Continuous polymerization preparation method of fast crystallized and flame-retardant PET (Polyethylene Terephthalate) copolymer

A copolymer and crystallization technology, which is applied in the continuous polymerization preparation of flame-retardant PET copolymers and in the field of fast crystallization, can solve the problems that flame-retardant copolymers do not have fast crystallization, and achieve fast injection molding, fast crystallization speed, and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

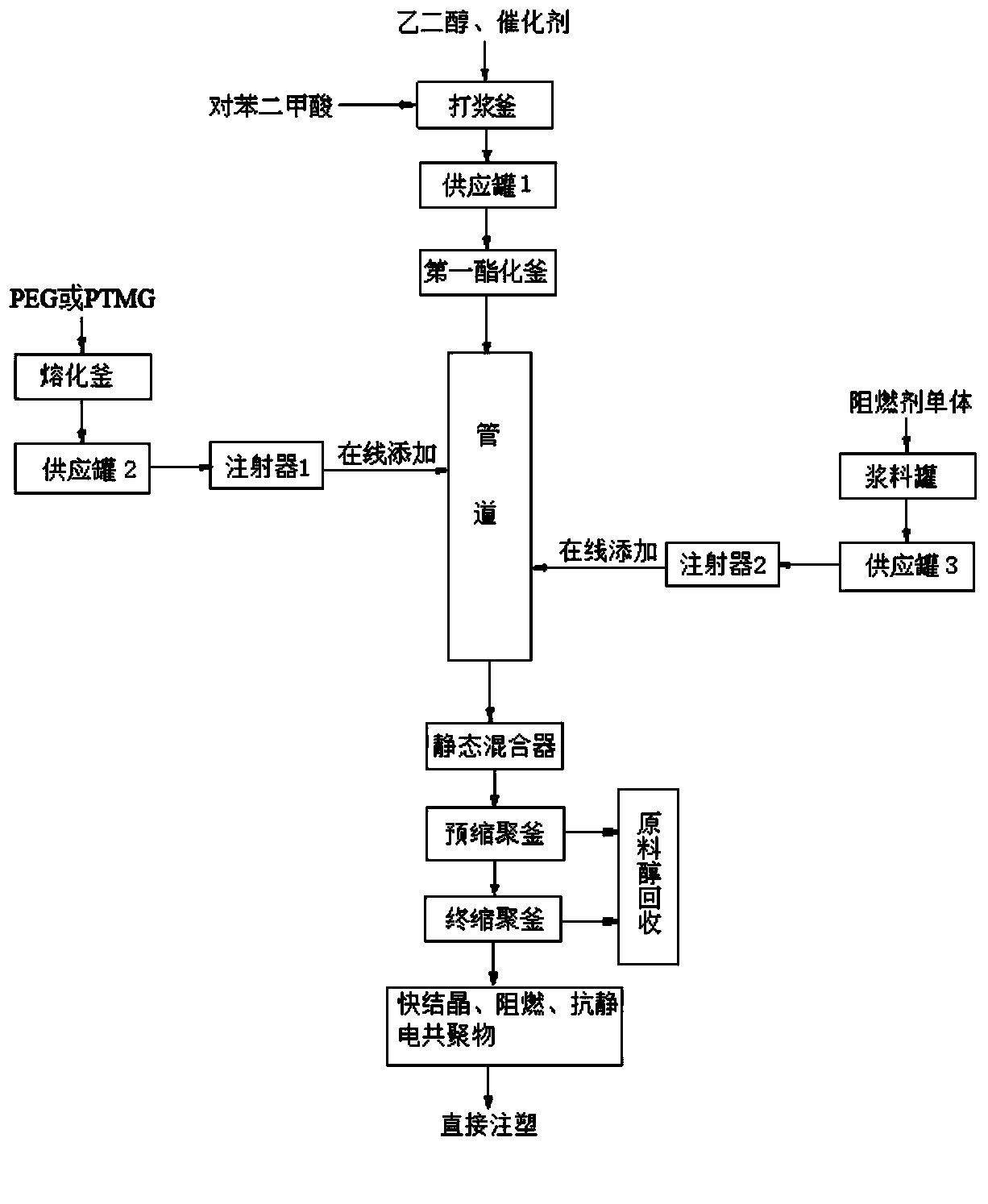

Method used

Image

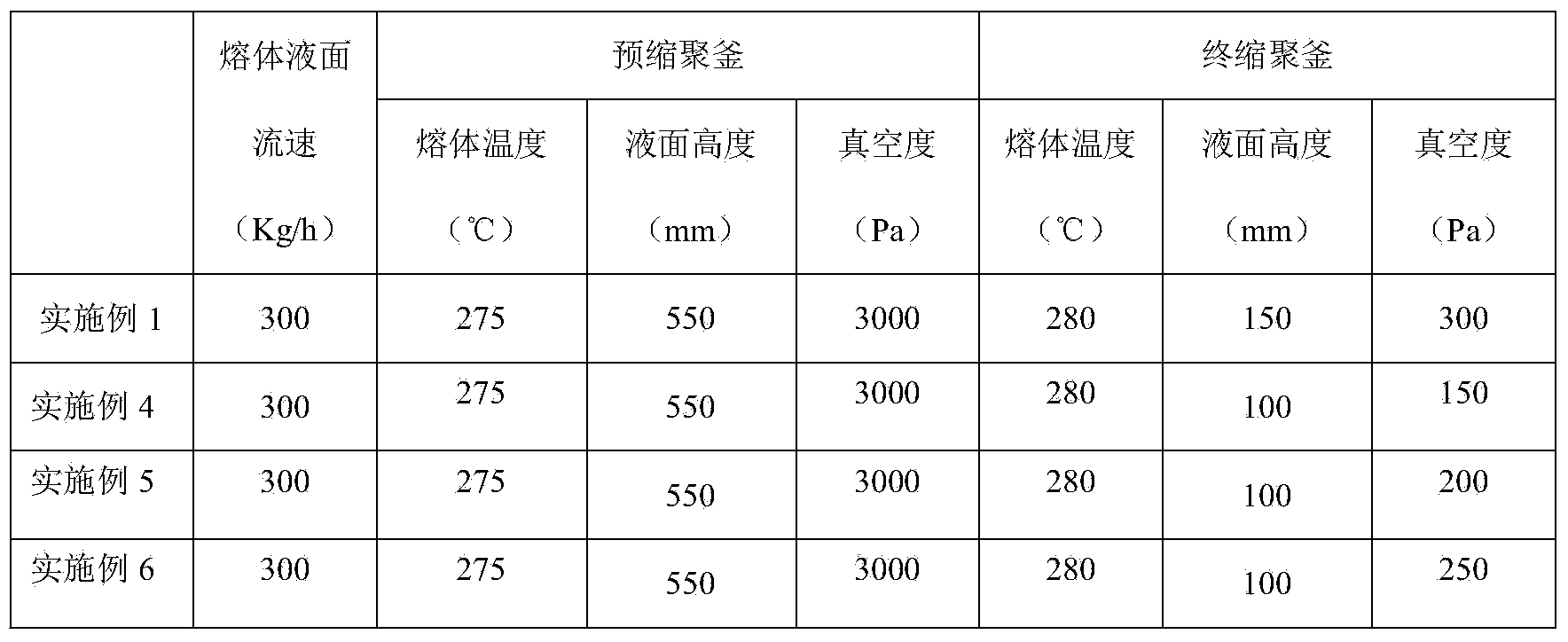

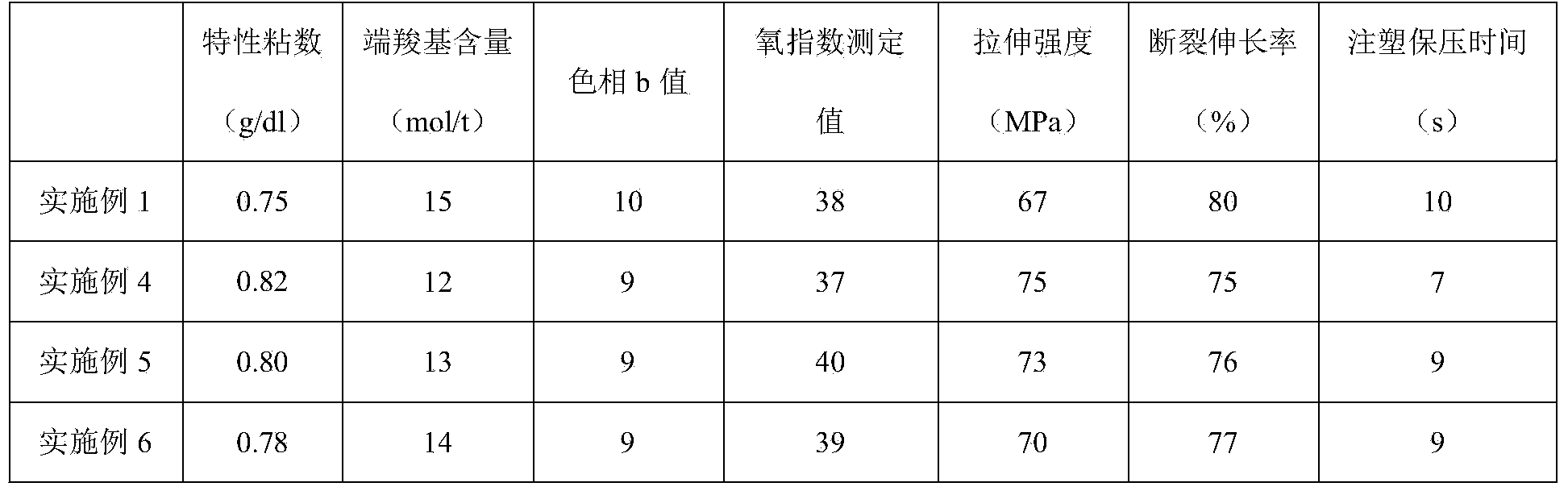

Examples

Embodiment 1

[0056] 1. Put terephthalic acid and ethylene glycol into the beating kettle with a molar ratio of 1:1.15 in the continuous polyester polycondensation production device of small flexible modified polyester with a daily output of 5 tons, and add nucleating agent 4000 mesh talcum powder at the same time Beating together, the beating time is 40 minutes, put into the slurry supply tank 1 after the beating is finished; the addition amount of the nucleating agent is 0.5% of the total mass of terephthalic acid and ethylene glycol;

[0057] 2. Pump the slurry obtained in step 1 into the first esterification reaction kettle to carry out the esterification reaction, and the esterification temperature is 258° C.; control the flow rate so that the esterification rate reaches 92% after passing through the first esterification reaction kettle; Into the pipeline, through the syringe 1 and syringe 2 in turn;

[0058] 3. Melt PEG with a molecular weight of 1000 in a melting tank at a melting te...

Embodiment 2

[0064] 1. Put terephthalic acid and ethylene glycol into the beating kettle with a molar ratio of 1:1.15 on the small flexible modified polyester continuous polyester polycondensation production plant with a daily output of 5 tons, and add nucleating agent 6000 mesh talcum powder at the same time Beating together, the beating time is 50 minutes, put into the slurry supply tank 1 after the beating is finished; the addition amount of the nucleating agent is 0.3% of the total mass of terephthalic acid and ethylene glycol;

[0065] 2. Pump the slurry obtained in step 1 into the first esterification reaction tank to carry out the esterification reaction. The esterification temperature is 265° C., and the flow rate is controlled so that the esterification rate reaches 91% after passing through the first esterification tank; Into the pipeline, through the syringe 1 and syringe 2 in turn;

[0066] 3. Melt PEG with a molecular weight of 2000 in a melting tank at a melting temperature o...

Embodiment 3

[0072] 1. Put terephthalic acid and ethylene glycol into the beating kettle at a molar ratio of 1:1.15 on the small flexible modified polyester continuous polyester polycondensation production plant with a daily output of 5 tons, and add nucleating agent 5000 mesh talcum powder at the same time Beating together, the beating time is 35 minutes, put into the slurry supply tank 1 after the beating is finished; the addition amount of the nucleating agent is 0.4% of the total mass of terephthalic acid and ethylene glycol;

[0073] 2. Pump the slurry obtained in step 1 into the first esterification reaction tank to carry out the esterification reaction. The esterification temperature is 255° C., and the flow rate is controlled so that the esterification rate reaches 91% after passing through the first esterification tank; Into the pipeline, through the syringe 1 and syringe 2 in turn;

[0074] 3. Melt PEG with a molecular weight of 800 in a melting tank at a melting temperature of 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com