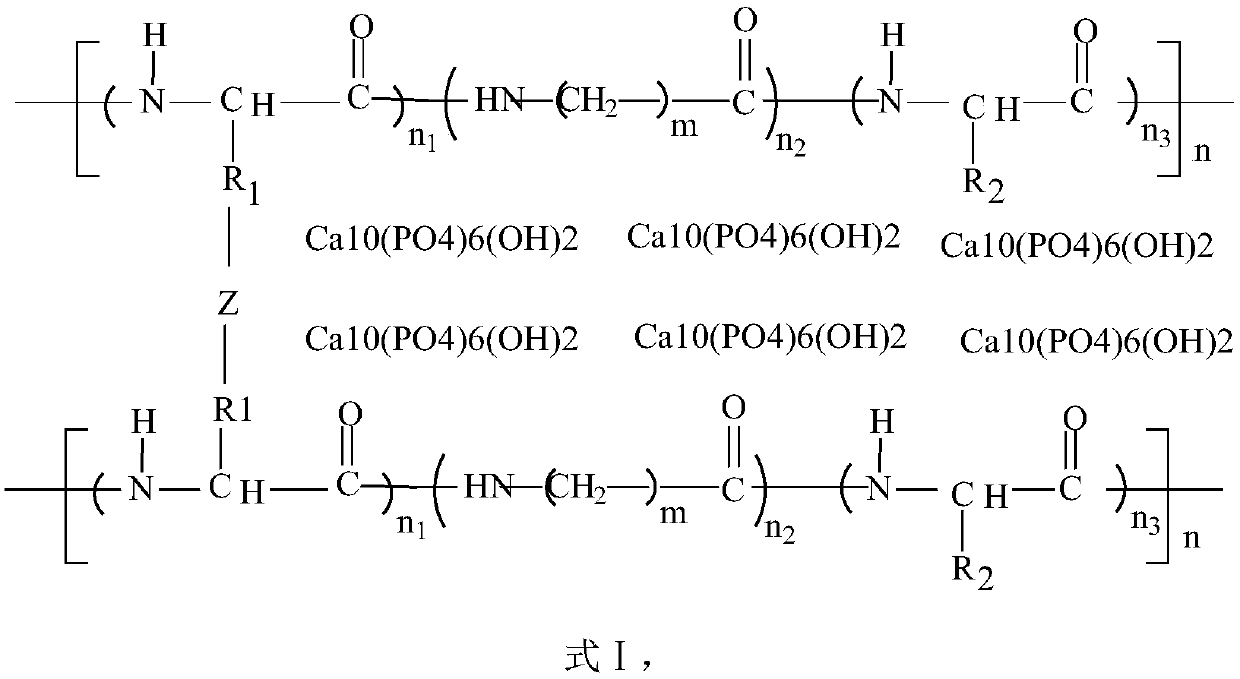

Temperature and modulus dual-controlled nano-hydroxyapatite and polyamino acid composite bone graft material and preparation method thereof

A nano-hydroxyapatite, polyamino acid technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve problems such as material remodeling, and achieve good biological activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

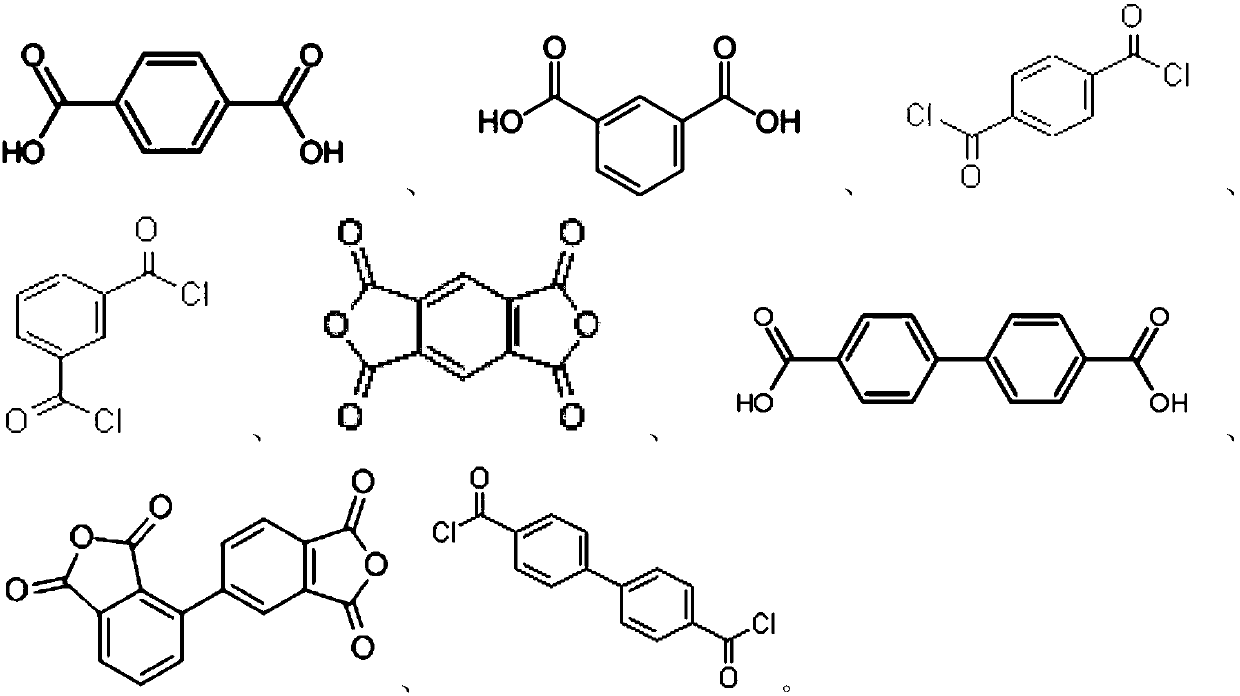

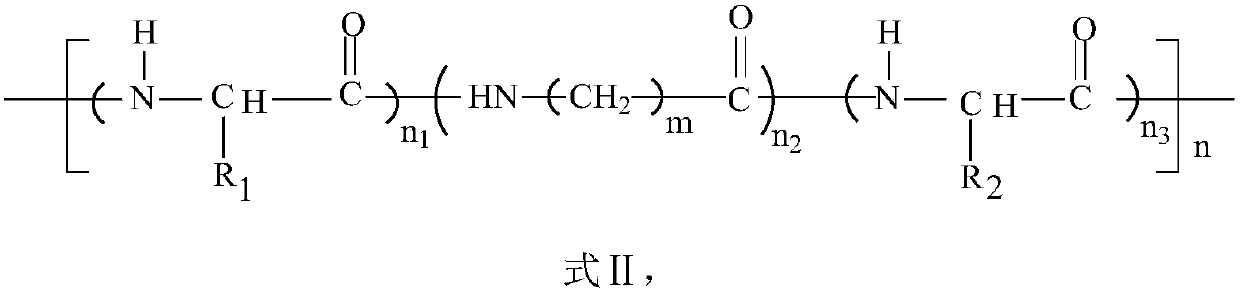

[0057] Example 1 Preparation of nano-hydroxyapatite polyamino acid composite bone graft material of the present invention

[0058] Weigh 116.16g of ζ-aminoheptanoic acid, 13.1g of hydroxyproline, 5.85g of lysine, and 9.91g of phenylalanine respectively, put them into a 250mL three-necked bottle, add 50mL of distilled water, protect with nitrogen, stir and heat up Dehydrate at 180°C (you can judge whether the dehydration treatment has been completed by observing whether the amino acid begins to melt). After dehydration is completed, continue to heat up to 210°C, pre-polymerize for 1 hour in a molten state, then continue to heat up to 220°C for polymerization for 3 hours, complete the first-stage reaction, and obtain the polyamino acid molecular chain shown in the aforementioned formula II;

[0059] The straight-chain amino acids in the reaction are (m=6, ζ-aminoheptanoic acid), with a reactive side group R 1 The amino acid is (hydroxyproline) and (Lysine), with inert or ...

Embodiment 2

[0064] Example 2 Preparation of nano-hydroxyapatite polyamino acid composite bone graft material of the present invention

[0065] Weigh 117.9g of ε-aminocaproic acid, 6.55g of hydroxyproline, and 8.26g of phenylalanine respectively, put them into a 250mL three-necked bottle, add 50mL of distilled water, protect with nitrogen, stir and heat up to 180°C for dehydration (can be Whether the dehydration treatment has been completed can be judged by observing whether the amino acid begins to melt). After dehydration is completed, continue to heat up to 210°C, pre-polymerize for 1 hour in a molten state, then continue to heat up to 220°C for polymerization for 3 hours, complete the first-stage reaction, and obtain the polyamino acid molecular chain shown in the aforementioned formula II;

[0066] The straight-chain amino acids in the reaction are (m=5, ε-aminocaproic acid), with a reactive side group R 1 The amino acid is (Hydroxyproline), with inert or carboxylic side groups R...

Embodiment 3

[0071] Example 3 Preparation of nano-hydroxyapatite polyamino acid composite bone graft material of the present invention

[0072] Weigh 117.9g of ε-aminocaproic acid, 5.85g of lysine, and 9.91g of phenylalanine respectively, put them into a 250mL three-necked bottle, add 50mL of distilled water, protect with nitrogen, stir and heat up to 180°C for dehydration (can be dehydrated by Whether the dehydration treatment has been completed can be judged by observing whether the amino acid begins to melt). After dehydration is completed, continue to heat up to 210°C, pre-polymerize for 1 hour in a molten state, then continue to heat up to 220°C for polymerization for 3 hours, complete the first-stage reaction, and obtain the polyamino acid molecular chain shown in the aforementioned formula II;

[0073] The straight-chain amino acids in the reaction are (m=5, ε-aminocaproic acid), with a reactive side group R 1 The amino acid is (Lysine), with inert or carboxylic side groups R ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com