Injection mould for studying tool box stationery series

A technology for injection molds and stationery, which is applied in the field of injection molds for school kits, can solve the problems of resource waste and low efficiency, and achieve the effects of improving production efficiency, improving injection molding quality, and preventing mold collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

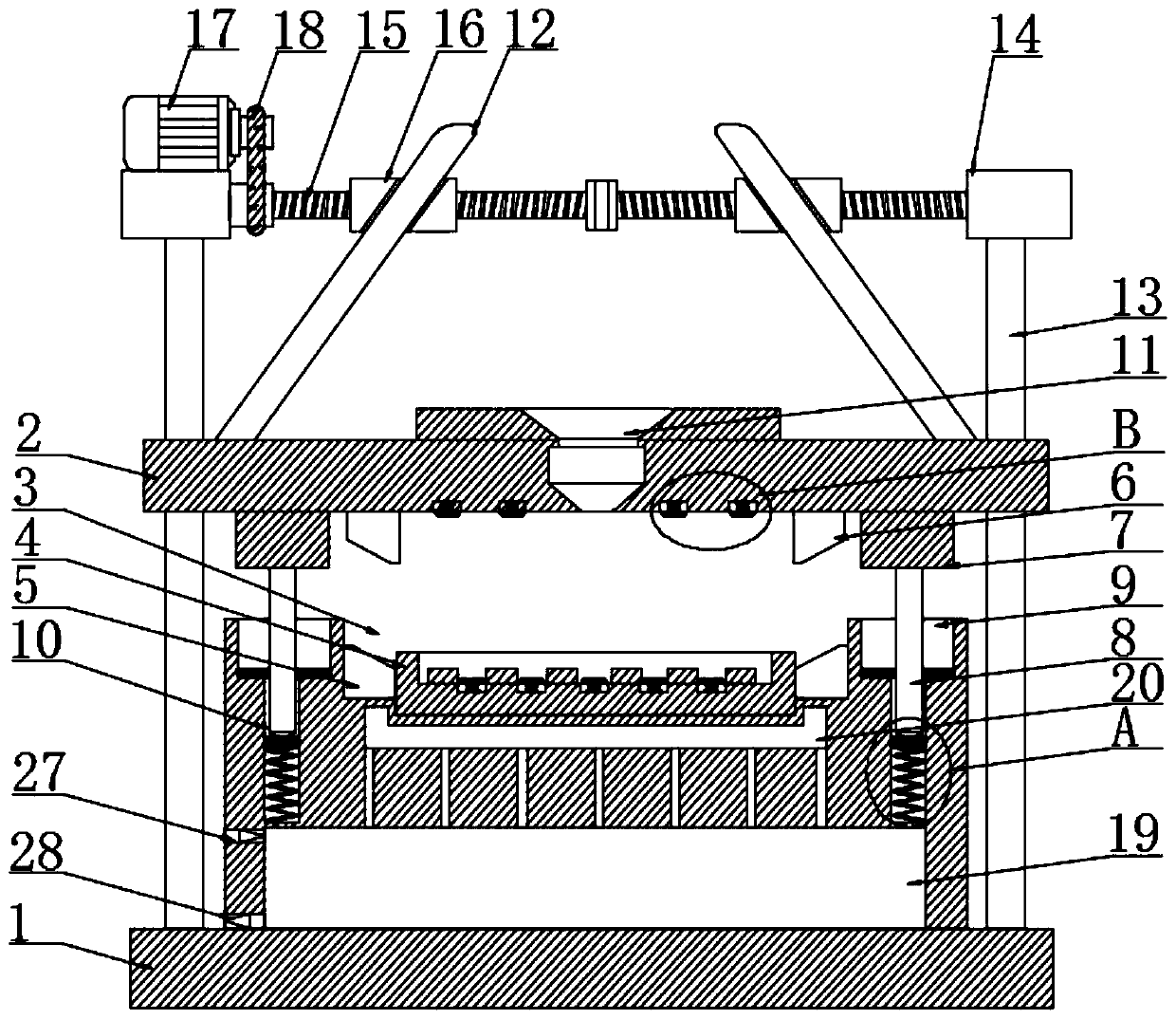

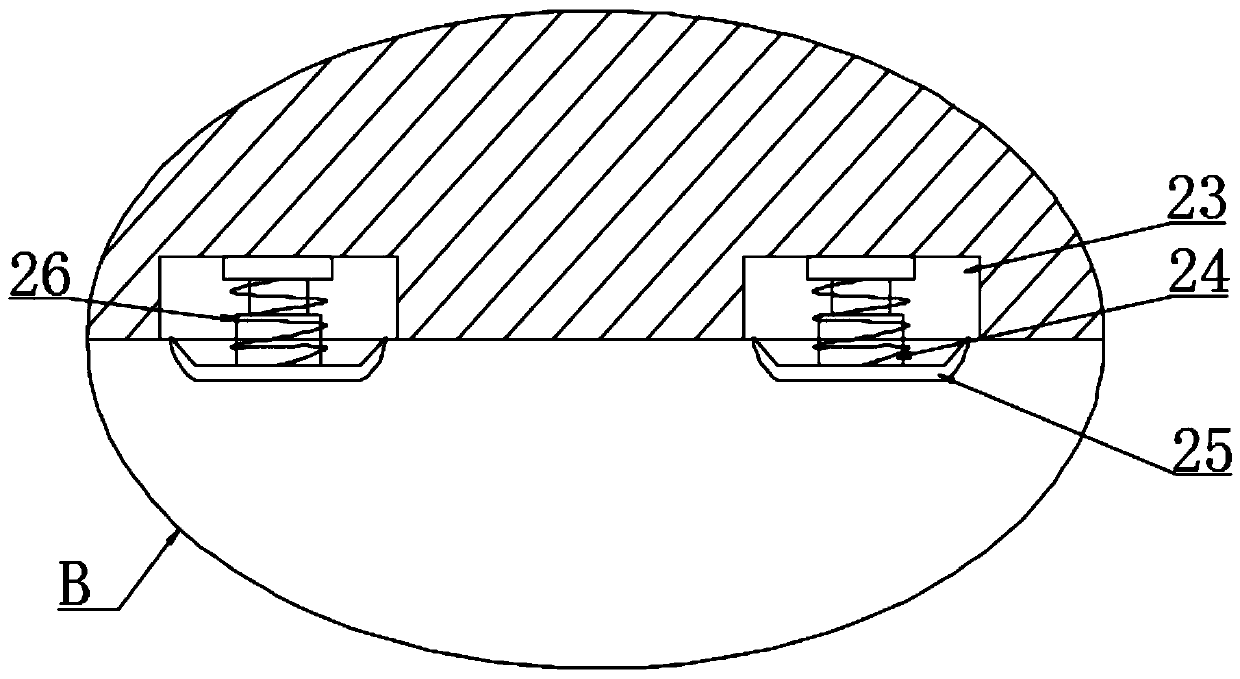

[0025] according to Figure 1-3 The shown injection mold of a series of school kit stationery includes a lower mold base 1, the top of the lower mold base 1 is provided with an upper mold base 2, and the top of the lower mold base 1 is provided with a first groove 3. The middle part of the first groove 3 is provided with a card slot, and an injection molding template 4 is movably connected in the clip groove, and a first clamping block 5 is movably connected between the inner wall of the first groove 3 and the injection molding template 4. The bottom of the mold base 2 is fixedly connected with a second block 6, and the outer side of the second block 6 is fixedly connected with a protrusion 7, and the bottom of the protrusion 7 is fixedly connected with a limit pin 8, and the outer side of the first groove 3 is provided There is a second groove 9, the bottom of the second groove 9 is provided with a limit hole 10, the top of the upper mold base 2 is provided with an injection ...

Embodiment 2

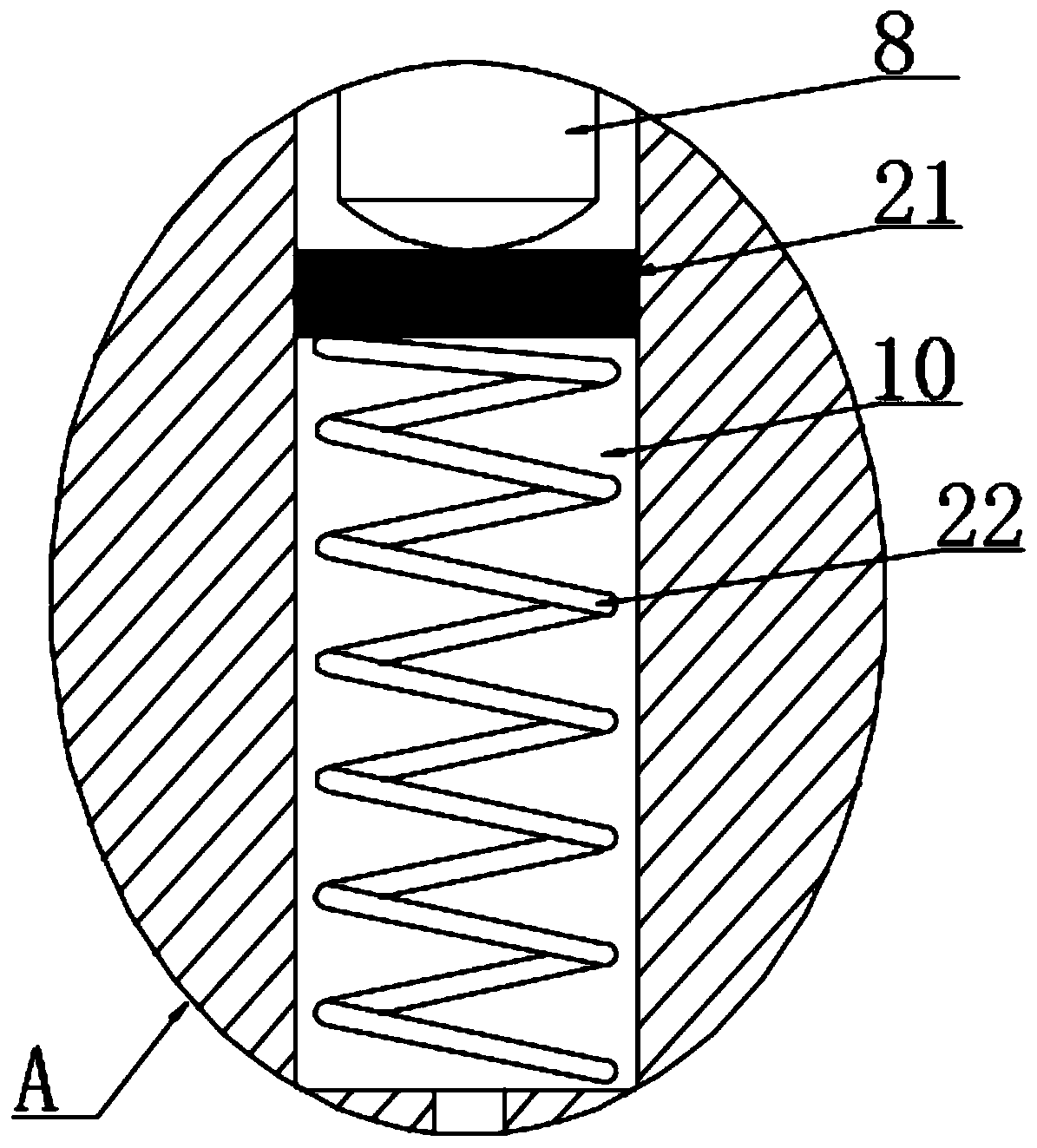

[0028] according to figure 2 As shown in the injection mold of a school kit stationery series, the lower mold base 1 is provided with a cooling liquid tank 19, and the bottom of the slot is provided with a cooling tank 20, and the cooling liquid tank 19 is connected with the cooling tank 20 are connected with a number of evenly distributed first through holes, and a second through hole is provided between the bottom of the limiting hole 10 and the coolant tank 19, and a piston 21 is slidably connected in the limiting hole 10. A first spring 22 is arranged between the piston 21 and the bottom of the limiting hole 10, which communicates with the cooling box 20 through the cooling box 20, so that the temperature of the cooling box 20 can be kept at a low temperature. When injection molding, the limiting pin 8 is inserted into the limiting hole 10. Let the piston 21 slide down to compress the gas so that the coolant enters the cooling box 20 from the first through hole to cool th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com