Pen core plastic mould for electronic pens

A technology of plastic molds and electronic pens, applied in the field of molds, can solve the problems of reduced production, low production efficiency, and increased costs, and achieve the effects of improving work efficiency, simple device structure, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

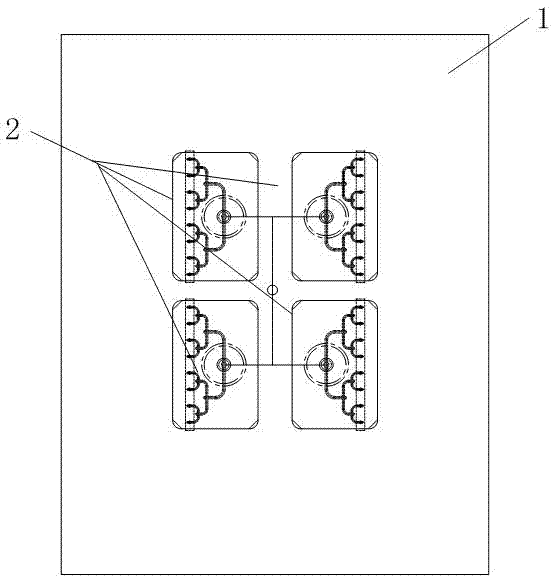

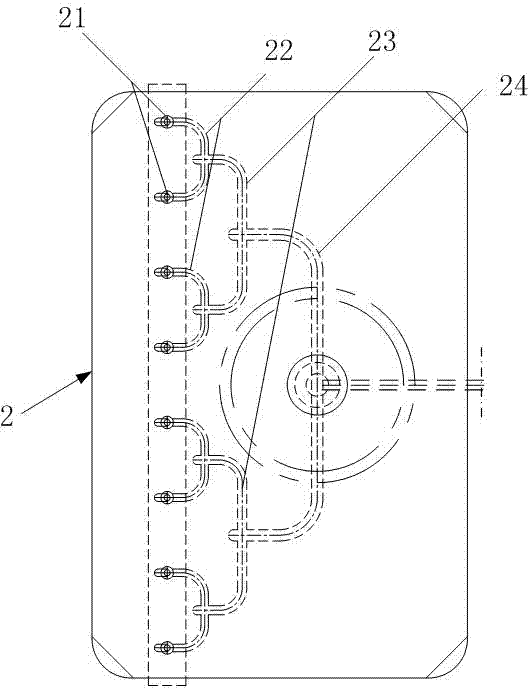

[0012] Such as figure 1 , figure 2 As shown, the refill plastic mold of the electronic pen includes a static template, a cavity plate 1 and a moving template. The cavity plate 1 is provided with a cavity 21, and the cavity plate 1 is provided with 4 identical and “Tian” characters. Cavity groups 2 distributed in different shapes, 4 cavity groups 2 are connected through "work" type main channels, each cavity group 2 is provided with 8 cavities 21 of the same size, 8 cavities 21 along the The vertical direction is parallel and arranged side by side, every two cavities 21 are a unit, and the two cavities 21 of each unit are connected with the first runner 22, and the eight cavities 21 are connected with four same-shaped first runners. A runner 22, every two first runners 22 is a group, the first inlet of the two first runners 22 of each group is connected with the second runner 23, and the four first runners 22 are connected There are two second runners 23 with the same shape,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com