Automatic temperature control type water-reducing agent production device

A technology for production device and water reducing agent, applied in feeding device, control/adjustment process, chemical/physical/physical-chemical stationary reactor, etc., can solve the problem of high probability of temperature control error, low temperature control efficiency, and troublesome operation. and other problems, to achieve the effect of convenient operation, improved temperature control efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

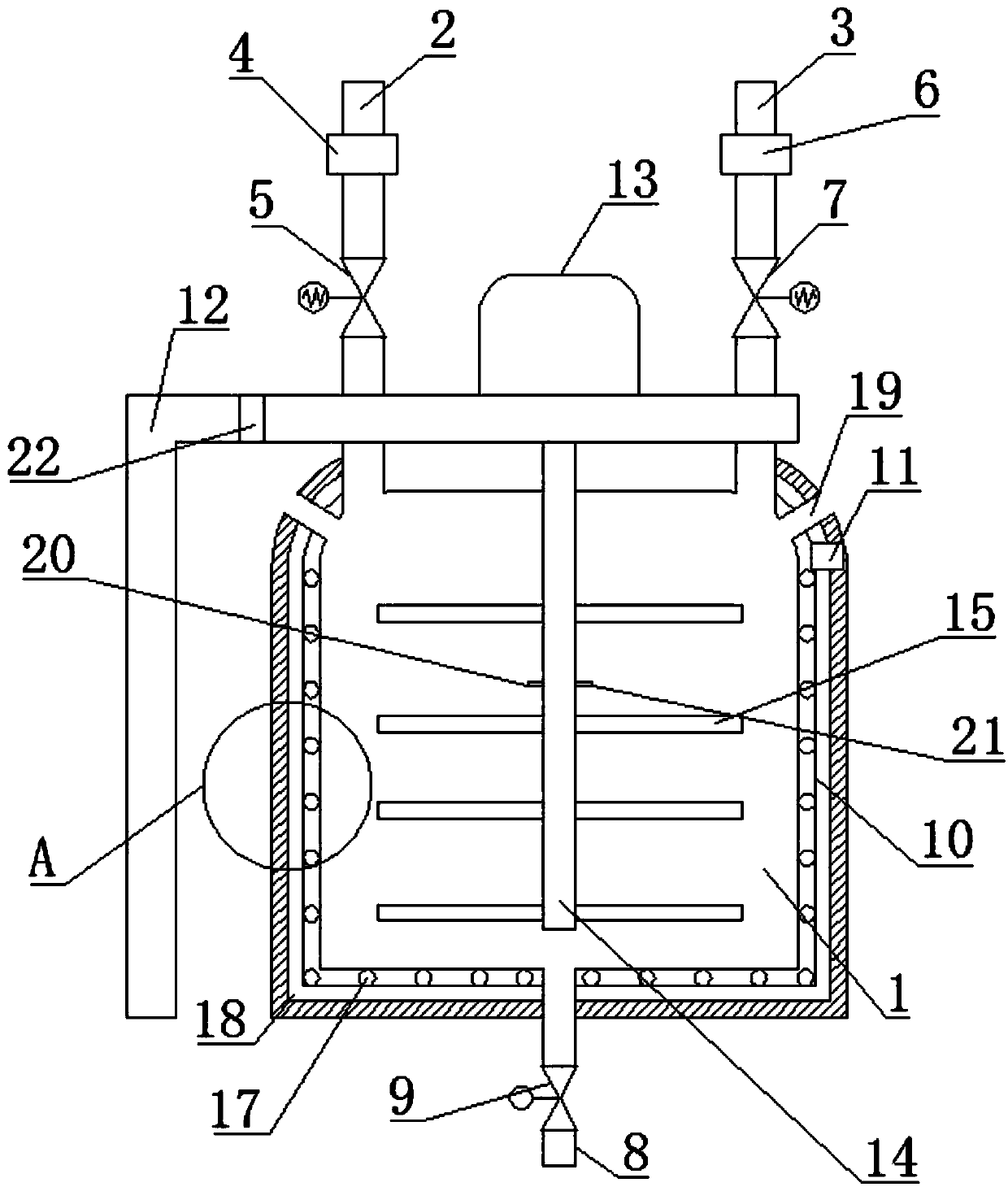

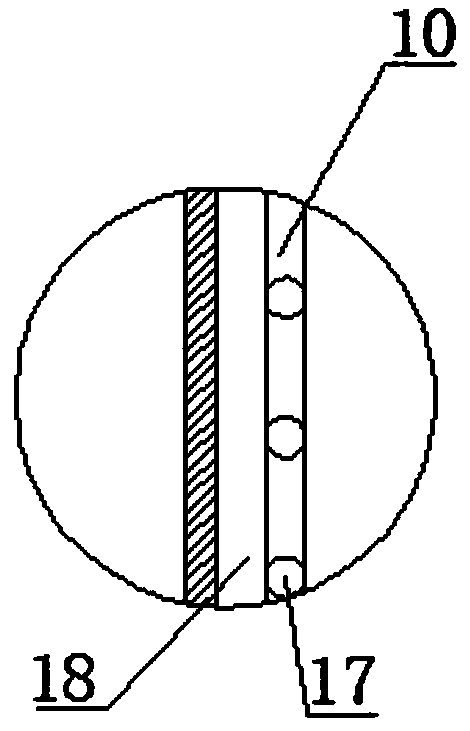

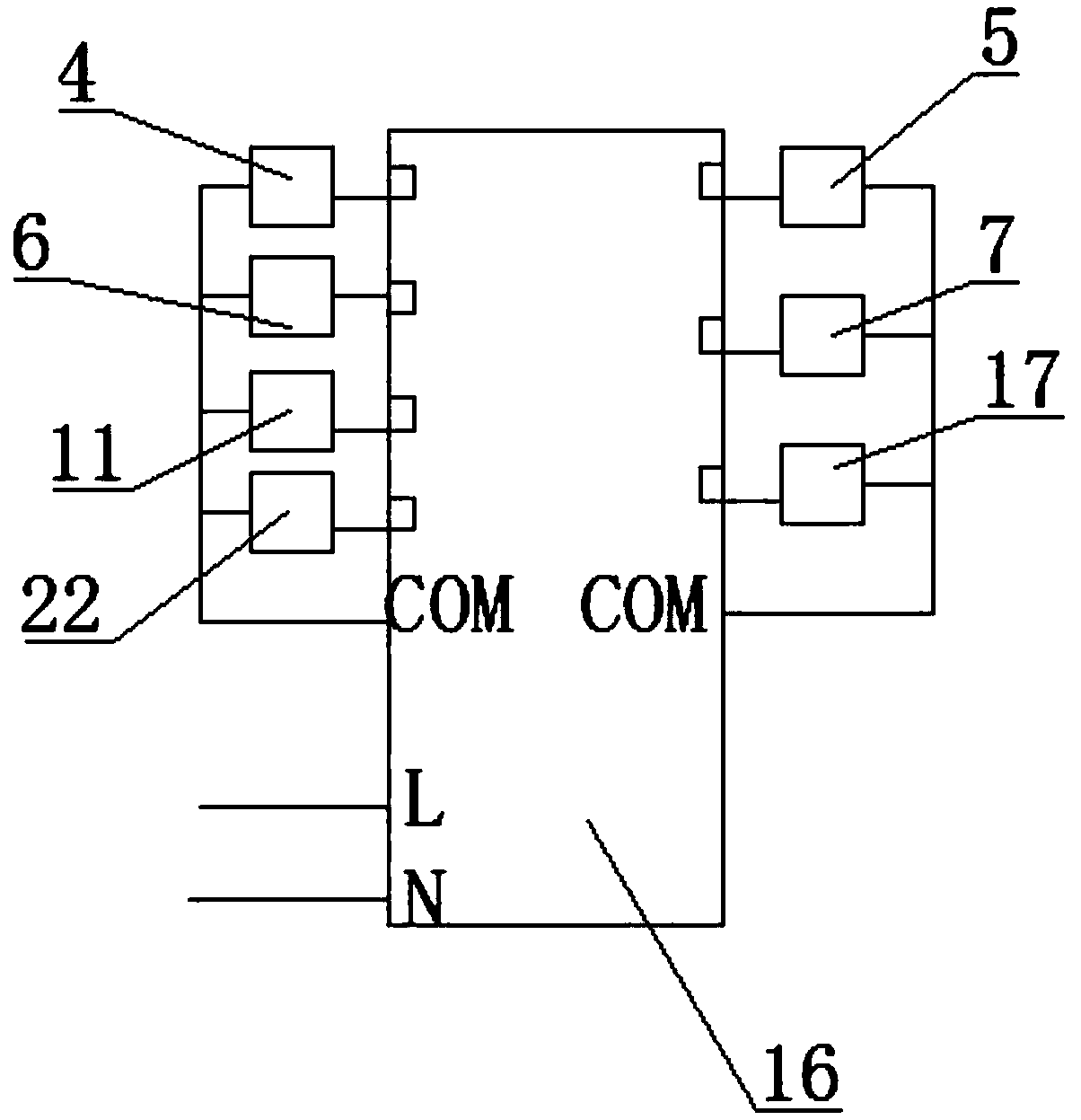

[0017] Example. An automatic temperature control type water reducing agent production device, which is composed of Figures 1 to 3 As shown, the reaction box 1 is included, and the top of the reaction box 1 is provided with a first feed pipe 2 and a second feed pipe 3; the first feed pipe 2 is provided with a flow sensor A4, and an electromagnetic sensor is provided below the flow sensor A4. Valve A5; the second feed pipe 3 is provided with a flow sensor B6, and a solenoid valve B7 is provided below the flow sensor B6; a discharge pipe 8 is provided at the bottom of the reaction box 1, and a discharge valve 9 is provided on the discharge pipe 8 A heating layer 10 is arranged in the side wall of the reaction box 1, and a temperature sensor 11 is arranged outside the heating layer 10; a fixed frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com