Mold opening control method and injection molding machine thereof

A control method and molding machine technology, applied in the field of mold opening control method and injection molding machine, can solve the problems of affecting the quality of injection molding, shortening the life of the machine, vibration and shaking of the machine, etc., so as to improve the efficiency of injection molding, improve the Injection molding quality and the effect of extending machine life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

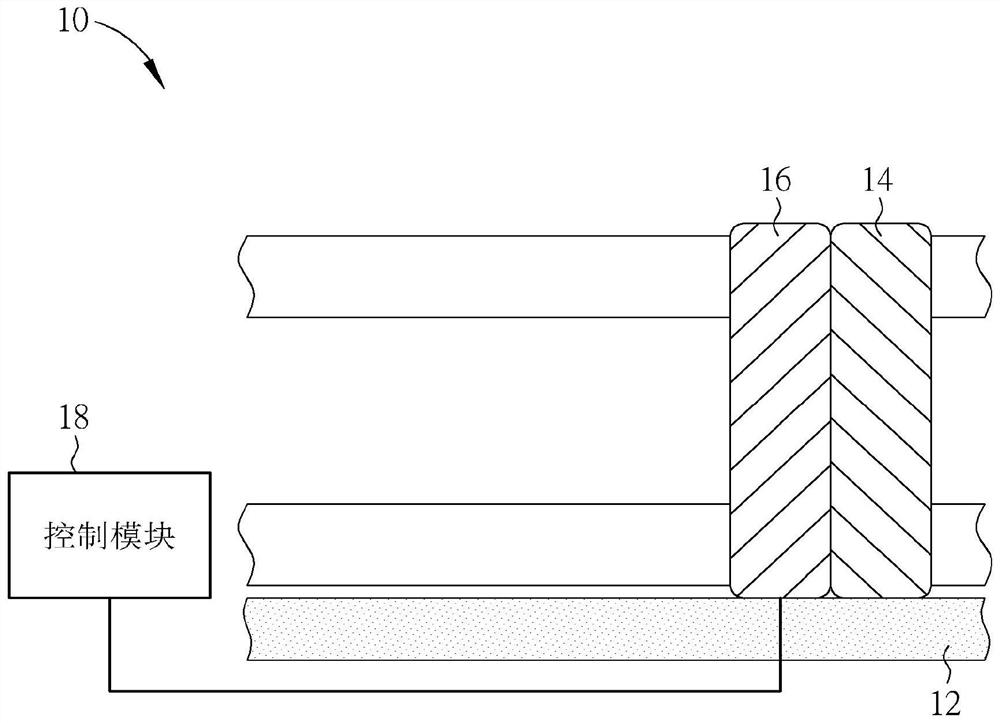

[0020] Please refer to figure 1 , which is a partial schematic diagram of the injection molding machine 10 proposed according to an embodiment of the present invention, as figure 1 As shown, the injection molding machine 10 can be an automatic machine commonly used for the injection molding process (the relevant descriptions of the automatic mechanism action of the machine and the principle of the injection molding process are commonly found in the prior art. To simplify the description, here This will not be described in detail) and includes a base 12 , a static mold 14 , a movable mold 16 , and a control module 18 . The static mold 14 is arranged on the base 12, and the movable mold 16 is movably arranged on the base 12 to be operatively close to the static mold 14 to carry out the mold closing process or away from the static mold 14 to carry out the mold opening process, so as to be compatible with the static mold 14 jointly execute the injection molding process.

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com