An energy-saving and environment-friendly sulfur melter

An energy-saving and environment-friendly sulfur melter technology, which is applied in the direction of sulfur compounds, sulfur preparation/purification, chemical instruments and methods, etc., can solve problems such as heat waste, increased energy consumption, and uneven heating, so as to improve utilization rate and reduce The effect of maintaining uniform loss and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

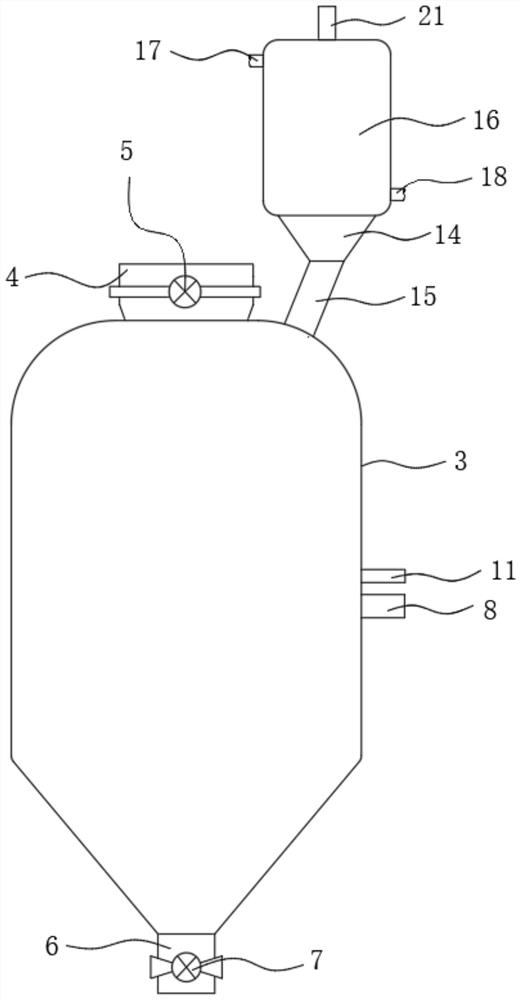

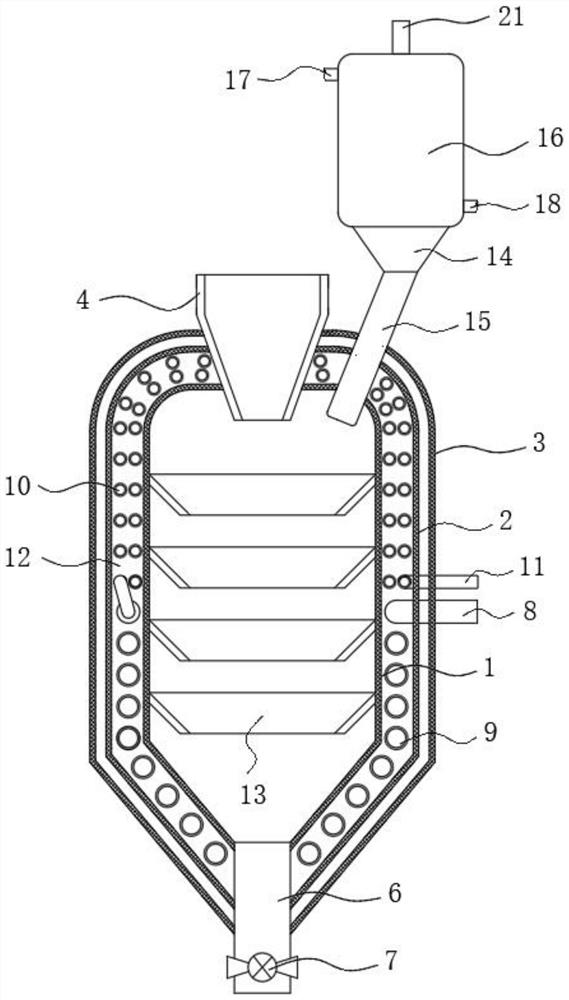

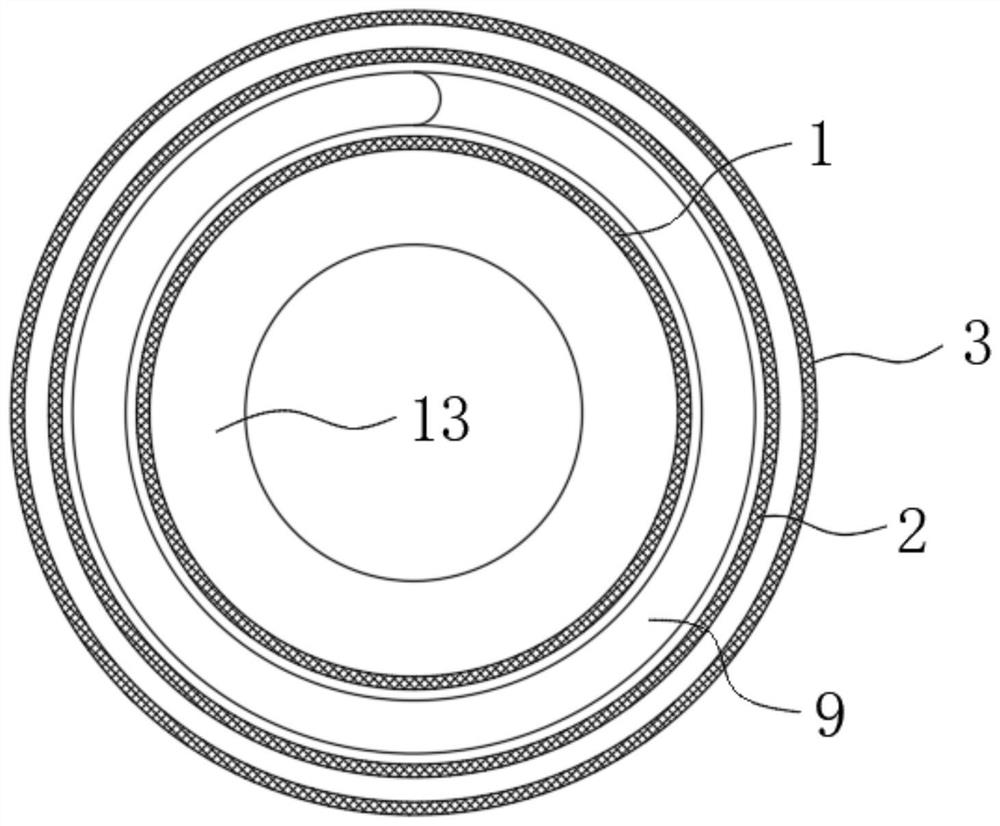

[0029] refer to Figure 1-5 , an energy-saving and environment-friendly sulfur melting device, comprising a tank body 1, the upper end of the tank body 1 is connected with a feed pipe 4, and a first valve 5 is installed on the feed pipe 4, and the first valve 5 is opened to pass the solid sulfur raw material through the feed pipe. The feed pipe 4 is discharged into the tank body 1, the lower end of the tank body 1 is connected with a discharge pipe 6, and a second valve 7 is installed on the discharge pipe 6, and the sulfur liquid obtained in the tank body 1 can be passed through by opening the second valve 7. The discharge pipe 6 is discharged, and the outer side of the tank body 1 is sequentially sleeved with the inner shell 2 and the outer shell 3 from the inside to the outside. 2 and the outer shell 3 are hermetically connected, and the lower end of the discharge pipe 6 runs through the inner shell 2 and the outer shell 3 in turn and is respectively sealed and connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com