Plastic mold for electronic pen holder

A plastic mold and electronic pen technology, applied in the field of plastic molds, can solve problems such as complex structure, low production efficiency, and lower product qualification rate, and achieve the effects of simple device structure, improved work efficiency, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

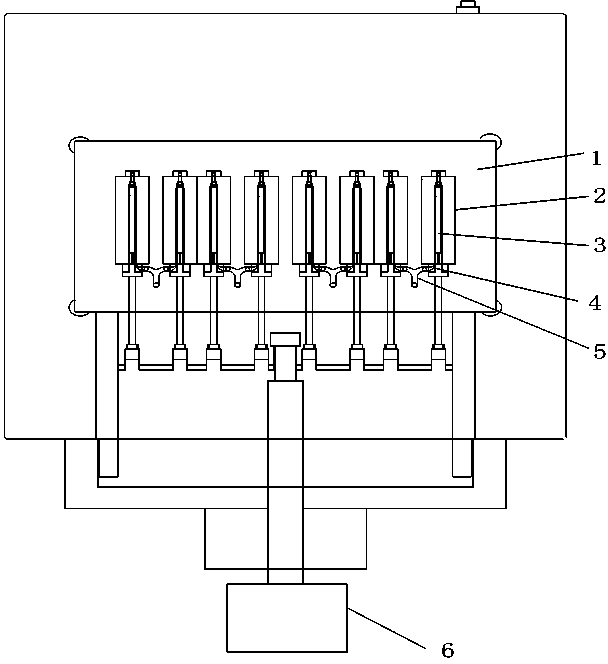

[0011] Such as figure 1 As shown, the plastic mold of the pen holder of the electronic pen includes a static template, a cavity plate 1 and a movable template. The cavity plate 1 is provided with a cavity 2, a gate 4 connected with the cavity 2, and a gate 4 communicated with the cavity plate 1. There are 8 cavity 2 on the cavity plate 1, the dimensions of the 8 cavities 2 are exactly the same, and the 8 cavities 2 are arranged in parallel in the horizontal direction, and every two cavities 2 are One unit, the two cavities of each unit are connected through 2 through the runner 5, and the runner 5 is connected with the corresponding gate; the shape of the cavity 2 is consistent with the shape of the penholder; one side of the cavity 2 is set There is a chute, and each chute is provided with a push rod 3, the push rod 3 is opposite to the cavity 2, and one end of each push rod 3 is fixed on the connecting rod, and the connecting rod is drivingly connected with the piston rod of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com