In-mold product injection molding and foaming integrated process and mold

A product and mold technology, which is applied to the integrated process of injection molding and foaming of in-mold products and the field of molds, can solve the problems of uneven foaming, poor appearance and uneven surface of foamed products, and achieve good cushioning. Performance and thermal insulation, overall weight reduction, good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

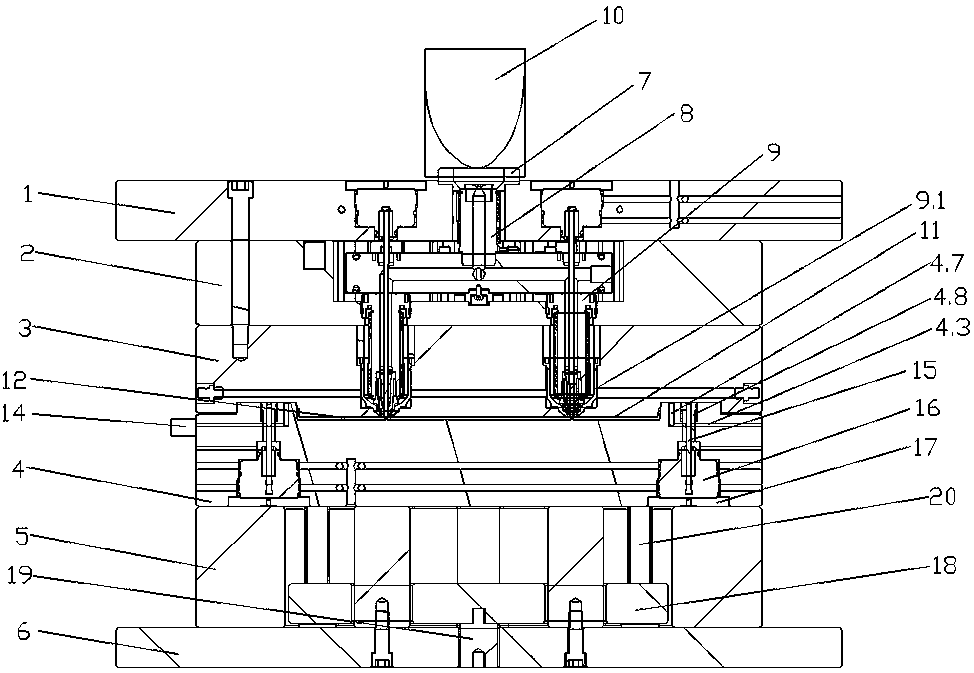

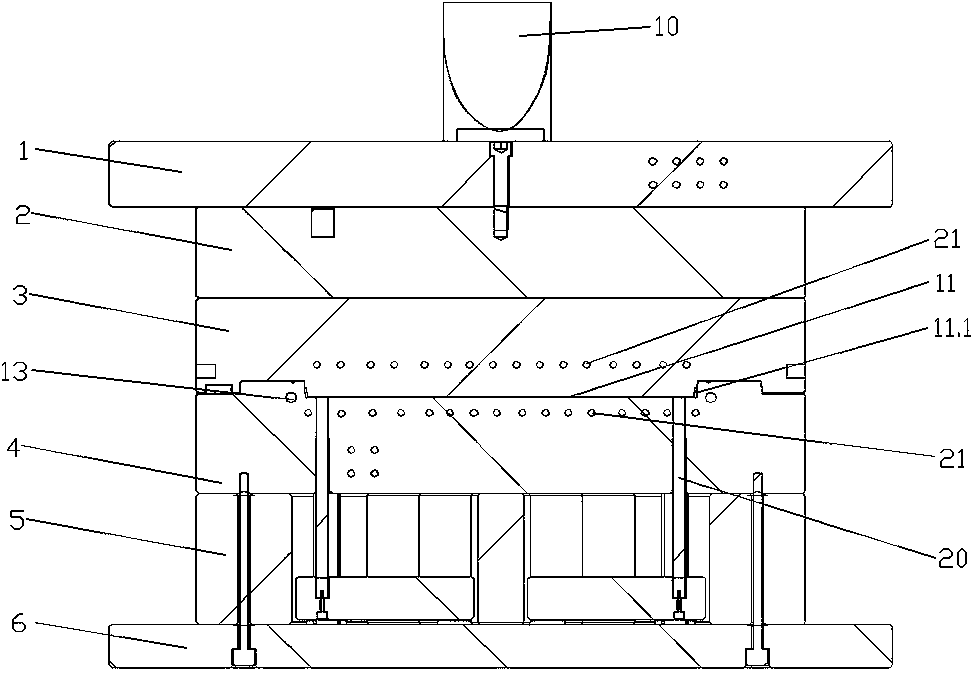

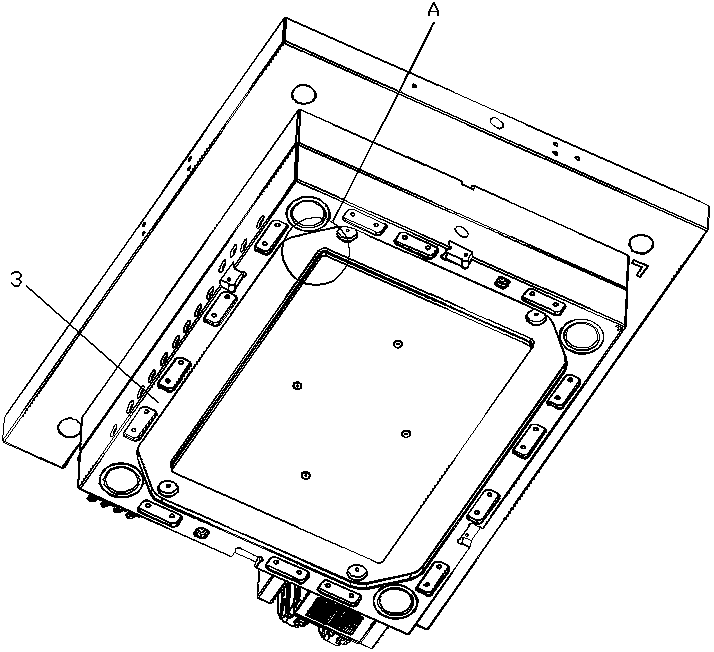

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] like Figure 1 to Figure 7 As shown, this embodiment provides an integrated process of injection molding and foaming of in-mold products, including the following steps:

[0035] S1. Ingredients: Mix plastic particles and foaming agent evenly according to a certain ratio;

[0036] S2. Feeding: transport the mixed foaming raw material to the injection molding machine, and the foaming raw material is heated and plasticized in the injection molding machine to form a molten foaming raw material fluid, which is stored in the injection molding machine;

[0037] S3. Mold vacuuming: the gas in the mold cavity is pumped out through the air pumping device, and the air needle moves to seal the exhaust channel, so that the mold cavity is in a vacuum state;

[0038] S4, open the valve: open the oil pressure valve, so that the foaming raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com