Anti-whitening flame-retardant polypropylene ribbon and preparation method thereof

A flame retardant polypropylene and polypropylene technology, applied in the field of materials, can solve the problems of poor tightening force of flame retardant cable ties, poor surface migration resistance of materials, product performance hazards, etc. The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

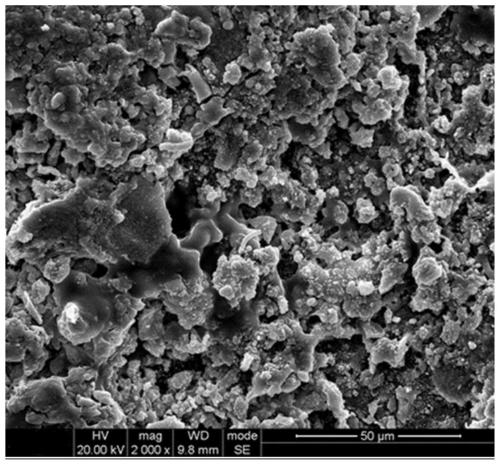

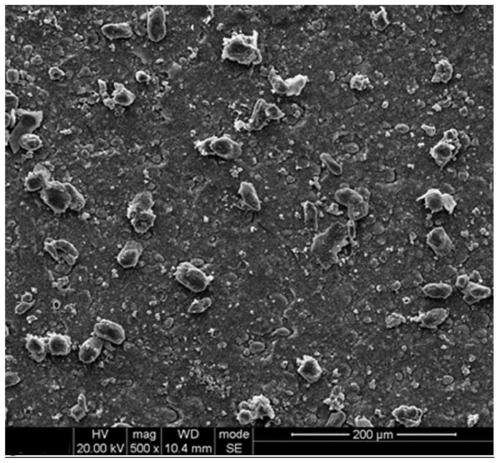

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention is described in further detail. Example

[0028] A preparation method of an anti-whitening flame-retardant polypropylene cable tie, comprising the following steps:

[0029] (1) First, blend 5-25 parts of phosphorus-containing monomers with 0.1-0.5 parts of initiator in a high-speed mixer, and then dissolve them in acetone; in a medium mixer with a temperature of 40-120°C, and then fully mix until the acetone volatilizes, recover the acetone and the solid mixture separately, add the mixture into an extruder at 100-200°C, extrude and granulate, and obtain Phosphorus-containing monomer grafted toughening agent is a flame retardant toughening agent; wherein, the speed of the high mixer is 200-800r / min. Wherein, the initiator is one of cumene peroxide, potassium persulfate, sodium bisulfite, N,N-dimethylaniline, and cerium sulfate, preferably sodium bisulfite.

[0030] (2) Put 60-80 parts of polypropylene, 7-30 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com