High-transparency food-grade polypropylene special material and production method thereof

A production method and technology of polypropylene, which is applied in the field of polypropylene production, can solve problems such as the inability to meet downstream rapid processing and molding, no patented technology has been retrieved, narrow molecular weight distribution, etc., achieve easy molecular weight distribution, reduce equipment investment and production costs, The effect of broad molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

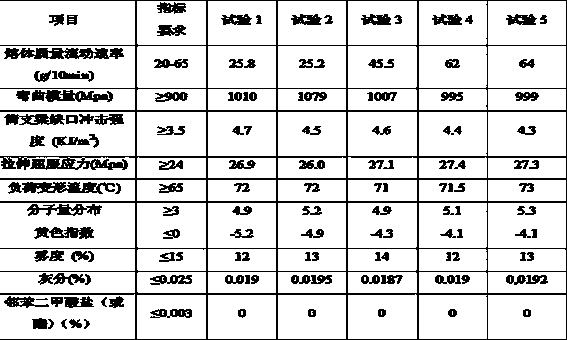

Examples

Embodiment 1

[0037] A special material for high-transparency food-grade polypropylene, the preparation of which comprises the following steps:

[0038] (1) Refining of propylene and ethylene raw materials;

[0039] (2) Under the system of specific catalyst Cat-Ⅱ and external electron donor D-Ⅱ, ethylene and propylene are subjected to binary random copolymerization in the gas-phase fluidized bed reactor of the Unipol process polypropylene device,

[0040] (3) Degassing of polymerized products,

[0041] (4) Polymerized powder and specific additives are co-extruded and granulated to obtain products; propylene and ethylene are used as raw materials, and propylene and ethylene enter the gas-phase fluidized bed reactor of the Unipol process polypropylene device after being refined, and a specific catalyst Cat- Ⅱ, and the binary random copolymerization reaction is carried out under the external electron donor D-Ⅱ system to obtain polypropylene with a controllable melt index range of 20-65g / 10min...

Embodiment 2

[0043] On the basis of Example 1, Cat-II catalyst, with MgCl 2 or C 4 h 10 MgO 2 as carrier, TiCl 4 is the active center, Al(C 2 h 5 ) 3 It is a cocatalyst; the external electron donor D-II is a silane substance; it is convenient for binary random copolymerization of ethylene and propylene in the gas-phase fluidized bed reactor of the Unipol process polypropylene device.

Embodiment 3

[0045]On the basis of Examples 1-2, the specific additives include primary antioxidants, auxiliary antioxidants, acid scavenger, antistatic agents and anti-reflection agents; specific additives and polymer powders make the appearance of the product made smooth and the molding shrinkage Low, high transparency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Charpy notched impact strength | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com