Elastic casting film and preparation method thereof

An elastic film and cast film technology, applied in the field of cast film, can solve the problems of inability to meet consumer needs, hidden dangers of safety and health, and increased body space, and achieve good processing stability, rapid injection moldability, skin soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

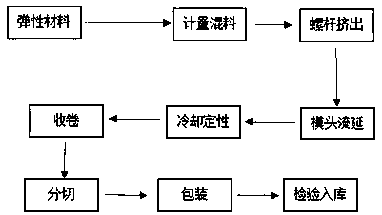

[0022] A method for preparing a cast elastic film, the cast film has a single-layer structure from top to bottom, and the elastic cast film is formed by a single-layer cast extrusion manufacturing method; figure 1 The flow chart of the preparation method of the cast film provided by the present invention, the preparation method specifically includes the following steps:

[0023] S1: Feed the polyester thermoplastic polyurethane elastomer material into the screw extruder, melt it into a fluid at a temperature of 50~200°C, and then extrude it through a die to form a cast film;

[0024] S2: Stretch and transfer the cast film obtained in S1, and cool and press the material to shape at a temperature of 15-35°C;

[0025] S3: Rewinding, cutting, and packaging the surface of the material obtained in S2 to obtain the cast elastic film;

[0026] Wherein, in S1, the temperature of the die head is 140-200°C.

[0027] The thickness of the casting film is 5um.

Embodiment 1-1

[0029] A method for preparing a cast elastic film, the cast film has a single-layer structure from top to bottom, and adopts an elastic cast film formed by a single-layer cast extrusion manufacturing method; the preparation method specifically includes the following steps:

[0030] S1: The polyester thermoplastic polyurethane elastomer material is fed into the screw extruder, melted into a fluid at a temperature of 160°C, and then extruded through a die to form a cast film;

[0031] S2: Stretch and transfer the cast film obtained in S1, and cool and press the material to shape at a temperature of 25°C;

[0032] S3: Rewinding, cutting, and packaging the surface of the material obtained in S2 to obtain the cast elastic film;

[0033] Wherein, in S1, the temperature of the die is 180°C.

[0034] The thickness of the casting film is 5um.

Embodiment 1-2

[0036] A method for preparing a cast elastic film, the cast film has a single-layer structure from top to bottom, and adopts an elastic cast film formed by a single-layer cast extrusion manufacturing method; the preparation method specifically includes the following steps:

[0037] S1: The polyester thermoplastic polyurethane elastomer material is fed into the screw extruder, melted into a fluid at a temperature of 50°C, and then extruded through a die to form a cast film;

[0038] S2: Stretch and transfer the cast film obtained in S1, and cool and press the material to shape at a temperature of 35°C;

[0039] S3: Rewinding, cutting, and packaging the surface of the material obtained in S2 to obtain the cast elastic film;

[0040] Wherein, in S1, the temperature of the die is 140°C.

[0041] The thickness of the casting film is 5um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com