Precipitation-resistant halogen-free flame-retardant reinforced nylon material and preparation method thereof

A technology that is resistant to precipitation and nylon, applied in the field of materials, can solve the problems of red phosphorus flame retardants such as resistance to humidity and heat, poor surface migration resistance, lack of toughness and elasticity, corrosion of electrodes or components, etc., to achieve easy industrialization, improve mechanical properties, The effect of high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

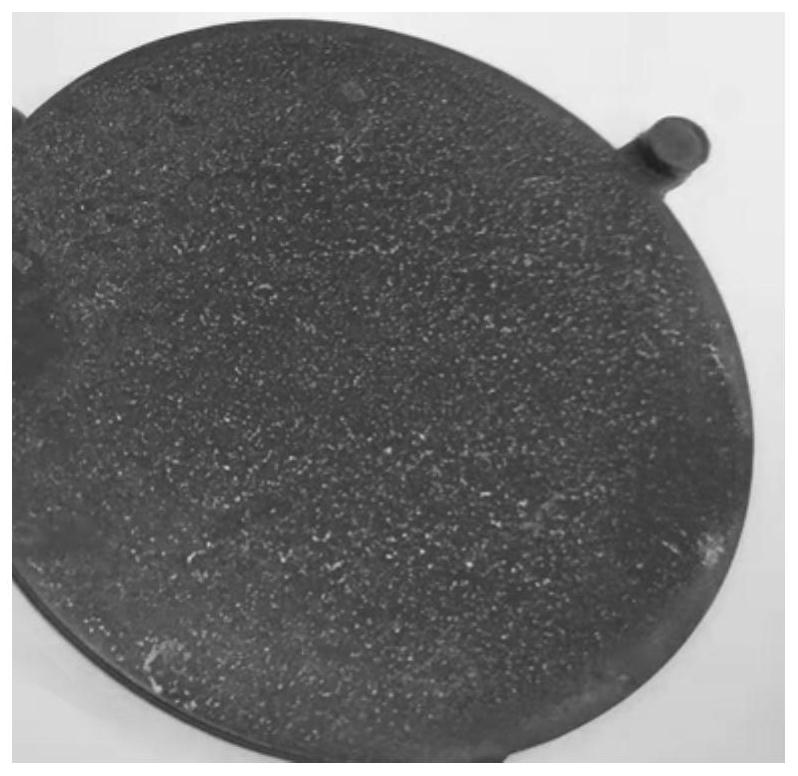

Image

Examples

Embodiment

[0034] A method for preparing a precipitation-resistant halogen-free flame-retardant reinforced nylon material, comprising the following steps:

[0035] (1) First, dissolve the surface modifier in absolute ethanol to obtain a mixed solution; then add melamine cyanurate to a high-speed mixer at 40-100°C, and then add the surface modifier solution obtained in the above steps , until the absolute ethanol volatilizes completely, raise the temperature to 120-190° C. and continue mixing for 5-35 minutes; obtain surface-modified melamine cyanurate. Wherein, the surface modifier is one of epoxy resin, tetrahydrophthalic anhydride, polyamide polyamine epichlorohydrin, adipic acid dihydrazide, N-aminoethylpiperazine, preferably polyamide polyamine Amine epichlorohydrin

[0036] (2) Blend the phosphorus-containing monomer and the initiator in a high-speed mixer, and then dissolve it in acetone; add the mixed solution obtained above into a medium mixer containing a toughening agent at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com