Injection mold capable of achieving quick molding

A fast technology for injection molding, applied in the field of mold manufacturing, can solve the problems of slow cooling of injection molding liquid and low efficiency of injection molding, and achieve the effect of fast mold opening and closing speed, high work efficiency and fast injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

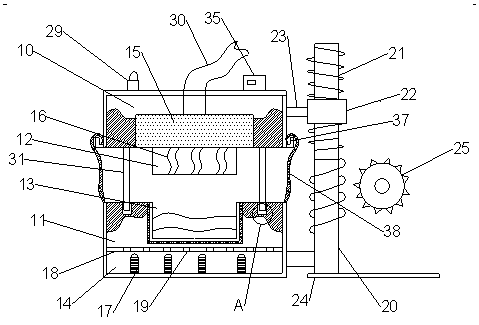

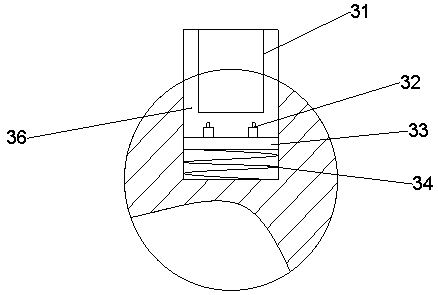

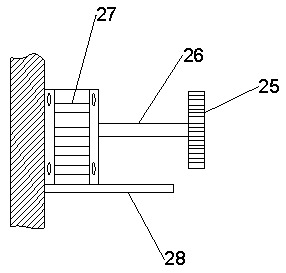

[0023] see Figure 1-3 , a rapid prototyping injection mold, comprising an upper mold base 10 and a lower mold base 11, the upper mold base 10 is provided with an injection liquid tank 15, and the top of the injection liquid tank 15 is connected with an injection liquid inlet pipe 30, through which the injection liquid The inlet pipe 30 can input the injection molding solution into the injection molding solution tank 15 . One side of the top of the upper die base 10 is provided with a controller 35, the other side of the top of the upper die base 10 is provided with an alarm 29, the lower surface of the upper die base 10 is fixedly equipped with a punch cavity 12, and the punch The inside of cavity 12 is provided with several injection molding tubes 16, and the tops of injection molding tubes 16 are connected to the bottom of injection molding solution tank 15, and the injection molding solution inside injection molding solution tank 15 can be delivered to punch cavity 12 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com