Injection molding machine and plasticizing component thereof

A technology for injection molding machines and components, applied in the field of injection molding machines, can solve problems such as incomplete mixing, uneven mixing, poor color mixing, etc., and achieve the effect of improving the mixing effect and injection molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

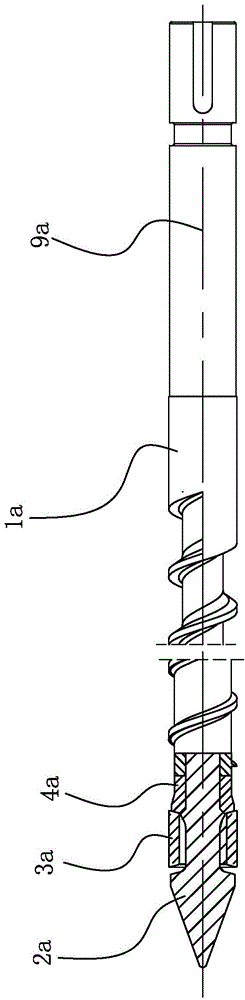

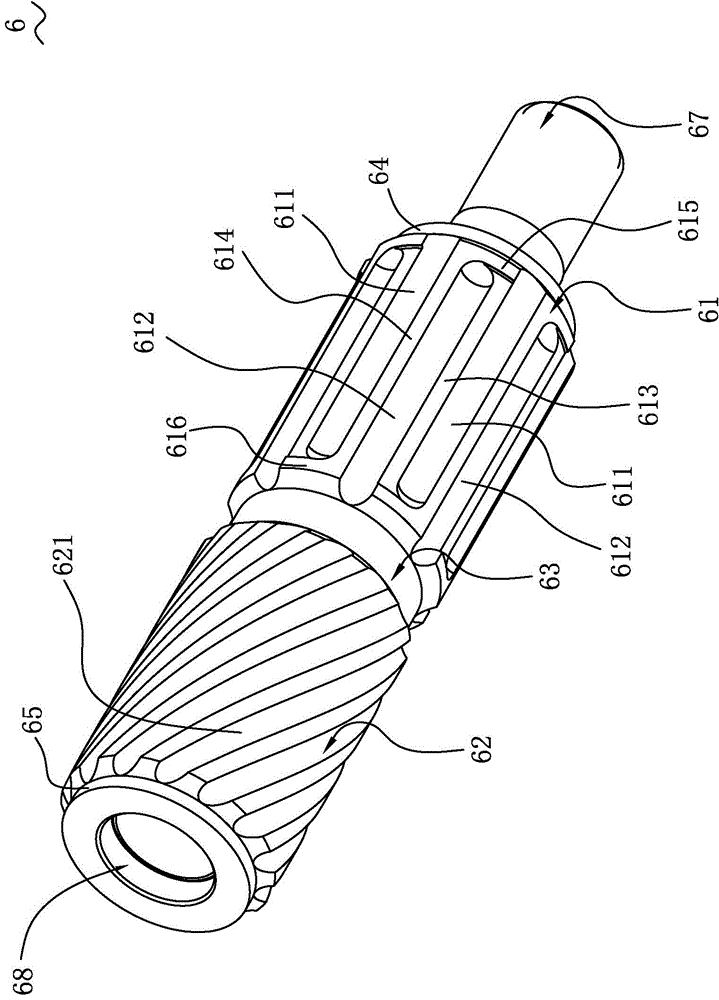

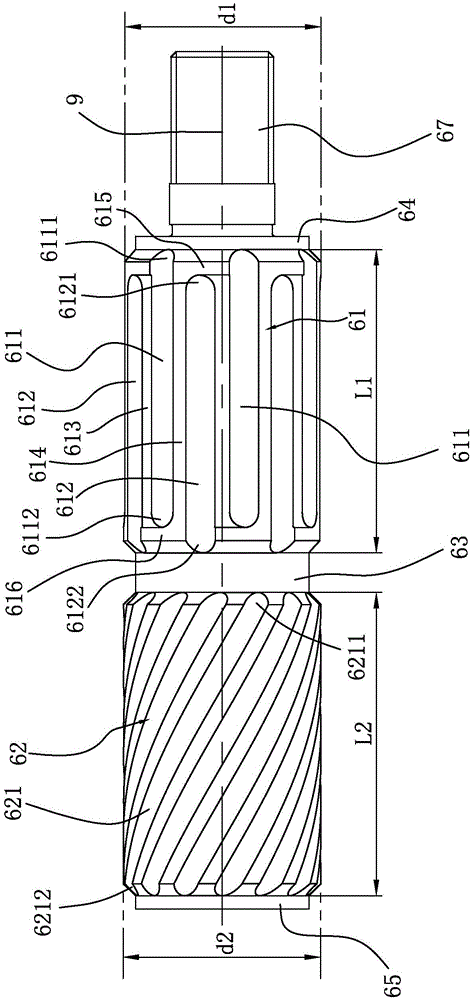

[0023] see Figure 2 to Figure 4 , the plasticizing assembly of the injection molding machine of the present invention has a central axis 9 (that is to say, the plasticizing assembly is roughly symmetrical along the central axis 9 ). The plasticizing assembly includes a screw 1 and a barrel (not shown in the figure) that cooperate with each other, wherein a compound mixing head 6 is provided at the top of the screw 1 . The composite mixing head 6 includes: a mixing part 61, which is used to cooperate with the inner wall of the barrel to form a plurality of glue passages, each glue passage can allow the passage of molten rubber and effectively block unmelted The passing of particles; and a splitter 62, which is further extended forward by the front end of the mixing part 61, in order to cooperate with the inner wall of the barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com