, due to addition of the anti-ultraviolet absorbent, the polyurethane elastomer disclosed by the invention is excellent in anti-yellowing property. Moreover, the injection molding period and the intensity of the thermoplastic polyurethane elastomer can be balanced by regulating and controlling the use amount of a catalyst. The preparation method of the polyurethane elastomer is environmentally friendly, economical, high in weatherresistance, high in injection molding speed and high in processing efficiency, and can be widely applied to injection molding of products such as a shoe material, a triangular belt and sheet rubber.

Owner:清远新力化机有限公司

Blow molding nozzle and blow molding machine

The invention discloses a blow molding nozzle and a blow molding machine, and relates to the technical field of blow molding machine. The blow molding machine comprises a frame body, supporting columns are fixedly installed at the peripheral corners of the outer surface of the lower end of the frame body, a first equipment box is fixedly installed on one side of the outer surface of the upper endof the frame body, a third equipment box is fixedly mounted on one side, located on the first equipment box, of the outer surface of the upper end of the frame body, a second equipment box is fixedlymounted on the side, located on the third equipment box, of the outer surface of the upper end of the frame body, a plurality of visible windows are fixedly mounted on the periphery of the second equipment box, detection box doors are movably installed on the two sides of the middle position of the outer surface of the front end of the third equipment box, and a control radio station is fixedly installed on the outer surface of the upper end of the frame body and located in front of a storage tank. According to the blow molding nozzle and the blow molding machine, fully stirring materials canbe carried out, so that the materials are more viscous, injection molding is facilitated, the fact that injection molding products are quickly cooled is advantageously achieved, and the injection molding on injection molding products is quickly carried out.

Owner:平湖市中美包装科技有限公司

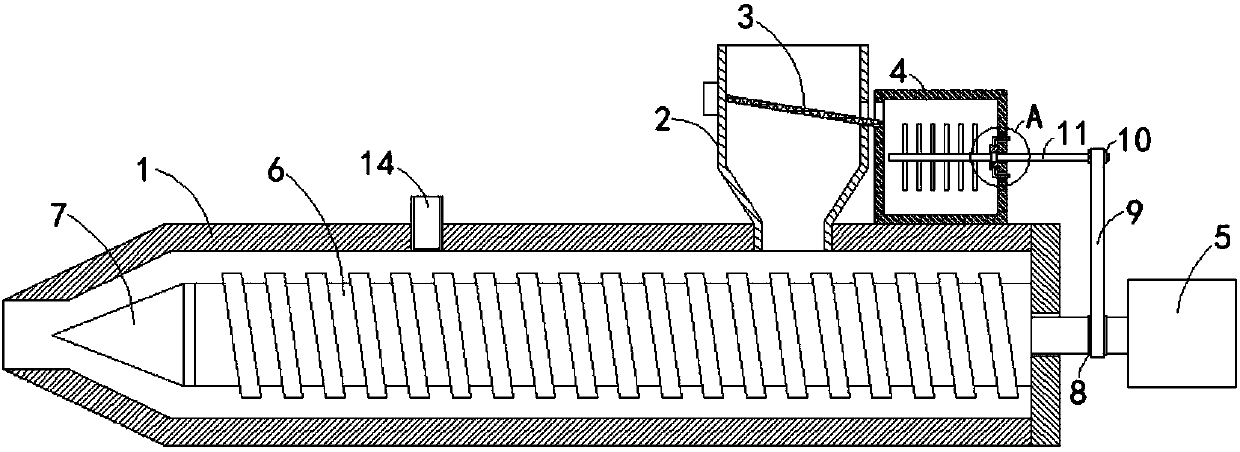

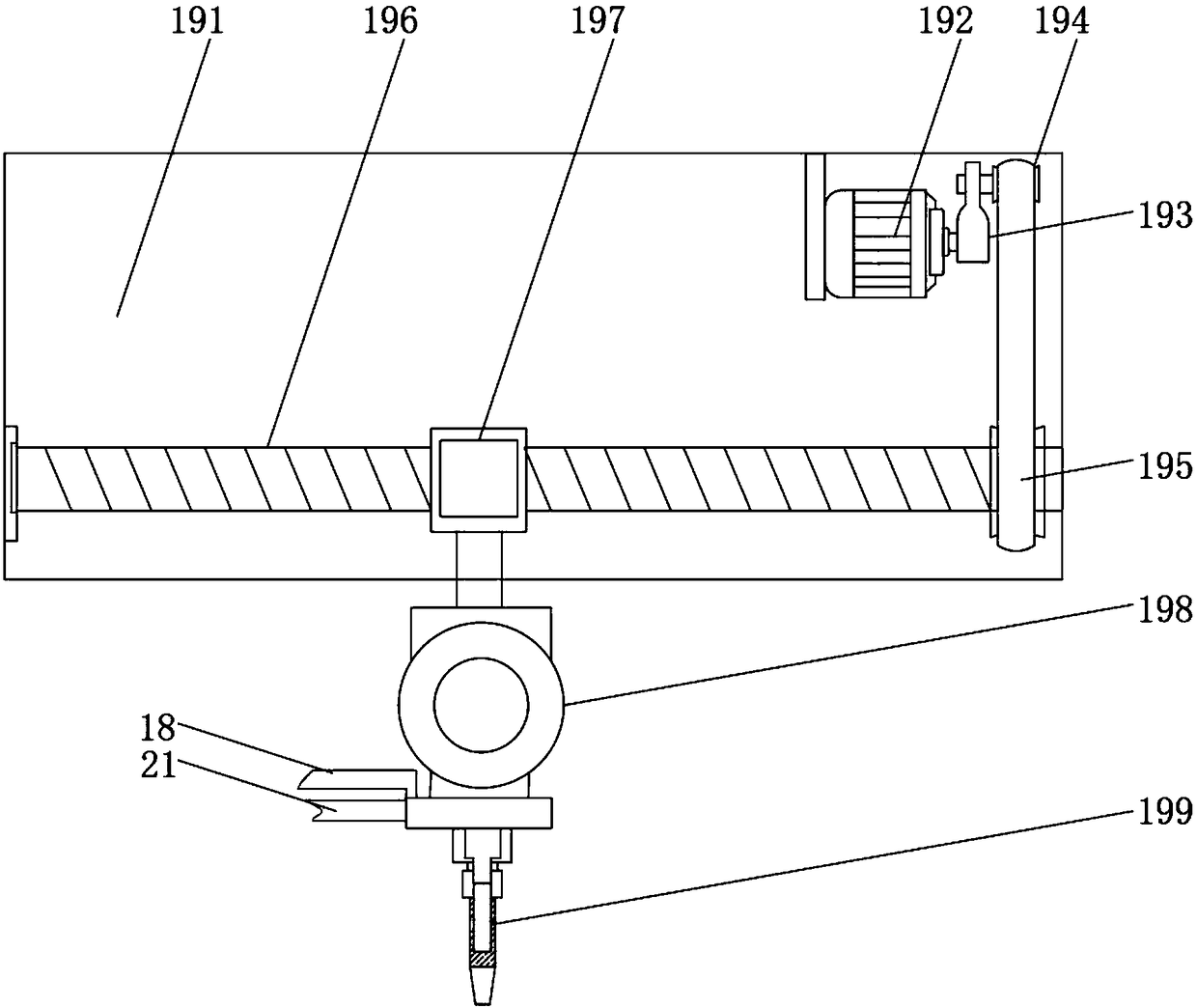

Injection device for injection molding machine

The invention discloses an injection device for an injection molding machine. The injection device comprises a main barrel; a charging hopper is arranged at the upper end of the main barrel; an oblique filter screen is arranged in the charging hopper; the upper end of the filter screen is fixedly connected with the inner wall of the charging hopper; the lower end of the filter screen penetrates through an opening in the side wall of the charging hopper and extends to the outer side of the charging hopper; the upper end of the main barrel is fixedly connected with a box body; a strip-type opening corresponding the filter screen in position is formed in the side wall of the box body; a breaking mechanism is arranged in the box body; the breaking mechanism is connected with a driving motor through a transmission mechanism; an axial through hole is formed in the main barrel; the interior of the main barrel is connected with a threaded rod by threads; one end of the threaded rod is connected with a nozzle; the other end of the threaded rod is connected with a driving shaft of a driving motor; and the driving shaft penetrates through the rear side wall of the main barrel and is fixedly connected with the threaded rod. The charging hopper can be effectively prevented from being blocked, rapid injection molding on a mould is realized, and the injection device is convenient to operate.

Owner:安徽长正升科技有限公司

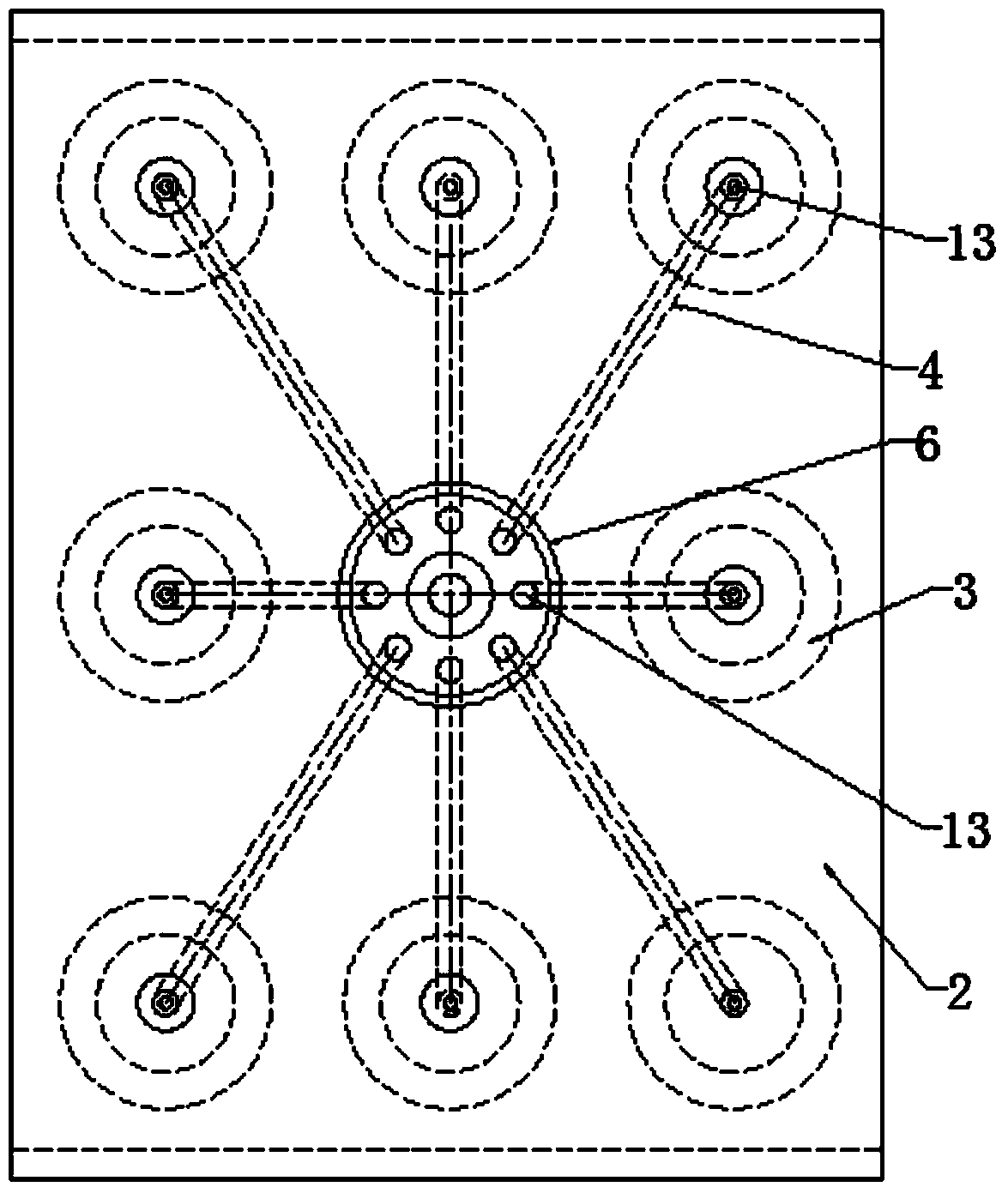

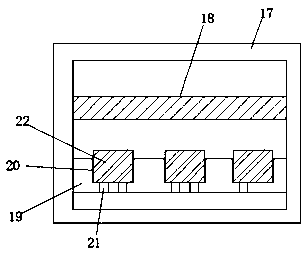

Plastic mold for electronic pen holder

InactiveCN103481464AGuaranteed qualityLess prone to glitchesInjection mouldingMechanical engineering

The invention provides a plastic mold for an electronic pen holder. The plastic mold comprises a static template, a cavity plate and a dynamic template, wherein eight cavities, sprues communicated with the cavities and runners communicated with the sprues are formed in the cavity plate, the overall dimensions of the eight cavities are completely consistent, the eight cavities are arranged in parallel along the horizontal direction, every two cavities are taken as a unit, the two cavities in each unit are communicated with each other through the runner, the runners are communicated with the corresponding sprues, the shape of the cavities is consistent with the shape of the pen holder, sliding chutes are formed in one sides of the cavities, push rods are arranged in the sliding chutes and are opposite to the cavities, and one ends of the push rods are fixed on connecting rods which are connected with piston rods of air cylinders by driving. Through the structure that one runner corresponds to two cavities for simultaneous injection molding, glue entering the cavities is ensured to be equal, and then the air cylinders are adopted for driving the push rods to complete molding. The plastic mold is simple in structure and fast in injection molding, and can increase the yield and effectively improve the working efficiency.

Owner:TAKAHATA PRECISION SUZHOU

A kind of preparation method of polypropylene filter plate

A preparation method of a polypropylene filter plate, the method is rapid injection molding, including a diaphragm core plate, the material is put into the barrel of a stirring dryer, and the temperature of 70°C is set for drying treatment, and the temperature set by the injection molding machine is The middle of 210°C is 240°C, set the mold clamping and locking twice, set the clamping pressure to 20000KN for the first mold clamping and locking, set the injection feed advance to segmented, and the first setting time is 35 seconds, The injection propulsion pressure is 11.0MPa, the second setting time is 25 seconds, the injection propulsion pressure is 9.0MPa, the third setting time is 20 seconds, the injection propulsion pressure is 7.0MPa, the fourth setting time is 10 seconds, the injection propulsion The pressure is 6.0MPa, the fifth section is the pressure holding section, the setting time is 3 minutes, the pressure holding push pressure is 4.0MPa, the second clamping pressure is 28000KN, the sealing surface slide block is automatically pulled out before the mold clamping, and the mold is cooled. Hold the pressure for 14-16 minutes, the slider will automatically reset when the second filter plate is closed, and the polypropylene filter plate will be injected into the polypropylene filter plate in sequence.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

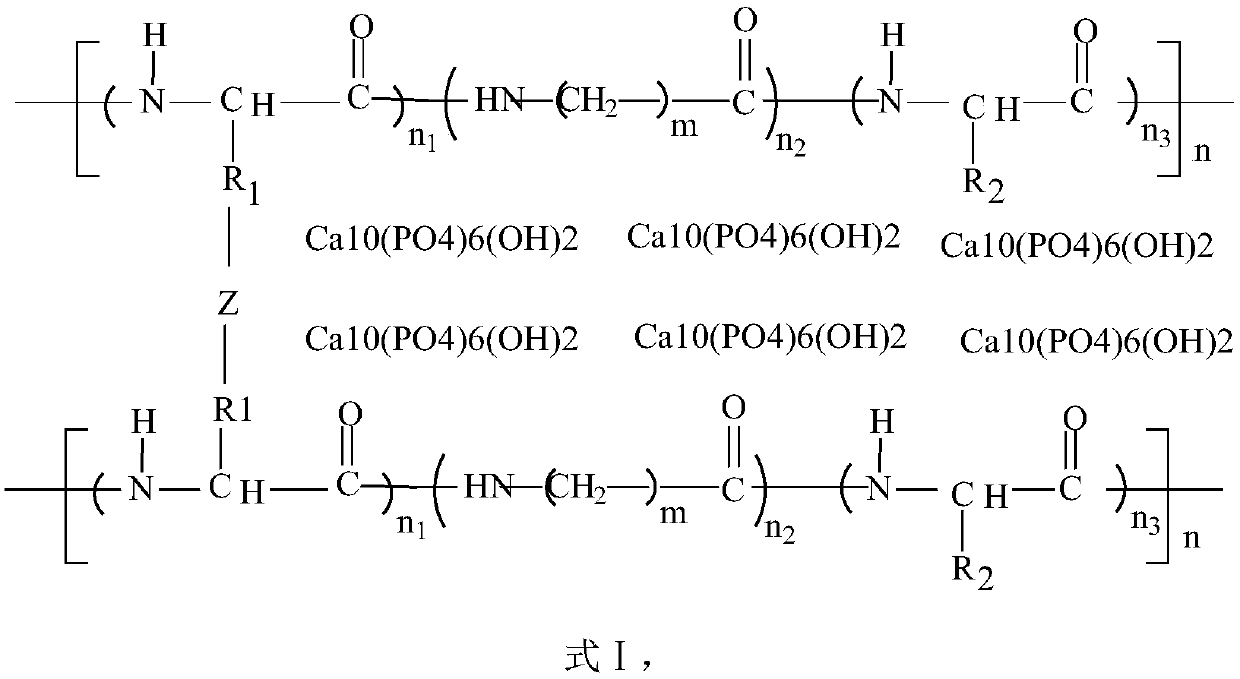

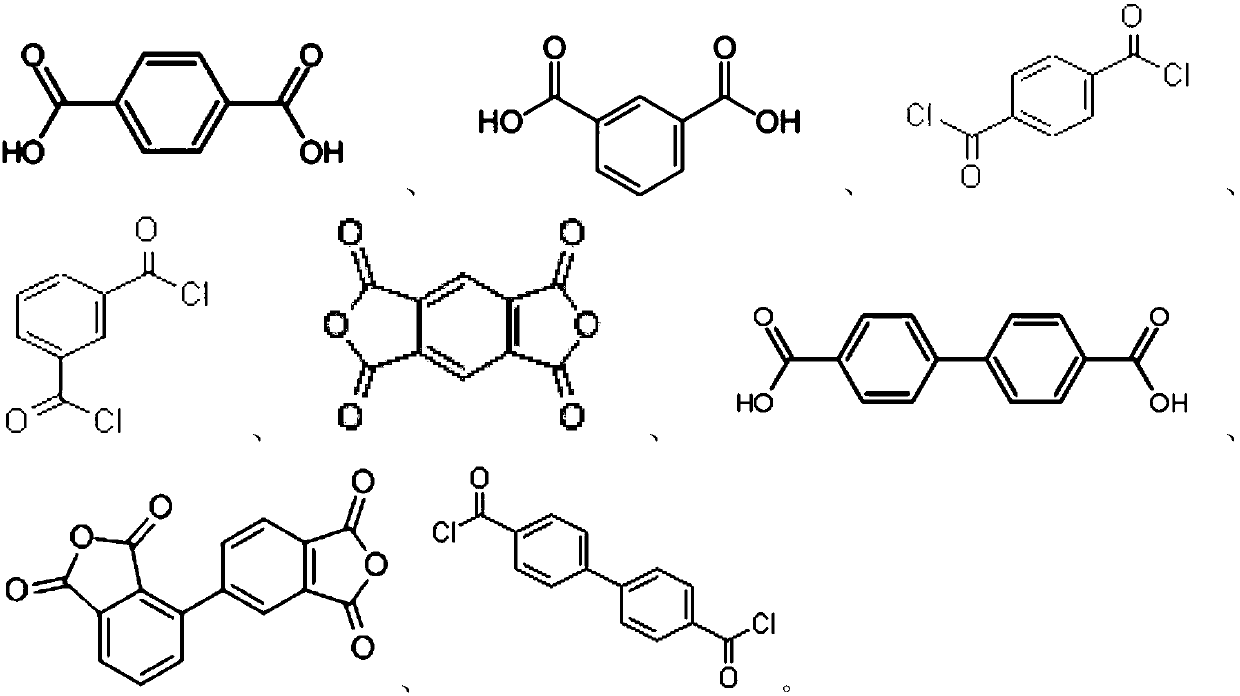

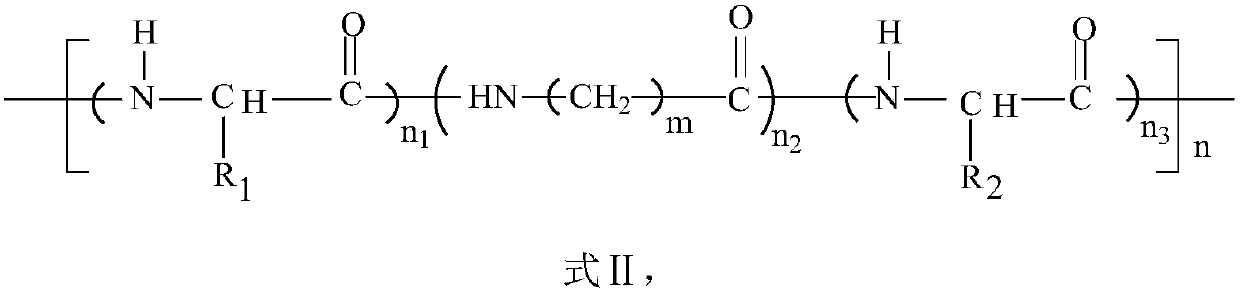

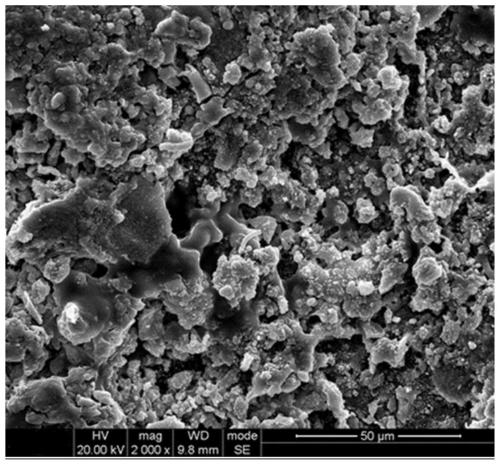

Temperature and modulus dual-controlled nano-hydroxyapatite and polyamino acid composite bone graft material and preparation method thereof

InactiveCN110639062ANo toxicityNo stimulationTissue regenerationProsthesisNano hydroxyapatiteBiocompatibility

The invention discloses a temperature and modulus dual-controlled nano-hydroxyapatite and polyamino acid composite bone graft material. The temperature and modulus dual-controlled nano-hydroxyapatiteand polyamino acid composite bone graft material is formed by polyamino acid and nano-hydroxyapatite in an in-situ composting mode, and the structure of the temperature and modulus dual-controlled nano-hydroxyapatite and polyamino acid composite bone graft material is shown as a formula (I) (please see the specifications for the formula (I)). The invention further provides a preparation method andapplication of the composite bone graft material. The temperature and modulus dual-controlled nano-hydroxyapatite and polyamino acid composite bone graft material comprising a bionic structure and prepared through the preparation method has the mechanical property approaching to that of human bones and has the deformation temperature and elasticity modulus which can be adjusted and controlled; secondary modeling is easy to be conducted, the material shape is adjusted immediately and conveniently according to the demands of patients in clinical use, and quick injection moulding can further beachieved; good biological activity, good biocompatibility and good biosecurity are achieved; and the proper thermal deformation temperature and mechanical properties can be selected according to the different clinical needs, and the temperature and modulus dual-controlled nano-hydroxyapatite polyamino acid composite bone graft material is clinically suitable for supporting of bone repair and reconstruction and supporting and repairing of immediate modeling of certain complex and irregular wounds.

Owner:中鼎凯瑞科技成都有限公司

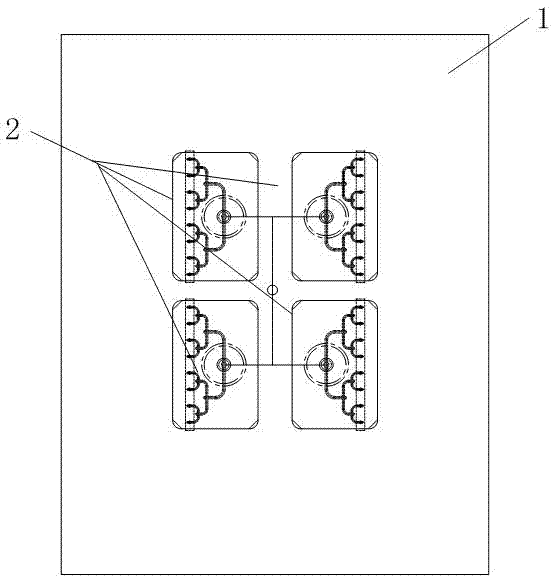

Water-drainage anti-skidding plastic tray and production process thereof

InactiveCN111571925AFast injection moldingPracticalRigid containersInjection mouldingMechanical engineering

The invention discloses a water-drainage anti-skidding plastic tray and a production process thereof. The water-drainage anti-skidding plastic tray comprises a water-drainage anti-skidding plastic tray body, wherein cross guide slots are formed in the surface of the water-drainage anti-skidding plastic tray body in a crossed mode in a diagonal direction; the inner parts of the cross guide slots are arranged in an inclined mode towards four corners from the center positions; gird lines are arranged on the bottom surface of the water-drainage anti-skidding plastic tray body; in a manufacturing process of an injection mould, an iron gauze layer spreads on the inner bottom surface of a mould cavity of a lower mould block, and a cross block is arranged on the bottom surface of a core block of an upper mould block in the diagonal direction; while the water-drainage anti-skidding plastic tray is poured by the injection mould, grid lines are arranged on the bottom surface of the formed water-drainage anti-skidding plastic tray, and cross guide slots are formed in the top surface, so that water-drainage and anti-skidding processing does not need to manually perform on the water-drainage anti-skidding plastic tray subsequently, time and labor are saved, and injection moulding of the water-drainage anti-skidding plastic tray is quicker.

Owner:界首市亚鑫塑业科技有限公司

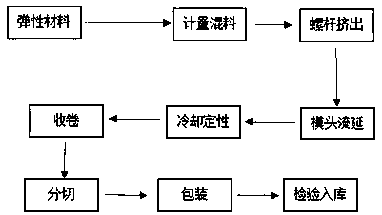

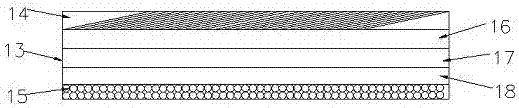

Elastic casting film and preparation method thereof

InactiveCN110204886AImprove plasticityImprove mechanical propertiesAbsorbent padsBaby linensPolyesterThermoplastic polyurethane

The invention discloses an elastic casting film. The elastic casting film is composed of 100% of polyester-type thermoplastic polyurethane elastomers and has excellent mechanical properties, good processing stability and quick injection molding formation performance. The elastic casting film has the following advantages that the original retractable elasticity can be improved, the original productshape can be maintained, and after retractable stretching, deformation is small without the function of external force under the static condition; the plasticity of the thin film is high, and moldingcan be conducted according to the shape of a final product; the elastic casting film can be applied to supplies, such as disposable hygiene products, garment supplies and disposable face masks, witha function of stretching a rebound demand structure, the demand for an original high-stretching and small-retraction-deformation structure is met, the safety and structural performance of the productare improved, the daily-increased demand of consumers for safe and fit products with soft skin feeling is met, and the elastic casting film can be applied to disposable pants-type hygiene products, elastic waistlines, outdoor jackets, protection garments and disposable face mask products.

Owner:娜菲鼎新(广东)科技有限公司

Anti-whitening flame-retardant polypropylene ribbon and preparation method thereof

ActiveCN111087688ASolve the problem of stress whitening of cable tiesImprove bindingPolymer sciencePolypropylene

The invention relates to an anti-whitening flame-retardant polypropylene ribbon and a preparation method thereof. The polypropylene ribbon comprises the following components in parts by weight: 60-80parts of polypropylene, 7-30 parts of a second component polymer, 10-20 parts of a flame-retardant toughening agent, 0.5-3 parts of an anti-whitening agent and 1-3 parts of other aids. The flame-retardant toughening agent is creatively prepared through reaction and co-extrusion and is compounded with a stress whitening resistant agent, so the special requirements on mechanical performance, low-temperature toughness, damp and heat resistance, whitening resistance and the like are met of the ribbon while the flame-retardant requirement of the ribbon is met, and a flame retardant is not separatedout. By adopting the flame-retardant toughening agent, the problem that a traditional flame retardant is difficult to disperse in polypropylene is greatly improved, and material uniformity is powerfully improved. Meanwhile, the produced polypropylene ribbon has the characteristics of high production efficiency and easiness in demolding, and the requirement for production of 64 products in one mold or even higher production requirements are met.

Owner:NANJING JULONG SCI&TECH CO LTD

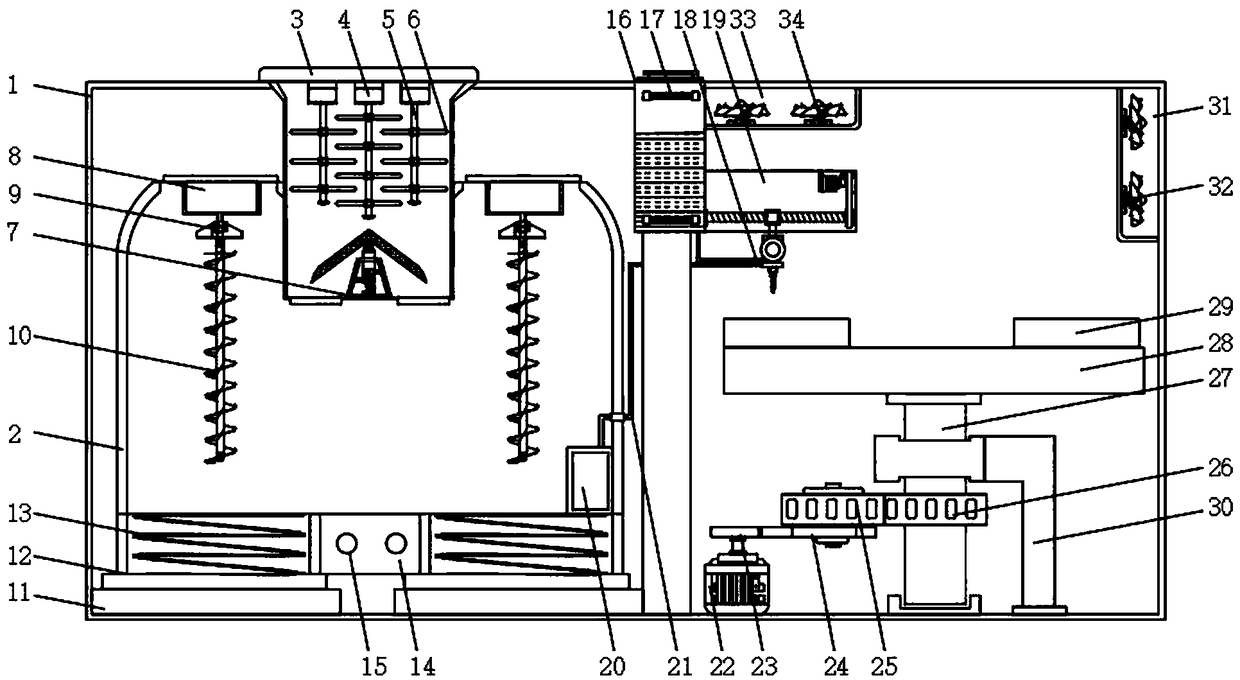

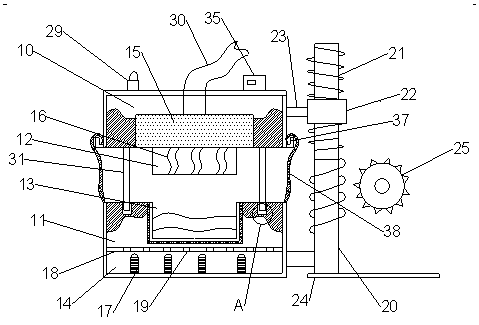

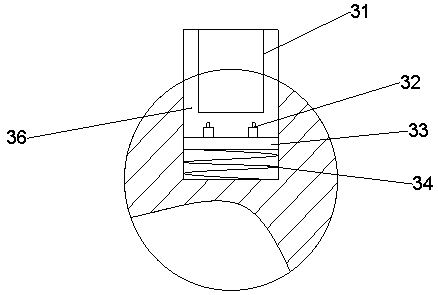

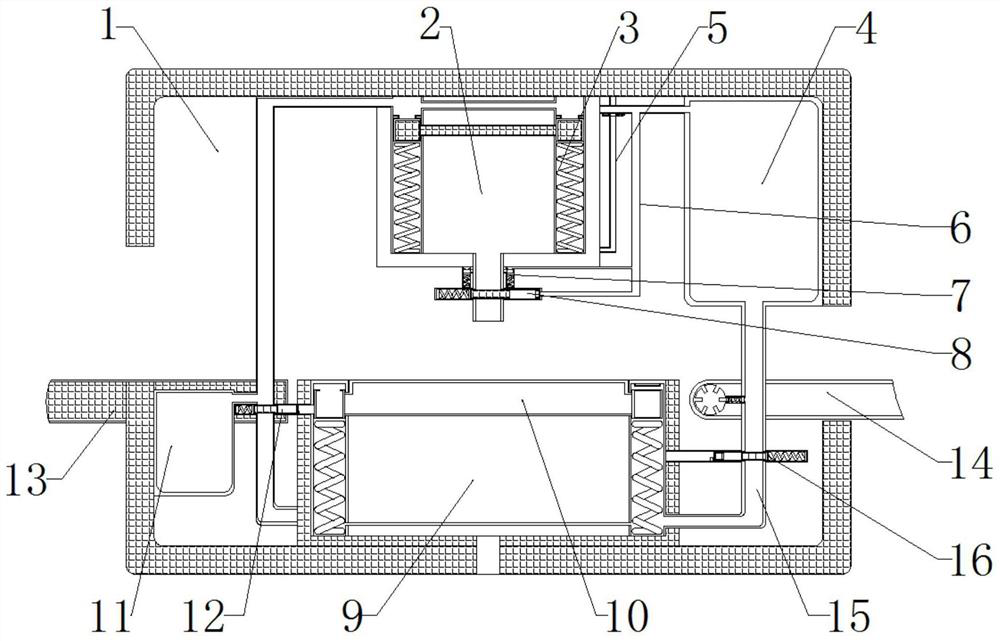

Hot-melt injection molding and hot-melt packaging machine

InactiveCN108099089ATo achieve the purpose of multi-stage crushingGuaranteed work efficiencyCoatingsHot meltEngineering

The invention discloses a hot-melt injection molding and hot-melt packaging machine, comprising an outer working frame, wherein a hot-melting box is fixedly connected with one side of the bottom of the inner wall of the outer working frame; a smashing and feeding device is fixedly connected with the center of the top of the hot-melting box; a crushing motor is fixedly connected with the top of theinner wall of the crushing and feeding device; the output shaft of the crushing motor is rotatably provided with a crushing rotation shaft; a crushing knife is arranged on the outer wall of the crushing rotation shaft; the bottom of the inner wall of the crushing and feeding device is fixedly connected with a secondary crushing device; both sides of the top of the inner wall of the hot-melting box are fixedly connected with stirring work boxes; and stirrers are rotatably arranged below and connected with the bottoms of the stirring work boxes through stirrer mounting shafts. The hot-melt injection molding and hot-melt packaging machine of the invention relates to the technical field of packaging machinery. The hot-melt injection molding and hot-melt packaging machine makes multi-stage crushing and melting of packaging plastics more uniform and stable and realizes air circulation; a rapidly-feeding rotating workbench can increase work efficiency and reduce the labor intensity of workers.

Owner:TIANCHANG TIANXIANG GRP

High-transparency food-grade polypropylene special material and production method thereof

InactiveCN111303327AMelt index controllableMelt index range controllableBulk chemical productionPolymer sciencePtru catalyst

The invention discloses a high-transparency food-grade polypropylene special material. The preparation comprises the following steps: (1) propylene and ethylene raw materials are refined; (2) in a specific catalyst Cat-II and external electron donor D-II system, ethylene and propylene are subjected to a binary random copolymerization reaction in a Unipol process polypropylene device gas phase fluidized bed reactor; (3) a polymerization product is degassed; and (4) polymerization powder and a specific additive are subjected to co-extrusion granulation to obtain the product. According to the high-transparency polypropylene special material and the production method of the high-transparency polypropylene special material in a Unipol gas-phase fluidized bed process, the transparent polypropylene special material obtained by adopting the production formula is green and environment-friendly, does not contain any plasticizer, and has a relatively high melt index and moderate impact strength and flexural modulus.

Owner:云南云天化石化有限公司

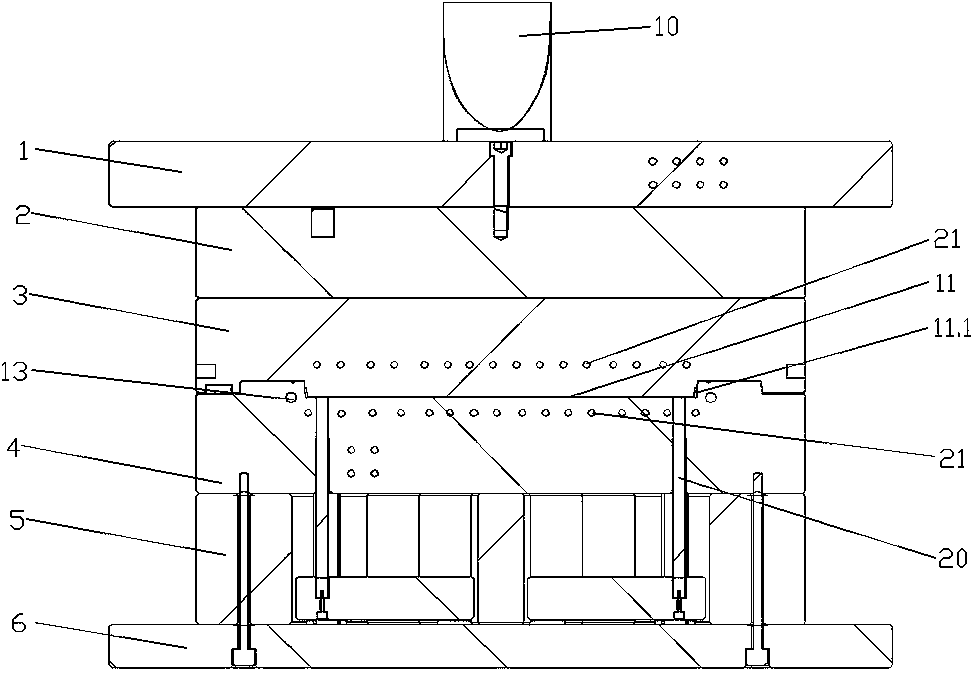

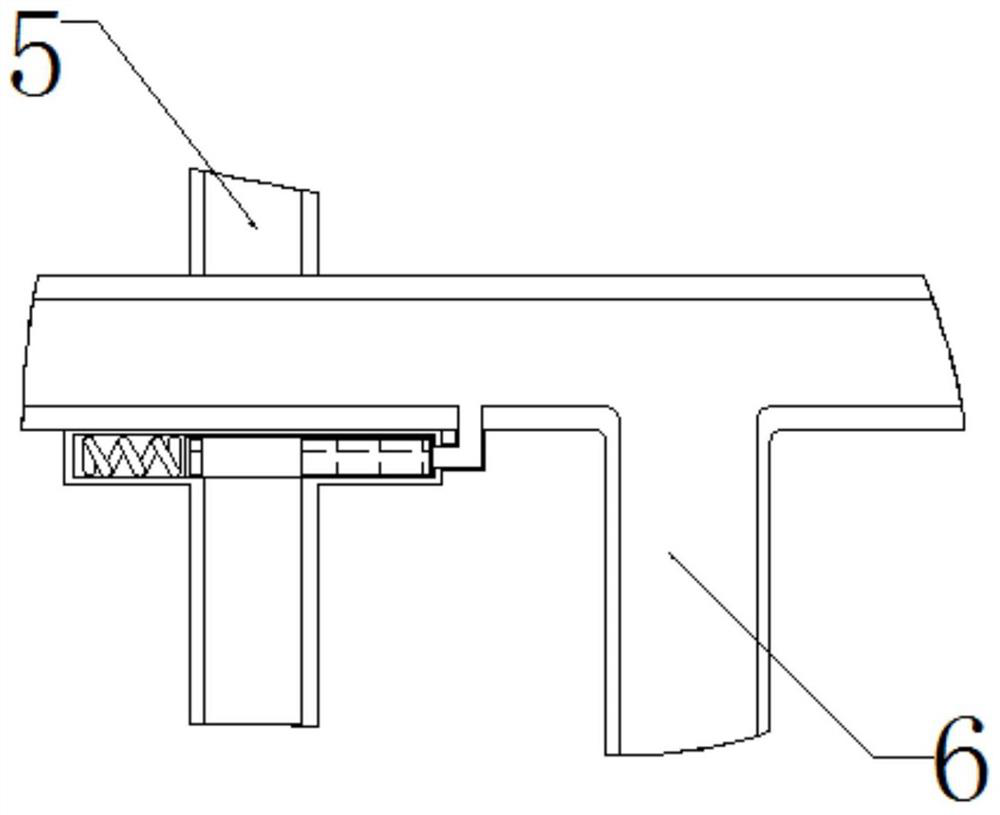

Injection mold for instrument board

The invention discloses an injection mold for an instrument board. The injection mold for the instrument board comprises a frame, an air cylinder is connected to the top end of the frame, a piston rodof the air cylinder extends into the frame and is internally provided with an upper mold seat in a welded mode, a male mold is welded to the bottom end of the upper mold seat, a female mold is arranged below the male die, first grooves are formed in the side walls of two sides of the frame, and sliding blocks are slidably connected to the side walls of one sides of the first grooves. Telescopic rods welded to the side walls of the bottom ends of the first grooves are installed at the bottom ends of the sliding blocks, springs are connected between the telescopic rods and the sliding blocks, and connecting plates are welded between the sliding blocks and the female mold. A fixed plate is welded to the side wall of the bottom end of the frame, a second groove is formed in the top end of thefixed plate, cooling liquid is arranged in the second groove, and limiting plates are welded to two sides of the top end of the fixed plate. The injection mold for the instrument board can perform rapid injection molding on the instrument board, can not only accelerate the cooling speed of the injection mold and improve the molding efficiency, but also can carry out simple cleaning on the outer wall of the male mold.

Owner:安徽志航科技有限公司

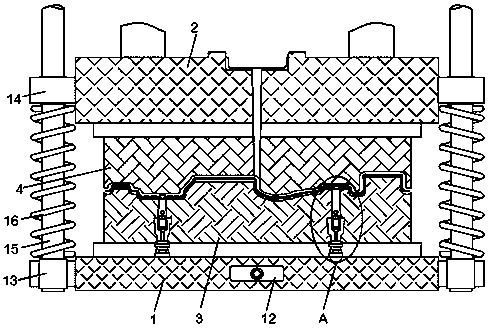

Automobile door panel injection mold

PendingCN110053215AEasy to use for a long timeFast injection moldingDomestic articlesHydraulic cylinderEngineering

The invention discloses an automobile door panel injection mold. The automobile door panel injection mold comprises a fixed mold base and a movable mold base. A fixed mold core and a movable mold coreare welded to the upper end of the fixed mold base and the lower end of the movable mold base correspondingly. The top end of the fixed mold core corresponds to the bottom end of movable mold core. Two micro hydraulic cylinders are arranged in the fixed mold core. Ejector pins are connected with output shafts of the two micro hydraulic cylinders. The ejector pins are sleeved with an ejector pin plate. An electromagnetic relay is arranged on the fixed mold base. By arranging the micro hydraulic cylinders controlled by the electromagnetic relay in the fixed mold core, the micro hydraulic cylinders are used for driving the ejector pins of a two-section structure to move up and down in a fixed model base and a cavity, thus, the ejector plate with a large area is used for providing lifting support action force for a door panel model, the door panel model can be quickly separated from the cavity, and the pressure borne by the ejector pins is reduced; and a guide rod fixedly connected with the fixed mold base achieves the support effect for up and down movement of the movable mold core, and the demolding efficiency and accuracy are advantageously improved.

Owner:江苏宇豪新材料科技有限公司

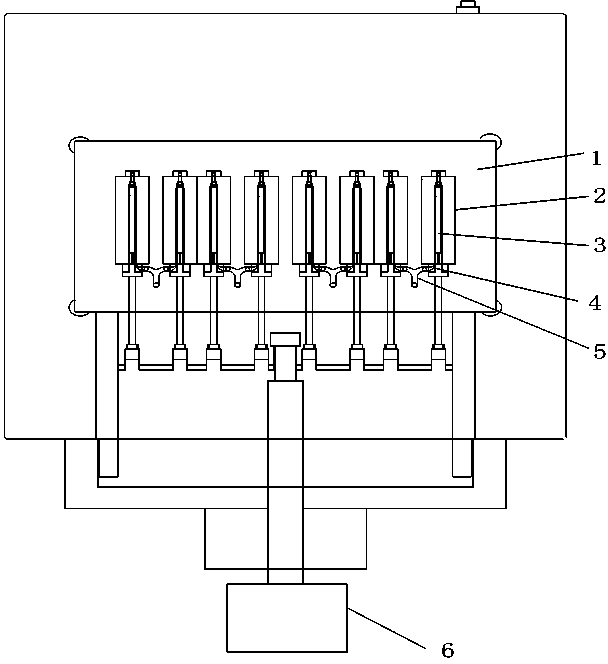

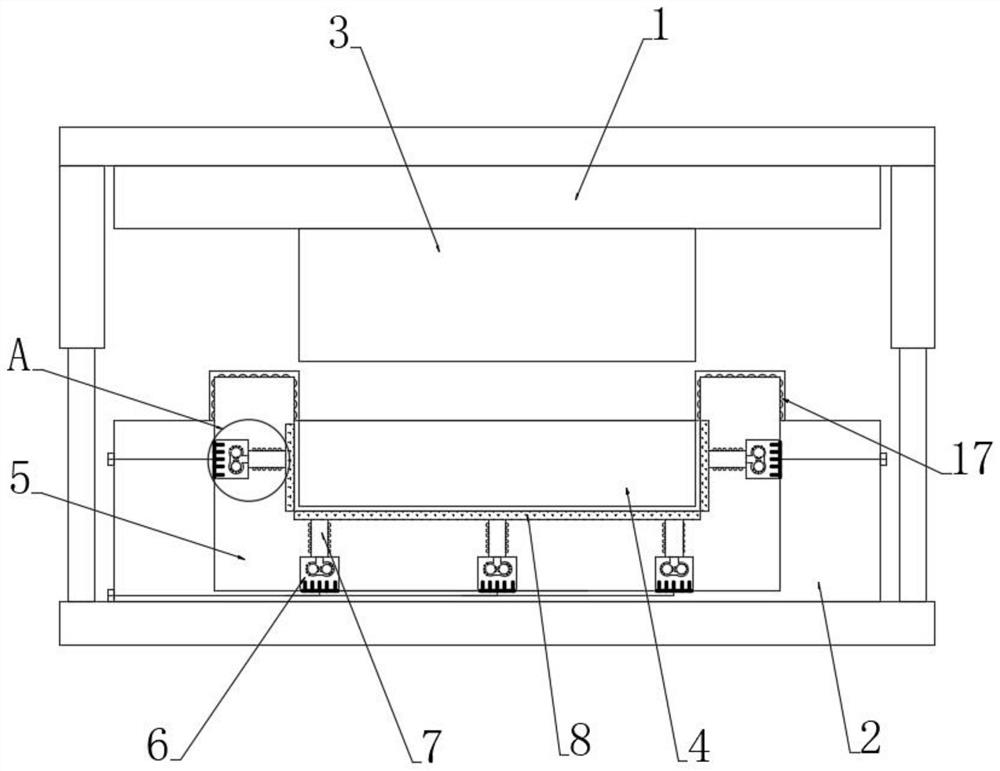

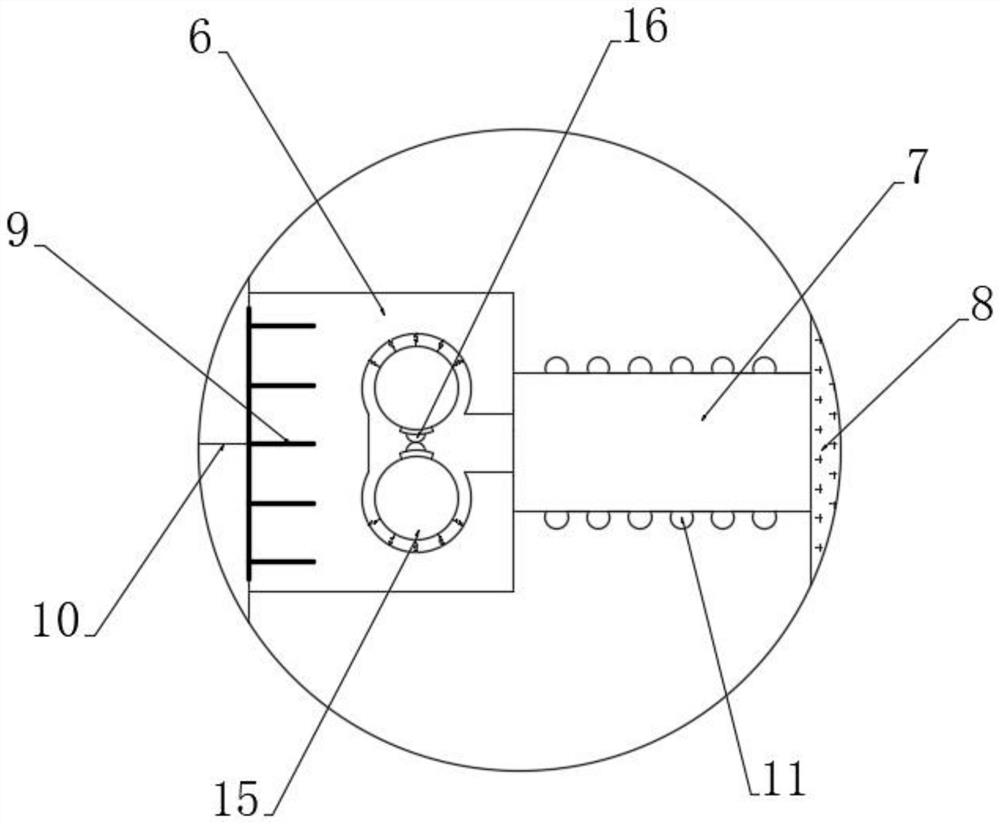

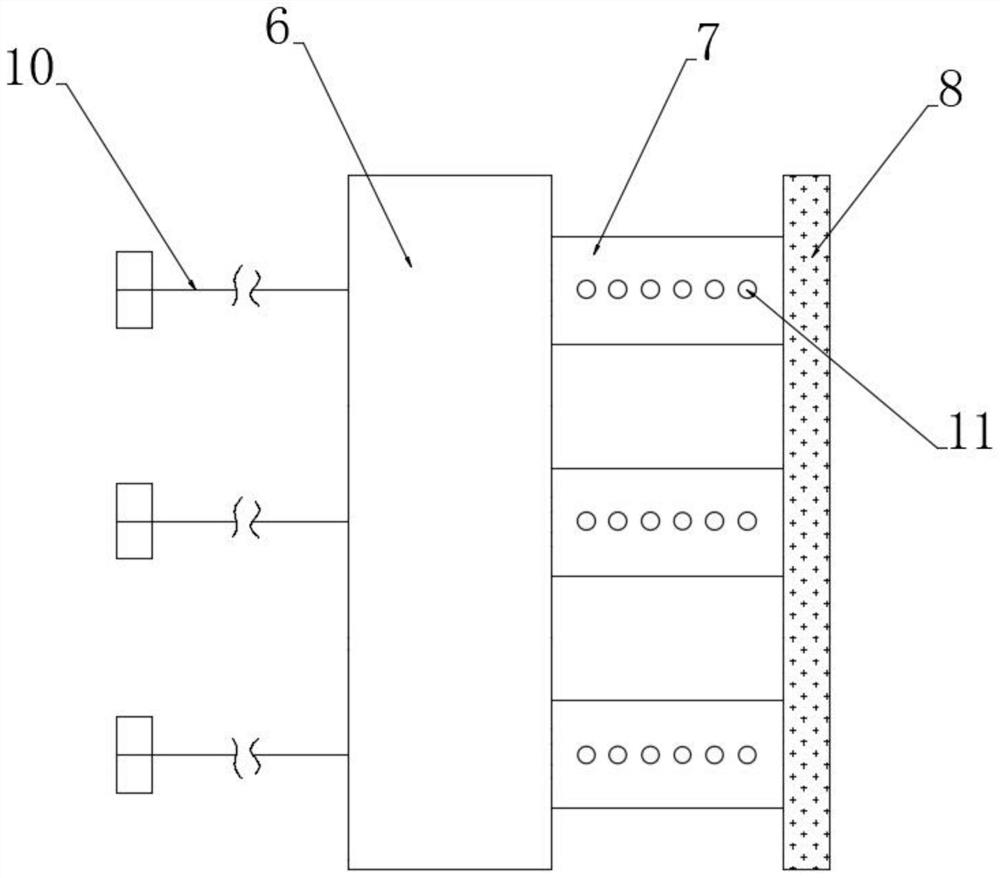

Special mold injection molding device for new energy vehicle interior decoration

InactiveCN107234782AFast injection moldingSimple structure and principleDomestic articlesInjection portNew energy

The invention discloses a special mold injection molding device for a new energy vehicle interior decoration. The special mold injection molding device comprises two groups of main runners, a branch runner, injection molding nozzles and cooling water pipes; the top ends of the main runners communicate with a material injection hole; the branch runner vertically communicates with the two groups of main runners; multiple groups of injection molding nozzle runners are arranged at the lower end of the branch runner; the injection molding nozzles are formed in the injection molding nozzle runners separately and are connected with air blowing devices arranged on one sides of the corresponding injection molding nozzles; and the cooling water pipes are arranged on the outer walls of the main runners in a spiral shape separately. The special mold injection molding device has the advantages that the structure principle is simple, rapid injection molding to a mold can be realized, the production cost can be lowered, and the working efficiency is improved.

Owner:南通伯爵新能源汽车研究院有限公司

Injection mold capable of achieving quick molding

The invention relates to the field of mold manufacturing, and discloses an injection mold capable of achieving quick molding. The injection mold comprises an upper mold base and a lower mold base; aninjection molding liquid tank is arranged in the upper mold base, a male mold cavity is fixedly installed on the lower surface of the upper mold base, a plurality of injection molding pipes are arranged in the male mold cavity, and the tops of the injection molding pipes communicate with the bottom of the injection molding liquid tank; a condensation chamber is arranged at the bottom of the uppermold base, and a plurality of condensation pipes are arranged in the condensation chamber; a transverse baffle is fixedly installed on the top of the condensation chamber and provided with a pluralityof cold air outlets; a female mold tank is arranged on the upper side of the lower mold base and corresponds to the male mold cavity in the vertical direction; and vertical rods which are each of a vertical circular structure are fixedly installed on the two sides of the lower surface of the upper mold base, the two sides of the upper portion of the lower mold base are provided with cylindrical grooves in the mode of corresponding to the bottoms of the vertical rods, a pressing plate is arranged in each cylindrical groove, and two groups of contact heads are arranged on the top of each pressing plate. The injection mold has the advantages that the injection molding speed, the mold opening and closing speed and the working efficiency are high.

Owner:青岛益丰橡塑制品有限公司

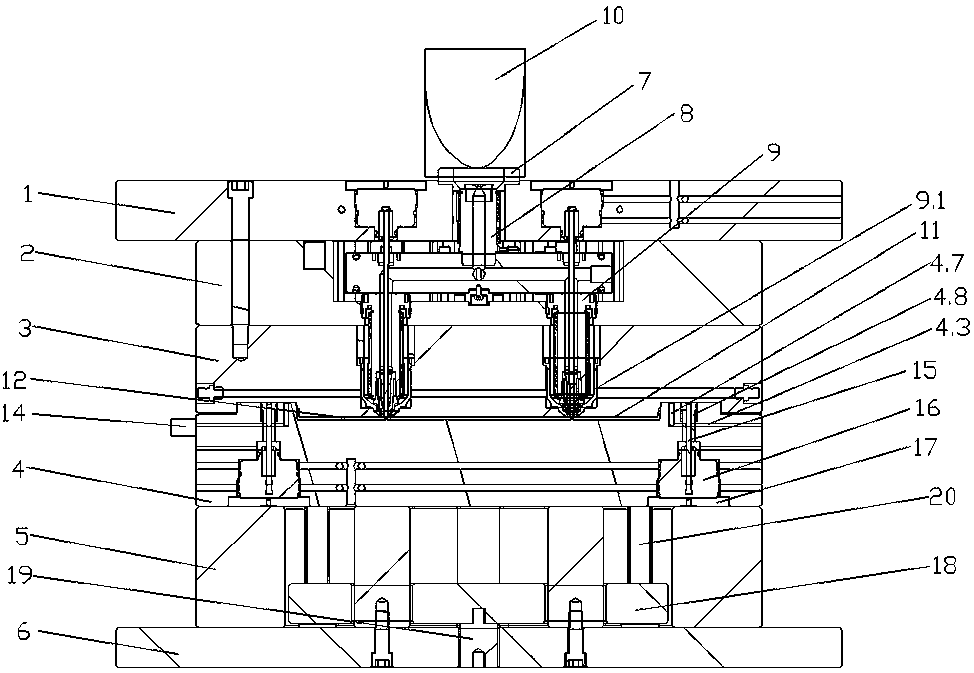

In-mold product injection molding and foaming integrated process and mold

The invention discloses an in-mold product injection molding and foaming integrated mold. The in-mold product injection molding and foaming integrated mold is characterized in that an oil pressure valve connected with a needle valve type hot runner is arranged on an injection molding machine, a forming groove formed through surrounding of an annular surrounding table is formed in a parting surface of a cavity, a first-stage forming bulge and a second-stage forming bulge are arranged on a parting surface of a mold core in a corresponding mode, a mold cavity of a product is formed among the forming groove, the first-stage forming bulge and the second-stage forming bulge, the wall surface of the portion, attached to the first-stage forming bulge, of the inner side wall of the forming groove are obliquely arranged downwards and inwards, a first cooling water channel used for cooling the outer side surface of the product is arranged at the position, located on the periphery of the forming groove, in the cavity, gas exhaust passages which can communicate with the forming groove and the outside of the mold are arranged at the positions, located on the two long side edges of the forming groove, in the cavity, a gas extracting device connected with the gas exhaust passages is arranged outside the mold, and gas pins capable of sealing or opening the gas exhaust passages are arranged in the cavity. The invention further discloses an in-mold product injection molding and foaming integrated process.

Owner:台州市黄岩美鼎模具有限公司

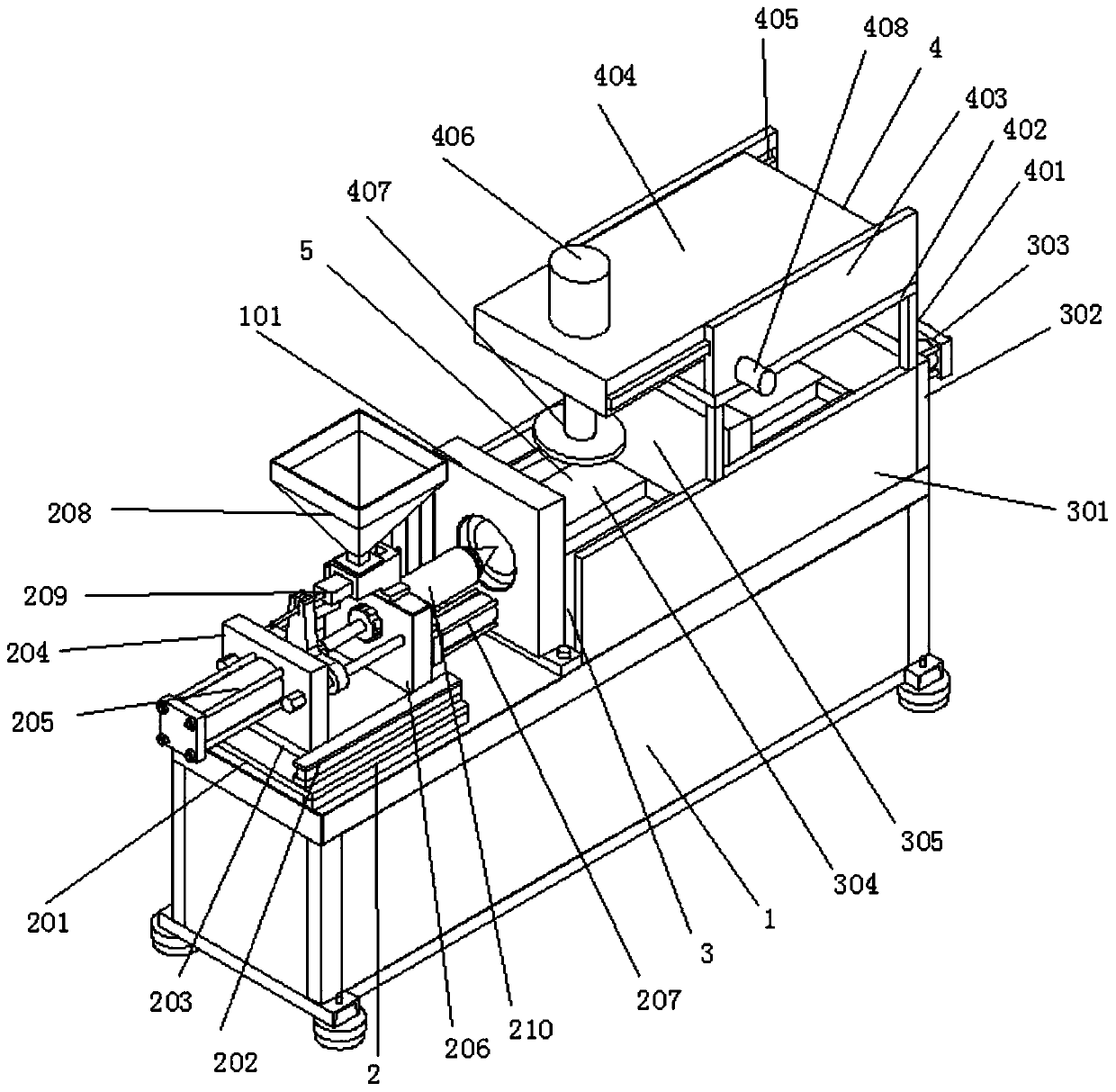

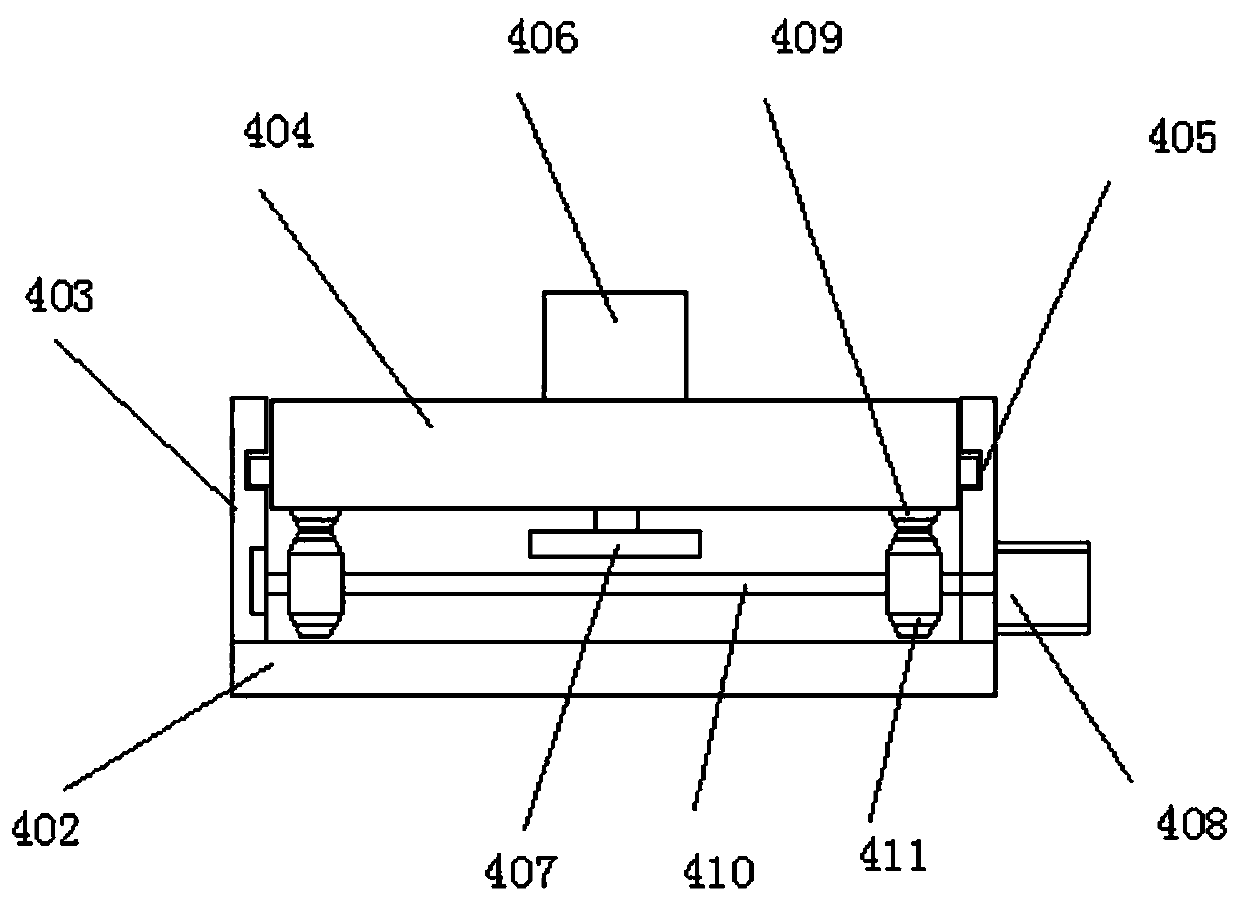

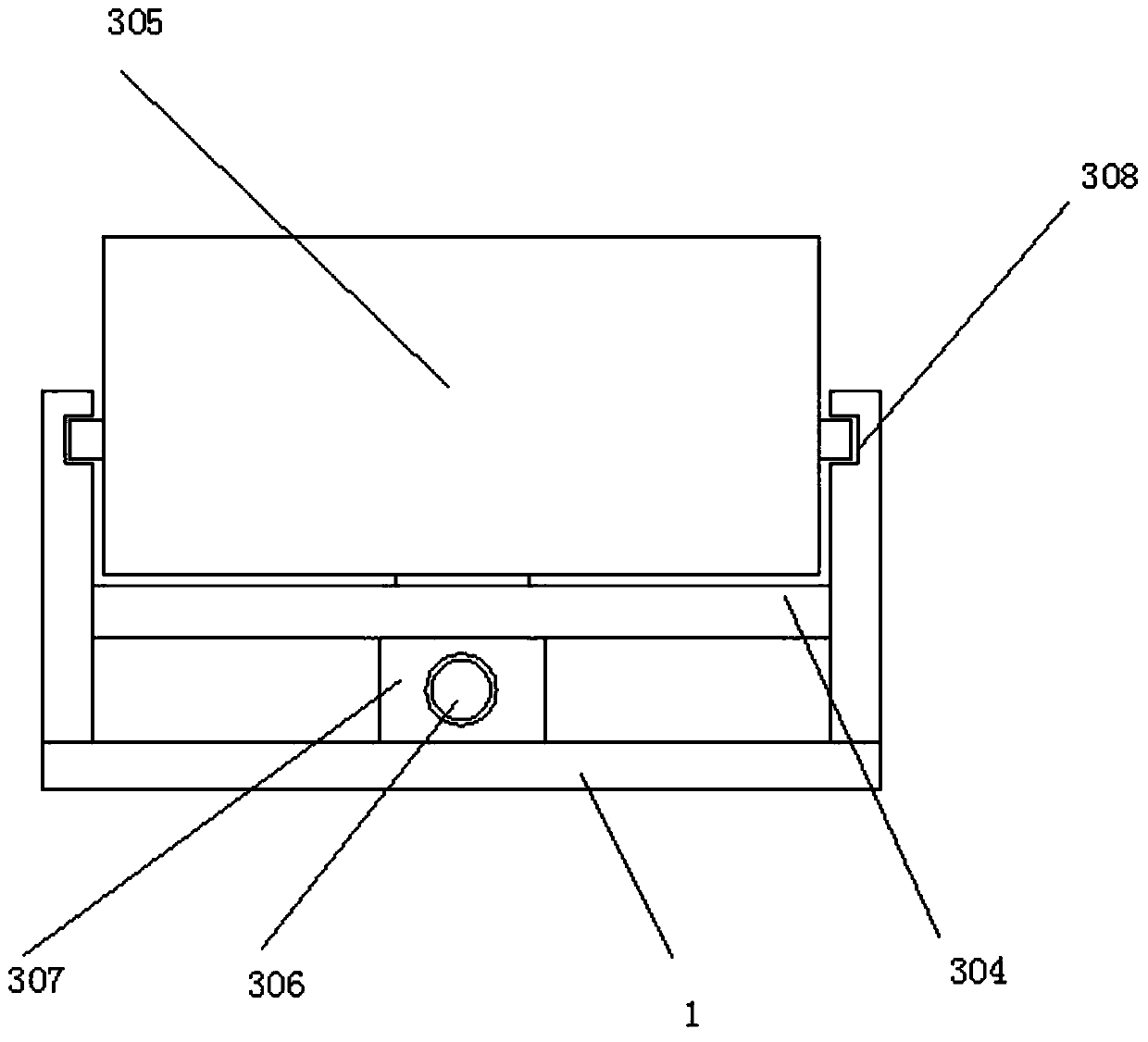

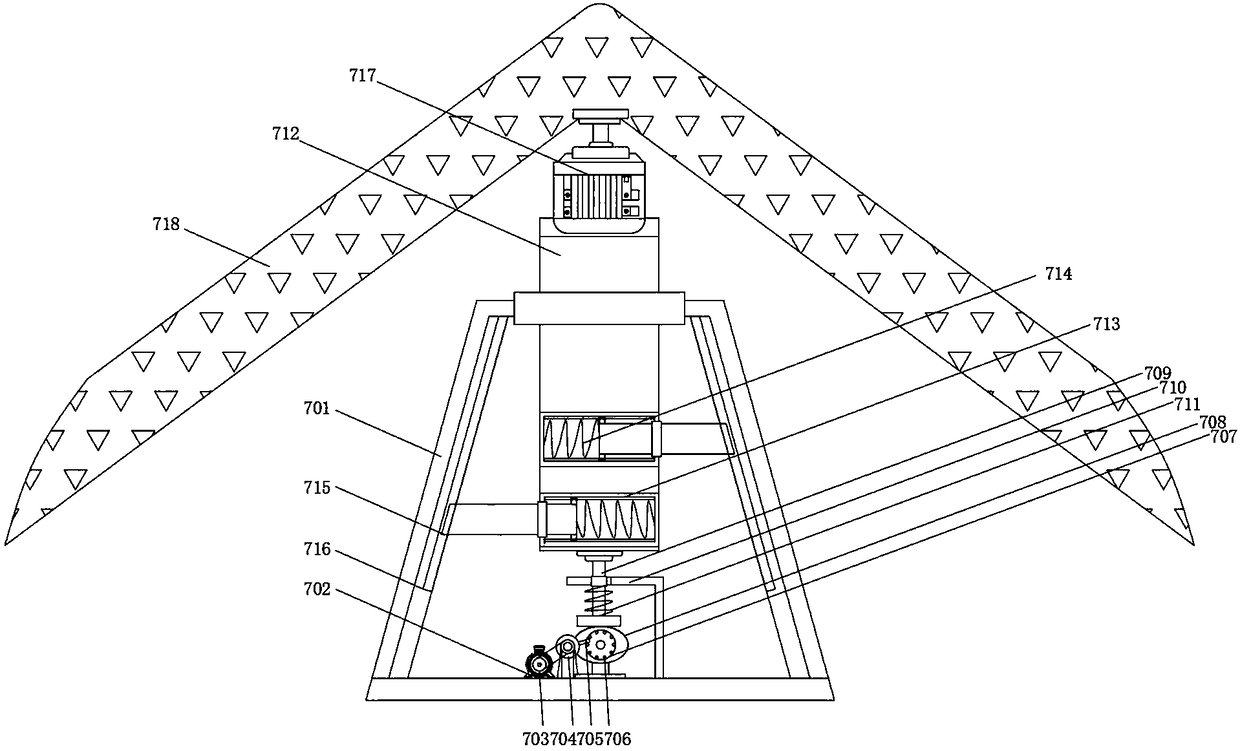

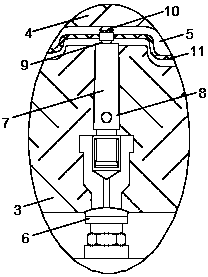

Hiking rubber shoe processing device capable of increasing injection molding pressure and realizing quick injection molding of cold gaps

The invention relates to the technical field of processing of hiking rubber shoes and discloses a hiking rubber shoe processing device capable of increasing injection molding pressure and realizing quick injection molding of cold gaps. The hiking rubber shoe processing device comprises a processing machine; an injection molding box is movably connected to the upper part of the interior of the processing machine; a reset track is movably connected to the interior of the injection molding box; a pressurizing box is movably connected to the upper right portion of the interior of the injection molding box; a charging pipe is movably connected to the right side of the exterior of the injection molding box; a connecting pipe is movably connected to the left side of the pressurizing box; a movable rail is movably connected to the lower portion of the injection molding box; and an injection molding rail is movably connected to the lower portion of the movable rail. A plastic pipe enters a moldthrough injection molding, is injected into the mold along with raw materials and is connected with a water pressure tank through a pressurizing water pipe; water is introduced into the reset rail through the pressurizing water pipe, so that the pressure during injection molding is further increased, thus the effect of increasing the pressure during injection molding is achieved, and bubbles andthe like generated during injection molding are reduced.

Owner:广州壹原贸易有限公司

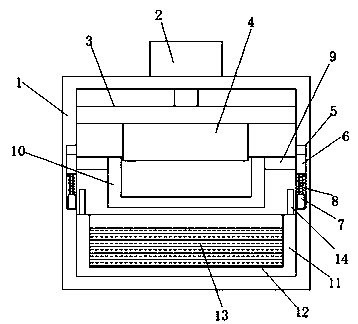

High-precision mold equipment with informatization and digitization functions

PendingCN112917852AAvoid affecting the molding effectUniform heat conductionInformatizationThermodynamics

The invention discloses high-precision mold equipment with informatization and digitization functions, and belongs to the technical field of molds. A plurality of heating plates are distributed in a heating cavity of a lower mold at intervals, the heating plates, a temperature sensing section layer and a heat conduction pad are matched to conduct heat for a female mold cavity, and temperature sensing memory deformation bodies are arranged in the temperature sensing section layer; a plurality of temperature sensing memory deformation bodies are used for sensing the temperature of each position in the heating cavity, when the temperature of a certain position does not reach a preset heating temperature, a heating wire at the position is in a heating state, so that the temperature of each position of the heating cavity is increased and is consistent; and when the temperature sensing memory deformation bodies sense that the temperature of the certain position exceeds the preset temperature, the temperature sensing memory deformation bodies stretch due to high-temperature deformation, contact pieces are pushed to be disconnected after stretching, a heating wire at the position is closed at the moment, the situation that the local temperature is too high due to continuous heating is avoided, the temperature is precisely regulated and controlled in real time through one-to-one cooperation between the plurality of temperature sensing memory deformation bodies and heating triggering bodies, and the product forming effect is effectively prevented from being influenced.

Owner:吉云

Blow molding nozzle and blow molding machine

The invention discloses a blow molding nozzle and a blow molding machine. The invention relates to the technical field of blow molding machines. A first equipment box is fixedly installed on one side of the upper outer surface of the frame body, and a third equipment box is fixedly installed on one side of the upper end outer surface of the frame body located at the first equipment box, and the upper end outer surface of the frame body is located at A second equipment box is fixedly installed on one side of the third equipment box, and several visible windows are fixedly installed around the second equipment box, and both sides of the middle position of the front end outer surface of the third equipment box are movably installed. There is a detection box door, and the outer surface of the upper end of the frame is located in front of the material storage tank, and a control station is fixedly installed. The device can fully stir the material to make the material more viscous, which is convenient for injection molding, and also facilitates rapid cooling of the injection molded product, so that the injection molded product can be quickly injection molded.

Owner:平湖市中美包装科技有限公司

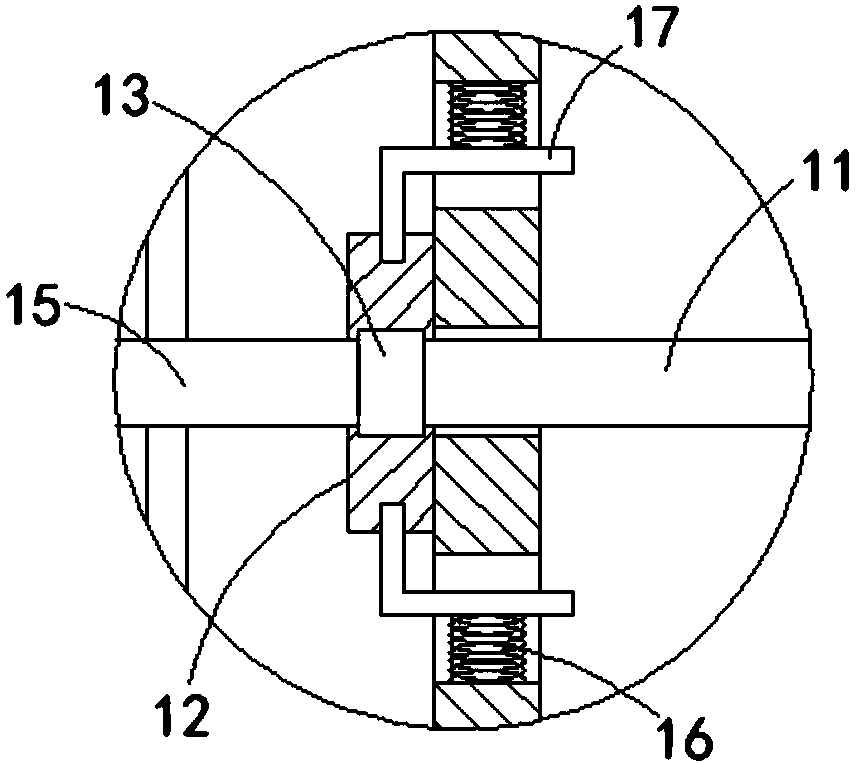

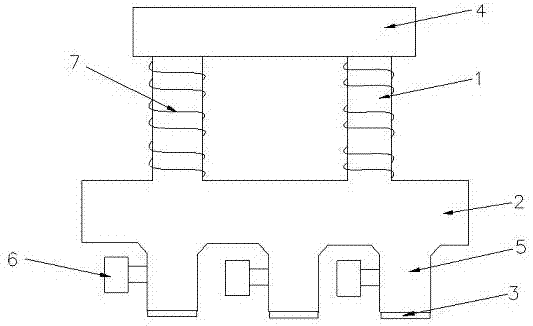

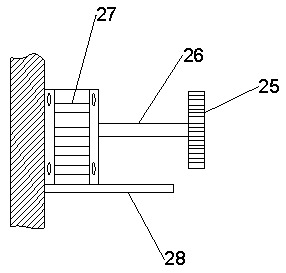

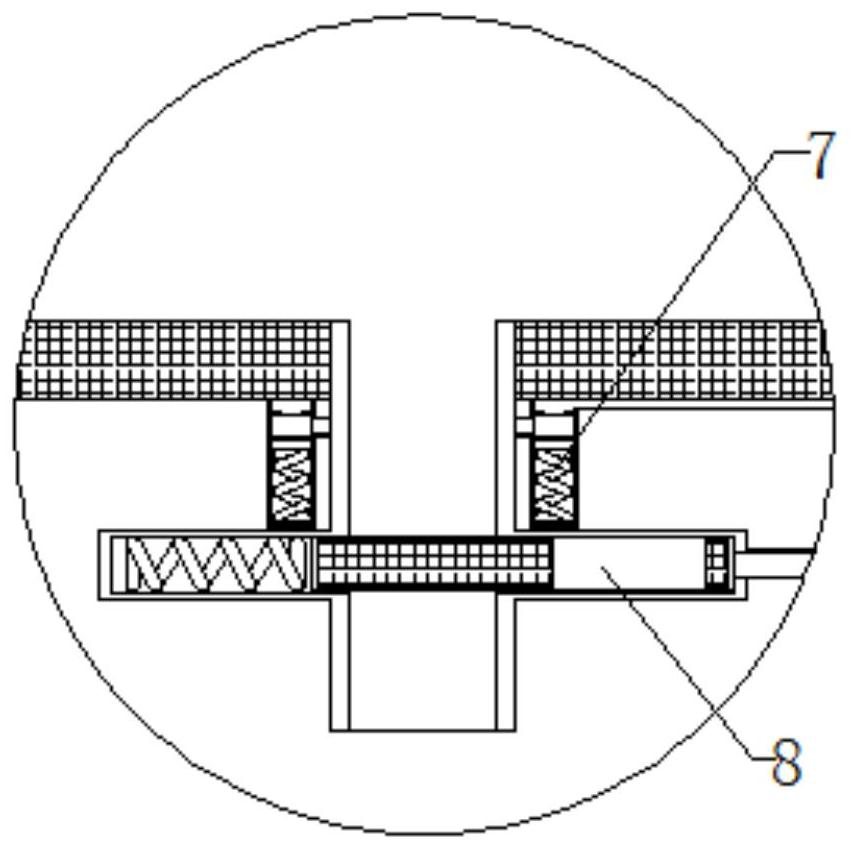

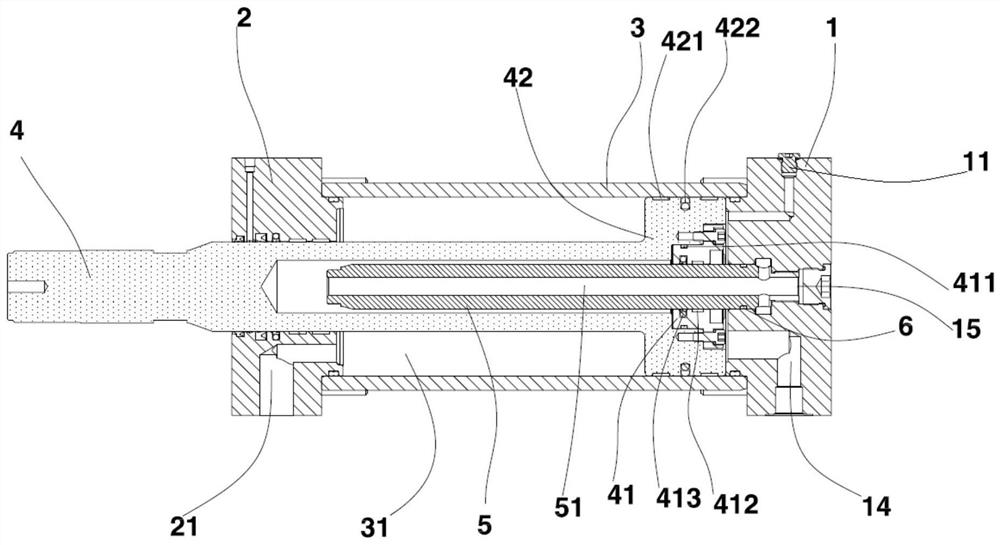

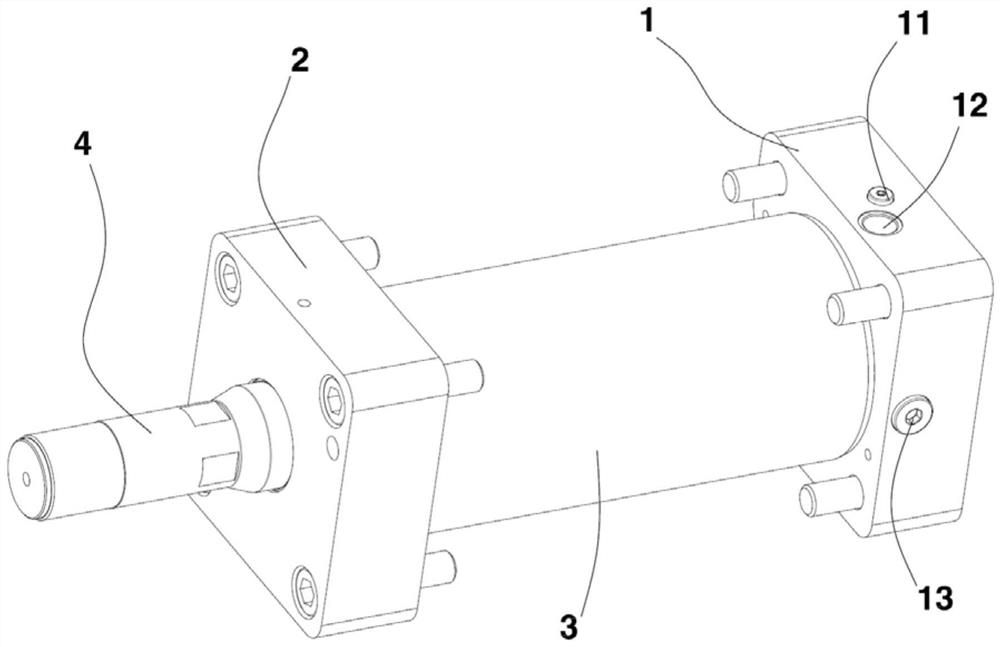

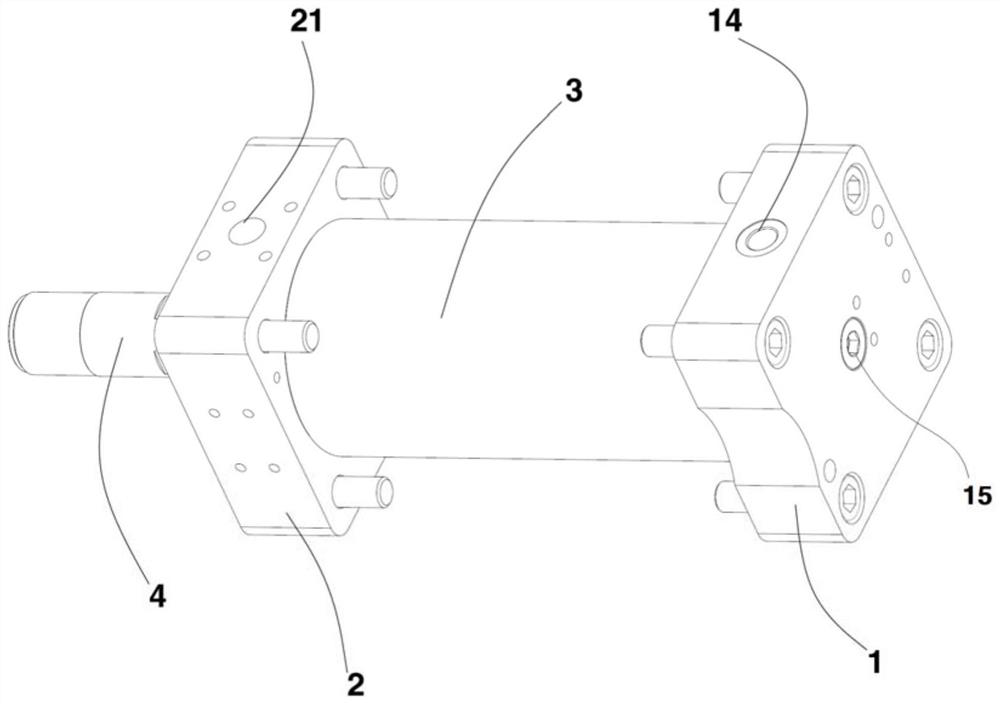

Double-cylinder quick injection structure of injection molding machine

A double-cylinder quick injection structure of an injection molding machine comprises an oil cylinder barrel, a front cover, a rear cover, a differential rod and a piston rod; the front cover and the rear cover are located at the two ends of the oil cylinder barrel, the differential rod is through front and back, the tail of the differential rod is arranged in the rear cover, and the head of the differential rod extends towards the front cover; and a cavity is formed in the rear portion of the piston rod, the piston rod is arranged outside the differential rod in a sleeving mode, and the head of the piston rod penetrates through the front cover and is connected with the front cover in a sliding mode. Through holes are oppositely formed in the two sides of the tail of the differential rod, an annular cavity surrounding the through holes is formed in the rear cover, and a first oil port and a second oil port which supply oil to the differential cavity through the annular cavity and the through holes are formed in the rear cover, so that the flow can be reduced, and control is more accurate; and rapid injection molding of the large-diameter piston rod can be achieved, and injection molding processing has the advantages.

Owner:宁波甬华塑料机械制造有限公司

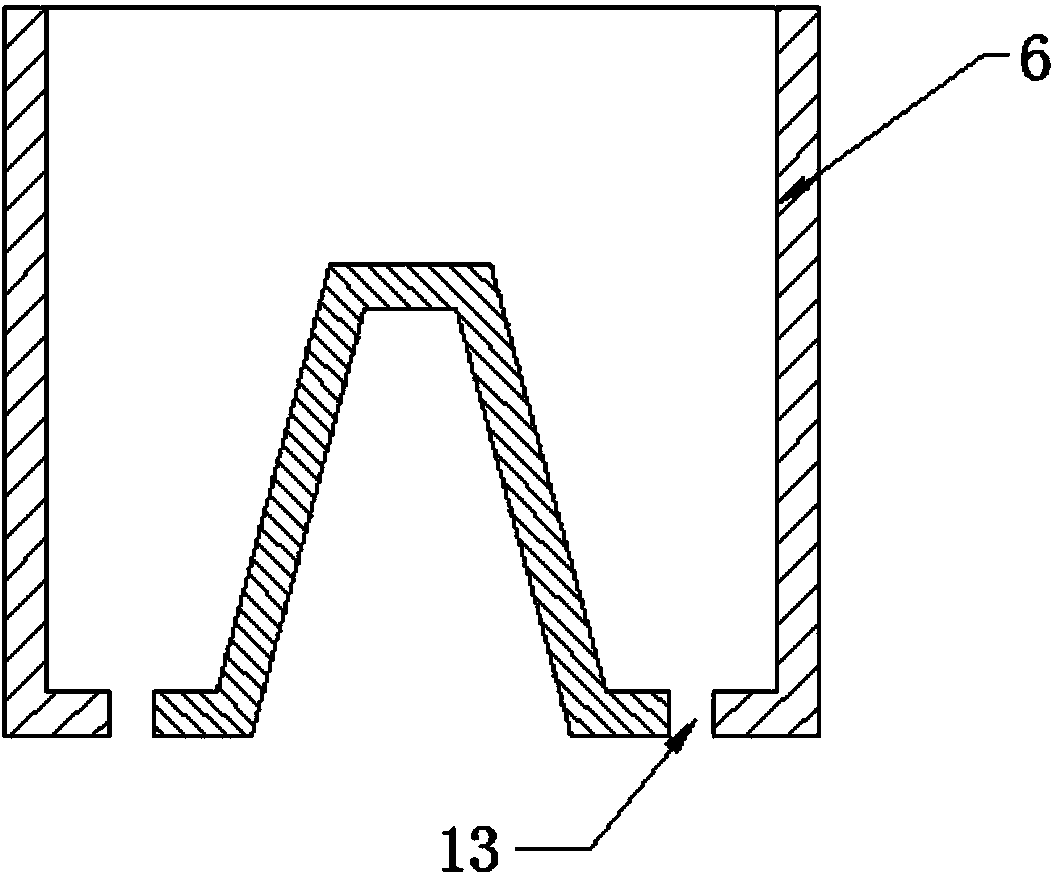

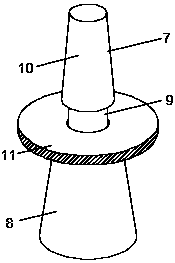

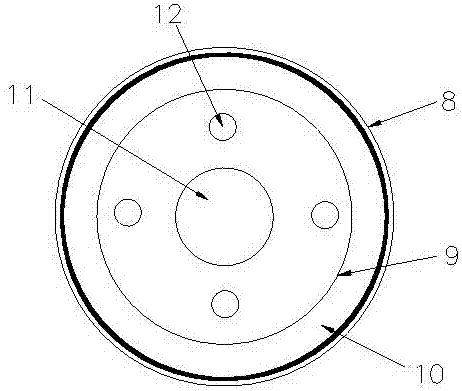

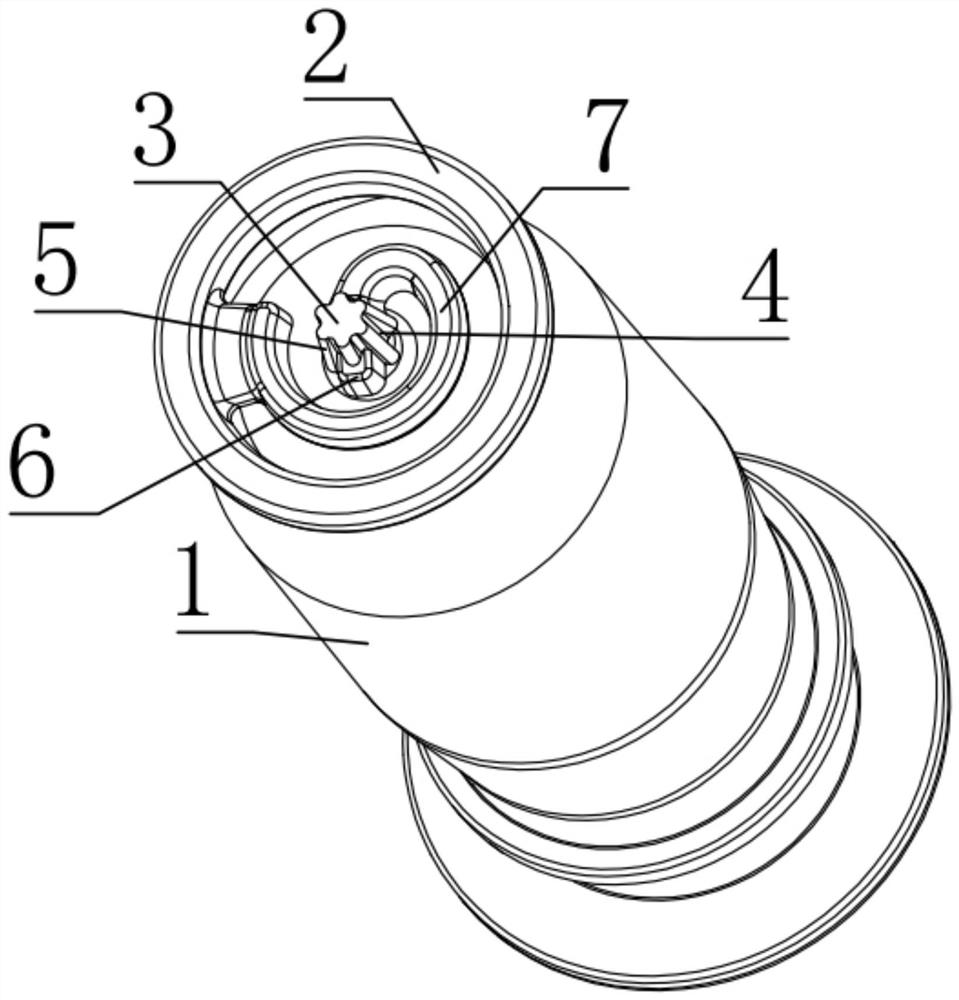

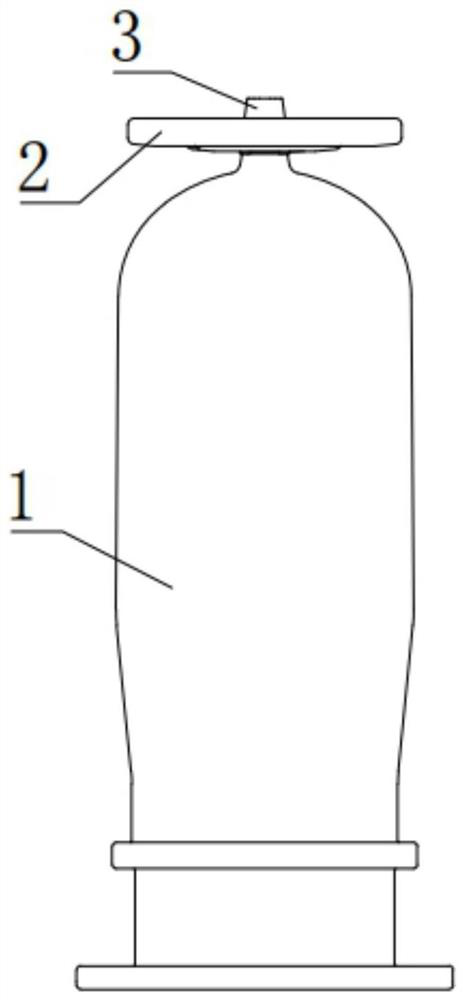

Hanging ring integrated bottle preform large in cooling area of pouring gate column and forming mold of hanging ring integrated bottle preform

The invention discloses a hanging ring integrated bottle preform large in cooling area of a pouring gate column. The hanging ring integrated bottle preform comprises a bottle preform body, a hanging ring and the pouring gate column. The pouring gate column is arranged at the closed end of the bottle preform body, the hanging ring is connected with the pouring gate column through a connecting part, and the connecting part is arranged in a space formed between the pouring gate column and the hanging ring in a non-linear manner. The pouring gate column is of a special-shaped column structure with a cooling area larger than that of a cylindrical pouring gate column. By means of the bottle preform, the heat dissipation area of the pouring gate column is increased, the heat dissipation area of the pouring gate column is increased, then the heat dissipation rate is increased, the whole production period is shortened, the production efficiency is improved by 20%, and bubbles and wiredrawing are avoided.

Owner:CHENGDU LIANYU PRECISION MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com