Automobile door panel injection mold

A technology for injection molds and door panels, applied in household appliances, other household appliances, household components, etc., can solve problems such as difficult and rapid demoulding, and achieve the effect of facilitating long-term use, improving stability, and improving demolding efficiency and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

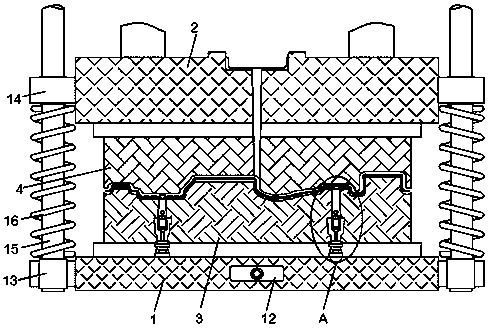

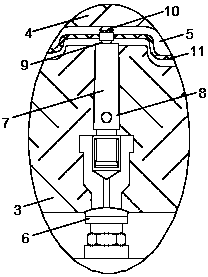

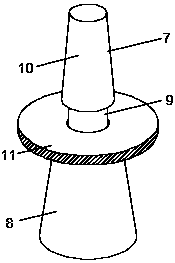

[0018] refer to Figure 1-3 , an injection mold for an automobile door panel, comprising a fixed mold base 1 and a movable mold base 2, the fixed mold base 1 is fixedly installed, the upper end of the movable mold base 2 is connected with a lifting device, so as to move the movable mold core 4 up and down, and the fixed mold base The upper end of 1 and the lower end of movable mold base 2 are respectively welded with fixed mold core 3 and movable mold core 4, and the top of fixed mold core 3 corresponds to the bottom end of movable mold core 4, and there are two miniature hydraulic cylinders 6 inside fixed mold core 3 , and two micro-hydraulic cylinders 6 output shafts are connected with ejector pins 7, ejector pins 7 are provided with ejector plate 11, ejector plate 11 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com